What is good about a stove made of wheel disks

The homemade design is of high build quality thanks to the metal used to make the discs.

The furnace has the following positive characteristics:

- Simplicity. Anyone can build it on their own. It is enough to have the necessary tools and accessories. The design is not complicated, which makes it affordable for making at home.

- Durability. A stove for a bath made of car rims can serve for many years, thanks to its thick metal. A large number of old car wheels were made in the Soviet Union, which significantly affects the quality of the metal. The welded connection of the main elements affects the integrity of the structure and guarantees performance.

- Compactness. You can use wheels of any diameter from different cars. This parameter opens up the possibility of assembling an oven of optimal dimensions. The size of the device will affect the size of the heated area of the room.

- No deformation. A stove made of truck discs withstands long-term exposure to temperature well. The material works in optimal mode constantly, despite changes in temperature and humidity parameters.

- Heat transfer and heating. A home-made stove is highly efficient, since it gives off all the heat that was obtained from the combustion of fuel. The metal heats up quickly due to its structure, which affects the speed at which the optimum temperature in the bath is reached.

- Fuel options. Several types of fuel can be used.

Since the entire surface of the stove made of discs is metal, safety rules must be provided. A protective structure should be constructed to avoid injury or burns.

In addition to the availability of the main components, a homemade stove has a number of other advantages:

- Simplicity in construction.

- Compact dimensions that you can choose yourself, based on the diameter of the discs.

- Fast heating and good heat dissipation.

- Durability due to the thickness and good quality of the steel.

- Resistant to deformation even with prolonged exposure to humidity and high temperatures.

- The ability to use various types of fuel - wood, coal, fuel pellets.

Bath with a disk stove

Among the shortcomings, we note the following points. Firstly, metal is a good conductor, and the oven becomes very hot when heated, which can cause burns and injuries. And secondly, the disc stove cools down as quickly as it heats up - approximately 1.5-2 hours after the last batch of fuel burns out. Therefore, it should not be considered as a permanent heating device, but it will be just right for heating a bath or utility rooms!

A strange, at first glance, idea to build a stove from steel wheels in practice turns out to be quite decent cost savings and a huge furnace resource. Of course, provided that most of the work on the construction of a bath stove from wheel disks was done by hand. But even if the most critical part of the work is performed by a professional welder, this will only slightly increase costs.

To be precise, the use of spare parts from heavy vehicles with disks larger than 19 inches for the manufacture of the furnace gives serious advantages that are not even in factory models of stoves:

- The huge wall thickness in different wheel models is 7-11 mm. As a result, a stove for a bath made of rims turns out to be heavier and more massive than a factory steel or cast iron structure.A wheeled stove cools down in two hours, while branded sauna stoves made of steel 3-4 mm thick cool down in 50-60 minutes;

- A stove made of discs for a bath is not afraid of thermal shocks, as in the case of cast iron furnaces, does not burn out and does not deform due to thermal stresses. With proper maintenance, a wheeled firebox can serve in a bath for a couple of decades without a significant decrease in heating efficiency;

- High quality stamped metal. After processing, the discs have high strength and rigidity, so that the steel ring of the rim, even when heated red-hot, is able to withstand a load under 2 tons of weight.

For your information! The sauna stove made of truck disks has one unique property. To ignite and quickly set the required heat, you can use a coal apartment briquette or washed anthracite in limited quantities. Any other stoves with a closed firebox in the bathhouse are fired only with wood.

After combustion, coal ash acts as a heat accumulator, so one bookmark is enough for 2-2.5 hours of heating. During this time, the owners have time to take a steam bath, and thoroughly dry the walls and floor of the bath.

Of the shortcomings of the idea of using wheel disks for the manufacture of a furnace body in a bath, one can only recall the not very convenient shape of the crown, due to which difficulties arise in assembling sealed containers for heating water. In some cases, the seams along the line of the joint of the disks have to be boiled with an autogenous boil or an intermediate transition zone must be installed.

Sauna stove designs

Any construction of a steel rim firebox begins with the selection of material. For manufacturing, you will need at least 3-4 pieces of rims without damage and visible defects. It is clear that it is best to build a furnace from the rims of a heavy truck. Wheels from Gazelle, Bychka, GAZon, mini-trucks of the Chinese car industry are simply small, the firebox turns out to be small, heating weakly and ineffectively. Such discs make excellent stoves for temporary huts and cabins.

Several wheel options can be used as a starting material:

- Standard wheel rim 8.5-20 from tractors based on KRAZ 65101. The convenient shape of the rim will require a minimum of alterations, and the wall thickness of 11 mm will make the stove in the bath eternal, even if it is fired with coal;

- Wheels 5425-3101012D or 4310-3101012 for KAMAZ, diameter 503-508 mm, rim width 310 mm and 216 mm, respectively.

We offer you to familiarize yourself with the Brick oven with your own hands: diagrams, masonry, drawings with the order and other video

All of the above options are found both in severely worn out and in a satisfactory condition. It makes no sense to buy new discs for arranging a stove in a bath, it is too expensive. For example, a new Krazov disc costs up to $ 100, they "go" for a very long time. There is a chance to buy a couple of old rims from a quarry driver, although they are extremely reluctant to part with the discs.

It is best to plan a sauna stove from KAMAZ disks. Firstly, the rim itself is almost 20% lighter, and secondly, KAMAZ wheels are much more affordable, so the chance of buying almost for free is much higher than looking for wheels from a tractor or loader.

Advice! Ideally, it is best to find a flangeless or diskless wheel model 5320-3101012 for building a furnace in a bath of KAMAZ disks.

This is a relatively new model designed for tubeless use. Basically, it's just a 179mm wide and 508mm diameter rim. For installation on the stove, no additional cutting with a grinder is required, and in addition, the disc is almost twice as light as the classic rim - 26 kg, versus 48 kg for the usual KAMAZ model.

You can build a good firebox for a steam room using any KAMAZ disks measuring 20 inches. When choosing, you must pay attention that the rim is not deformed, without traces of impacts or flaring of the bead.It is almost impossible to align bent metal with a thickness of 7-10 mm in a garage, and a crack can be welded.

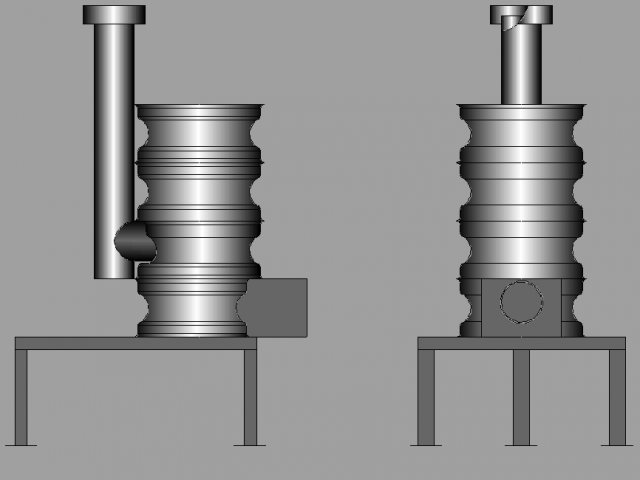

For the construction of a stove in a bath or steam room, two types of firebox are used:

- Vertical type of combustion chamber. The discs are put on in a pile and welded at the joints, resulting in a compact, strong and stable design;

- Barrel type combustion chamber. The furnace body is welded from three rims and mounted horizontally. This model is convenient for loading equipment from a dressing room or any other utility room.

The third option, combined, involves the arrangement of an ash pan and a combustion chamber made of red and refractory bricks in the bath. The discs are used on the stove for the vault, heater and hot water tank equipment only.

To build such a stove in a bath will require the experience and skill of a professional stove-maker. Otherwise, a load of 150 kg of discs and 50 kg of stones may cause cracks in the brickwork of the oven walls.

First of all, the discs need to be prepared: cleaned of debris, rust or paint residues using abrasive paper. After that, you can start manufacturing the structure, observing the stages of work in the specified order.

Water tank

To equip the upper chamber of the future stove, you need two wheel disks. Water will be heated in this tank, so it must be sealed. To do this, the central plates for fasteners are cut out from 2 discs with a grinder, only the rims are left. They are stacked on top of each other and welded together.

Cutting the disc core

The upper part of the tank is closed with a metal lid or a movable flap. For safety reasons, you can combine these two options and tightly weld a larger segment of the lid, making only a small opening through which water will be poured into the tank sliding or folding. A metal plate cut from a sheet is welded to the bottom of the chamber.

The device of the upper part of the stove

After welding, holes are cut in the upper part and at the bottom of the tank along the diameter of the chimney. It will pass through the entire tank, should tightly overlap with the walls and go out through the bottom.In the side of the tank at the very bottom, a thin tube is installed at an angle to the floor and closed with a tap to drain hot water.

From the two remaining rims, you need to make a heater and a firebox cover. The core is cut out of one, the second remains intact. The workpieces are placed one on top of the other and welded together so that the hub of the whole disc is in the middle (it will function as a lattice). From above, the container remains open - stones are poured here. The lower part of the cylinder will act as the upper part of the firebox.

Natural stones of a rounded shape, which are used in saunas and baths - diabases, basalt, peridotite, are best suited for arranging a heater. But they are quite expensive. Therefore, you can look for material for the stove at the nearest reservoir - these stones have been well hardened by moisture and the sun.

It is recommended to install the stove for a bath from rims on a solid and fire-resistant foundation. It can be constructed from a reinforced concrete screed, and the top surface can be faced with fire-resistant bricks.

When the base is dry, you can proceed to the bottom of the oven. For a stove with masonry 62 * 62 cm, 60 pieces of red heat-resistant bricks are needed. They are fastened with clay diluted with water and laid in a square. Do not forget to provide a cavity for the blower and an opening for the door. Attach the grate to the top of the masonry.

Assembling the stove

All parts of the structure are sequentially assembled. The metal part is connected to the brick, the firebox and blower are closed with doors cut from a metal sheet.

Diagram of a stove-heater for a bath from rims

On a note! For comfortable use, it is advisable to equip the door with a handle made of one large bolt. And so that firewood or coals do not accidentally fall out - also with a latch from a narrow plate of metal and a small loop.

Next, a second piece of pipe is welded to the central hole of the hub, located between the firebox and the stove, and sewn to the upper part of the chimney through the water tank. Stones are placed in the stove: at the bottom - large and medium, on top - small.

To strengthen the structure, metal channels are welded to the rim of the heater and water tank, which are installed at a slight angle to the upper part of the body. The pipe is led out into a chimney lined with refractory bricks and equipped with a damper.

We suggest that you familiarize yourself with Is it possible to warm up during menstruation

Such a stove will heat up the steam room and the water in the tank in just an hour.

After preparing all the components that are needed to make the heater, you can proceed to the assembly process.

Brick oven

- Creation of a tank for heating water. It is necessary to assemble a single structure from two elements by welding. The inner part is preliminarily cut out in them. To create the bottom, a metal sheet is used, in which a hole is cut for the outlet of the chimney. It is placed near the main wall, after which the pipe is hermetically welded. The tank must close, for this part of the sheet is welded, and the second is made in the form of a shutter. On the side, in the lower part of the upper disc, a hole is made for installing the crane. The second disc is reserved for the heat exchanger body for good heating of the room.

- Leak test. Control of a homemade stove from car disks for lack of penetration is performed by filling it with water. If a defect is found, additional welding work should be carried out. They are performed after draining the liquid from the tank using a tap.

- Connecting the lower two discs for the heater and the firebox. The work is carried out using a welding machine. In the resulting hollow structure, you need to attach the lattice. It is welded to the upper disc and is intended for placing stones. The bottom element does not need to clip the inner elements. A hole is made on the side, and a door is attached.

- Erection of the foundation. You need to make a solid base on which the oven will be installed. To do this, you can use bricks and fill them with mortar. Greater reliability is achieved through the use of fittings.

- Bricklaying. The work is carried out after the foundation has dried. Fire-resistant brick is laid in a square, forming a firebox. Clay is used as a binder. It is necessary to carry out the masonry with high quality and do not forget about the holes for the blower and the installation of grates.

- Strengthening the furnace. To ensure a strong connection between the upper and lower metal structures, channels are used.

Sauna stove made of discs

A sauna stove made from truck rims can produce heat from a variety of materials. The following fuels are used - coal, firewood, briquettes, pellets. The easiest way to heat a bath is to use firewood, as it is easy to light it. It is necessary to select the best fuel option based on their cost and availability in the region.

There is also another option for creating a furnace from discs, without erecting a brick base. Which option to choose is up to you.

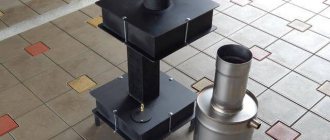

Oven for cauldron and barbecue

The stove under the cauldron can also be used as a barbecue. This device can be made with just two disks from the wheels of a car. If you need a larger design, then there are no restrictions, you can use wheels from GAZ-53 and UAZ.In one of them, the bottom is cut, and after the rim, they are welded together. The unit must be installed securely on any surface; for this, legs are fixed to the lower section using a welding machine. The holes for the hub must be plugged, while the side holes are left, through them air will penetrate into the firebox. In order to carry the case conveniently, handles should be welded to it from the outside, and an opening should be made in the side part for installing the door. The latter should be made from a piece that sits on the hinges. We can assume that the oven from the discs is ready for this. As practice shows, a cauldron can fit on it, and, if necessary, five skewers with meat.

Materials and equipment for work

To make a stove from wheel disks with your own hands, you will need the following set of tools:

- Grinder with circles for metal or a gas cutter.

- Welding machine and electrodes.

- Protective devices: glasses, gaiters.

- 2 cuts of 50 cm each of a metal pipe 5 mm thick and 160 mm in diameter.

- Iron sheet 8 mm.

- Door hangers (can be replaced with large bolts and nuts)

- Refractory bricks.

- Cement-sand mortar for masonry and clay.

- 4-6 steel channels.

To erect the hull, you will need 4 disks from a truck, for example, KrAZ. Such wheels will make a stove with a diameter of 0.5 m and a wall thickness of 1 cm - this is quite enough to heat a bath or other utility room.

Making a furnace in the form of a heat generator

If you decide to make a stove from discs, then you can take Buleryan as a basis for the design. The original will cost a lot of money, but the handmade product will cost less. If you find three wheels from a GAZelle or UAZ, then you can assume that half of the work has already been done. Sheet metal and pipes will be needed, the diameters of the latter should be equal to the limit from 100 to 150 mm. Prepare a short nipple with a diameter of 76 mm.

When an oven is made from discs using this technology, the most difficult thing will be to cut out the inner part. At the same time, it is not very convenient to work with an angle grinder, because the metal is quite thick. It's best to use a torch, but if you don't have one, the first tool mentioned will do. With the help of a welding machine, the discs must be hermetically joined in such a way that a body is obtained. The back part must be covered with a metal sheet, to which the chimney pipe is welded. On this branch pipe, if desired, you can install a damper, it will allow you to adjust the draft. However, the presence of a damper is not necessary if the oven will have air regulation. To do this, a branch pipe with a damper with a spring-loaded axis must be built into the door located at the front. A plate is installed inside the firebox, which will divide the space into two parts. This technique will become more understandable if you familiarize yourself with the Buleryan design. A secondary chamber will be located on top, where the chimney pipe is welded. When a furnace is made from Buleryan-based discs, the structure can have any diameter, orientation in space and length. Everything will depend on the size of the disks and their number.

Fire safety rules for arranging homemade stoves

An oven made of car disks predominantly warms with infrared radiation. To convert this flow into warm air, the stove must be shielded: surrounded by a casing of steel sheets installed at a distance of 7-10 cm from the heater and with the same clearance from the floor.

Safety rules for the operation of metal furnaces:

- A reinforced concrete slab or steel sheet must be laid on the floor so that the refractory structure extends beyond the contours of the furnace at least 60 cm in each direction - this will protect against fire if coals accidentally fall out of the furnace.

- The metal stove and chimney must not come into contact with flammable materials. Use insulating spacers if necessary.

- Always check for traction in the channels before firing. If it is not there, you need to warm up the chimney with a small amount of burned wood or clean the passages and ash pan.

- Do not use liquid igniters - they can cause fire to be thrown out of the firebox opening.

Terms of use and maintenance

It is impossible to cook dishes immediately on a newly made stove. Paint, oil or brake fluid remains on car rims. Therefore, first, the stove is ignited in order to clean the device from residues. Otherwise, when burned, they will emit an unpleasant odor, which will saturate the food. To do this, the firebox is completely filled with firewood, laying them over the top. With the help of a special liquid, a fire is kindled and the fuel is allowed to burn out to the end.

After the stove has cooled completely, the ash is poured. The walls of the structure are cleaned with a metal brush and sandpaper from paint residues. After such cleaning on the stove, you can cook pilaf, shish kebab or other delicious dishes.

For cooking, fuel is put in through the door. After adding some wood chips and bark, light the flame with matches. The oxygen coming from the bottom holes feeds the flame, and the smoke goes into the chimney. Thanks to the successful design, there will be good draft and suitable conditions for cooking.

Important! Do not use large portions of wood during cooking. It is important to keep warm evenly. A strong flame will only ruin the dish and burn the food.

After the end of the process, they wait for the stove to cool down and begin to clean it. Fine ash and residual fuel will fall out on their own through the holes in the lower disc. To free the device from large residues of fuel, turn it over and shake it out through the door.

The classic version of the vertical heater

The horizontal type stove is no different from sauna stoves and stoves made of large-diameter water pipes or propane cylinders. For the manufacture of the simplest furnace from disks, it is necessary to select three KAMAZ rims.

Two are left unchanged, the third is subjected to additional trimming and the flange wall is removed. Simply put, it is necessary to cut out the bottom of the disc with an oxygen cutter or a powerful grinder, leaving only the rim. A metal grate of the grate is placed inside the rim and welded to the disc walls.

The ends of the two remaining wheels are welded with thick sheet metal, at least 5 mm thick. Sheds are welded onto one of the disks and equipped with a door, a hole is left in the lower part for cleaning the ash pan of the stove. Usually, a pull-out metal tray or a sector valve is used for these purposes. The sauna stove must be equipped with a blower damper without fail.

A chimney flange is cut into the third disc, after which all three elements are stacked on a metal support, the joints between the rings are aligned and welded. The most valuable thing about this design is the simplicity and ease of installation. The stove can be installed in a bath without any foundation. It is enough to lay a sheet of steel on the floor on a heat-insulating substrate, and the oven can be mounted.

We suggest that you familiarize yourself with How to assemble a log house from a bar

This scheme is ideal for installation in a small bathhouse in the country. At the end of the season, a structure weighing just over 100 kg can be taken away or put into storage.

The idea to use rims from heavy trucks appeared a long time ago, almost half a century ago. In the first heavy trucks serving trucking companies during the cold season, it was necessary to warm up the water before pouring it into the radiator.Therefore, drivers and locksmiths came up with the design of a stove made of discs, which later migrated to cabins and garages, and then was used in the bathhouse.

The upright wheel stove could be used anywhere. Moreover, with the help of a mobile stove, even a tent or a light wooden shed could be turned into a bathhouse, even without a chimney. In a properly cooked stove, a fire was made from discs on oiled rags, then coal and firewood were used.

The design of the furnace, its structure and principle of operation are clear from the photo below.

The stove body is assembled from four discs from ZIL 131, URAL or KAMAZ. The set of stacked steel rims reaches a height of almost 90 cm, and given the weight of water in the upper tank and stones, it becomes clear that the structure turns out to be rather unstable.

To protect the bath from fire, it is necessary to make a classic concrete foundation with thermal insulation for the stove, and for the lower ring, which acts as an ash pan, use a model 43118-3101012 disk with a maximum rim diameter of 560 mm. The wide part is welded with sheet metal, the head of the ash pan is cut to make it easier to connect to the combustion chamber.

The next two rings are cut on one side and welded together to form a solid cavity. This is the furnace firebox. As in the ash pan, so in the combustion chamber in the disc wall, it is necessary to cut a hatch for loading firewood or a briquette.

The upper part of the stove is a water tank and a stove. It, like the ash pan, is best made of high-speed rims with high sides. In the central part of the structure, a thick-walled metal pipe is welded, to which the chimney barrel will be attached.

Before assembly, all parts of the stove must be cleaned mechanically, without firing, preferably with a sandblaster or a brush with metal bristles. The body metal is quite thick, 6-9 mm, so the welding line will need to be cut at an angle of 60 °.

The joint is welded in three passes, if possible, then it is better to weld the stove from the discs using a powerful three-phase industrial model welder. It is impossible to efficiently weld metal for the oven into a bath with a garage inverter with a capacity of 2.5 kW. In this case, the furnace body is only seized with welding spots, and the entire seam is made with an acetylene torch.

After welding, the seams are cleaned, and the furnace body is painted with heat-resistant paint. All furnace structures made of wheel disks are classified as very hot; after warming up, the walls are capable of burning even at a distance of up to a meter from the surface. Therefore, after installing the oven in the bath, you will need to make a removable screen of aluminum foil glued to a galvanized sheet.

You can get a homemade oven after preparing the necessary components and accessories.

The manufacture of a furnace for a bath involves the use of the following materials and tools:

- welding machine with electrodes;

- a grinder on which a cutting wheel for metal is installed;

- metal sheets (optimal thickness 8 mm);

- smoke exhaust pipe, 160 mm in diameter;

- canopies for the door;

- channel;

- fire-resistant brick;

- clay, sand for solution preparation;

- gloves and goggles for personal protection.

The main component for the furnace is 4 rims from a truck, for example, ZIL-130. They allow you to create a firebox with a diameter of 50 cm.This design will have walls 1 cm thick.

Before you make a stove from discs, you need to know why exactly 4 pieces are used.

Each element plays a role:

- the first - a brick firebox is located in it. The fuel is placed through the door, which is mounted on it.

- the second is for stones. The hot stones help produce steam after being exposed to water.

- the third - exchanges heat between the stove and the room. Thanks to this, it is possible to maintain the desired temperature.

- the fourth - heats the water.

Furnace diagram