Circulation pump device Grundfos

Glandless circulation pump for home heating system

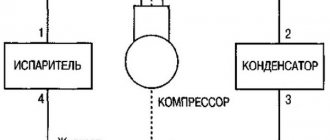

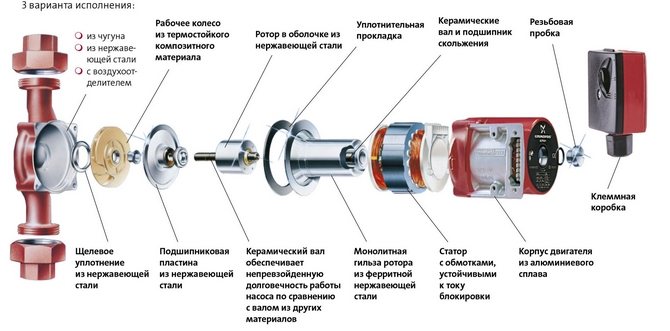

According to their design, Grundfos circulation pumps for heating are divided into two types: with a "wet" and with a "dry" rotor. The first of the constructions historically appeared before the second version. It is based on a body made of cast iron, steel, bronze or aluminum, inside which a movable rotor is located in an aqueous medium. An impeller is installed on the shaft, which sets the working fluid in motion.

Pumps with a "dry" rotor began to be produced a little later, the engine and the liquid in them are separated from each other. First class pumps are highly reliable thanks to liquid lubrication. But at the same time, the efficiency of such devices is very small (no more than 50 percent).

For units with a "dry" rotor, the efficiency is slightly higher (it reaches 70%). These models are most often used for industrial purposes, where operating conditions involve pumping large volumes of water. For domestic needs, circulating pumps operating on a "wet" circuit are usually used.

Advantages of Grundfos circulation pumps

This equipment from the Danish manufacturer has rightfully earned its popularity. It is chosen for its many benefits.

Let's consider the main ones:

- Reliability and high efficiency.

- Versatility. The units can be connected to systems with any configuration.

- Small size and light weight. Any device from the catalog can be placed even in a residential area.

- Virtually silent operation. The pump will not interfere with you if you install it in a private house or apartment. The increased noise level is observed only in very powerful models. But they are not suitable for household use.

- Easy to install. You can connect the equipment to the pipeline on your own (provided that you are at least a little familiar with such work).

- High performance. The Grundfos pump is capable of moving arbitrary volumes of coolant through a closed pipeline. It easily pumps liquid both horizontally and up floors.

- Good economy. These units operate almost without losses and consume little energy.

- Ease of inclusion. To start the equipment, simply connect it to the mains.

- Convenient temperature controls. You will be able to adjust the temperature on initial connection. Further, the device will independently maintain the selected temperature regime.

- Large selection of models. The manufacturer produces a series of units designed for specific conditions of use. You can easily find a suitable model (or we will advise you if you have any difficulties).

Specifications

The main technical indicators to which attention is paid when choosing a suitable equipment model are:

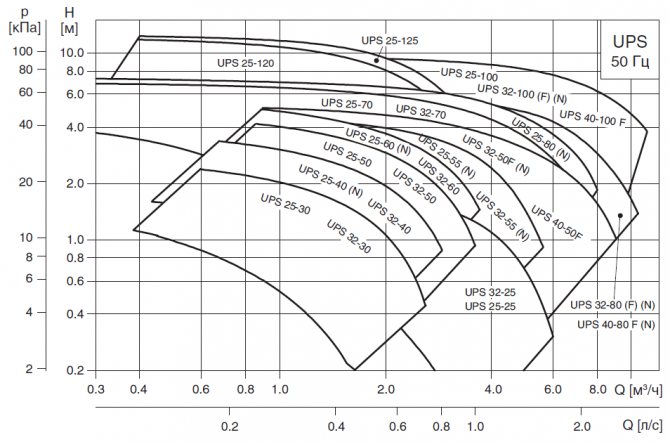

- a graph of the dependence of the fluid pressure on the amount of its supply to the system;

- power consumed by the engine of the unit from the network;

- coolant performance;

- permissible temperature of the pumped medium;

- dimensions and weight of the device.

Devices are selected according to power depending on the volume of pumped water

The first of the characteristics makes it possible to understand what volumes of water are pumped by the pump, depending on the pressure developed in the system. The higher this indicator, the less water resource must be passed through the unit to obtain the required pressure. To correctly select a sample of equipment, the operating point must be located under the curve of the graph. When choosing this indicator, it is desirable to provide a supply margin of at least 20%.Another parameter is directly related to it - pump performance.

The power taken from the network is determined by the amount of current in the load and the supply voltage (220 or 380 volts). This parameter is taken into account when selecting protection devices for current supply circuits and when calculating the cross-section of wires that are part of the supply lines of power supply. The specified value depends on the performance of the pumping equipment, which increases with its increase.

The dimensions of the purchased sample and its weight are also taken into account when choosing a suitable model. This also applies to the operating conditions of the pump - the minimum and maximum permissible temperature of the pumped medium. The reliability and durability of the purchased sample depends on the correct selection of this indicator.

Key features of Grundfos circulation models

Consider the models of Grundfos circulation pumps that are on the market today.

Magna

The devices presented in this series are designed to provide the possibility of circulation of the heating medium in heating systems with variable flow rates. You can position the appliance anywhere to optimize your energy consumption.

The main task that the pump of this series performs is the regulation of the water circulation parameters. It is for this function that the design of the unit with its controls is intended. It is also necessary to take into account how the pump parameters correspond to the communication requirements.

With a pressure of 16 bar, Grundfos Magna pumps can be used in large houses with long circuits. Users note, note the benefit of the indication system of pumps of the Magna line, which in some versions is represented by several fields of light notification.

Double circulation pumps GRUNDFOS MAGNA3 D 32-80

UPS

This series is represented by three-speed models, which are available in two main modifications - at 50 and 60 Hz. In the UPS 100 line, there are over 25 models of circulation pumps, the price of which starts from 6,000 rubles and ends with 40,000 rubles.

The Grundfos UPS 100 series includes wet rotor circulation pumps. In the design of such units, the working elements and the engine are located in one housing, while the rotation shaft and the impeller fixed on it are isolated from the pumped working medium.

Thanks to this design, it is possible to use only two sealing glands, without mechanical seal, due to which the unit is simpler and at the same time more reliable. All pump models are equipped with ceramic bearings for a long service life.

During the operation of the pump, they are lubricated by the pumped liquid. In addition to heating systems, such devices can be installed in the following areas:

- industrial heating and water pumping systems;

- heat pump systems;

- underfloor heating systems;

- geothermal heating;

- heat recovery systems;

- air conditioning;

- refrigeration units.

In addition to the operational advantages of these devices, it is worth noting their high performance, the efficiency reaches 80%. The units are distinguished by their reliability, maintainability of the design, and long service life. Another important advantage is the ability to operate in three speed modes, due to which you can adjust the pump to any operating mode.

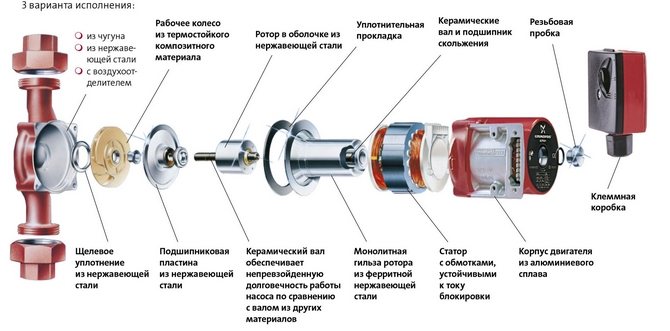

Circulation pump device Grundfos UPS

The advantages of Grundfos UPS 100 series pumps are:

- simple electrical connection;

- no need for additional electrical protection. This is due to the fact that current-resistant blocking of the motor winding is used here;

- hollow shaft design, air escapes from the chamber through the hole in it;

- no maintenance required.

The downside is a fairly high noise level during the operation of the device (only models with a dry rotor do not emit any distracting sounds) and high cost. However, due to the high reliability of the design, its price is absolutely justified.

As already noted, the Grundfos company in the UPS 100 line represents more than 25 models of circulation pumps. Let's consider the most popular modifications:

- Grundfos UPS 25-40 (7,000 rubles);

- Grundfos UPS 32-100 (35,000 rubles);

- Grundfos UPS 40-50F (27,000 rubles);

- Grundfos UPS 20-60 130 (10,000 rubles).

How to calculate the capacity of a circulation pump for heating and hot water supply?

The most affordable is the Grundfos UPS 25-40 circulation pump. This is a small unit, which is characterized by economical energy consumption and practically does not make noise during operation. Such a pump belongs to devices with a dry rotor, in which the rotor and the engine do not come into contact with the working fluid.

The unit has three fixed circulation speeds, which can be switched by means of a lever located on the terminal box. Thanks to the built-in automation, you can set any operating mode - continuous, by timer or based on the characteristics of the coolant.

The main technical characteristics of Grundfos UPS 25-40 are as follows:

- the power is 25/38/45 W;

- working pressure reaches up to 10 bar;

- temperature of the pumped-over liquid -25 + 100 ° С;

- working consumption is 1.6 m³ / hour;

- the head reaches up to 4 m;

- threaded connection standard - G 1 ½.

More functional models are considered to be a circulation pump UPS 25-60 and UPS 20-60. Such units, in addition to heating systems, can be used in hot water supply, cooling and air conditioning systems. The models are designed for pipelines with a stable flow rate of the working medium, the pressure of which is not more than 10 bar, and the hydrostatic head is 1.62 m. In the UPS 20-60 pump, the nominal flow rate is increased to 2.3 m³ / hour.

The body of the described models is made of cast iron, the impeller is made of a corrosion-resistant composite alloy. The installation length of the pump is 130 mm.

You can buy a UPS 25-60 circulation pump with nuts for 7,000 rubles. The unit is distinguished by a simple and reliable design, its quality meets high German standards. The device can operate at three speeds, with which a shaft made of ceramic can rotate, like bearings. The power of the described circulation pump is 60 W, the capacity is 71 l / min.

The Grundfos UPS 25-80 model belongs to the category of expensive ones, its price is 13,000 rubles. Such equipment is used to circulate hot and cold water. The case is small, so you can mount it anywhere.

The structure is made of cast iron, the impeller is made of a heat-resistant composite material, which contributes to the high anti-corrosion properties of the unit. Such devices can be used for one-pipe, two-pipe heating systems. The circulation pump Grundfos UPS 25-80 has a power of 165 W. The unit capacity is 125.25 l / min. The lift height is 8 m. The maximum liquid temperature is 110 ° C. The pressure is 10 atm.

Recommendations for the selection of circulation pumps series UPS

The most important factor on the basis of which a circulation pump is selected is the flow rate of the heating system. It is on the basis of the flow rate that the required throughput of the pump is determined - the volume of water that it must drive along the circuit for one hour.

In the table we present the main parameters of circulation pumps series 100 (with nuts) UPS.

| Name of the Grundfos circulation pump | Main settings |

| UPS 25-40 | 1 * 220 V, thread 1, productivity - 2.93 m³ / hour |

| UPS 25-60 | 1 * 220 V, thread 1, productivity 3.80 m³ / hour |

| UPS 32-40 | 1 * 220 V, thread 1 ¼, productivity 2.92 m³ / hour |

| UPS 32-60 | 1 * 220 V, thread 1 ¼, productivity 3.72 m³ / hour |

| UPS 32-80 | 1 * 220 V, thread 1 ¼, productivity 10.40 m³ / hour |

Alpha

Distinctive features of the Grundfos Alpha circulation pump are the ability to work with climatic equipment. Unit capacities are based on classic circulation pumps. Most popular models: Grundfos Alpha2 L 25 60, Grundfos Alpha2 L 25 40.

In the basic configuration, Grundfos Alpha provides a throughput of 3 m³ / h, and the head of the equipment reaches 6 m. The advantages of the models are in the temperature of the pumped liquid, which can vary from 2 to 110 ° C.

The most modern modifications are characterized by the unique ability to automatically make settings. All that is required of you is to place the pump in the communication circuit, then it will calculate the appropriate operating parameters itself.

Advantages and disadvantages

The pump in the underfloor heating system works silently - it can be located in the house next to the living rooms

The advantages of pumps from a Danish manufacturer include:

- high work efficiency;

- reliability of all units and parts;

- low level of intrinsic noise;

- versatility of application.

Grundfos pumps are used as part of heating systems and are in demand for organizing hot water supply (DHW) circuits. In addition, they can be installed in floor heating systems or in climatic equipment.

The versatility of Grundfos units is also manifested in the fact that after purchasing them, the user will be able to work with the following types of coolants:

- water heated to a certain temperature;

- antifreeze that does not contain solid components;

- heat carrier with the addition of ethylene glycol in a volume of not more than 40 percent.

The advantages of equipment samples of this class include the operation of the rotor in direct contact with the coolant; it is separated from the rest of the units by a metal glass made of stainless steel. In addition, in these models, the inlet and outlet pipes are located at the same level, which leads to the quiet operation of the entire unit. The significant advantages of products from a Danish manufacturer include:

- optimal ratio of the declared price and quality;

- high rates of energy efficiency;

- a large selection of models that can satisfy the most demanding customer;

- long service life and advanced technical support system.

The characteristic disadvantages of Grundfos pumps are considered to be a relatively high price per unit of goods (from 6500 rubles) and the absence of a cable for connecting to the mains in the kit.

DIY step-by-step installation instructions

In order for the unit to perform its task effectively, it must be installed on a horizontal plane. Equipment with a wet rotor is placed on the supply circuit, and with a dry one - on the return. The fact is that in the "dry" version, rubber or paronite gaskets are used, which deteriorate rather quickly under the influence of high temperatures.

It is advisable that a coarse filter is installed in front of the heating pump. It is necessary to protect the equipment from the ingress of small impurities into it. This will extend the service life of the equipment.

It happens that in the territory where the equipment is installed, the electricity is cut off. In order for the pump to work continuously, an additional bypass must be installed.

Some users during installation cannot determine the correct direction of the nozzles. The manufacturer took this feature into account, therefore, on the body of the pressure equipment, you can see an arrow showing in which direction the rotor rotates, and, accordingly, the coolant.

As a rule, circulation equipment is sold without fasteners, so they will have to be purchased separately.When connecting the device to the network, professionals recommend using a separate cable coming from the switchboard.

The main stages of the work:

- All liquid is drained from the heating circuit. If it has been in operation for a long time, a high-quality flushing is recommended.

- Bypass sections are cut to connect equipment. A bypass is placed between the inserts, which must complement a check valve or ball valve. This will protect the plastic inserts during the welding process.

- The bypass pipeline is equipped with shut-off valves.

- A coarse filter is mounted.

- In the upper part of the bypass, a Mayevsky valve or an automatic air valve is installed.

- The pump crashes. If the model is equipped with a "wet" rotor, then it should be placed horizontally.

- It is best to use a separate grounded outlet for the mains connection.

- The pump is filled with a coolant, its performance is checked.

At first glance, it seems that the installation is not difficult. But this is for advanced users only. In practice, various problems may occur, therefore it is recommended to carefully study the instructions supplied with the equipment. If experience is not enough, it is best to invite a specialist who will take into account all the requirements and correctly configure the unit. Read the wood burning stoves on our website.

Selection features

The size of the union nut depends on the diameter of the pipes to be connected.

When choosing the right sample of pumping equipment from Grundfos, much attention is paid to the diameter of the union nuts. It is selected depending on the size of the pipe being prepared for installation in the heating system:

- if a polypropylene pipe with a standard size of 20, 25 mm is used - nuts with a diameter of 25 mm are suitable for installation;

- when using pipes with a larger diameter (or steel billets from 25 mm and above), it makes sense to purchase equipment designed to use union nuts with an inner diameter of 32 mm.

If the listed requirements are met, the installation of the equipment will not cause serious problems if you follow the instructions in the instructions.

Pump energy efficiency

Renowned European pumping equipment manufacturers have made great strides in optimizing energy consumption by introducing several wet rotor models to the market. This was achieved through the use of modern DC motors, controlled by a controller. Such models belong to the equipment of class "A", which is considered the most efficient in terms of minimizing energy losses - their consumption does not exceed 0.09-1.3 kW).

Grundfos specialists have developed a whole series of energy-saving pumps called ALPHA2 and MAGNA3. The first ones are distinguished by simple functionality and are intended for use in heating and hot water supply systems in private houses. Models of the second type have the AUTOAdapt function, which allows you to automatically set the optimal power consumption mode. Their capabilities correspond to modern requirements for indicators of efficiency and productivity of equipment of this class. They are designed for use in heating systems of private houses and industrial enterprises.

Overview of other models

The Grundfos concern offers two more models:

- Magna.

- Alpha.

Magna

This model has three categories: large pumps, medium and small. For heating systems of private houses, the last two groups are used.

The peculiarity of the model is that it can be used for heating, and for hot water supply, and for air conditioning systems. The device is provided with a control unit that monitors the temperature and pressure inside the heating system. Low power pumps can be installed on underfloor heating.

Alpha

This is an innovative solution that allows you to move away from solving problems associated not only with manual configuration, but also automatic.If I may put it that way, it is a "smart pump". The pump installed in the heating system of the house decides on the basis of which mode it will work. And be sure that he will choose the best option. And this is an even distribution of heat throughout all rooms, plus good savings in fuel and electricity.

If, for some reason, changes occur in the heating, the device adjusts itself to them. In this case, you can set the pump to certain mode settings. For example, reduce fuel consumption at night or when there is no one in the house. Plus, a unit is installed in the power supply system, which is responsible for converting the frequency of the current.

Modes of operation

The modern recirculation pump for heating belongs to multifunctional devices. Various samples of this equipment are capable of operating in the modes indicated in the passport, including "fixed speed". All of them are equipped with a synchronous motor, the operation of which is controlled by an integrated processor. During the operation of the unit, the control unit registers the following basic parameters:

- current strength;

- rotor speed;

- temperature in the working area and others.

Its presence allows you to adapt to a specific heating network with an optimal energy consumption mode.

Parsing the pump with your own hands

If repair is necessary, the equipment must be taken to the service, if the device is under warranty

Any user who has studied the design well can disassemble the purchased sample of pumping equipment, if desired. The need for this often arises when it is necessary to repair it or overhaul with the replacement of worn parts. After complete disassembly, the main working units of the mechanism are inspected, and then checked for wear.

The main focus is on examining the condition of the "wet" rotor. It should be removed and replaced with a new part in the presence of a repair specialist who can control this difficult operation.