Boiler heat exchanger

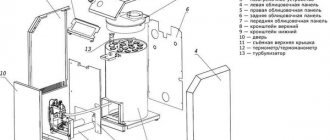

At the beginning, remember that the heat exchanger is the main element, as such, in the device of a gas boiler. It is through the heat exchanger that the heat energy from the combustion gas is transferred to the heat carrier (primary heat exchanger) and through the heat exchanger is transferred from the hot heat carrier to the cold one (secondary heat exchanger). It is worth noting that both of these heat exchangers are very often replaced by a mixed heat exchanger, which is better known as a bithermal heat exchanger. In the first photo we look at the location of the heat exchanger in a gas boiler with a closed combustion chamber.

The second photo shows the appearance of the heat exchanger.

Types of gas boilers

According to the principle of operation, gas boilers are divided into two groups:

- convection;

- condensing.

The first group of boilers is considered to be traditional equipment that produces heating by burning gas, while part of the heat goes away along with flue waste. The principle of operation of such a boiler is simple, understandable, and the price is relatively low.

The second type of boilers is developed according to new technologies that allow more complete use of the heat of combustion of gas. This allows you to get an efficiency of about 15-20 percent higher than that of the convection model. This means corresponding fuel savings and cheaper heat. However, it is noticeably higher than that of convection.

Many European and world-class companies are engaged in the development and production of gas boilers. Almost all modern models are equipped with a reliable automated protective system that does not require manual control, which is responsible for supplying fuel and maintaining the temperature in a given mode. Models equipped with a gas pressure controller are guaranteed against overheating, fire and other similar breakdowns, as it will immediately stop supplying gas in the event of pressure drop, fuel leakage or flame extinguishing.

2013-01-23 10 529

In many European gas boilers, a bithermal heat exchanger is installed. Judging by the assurances of manufacturers, this reduces the production cost and practically does not affect the heat transfer and efficiency of heating equipment.

On the Internet, on the contrary, you can find many articles warning against buying boilers with a bithermal heat exchanger. To figure out where the truth is, you need to learn about the design and operation of the device.

Heat exchangers made of steel

The steel heat exchanger is technologically the easiest to manufacture. Hence the low cost of such boilers, and hence their availability.

Steel, as a material, has good ductility, and therefore, under the influence of temperatures, a heat exchanger made of steel is less susceptible to thermal deformation.

At the same time, steel is susceptible to corrosion, which means that the service life of a boiler with a steel heat exchanger is relatively shorter. And the weight of such boilers is large, but the efficiency is not the best.

Functioning

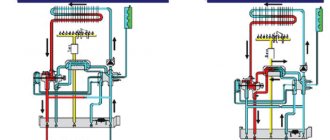

Let's take a look at how this device works. In this case, heat from the plates is transferred to the outer tube, then to the water in the radiator panel. In winter, if the heating is turned on, when hot water is closed, it circulates in the device, and the DHW circuit is shut off.

After the hot liquid starts up, the radiator closes and the DHW circuit opens. In this case, the heat from the outer pipe, the heat exchanger, is transferred to the water, which flows mainly in the inner part of the equipment.

After the water closes, the heating process functions again.When choosing suitable equipment for space heating, you need to pay attention on the design of any device.

It is necessary to decide in which cases a gas radiator should be installed, and in which cases equipment with a separating heat exchanger should be chosen.

Gas heating bithermal heat exchanger can be described as follows, it acts like a pipe in a pipe. The panel is heated in the outer tube, and the inner part prepares the DHW water.

Cast iron heat exchanger

The cast iron heat exchanger is not subject to corrosion, but requires careful maintenance and careful operation. These features result from their properties of cast iron and the main thing is the fragility of cast iron. Uneven heating, which most often occurs due to scale, leads to cracks in the heat exchanger.

Information: Flushing the coolant is an obligatory and basic element of the technical operation of a gas boiler. The coolant is being flushed

- Once a year, if used as a heat carrier - running water (not recommended),

- Once every 2 years, if used - antifreeze,

- Once every 4 years, if purified water is used.

Preventive work

In order to avoid difficulties in cleaning the heat exchanger, it is necessary to carry out periodic preventive maintenance. In this case, it is best to use any chemical method that involves a non-collapsible method, and use those substances that are in the composition of the reagents. After flushing the heat exchangers, it is necessary to treat them with a special solution, which will prevent the appearance of scale and rust on the walls of the units.

The ideal option is to install filter softeners or a special filtration system. This will provide the heat exchanger with protection against unnecessary fouling and deposits and will also reduce the hardness of the water. In addition, due to the rapid appearance of scale and the metal's susceptibility to corrosion, it is desirable to carry out frequent flushing of the bithermic heat exchanger, which makes it possible to prevent the formation of plaque on the metal. To reduce the appearance of scale, it is necessary to purify the water used in the system, in particular, to lower its hardness indicator. This is done through the use of special filters and reverse osmosis.

Flushing a bithermal heat exchanger is a necessary procedure, thanks to which it is possible to significantly extend the "life", that is, the service life of the equipment. Cleaning should be done as soon as the instrument becomes dirty, but it is advisable to flush with a reagent mixture every year.

Which boiler to choose with a bithermal or plate heat exchanger?

Home> Articles> Which boiler to choose with a bithermic or plate heat exchanger?

06.04.2014

We would like to start our article with the following: 1. Our company deals with gas boilers of the Italian company Immergas, and we will give an example on the boilers of this manufacturer.

2. We would like to note that Immergas manufactures a wide range of household wall-mounted gas boilers, there are more than 80 models of them. And the Immergas company in the model range has such boilers as with a bithermal heat exchanger, as well as boilers with two heat exchangers. You can choose any model you prefer:

EOLO Star 24 3E - boiler with one heat exchanger EOLO Mythos 24 2E - boiler with two heat exchangers

3. There are unknowing or unscrupulous sellers in our markets. They scare people with various photographs and samples of damaged heat exchangers, both bithermic and plate (secondary heat exchanger). Heat exchangers break and clog regardless of their design. Heat exchangers become clogged with scale, only if the boiler is used incorrectly and it does not depend on what design the gas boiler is (with one or two heat exchangers).Therefore, we will simply tell you why we chose boilers with a bithermal heat exchanger and its advantages.

4. We will immediately show photographs of boilers with two heat exchangers, so that there are no questions that problems do not arise in a boiler with two heat exchangers. And they are not clogged with scale, only in the stories of sellers;).

Based on our experience, we recommend boilers with a bithermal heat exchanger. Advantages of boilers with bithermic heat exchanger: 1. Faster preparation of hot water + higher efficiency for preparation of hot water. In a boiler with a bithermal heat exchanger, hot water is heated directly by the burner flame, which contributes to a faster heating of water, saving gas and electricity than in boilers with two heat exchangers.

In a boiler with two heat exchangers, in order to heat hot water, it is necessary to first heat the primary heat exchanger (for heating), when it in turn heats up, only then will it heat the hot water in the secondary heat exchanger. This leads to significant consumption of water, electricity and gas. Increases waiting time and not comfort.

Efficiency of a boiler with one heat exchanger - 93.4% Efficiency of a boiler with two heat exchangers - 91.7%

2. More comfort when controlling the water temperature... Since in a boiler with one heat exchanger, the burner flame heats directly the heat exchanger for hot water preparation, the temperature control is more accurate and faster. Also, such boilers adapt much faster to changes in the incoming cold water (temperature, flow, pressure).

Now, imagine: the cold water entering the boiler has changed in temperature (flow, pressure), then a boiler with one heat exchanger instantly reacts and changes the flame for heating. In order to adapt to the new conditions, a boiler with two heat exchangers initially needs to change the water temperature in the primary heat exchanger (heating) and only after that the temperature in the secondary heat exchanger will begin to change, and this leads to great discomfort.

3. More reliable design. A simple but very reliable design of a boiler with a bithermal heat exchanger is associated with the absence of such unreliable components as a three-way valve and a secondary heat exchanger. Fewer parts improves boiler reliability without sacrificing comfort and efficiency.

If scale begins to form in the heating circuit (if the boiler is used improperly), that is, there is a likelihood of scale particles detaching from the heat exchanger, then: In a boiler with two heat exchangers, these pieces of scale will fall directly into the secondary heat exchanger, thereby there is a high probability of breaking it, you will have to buy new secondary heat exchanger (costs up to 150 euros). In a boiler with a bithermal heat exchanger, this situation cannot be, since there is no secondary heat exchanger, and pieces of scale will go into the heating system, thereby not damaging the boiler.

4. More accessible service. A boiler with a bithermic heat exchanger, if scale forms, can be washed and cleaned without any problems. Then, in a boiler with two heat exchangers, it is practically impossible to flush the secondary heat exchanger, due to its design: such heat exchangers consist of a set of plates, the distance between which is 2-3 mm, and there is a high probability that when flushing the heat exchanger will clog even more (its cost comes up to 150 euros).

5. More affordable price of a boiler with a bithermic heat exchanger. Boilers with a bithermal heat exchanger are 10-15% cheaper. This is due to the absence of components such as a three-way valve and a secondary heat exchanger.

Myths about a bithermal heat exchanger: 1. The disadvantage of a bithermal heat exchanger is that the heat transfer in the hot water supply mode is limited. Taking the passports for a boiler with a bithermic heat exchanger and a boiler with two heat exchangers, you can see the following: That one and the second boiler prepare hot water in the same way. At Δt = 30 ° C the boilers can produce 11.1 liters / minute of hot water. This is sufficient for the simultaneous use of two parsing points. Thus, we see that the boilers do not differ in terms of hot water performance.

2. There are constant changes in hot water temperature. A modern boiler has a function: smooth flame modulation. This allows the boiler to precisely keep the water temperature at the set value, and quickly and accurately respond to changes in water temperature and its flow. Thus, you will always have hot water at the set temperature, regardless of the incoming cold water temperature and the hot water consumption.

3. The process of salt (scale) deposition is more intensive. Thanks to the functions: - smooth flame modulation - post-circulation water function - heat exchanger cooling function - anti-scale magnet - anti-scale magnet Scale formation in the hot water circuit is practically zero Only Immergas provides a 5-year guarantee on the bithermal heat exchanger in case of scale formation in the hot water system.

Often competitors (or simply untrained sellers) show such photos:

Let's analyze this photo in more detail:

1. It was originally a low-cost heat exchanger and saved on it. At Immergas, the heat exchanger consists of 6 tubes. This gives the advantage that the heat exchange area is larger, and therefore it does not need to be installed closer to the burner flame, in contrast to heat exchangers with 4 and 5 tubes, where the heat exchange area is much smaller, and it is necessary to obtain the boiler power in both cases - 24 kW. Accordingly, the temperature of the flame, which heats the walls of the heat exchanger, is lower.

Conclusion: the more the walls of the heat exchanger are heated, the higher the temperature inside its tubes, the faster and more intensively scale forms.

2. Scale formation occurs simultaneously over the entire area of the heat exchanger (it is heated evenly by the flame of the burner), as, for example, in the photo with a separate heat exchanger, it can be seen.

Conclusion: the photo of the bithermal heat exchanger shows that only one tube is clogged. Accordingly, this is not caused by the natural formation of scale, but by other problems (we will analyze them below).

3. Scale build-up on the heating circuit. The boiler operates in a closed heating system. The water there eventually becomes "dead". When it is heated, scale does not form on the walls of the heat exchanger in the future. If the heat exchanger is clogged in the heating system, then this is due to: a. The primary factory defect of the heat exchanger is water leakage from the heat exchanger tubes. b. Defect in the heating system, due to poor-quality installation of the heating system - water leakage in pipes, expansion tank, radiators, etc. In both cases, you have to constantly feed the heating system with new fresh water. And if you do this constantly, then scale will form on the walls of the heat exchanger, which will lead to a complete blockage in the tubes. And this does not depend on the design and type of heat exchanger. If you have to constantly recharge the heating system or increase the temperature of heating and hot water, then immediately call the service for diagnostics.

4. Why is the DHW circuit clogged? Initially, scale formation occurred in the heating circuit - from the beginning the heating circuit became clogged, and when the heating circuit ceased to be a "pillow" between the burner flame and the hot water circuit, the hot water circuit gradually began to clog, as the flame began to heat the hot water circuit directly directly ...

Subscriber's error: 1. Constantly energized the heating system and did not call the master. 2.I did not do the annual maintenance of the boiler, on which the master checks the water flow through the hot water supply. And also asks how the heating system worked in the winter. 3. Constantly increasing the temperature of heating (radiators warmed less) and hot water (it became gradually colder). How was it necessary to suffer and disrespect yourself? - call the master for replacement and repair, only until the passages are completely clogged. In this situation, the heat exchanger is only to be replaced.

Conclusion: If you are shown a heat exchanger clogged along the heating circuit and at the same time along the hot water circuit, then this is the reason in the heating circuit, but not as in the hot water preparation system. When the heating circuit is clogged, it is usually the subscribers themselves who do not want to contact the service or find a leak in the heating system to blame. And no matter what kind of heat exchanger or brand of boiler you install, the result will be the same.

When you open a hot water tap, boiling water flows, and you can scald. The boiler has a temperature setting mode. And the hot water will not be higher than the temperature set on the boiler. The maximum temperature can be set to 55 ° C. And there is a difference in the preparation of hot water in boilers, only during the heating season: - In a boiler with a bithermic heat exchanger, hot water first flows (but not more than 55 ° C in winter, when the heating system is operating), then it decreases to the set one. - It gradually heats up in a boiler with two heat exchangers. The disadvantage of this heat exchanger is when the boiler is operating in summer mode and the heating system is not working. To heat the water in the hot water heat exchanger, you have to wait until it heats up in the primary heat exchanger of the heating system. This is a big discomfort while waiting for hot water.

Summing up what is written above, it is the bithermal heat exchanger that is the ideal option in terms of high quality, reliability, ease of use and acceptable cost.

How to properly mount the equipment

You can install such equipment both independently and with the help of boiler installation specialists. The only condition that cannot be violated is to include the boiler in the gas system itself, because such work will have to be entrusted to a specialist. Moreover, such people must have special approvals and certificates. If the homeowner violates this provision, then first of all, he will be disconnected from the system, and secondly, a very large monetary fine will be imposed. But in order to independently connect a cast-iron gas boiler, you still need construction skills.

Cast iron boilers have an impressive weight, so if a hinged boiler is bought, then an impressive frame must be mounted under it. It is necessary to install such equipment in a boiler room.

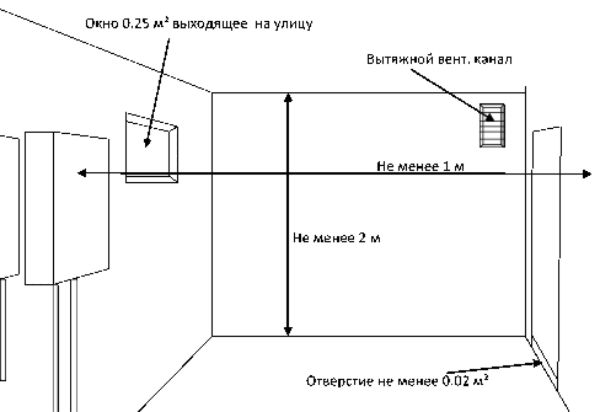

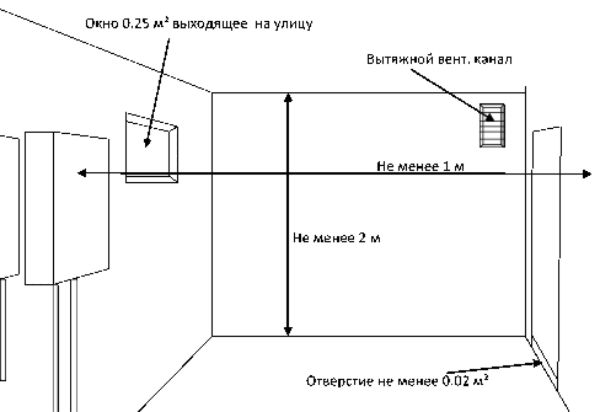

And there are special requirements for such a technical room:

- the ceiling height in the boiler room must be at least 3 meters, and the room must be at least 4 sq. meters. These parameters are suitable for a boiler with an average capacity, but the larger the boiler, the more it should be around the place. Usually such things are recommended by the manufacturer themselves;

- the presence of at least a single window, because there must be an air flow. The opening for the door must be 80 cm wide and the gap between the floor and the door leaf must be at least 35 mm;

- there must be a distance of at least 3.5 meters to electrical and gas installations or appliances;

- on the floor, in the place where the installation of the cast-iron boiler is planned, a cement screed is poured, and this place is reinforced with a steel plate. It is important to remember that the sheet of steel must be located under the entire surface of the bottom of the heating installation, and also protrude 3-4 cm outside on its front side;

- materials with refractory qualities, it is necessary to strengthen the entire part of the wall where the chimney pipe will pass.

It will be interesting for you >> The principle of operation of a double-circuit boiler "Bosch"

The main paper for self-preparation of the boiler for mounting it into the system should be an accompanying document in the form of instructions developed by the manufacturer.

Such a document gives the parameters and regulates the procedure for connecting the boiler to the main pipeline, to the chimney system, as well as to the return and supply system.

The principle of operation of the bithermic heat exchanger

The operating modes for home heating and hot water preparation are different. In the first case, the coolant heats up during fuel combustion and then moves along the circuit. The provision of water supply is implemented as a secondary option. The carrier is heated in the same way, the heat is given to the containers allocated for liquid for household needs. In this case, water does not have to move along the contour, it is in the tank.

Most boilers with such a heat exchanger are capable of serving only one circuit at a time. Parallel circulation of the heating medium for heating and water heating does not occur in this case. When the tap is closed, only the liquid belonging to the dwelling heating system moves through the exchanger. By opening the hot water supply, the consumer suspends heating for the heating system for the duration of the intake. Serving the two tasks in turn helps to focus more on the heat supplied by the burner.