Features of the

The unique chimney device consists of three parts:

- inner pipe made of stainless steel of excellent strength and heat resistance;

- heat-insulating material in the form of basalt or ceramic wool, polyurethane foam, vermiculite.

- protective outer tube made of galvanized / stainless steel.

To improve aerodynamics, the designers have provided a cylinder shape. All three layers of stainless steel sandwich pipes are glued together, and some parts of the chimney are mounted, as in drainage pipes, with sockets.

Double-walled sandwiches solve the problem of condensation formation on the walls of the chimney in cold weather due to the insulation included in the structure. This insulation prevents soot from forming on the inner surface and prolongs the service life.

To facilitate the assembly of the prefabricated structure, fittings are available for connection, channel rotation and other functions.

- The main length of the chimney is carried out in segments of 1 and 0.5 m in length.

- Horizontal sections (loungers) are connected using revision tees to eliminate pipe clogging.

- A tee for collecting condensate and cleaning the internal cavity is installed at the beginning of the vertical section of the channel. This often happens immediately after the chimney exits to the outside of the building. One of the outlets of the tee is threaded to remove condensation moisture.

- The corners for the device for turning the chimney by 90º are made of pipe materials and insulated with an insulator layer.

- Compensator for smooth changes in the linear dimensions of the sandwich when changing temperatures. In high-rise buildings, it is installed on each floor, and in one-story buildings above the floor.

- The roof abutment structure is designed as a single unit and serves to form the exit of the chimney channel to the roof.

- Node for eliminating leakage in the roof outlet. Installation is carried out around the chimney.

- A tip to keep debris, snow and dust out of the duct openings.

Is it possible to liner with a polymer stocking?

The stainless steel chimney can be sealed not only with sealants, but also with the FuranFlex polymer pipe. The peculiarity of the polymer stocking is that it consists of three layers:

- The inside of the thin-film sleeve is made of a material that is similar in properties to polyethylene, but at the same time resilient like rubber and resistant to high temperatures.

- The composite layer is made of fiberglass fibers and resins. The layer performs the function of reinforcement - it gives the pipe strength and rigidity. The main feature of the composite material is that when heated, it changes not only its size, but also its structure.

- The outer shell is made of high-strength fabric. It performs several functions: it determines the diameter of the pipe, protects the composite material from mechanical damage, and absorbs excess resin when heated.

FuranFlex polymer stockings are successfully used not only to restore the functionality of brick systems, but also to lining stainless steel chimneys. Since the stocking is initially flexible, it can be inserted into a system of any complexity. Bends and turns when sealing are not a problem. The material is resistant to corrosion at high temperatures, has high strength and can last for several decades.

Why are solid fuel devices considered?

It's simple - there are always more problems with them in these matters when compared with gas ones. Let us explain why:

- First of all, gas heaters are almost always factory-made products. That is, they must have a branch pipe of a certain section for connection to the chimney. The channel cross-sectional area is also discussed in the technical documentation of the model. That is, everything is quite simple - it is not allowed to narrow the channel in any of the sections of the upward chimney.

Factory-assembled boilers or furnaces always have a chimney connection. That is, the problem with the cross section of the chimney is no longer worth it - it should be no less than that specified in the technical documentation.

- The temperature of the gas combustion products leaving the chimney is incommensurably lower than that of the wood or other solid fuel generated during combustion.

- It is also difficult to compare the volumes of gas mixtures formed during the combustion of "blue" and solid fuel. The difference here is quite significant!

But solid fuel heating devices, stoves or boilers are very often created independently. Or they are "inherited" from the former owners of the house. And here it will never be superfluous to check the parameters of the chimney connected to such a device.

However, what concerns the height of the pipe and checking the draft - probably, it can be fully attributed to gas heating equipment. The cross-section is known, but it doesn't hurt to check the rest.

But let's start with the section.

Chimney installation rules

To ensure good traction, the height of the stainless steel chimney should be more than 5 m. Horizontal sections should not exceed 1 m in length. When passing the chimney of a fireplace, stove, boiler rooms through the roof with the presence of combustible materials, it is imperative to install a spark arrestor.

At the junction of the chimney with an overlap made of combustible material, a steel sheet must be fixed

When installing the system with your own hands, you need to pay special attention to passing through ceilings, walls, roofs. If the ducts are not insulated and made of stainless steel, the chimney pipes must be located at a distance of at least 1 m from the ceiling.

Important! It is unacceptable to join pipes in the thickness of the walls.

The minimum allowable distance from the ceiling, wall, floor is 70 cm.If a stainless steel pipe for a chimney passes through a non-combustible roof, then the minimum allowable gap between it and the ceiling should be at least 13 cm.

The total number of chimney turns is no more than three. When installing a stainless steel chimney with your own hands, the diameter of the pipe should not be less than the outlet of the heater.

Beneficial use of double pipes

The correct approach and competent study of the basic nuances will help you install the chimney sandwich yourself.

Due to this characteristic, a separate foundation for the oven is not required.

- Compactness, which, combined with lightness, allows you to easily transport products to their destination.

- Simple repair, thanks to which specialists can easily replace one of its parts in the chimney.

- Variety of fittings that will help you install the device with an exit through a roof or wall.

- The presence of a heat-insulating layer between the pipes, which allows the temperature to be reduced from the outside.

This advantage is aimed at improving the fire safety of the structure.

- Lack of stagnation and the possibility of effective smoke removal, because the inner surface of the pipe has a flat cylinder shape.

That is why so little soot is formed in the chimney pipes made of stainless steel sandwich.

- Anti-corrosion materials from which the products are made, therefore, condensate and chemical compounds of a destructive effect do not accumulate on the walls of the latter.

- Ease of operation.Regular preventive inspections of chimneys are, of course, necessary, but the design nuances of such products allow them to be performed not so often.

- Attractive appearance. Sandwich pipes do not need any additional finishing and they look great both outdoors and indoors.

Stainless steel chimney: pros and cons

Stainless steel chimneys are in demand due to their undoubted advantages, including:

- versatility and multifunctionality: stainless steel is suitable for all types of heating systems and for the construction of structures of any complexity;

- lack of hygroscopicity: stainless steel does not absorb condensation;

- resistance to corrosion, high and low temperatures, drops in air humidity, the effects of chemically aggressive substances;

- ease of assembly: sold as ready-made modules;

- profitability: cheaper than other chimney options;

- ease of use: individual elements are easy to replace as they wear out.

The disadvantages include the unaesthetic design.

How to calculate the cross-sectional area of a chimney?

There are several methods for calculating the optimal section. For example, from the size of the hearth combustion chamber or from the area of the blowing window of the furnace. But in this publication, attention will be focused on the methodology, which is based on the assessment of the volume of flue gases formed during combustion.

The combustion of wood and other solid fuels is always accompanied by a very significant smoke generation. And the chimney must be able to drain these volumes out in a timely manner.

On the basis of calculations and experiments, specialists have long compiled tables from which it is possible to obtain information on the specific smoke production for different types of solid fuels. That is, what volume of combustion products is formed when burning, say, one kilogram of firewood, coal, peat, etc.

We will also present such a table (in an abbreviated version). In addition to specific smoke generation, it shows the calorific value of the fuel (the amount of heat released during the combustion of one kilogram) and the approximate temperature of the combustion products at the exit from the chimney. The first of these characteristics does not interest us at a given moment - it just gives a general idea of the fuel efficiency. But the temperature, yes, is needed for calculations.

| Fuel type | Specific calorific value of fuel, kcal / kg, averaged | Specific volume of emitted combustion products from combustion 1 kg, m³ | Recommended temperature at the exit from the chimney, ° С |

| Firewood with an average humidity level - 25% | 3300 | 10 | 150 |

| Peat lumpy (in bulk), air drying, with an average moisture level not higher than 30% | 3000 | 10 | 130 |

| Peat - briquettes | 4000 | 11 | 130 |

| Brown coal | 4700 | 12 | 120 |

| Hard coal | 5200 | 17 | 110 |

| Anthracite | 7000 | 17 | 110 |

| Pellets or wood fuel briquettes | 4800 | 9 | 150 |

As you can see, the volumes are impressive. Even the types of fuel that give the minimum smokiness are already about 10 cubic meters for each kilogram burned. This means that, simply for reasons of physics and geometry, the section of the chimney channel should be able to constantly divert these considerable volumes outward.

From this and "dance" when calculating.

chimney

The volume of combustion products released during the combustion of solid fuel within an hour can be determined by the following formula (taking into account the thermal expansion of gases).

Vgh = Vsp × Mth × (1 Td / 273))

Vgч is the volume of combustion products generated within an hour.

Vsp is the specific volume of the generated combustion products for the selected type of fuel, m³ / kg (from the table).

Mtch is the mass of the fuel load burned during one hour. It is usually found as the ratio of the total fuel load to the time it is completely burned out. For example, 12 kg of firewood is loaded into the oven at once, and they burn out in 3 hours. This means that Mtch = 12/3 = 4 kg / hour.

Тд - gas temperature (℃) at the outlet of the chimney (from the table).

273 is a constant to bring the temperature parameters to the Kelvin scale used in thermodynamic calculations.

We suggest that you familiarize yourself with a wood-burning water heater with your own hands

Vgс = Vgч / 3600

To find out the cross-sectional area of the channel, which is guaranteed to pass this volume through itself at a certain speed of gas movement, it is necessary to find their ratio

Sc = Vgc / Fd

Sc - cross-sectional area of the chimney channel, m2.

Fd - gas flow rate in the chimney, m / s

A few words about this speed. For heating devices and structures of a household class, they usually tend to stop in the range from 1.5 to 2.5 m / s. With this, on the one hand, low speed, there is no significant resistance to the flow, there are no strong eddies that slow down the movement of gases.

If a cross-section is found (and this is its minimum value), then according to the known geometric formulas, one can find either the diameter for a pipe with a circular cross-section, or the length of the side - with a square cross-section, or choose the lengths of the sides with a rectangular one.

Below is a calculator that will simplify these calculations to the limit. It is necessary to indicate the type of fuel, the approximate consumption of its consumption (more precisely, the mass and burnout time of the full load) and the expected flow rate of gases in the chimney. The program will do the rest by itself.

- the minimum diameter for a circular section;

- the minimum side length for a square section;

- the cross-sectional area, over which, for example, you can choose the dimensions of the sides for a rectangular cross-section.

Go to calculations

Stainless steel: design nuances

There are many types of chimney materials for private homes. The pipes are divided depending on the purpose and functionality.

Insulated double-layer pipes allow the inner part to heat up as quickly as possible and contribute to the effective removal of smoke from the combustion center. They are installed outside the building in cases where it is not possible to carry out the internal wiring of the chimney.

The installation of a chimney sandwich can be ordered by specialized builders, but if you understand all the intricacies of the technology, you can install the smoke channel yourself.

This material is quite resistant to temperature extremes and has excellent anti-corrosion properties. Internal stainless steel products can withstand temperatures of 850̊C and even drops up to 1200̊C.

In the production of sandwich pipes, two grades of steel are most often in demand: 310S and 316 Ti. The temperatures of the working media for these materials are quite high, the maximum threshold reaches 1000 ° C. These two grades of stainless steel are especially preferred in chimney designs for baths and solid fuel boilers, where very high temperatures must be withstood. Such chimney products will last a very long time.

If you are looking for a high-strength construction, then the ideal option would be to manufacture the inner and outer shell of the pipe from the same stainless steel.

The thickness of the insulating layer affects the dimensions of the pipe section. In addition, the diameter of the chimney sandwich pipe depends on the location of the device. Internal pipes are selected depending on the power of the heater. The larger it is, the larger the cross-section of the product should also be.

Here are the main indicators of the dependence of the pipe diameter and the capacity of the furnace structure:

- cross-section of the product 50-600 mm - for gas turbine plants and wood-fired ovens;

- diameter 50-700 mm - for solid fuel boilers;

- 50-500 mm - for diesel generators and gas piston devices;

- 50-300 mm - for microturbine devices;

- up to 200 mm - for gas or diesel boilers.

We must not forget that it is not recommended to use fiberglass as an insulating layer, because it retains its operational characteristics only at a temperature not exceeding 350 С. And in structures for baths this indicator reaches 600̊ С.

Scope of use of stainless steel pipes

First of all, stainless steel pipes are used in the construction of water supply, heating and sewerage systems. It is here that the pipeline is constantly exposed to water, products made of ordinary metal are destroyed and rusty. Lime deposits form on the inner walls of conventional steel pipes, which gradually narrows their diameter. As a result, communications must be repaired or replaced.

Stainless steel pipes are completely devoid of these disadvantages. The only thing that somewhat limits their widespread use is the high price. Therefore, they are more often used in large centralized supply pipelines.

In enterprises that produce food for the population, food grade stainless steel pipes are in great demand. These products are not only resistant to corrosion, but also to the formation of plaque from microorganisms and fungi.

This useful quality is ensured by a perfectly flat inner surface. Through the pipes

move food solutions and finished food products without any damage to their quality. Finished products such as milk or lemonade are poured through stainless pipes that cannot replace plastic or metal products.

Stainless steel pipes are used in the construction of large pipelines for the delivery of oil and gas. The well-known streams that transport fuel to many countries of the world are made using this technology. In chemical plants, many tons of aggressive chemical solutions, including alkali and acid, are distilled through these pipes, without the slightest damage to them.

And now it is impossible to imagine the modern production of cars, ships and other vehicles without a stainless pipe. They are not only used as elements that protect the main components and assemblies from corrosion, but also create special strength with their help in combination with an attractive appearance.

In the construction and design of premises, a stainless profiled pipe has found application:

- On the street, with its help, stylish elements have been created that not only decorate, but also withstand high mechanical stress.

- For commercial and residential interiors, it is used to create beautiful and durable arches, railings and railings that emphasize the overall style.

Profiled stainless steel railing

In the production of furniture, such products are indispensable, even the expression "furniture pipe" has appeared. The supporting structures of beds, sofas and armchairs are assembled from it.

Separately, I would like to say about the use of stainless steel in the construction of stoves, fireplaces and other heating devices. Recently, a stainless steel chimney is used more and more often. A small lightweight stainless steel pipe is replacing bulky brick structures. The fact is that through the chimney, fuel combustion products are discharged, which are characterized by a high temperature and chemical composition, which negatively affects traditional metal and asbestos products.

The options for using stainless pipes are very wide, to list them all, a separate large review is needed.

Stainless steel products have undoubted advantages:

- high reliability and durability;

- corrosion resistance;

- ability to withstand high temperatures;

- resistance to many substances, the chemical composition of which negatively affects conventional materials;

- high aesthetic qualities.

Features of production

The production of these products differs from conventional materials in that during the melting process, elements are added that give strength and other properties to the steel. First of all, these are chromium, titanium, nickel and molybdenum. It is chrome plating that makes stainless steel products resistant to corrosion and gives a shiny look.

Stainless steel pipe is produced in two ways: seamless and welded.

With the seamless method, steel is poured into a billet in the shape of a pipe, then the process of calibration and surface treatment takes place inside and outside. Processing can begin in the cold or hot state of the product, respectively, they are called cold-deformed and hot-deformed pipes. The advantage of this method is the special strength of the products and the ability to manufacture pipes of any thickness.

The manufacture of products by a welded method has become more widespread. Its essence is as follows - a blank of a flat sheet is taken, rolled into a pipe, and the connection is made using a special welding device. Further, the products also go through the process of calibration and surface treatment.

By the way, profile stainless pipes - square and rectangular are produced in this way.

Chimney height.

Here we can do without complicated calculations.

Yes, of course, there are rather cumbersome formulas that can be used to calculate the optimal chimney height with great accuracy. But they become really relevant when designing boiler houses or other industrial installations, where they operate with completely different power levels, volumes of fuel consumed, heights and diameters of pipes. Moreover, these formulas also include an ecological component for the emission of combustion products to a certain height.

There is no point in listing these formulas here. Practice shows, and this is also stipulated in building codes, that for any of the theoretically possible solid-fuel devices or structures in a private house, a chimney (with natural draft) with a height of at least five meters will be sufficient. You can find recommendations to focus on an indicator of six meters.

In this case, it is precisely the height difference between the outlet from the device (for furnaces it is often considered - from the grate) to the upper edge of the pipe, without taking into account the worn umbrella, weather vane or deflector. This is important for those chimneys with horizontal or inclined sections. Let's repeat - not the total length of the pipe used, but only the height difference.

The height of the chimney is precisely the height difference between its inlet and outlet, and not the total length of the chimney, on which there may be horizontal or inclined sections. By the way, you should always strive to minimize the number and length of such sections.

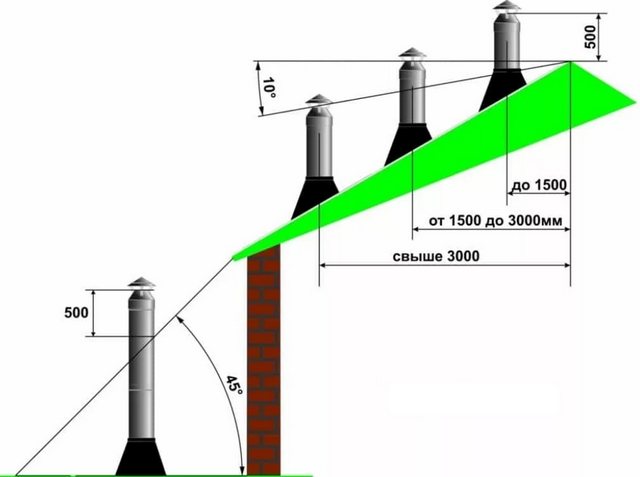

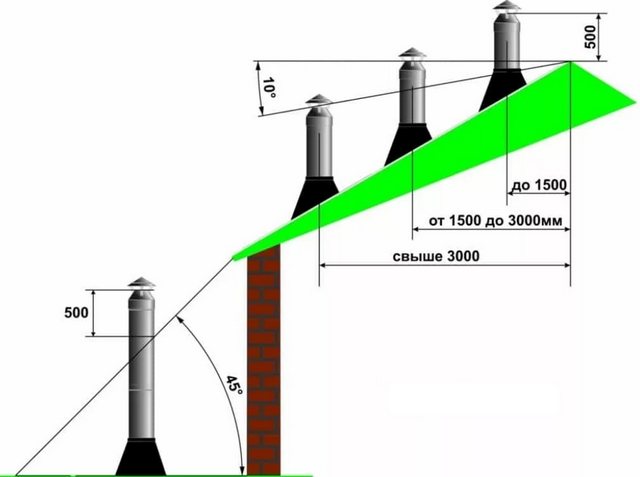

So, the minimum length is clear - five meters. Less is impossible! More? Of course, it is possible, and sometimes it is even necessary, since additional factors may intervene due to the specifics of the building (corny - the height of the house) and the location of the pipe head relative to the roof or adjacent objects.

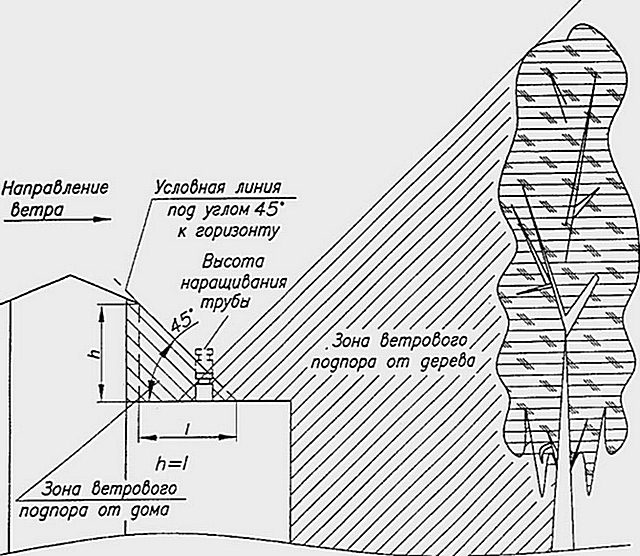

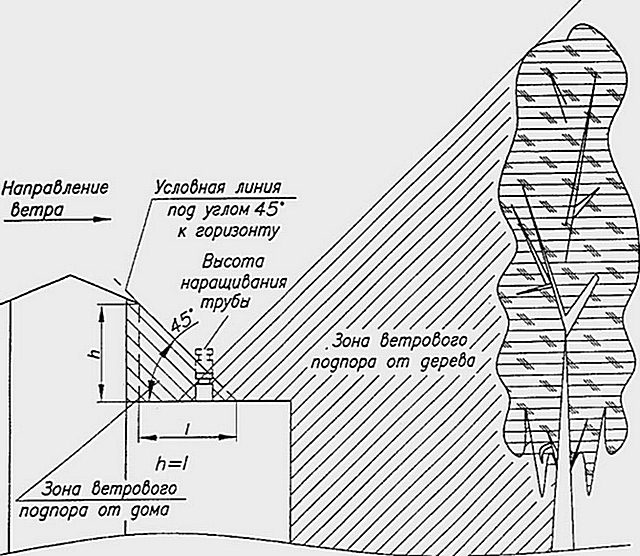

This is due to the rules of fire safety, and the fact that the head of the pipe should not fall into the so-called zone of wind support. If these rules are neglected, then the chimney will become extremely dependent on the presence, direction and speed of the wind, and in some cases the natural draft through it can completely disappear or be reversed ("topple over").

These rules are not so complicated, and taking them into account, it is already possible to accurately outline the height of the chimney.

chimney

Basic rules for the location of chimneys relative to building roof elements

- First of all, no matter what roof the chimney passes through, the cut of the pipe cannot be closer than 500 mm from the roof (it does not matter if it is pitched or flat).

- On roofs of a complex configuration, or on a roof adjacent to a wall or other object (say, the edge of the roof of another building, extension, etc.), the wind support zone is determined by a line drawn at an angle of 45 degrees. The cut-off of the chimney must be at least 500 mm higher than this conditional line (in the upper figure - the left fragment) ..

- By the way, the same rule applies even then, for a year, there is a tall third-party object next to the house - a building or even a tree. The figure below shows how the plotting is done in this case.

Tall trees near the house can also create a zone of dense wind backwater.

- On a pitched roof, the height of the pipe section protruding above the roof depends on the distance from the ridge (left fragment of the upper diagram).

- A pipe located at a distance of up to 1500 mm from the ridge must rise above it by at least 500 mm with its edge.

- With a distance from 1500 to 3000 mm, the upper edge of the pipe must not be lower than the level of the ridge.

- If the distance to the ridge is more than 3000 mm, the minimum permissible position of the pipe cut is determined by a line passing through the top of the ridge drawn at an angle of -10 degrees from the horizontal.

To reduce the dependence of thrust on the wind, special caps, deflectors, and weather vane are used. In some cases, the use of a spark arrester is also required - this is especially important for solid fuel devices.

It remains to sit down at the drawing of your house (existing or planned), determine the place of the pipe and then finally stop at some of its height - from 5 meters or more.

We offer you to familiarize yourself with How to make a bench in a bath with your own hands

Checking the planned pipe for the amount of natural draft

In fact, we have already determined the main parameters of the chimney - a sufficient section of its channel and height. But for devices with natural thrust, it will never be superfluous to check the strength of this very thrust. So that it does not happen that the built chimney suddenly refuses to fulfill its main functions.

Draft is, in fact, the pressure difference between the hot gases in the pipe and the outside air. It is this difference that stimulates the movement of the gas flow through the chimney channel.

It is believed that for normal operation of a natural draft chimney, this difference should be at least 4 pascal for each meter of pipe height (0.408 mm water column or 0.03 mm Hg). That is, for a five-meter pipe (our minimum), the thrust must be at least 20 Pa. This ensures both the normal evacuation of gases and the necessary supply of air for the continuous combustion of the fuel.

ΔP = Htr × g × Patm × (1 / TV - 1 / Tds) / 287.1

ΔP - natural draft in the pipe, Pa.

Htr - chimney height, m.

g - acceleration of gravity (9.8 m / s²);

Patm - atmospheric pressure. A value of 750 mm Hg is considered normal. However, the area for which the calculation is carried out may have its own specifics. It must be understood correctly that sea level is considered the norm. And with an increase in altitude, this rate begins to decline. And - quite significantly. So, when calculating, you will need to be guided by the norm for your region of residence.

Atmospheric pressure is usually measured in millimeters of mercury. However, for the calculation in the SI system, it is required to translate it into pascals. This is not difficult if you know that 1 mm Hg. Art. = 133.3 Pa.

TV - outdoor temperature. Moreover, reduced to the Kelvin scale, that is, C ° 273.

Tds is the average temperature of gases in the chimney. It is defined as the arithmetic mean of input and output indicators, followed by conversion to the Kelvin scale.

287.1 - gas constant of air. It would be more correct to choose this value for the specific chemical composition of the exhaust gases. But in our case, the error will not be significant, strongly affecting the final result.

A few important notes on inlet and outlet temperatures.

You should always strive for its optimal values. Statistics show that most fires occur with sauna stoves, in which there is practically no heat removal, heat builds up in the steam room in a short time, and the chimney usually heats up to dangerous temperatures.Therefore, you need to be able to control the temperatures in the pipe using available means - gates, valves, devices for additional heat recovery (for example, hot water tanks).

In household and heating stoves, this is easier, but control is still necessary. In boilers, where the very essence of the work lies in the constant release of heat to the circulating coolant, these questions are not so acute.

The 900 ÷ 600 ℃ mode (entry and exit), found in some sauna stoves, is extremely dangerous in all respects, and should not even be considered! A reasonable framework (and even then - their upper limit) is 600 ÷ 400 degrees for household brick and metal stoves. Usually, they try to withstand in the range of 400 ÷ 200 ℃. For gas equipment, the lower limit may fall below 100 degrees.

If all the initial values for substitution in the formula are known, you can proceed to the calculation. To do this, we again suggest using the capabilities of a special online calculator.

Go to calculations

If the obtained pressure difference falls within the norm (more than 4 Pa per meter of pipe height), then the check can be called successful.

The main parameters of the chimney have been obtained - you can proceed to the choice of materials and detailed design.

Sandwich pipe installation: highlights

All work on installing a sandwich chimney begins with marking and cutting out all the necessary technological holes. This refers to the ceiling or wall, as well as the roof itself. It should be borne in mind that the distance from the pipe to unprotected wooden structures should not be less than 40-45 cm. For fire safety purposes, let it be more than less. Otherwise, the use of protective screens is imperative!

Options for sandwich pipes for a bath

Installation of the "designer-chimney" is started from the bottom up. First of all, a single-circuit pipe is installed on the furnace. Due to the lack of insulation, heat transfer is significantly increased. For example, a single-circuit sandwich pipe for a bath can be equipped with a hinged one. It is possible to use a cylindrical metal mesh for stones, which greatly increases the efficiency of the stove. The use of special economizers-convectors on the first chimney segment also increases the heat transfer coefficient.

The so-called starter adapter is mounted on the installed "single-circuit sleeve". It is needed in order to reliably and beautifully connect a single-wall pipe with a sandwich. Then a gate is mounted to adjust the draft level or a double-circuit chimney is immediately put on.

The following nuance should be clarified: sandwich pipes can be assembled in two ways ("by smoke" and "by condensate"). "On smoke" is when the upper pipe is pushed onto the lower one. At the same time, the smoke does not meet any obstacle. “By condensation” - the opposite is true: the upper segment is inserted into the lower one. For an optimal result, we put on the inner pipe sleeves “for smoke”, and the outer ones “for condensate”. For a better sealing effect, it is advisable to use a special heat-resistant sealant and crimping clamps.

Calculate the height of the chimney to the ceiling in such a way as to exclude the junction of the segments in the area of overlap. This will increase the degree. And now the most important point. Many people consider sandwich chimneys to be the absolute standard of safety and do not install a passage box in the ceiling passage, relying only on the thermal insulation of the pipes themselves.

The result is often very disastrous. It is compulsory to use the pass-through ceiling box. It will protect wooden structures from heat and fire. It can be covered with expanded clay, but not with sand. It is possible to use the same mineral wool as a heat insulator.

When passing the chimney through the roof, it is reasonable to use an element such as a flash master

... This is a special sealant for roofing passages, which in the common people is called a "flash drive".The element is necessary and practical, you cannot do without it. Here, a metal element of the roof cut is also used, which ensures a reliable and stable position of the chimney.

Chimney support bracket

Portable enamel sandwich

Ceiling cut

Depending on the design of the chimney, a "revision" is sometimes installed in the lower part. This sandwich pipe element is usually installed on a side chimney, which has a horizontal section. There is a small door for. A very convenient and necessary moment.

On the upper part of the chimney, spark arresters and umbrella-deflectors are installed. Purpose: to extinguish sparks and protect the pipe from atmospheric precipitation and debris.

When installing sandwich pipes for a chimney, you should exclude their touching various communications (electrical wiring, gas pipelines, water and sewer pipes, ventilation ducts). Following the manufacturer's instructions for assembling such a "constructor", you can easily do the installation of a chimney from a sandwich pipe with your own hands. It will not be difficult, although you still have to “move your brains” and work with your hands.

Quote of wisdom: He who does not need someone else's, but lives independently, is richer than everyone.

Between the two pipes of the chimney structure (external and internal) there is a material for thermal insulation. Basically, it is mineral wool (basalt or ceramic).

We offer you to familiarize yourself with Ventilation from sewer pipes - myth or reality?

Sometimes the natural material vermiculite acts as a heater. To use it for its intended purpose, it is preliminarily crushed to a granular state, and then fired in a special furnace.

Such procedures are necessary to obtain the highest quality characteristics:

- resistance to high temperatures and their drops;

- low weight;

- strength, etc.

Vermiculite is much more expensive than mineral wool, but it is distinguished by the ability to maintain its quality characteristics at an operating temperature of the chimney of 1150̊ С.

But ceramic wool is more heat-resistant and can withstand an operating temperature of 1260̊C, i.e. more than twice that of the previous material. Accordingly, the price of sandwiches with such a filler will be higher than pipes with basalt wool or vermiculite.

It is important to remember that the dimensions of the chimney sandwich pipe depend on the diameter of the boiler outlet. During installation, the product is mounted on it; therefore, the cross-section of the sandwich pipe must necessarily exceed the outlet pipe.

Today, chimney sandwiches with a cross-sectional area of 0.5 and 1 m are more in demand, but there are also diameters in the range of 110-300 mm. In the line of standard sizes of pipes for a chimney structure, there are other options, but much less often.

Pipe connecting elements have corners:

- 90̊ С - for corners and tees;

- 135 ° C - only for tees.

The thickness of the inner wall is 0.5-1 mm, and the outer -0.7 mm The indicator of the thickness of the layer of internal thermal insulation ranges from 2.5-6 cm, and the outer diameter of the sandwich structure is 200-430 mm.

Step-by-step assembly of the chimney in the house

The correct operation of the boiler largely depends on the high-quality installation of the chimney.

Build Algorithm:

- A tee with a condensate trap and revision is connected to the branch pipe of the heating unit.

- Holes are cut: round or square in the attic, oval or rectangular in the roof.

- The pipe is built up to the required height. At the level of the overlap, a ceiling-pass device is put on it, which is fixed in the overlap and filled with thermal insulation. In the opening cut in the roof, the chimney is also necessarily insulated.

- After passing the hole in the roof, a special "skirt" is put on the pipe, which is needed to protect it from leaks. The base of the "skirt" is fixed to the roof.The top of the pipe is equipped with a deflector to protect it from rain, wind and clogging. If the roof is made of combustible materials, an additional spark arrester is installed.

- The joints are tightened with clamps and treated with a sealant, if necessary, the structure is reinforced, fixing it with brackets inside the attic.

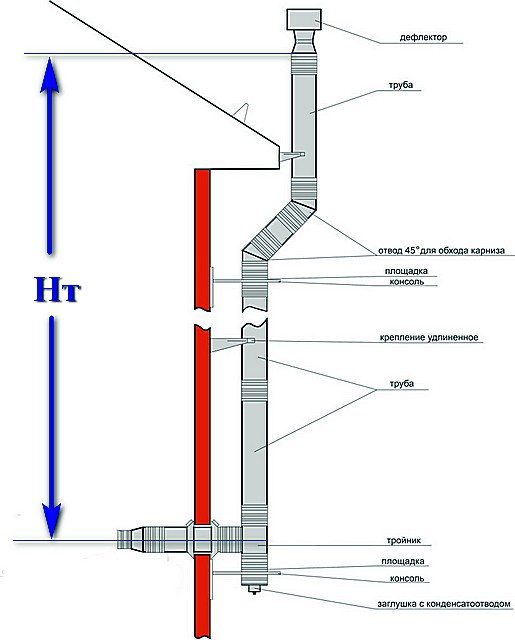

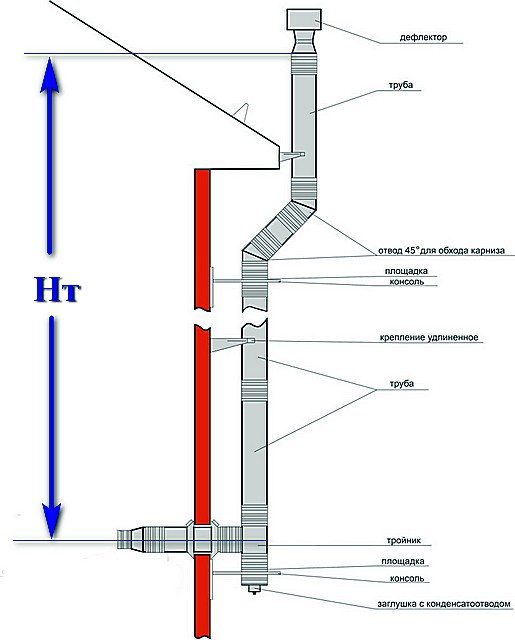

Outdoor installation

- Mark the place of passage of the chimney in the wall and cut out a hole taking into account the thermal insulation.

- Connect the passage pipe with the pipe of the heater and bring the chimney out into the street. Isolate the passage of the wall.

- Attach a tee with a drip and revision to the output pipe.

- The chimney is built up to the required height, if necessary, the structure is fixed with a bracket every two meters. The joints are tightened with clamps, covered with sealant. A conical nozzle - a deflector - is attached to the top of the pipe.

- Cover the chimney with a protective compound so that rust does not form.

- If the structure is made of single-layer pipes, insulate along the entire length.

It's important to know! When assembling the chimney, the sandwich pipes are connected so that from the outside the upper pipe is put on the lower one. Single-wall pipes during the installation of the internal chimney are connected "by smoke": the upper one is put on the lower one, the external one - "by condensate", that is, the upper one is inserted into the lower one.

We recommend that you familiarize yourself with: How to ensure the sealing of a chimney on a roof made of corrugated board

Types of connecting elements

The heating device, in addition to sandwich pipes, includes other fittings, for example:

- chimney-convector, used for the exit of combustion products outside the building;

- knee, consisting of several parts, which are joined together at an appropriate angle. With the help of the knee, you can change the direction of the output of combustion products;

- a tee that performs the function of removing condensate and smoke is used very often;

- an adapter for connecting some pipes, the most common element;

- revision - to clean the structure from soot;

- kagla regulating traction;

- rosette - for decorating the chimney;

- weather vane and cone that protect the heating system from natural precipitation;

- a fungus made of galvanized steel sheet, which protects the chimney structure from snow and rain. Installed at the very edge of the outlet pipe.

All these connecting elements can have diameters: 120, 150,200 mm and are used depending on the design features of the chimney device and other factors. The diameter of the inner pipe always corresponds to the size of the chimney sandwich and its accessories.

Types of material

Various polymers are at the heart of the sealants that are used to work with chimneys. Each group has its own properties that give the sealant certain characteristics. On sale, the material can be found in a plastic tube with various volumes. A strict separation can be carried out according to the quantitative composition. It is more convenient to use one-component sealants for chimneys that have already been prepared at the factory. Two-component sealants are also available, but their application requires a certain skill, so they are more often used by professionals in their field. Mixing of components must take place at a certain temperature and in strict proportions, which is the key to a long service life. According to the maximum temperature that can be maintained, chimney sealants are divided into:

- heat resistant;

- heat resistant.

The second option of sealants is great for performing work on surfaces where heating occurs only up to 350 degrees Celsius. For example, they are used when decorating or repairing the outer surfaces of fireplaces or stoves. Such sealants are indispensable for the elimination of cracks in the brickwork of these devices. Also, heat-resistant compounds are used to seal sandwich chimneys and pipe-to-roof junctions.Such sealants have also won their place in the field of automobile engines.

The first version of chimney sealants is called heat-resistant for a reason. This is explained by the simple possibility of using it in places where the temperature can reach 1500 degrees Celsius. Thanks to this sealant, you can seal the gap in the places of casting or masonry. If it becomes necessary to repair the chimney at the very base or at the seams, then such a sealant is best suited. Allowed to use in areas where direct contact with open fire is possible. The sealant has not only heat resistance, but also refractory properties. Since different areas in chimneys can be heated to different temperatures, an appropriate sealant is selected for them.

Advice! If there is no exact information about what the maximum temperature is possible in a certain area, then you can use a pyrometer, which will quite accurately determine the degree of heating without direct contact.

Heat resistant

The specified temperature of heat-resistant flues is extreme. This means that products with lower operating temperatures are available. This type of sealant is made on the basis of silicone. At the same time, additional additives are introduced into it, which make it possible to achieve the required stability. Iron oxide is added to certain types of sealants. He is responsible for the properties obtained, and also paints the sealant in a color close to the shade of red heat-resistant brick. Therefore, repairing a brick chimney, you can achieve an ideal result. Depending on the material from which the chimney is made, a sealant is selected, which contains acetic acid or is made without it.

If we are talking about metal chimneys, then it is better to use the second option. The acid has a negative effect, causing corrosion, which will subsequently lead to new damage. In addition, from direct contact with some materials, oxides are formed, which do not allow the required tightness to be achieved. In the process of polymerization of the acid-free sealant, a small amount of water and alcohol are released, which evaporates quickly. These elements do not react, which is necessary to achieve the desired result.

High temperature resistance is not the only property of this kind of chimney sealant. They perfectly resist ultraviolet radiation, which is important if it is necessary to repair the chimney, which is located above the roof. Due to the strong film that forms after the sealant dries, moisture does not get on the damaged surface, which prolongs the life of the metal. This also makes it possible to prevent rainwater from entering the gap between the chimney and the roofing material through which it exits. Due to their ability to penetrate into small pores, sealants have good adhesion to a variety of materials, which include ceramics, concrete and wood.

An important property of the sealant is its plasticity, which remains even after complete drying. On the one hand, this makes it possible to compensate for the thermal expansion, which occurs, for example, in a metal chimney when heated, on the other hand, this property neutralizes possible vibrations without cracking the sealant itself. The polymerization rate of the sealant is entirely dependent on the environmental conditions as well as the freshness of the product. The less time has passed since the date of manufacture, the faster it will harden. The more the parameters differ from the ideal ones, which are indicated on the package, the faster or slower drying will occur.

Heat resistant

Silicone has maximum temperature limits, so a different base is required for refractory compounds.Silicate is used for these sealants. A temperature of 1300 degrees Celsius is considered normal for silicate-based compositions, its short-term increase to the value indicated above is allowed. Heat-resistant compounds are ideal when the sandwich chimney is being installed and it is necessary to glue the seam between them. One of the nuances of heat-resistant sealants is poor adhesion to smooth surfaces. In this case, partial abrasion will be required to achieve roughness. Unlike the previous version, such a sealant, after drying, loses its elasticity and, if necessary, disassembly of the elements will crumble.

Advice! If there is a need to use such a sealant in an open fire, then the package must be marked accordingly.

Choosing the right chimney

The dimensions of the chimney used simultaneously for several heating devices is a separate topic for conversation.

If it is necessary to remove smoke from a number of heating devices, then the chimney is calculated taking into account all heating devices used in the system, their type, power, fuel consumed.

- For example, in a house with a single chimney, several heating devices, a boiler for a common heating system and a fireplace are installed.

- It immediately becomes clear that we have completely different systems. The chimney diameter of the fireplace does not correspond at all to the diameter of the boiler chimney.

- As a rule, fireplaces run on wood fuel, and boilers for the heating system at home run on natural gas.

Is it possible to combine these 2 completely different systems? Can. Moreover, with the correct placement of heating devices, they not only will not create problems, but will also complement each other.

How does this happen?

- One chimney includes a boiler and a fireplace. During operation, the boiler periodically turns off and goes into standby mode. At this time, we have a fireplace. Therefore, a normal temperature is maintained in the chimney, the gases do not cool down.

- Hence the absence of condensation and good draft during the subsequent start-up of the boiler.

- But the size of the chimney for the fireplace should be much larger than for the boiler. And if we use only the boiler without starting the fireplace, we may have problems with excessive draft, leading to improper operation of the boiler.

- As we know, the chimney diameter for a fireplace is calculated at a ratio of 1:10 to its firebox. It becomes clear that such a chimney diameter is very large for a boiler. People rarely use the fireplace, and the heating boiler works constantly in the winter.

- So, you need to make a chimney with a smaller diameter, suitable for the boiler? No, that would be a big mistake. When the boiler works on its own, everything will be fine. When the fireplace starts up, increased aerodynamic resistance will be created in the chimney.

Two-way chimney. Fig. one

As a result:

- improper operation of heating devices;

- ingress of carbon monoxide gases into the room.

This is already life threatening. Carbon monoxide poisoning is often fatal.

How can this issue be resolved?

Our advice is to use a two-way chimney.

Two-way chimney. Fig. 2

- the possibility of using various heating devices simultaneously and separately in one chimney;

- stable operation of each device;

- savings in construction and installation;

- saving space.

When installing such a chimney, it is necessary to comply with all conditions for the correct operation of each device. If the fireplace can function perfectly with a brick chimney, then a sleeve must be made for the boiler. This will protect the brick from the alkaline effects of condensation.

The "Fireplaces and Stoves" store offers a wide range of stove pipes and chimneys from reliable manufacturers.In our catalog you will find single-walled chimney systems for liner and protection against aggressive condensation of brick ducts. We also have double-walled models with a heat-insulating layer, with the help of which chimneys are equipped outside the room. Sandwich pipes do not allow flue gases to cool down quickly, preventing a decrease in draft in the cold season.

When choosing a chimney for a bathhouse, a cottage or a small country house, it is important to purchase truly high-quality products. This is the only way to ensure the correct operation of modern heating equipment. Our task is to help you make the right decision!

In this case, some factors are important:

- The high-quality functioning of the entire sandwich structure is in direct proportion to the strength of the material used in its manufacture.

- Sandwich pipe dimensions.

- The density of the insulation layer.

- Type of pipe seam (rolled, laser).

Service life of sandwich pipes

The guaranteed service life for different products of the system varies from 10 to 15 years. Such an indicator is real only if all the requirements for installing the chimney are strictly observed: the correct choice of material, thickness of the seal, etc. Often all these conditions are not met, therefore the service life is reduced, which ultimately leads to a complete replacement of the chimney after about five years. And it happens that before.

What are the common reasons for early structural failure? There are many of them, but often even a factory defect can disable a structure already at the very beginning of its operation. Therefore, experts recommend with particular care to choose pipes for the chimney and check them for defects.

The timeliness of preventive cleanings in the system is of no small importance. Even with the slightest detection of deviations from the norm in the design, operation should be stopped, and repair work or complete replacement of the chimney should be carried out.

If you follow all the rules when buying and operating a sandwich installation, then it will serve you for a very long time. Otherwise, an accident may occur with the ensuing negative consequences. If you doubt your abilities regarding the correct purchase of components and their installation, then in this case it is better to trust the specialists.