Cast iron batteries: pros and cons

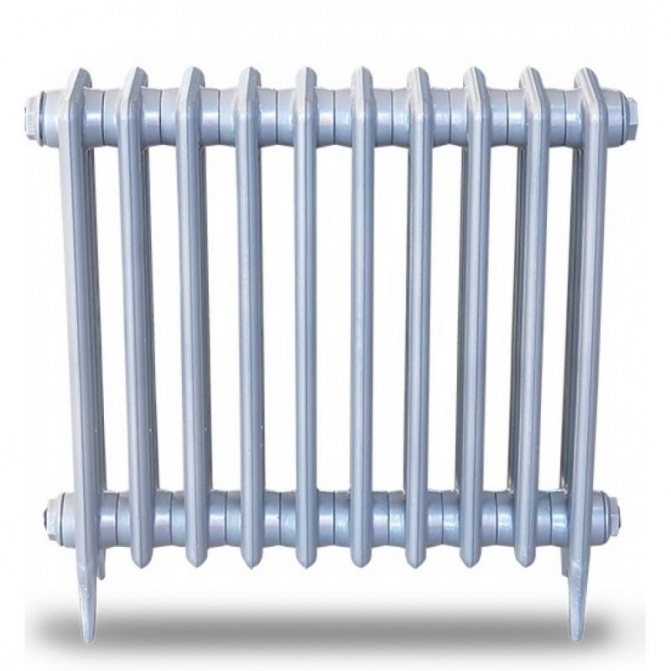

For many consumers, parting with old cast iron radiators is alarming. Although they are tired and often make noise, for decades they have warmed apartments without requiring special care. Today, the parameters of cast-iron heating radiators are such that they are qualitatively different from their Soviet "counterparts", still not claiming the attention of the owners.

- If the old "accordions" weighed more than 7 kg per section, then modern cast-iron batteries - 4 kg, which greatly lightens the load on the wall and clamps.

- The volume of the Soviet counterparts was 1.5 liters, while the new models - 0.8 liters, which is almost two times less.

- Their price is still the lowest on the market. Although aluminum is also considered an inexpensive metal, a comparison of cast iron and aluminum radiators will show that the former are more cost effective.

- Modern cast iron batteries consist of sections that have become much easier to mount, add or remove.

- Their thermal power is still capable of effectively heating apartments, therefore, when it is necessary to change old Soviet structures, many consumers wonder which radiators are better: cast iron or bimetallic, aluminum or steel? Or replace them with a new cast iron version?

It is unlikely that such questions and doubts would arise if people knew the features of a centralized heating system for apartments and the technical parameters of modern radiators.

Advantages and disadvantages of cast iron radiators

Cast iron radiators are made by casting. The cast iron alloy has a homogeneous composition. Such heating devices are widely used both for central heating systems and for autonomous heating systems. The sizes of cast iron radiators may vary.

Among the advantages of cast iron radiators are:

- the ability to use for a coolant of any quality. Suitable even for heat transfer fluids with a high alkali content. Cast iron is a durable material and it is not easy to dissolve or scratch it;

- resistance to corrosion processes. Such radiators can withstand the coolant temperature up to +150 degrees;

- excellent heat storage properties. An hour after the heating is turned off, the cast iron radiator will radiate 30% of the heat. Therefore, cast iron radiators are ideal for systems with irregular heating of the coolant;

- do not require frequent maintenance. And this is mainly due to the fact that the cross-section of cast iron radiators is quite large;

- long service life - about 50 years. If the coolant is of high quality, then the radiator can last a century;

- reliability and durability. The wall thickness of such batteries is large;

- high heat radiation. For comparison: bimetallic heaters transfer 50% of the heat, and cast iron radiators - 70% of the heat;

- for cast-iron radiators, the price is quite acceptable.

Among the disadvantages are:

- great weight. Only one section can weigh about 7 kg;

- installation should be carried out on a previously prepared, reliable wall;

- radiators must be painted. If after a while it is necessary to paint the battery again, the old layer of paint must be sanded. Otherwise, heat transfer will decrease;

- increased fuel consumption. One segment of a cast iron battery contains 2-3 times more liquid than other types of batteries.

Comparison of cast iron and steel

Sometimes the question "which is better" when it comes to different types of radiators is not entirely correct.Often, heaters are simply used in different types of heating systems, so it makes no sense to compare their technical characteristics.

The question is which batteries are better, cast iron or steel, from the same category. Comparing these devices will prove it:

| Parameters / 1 section | Steel radiators | Cast iron batteries |

| Thermal power | from 317 W | from 120 to 160 W |

| The weight | from 7.8 kg | 0t 3.5 kg to 7 kg |

| Volume | from 3.3 l | 0.8 l |

| Design | panel | section |

| Operating pressure | 8.7 Bar | 9 bar |

| Shelf life | 10 years | 35 years |

| Heating the coolant | +110 | up to +150 |

| Resistance to water hammer | no | Yes |

| Corrosion resistant | no | Yes |

As can be seen from the table, the question is not whether steel or cast-iron batteries are better, but that the former perform well in autonomous systems, where there are no water shocks and the coolant is clean, and the latter, under central heating conditions.

Steel panels have several disadvantages that are absent from cast iron counterparts:

- In the event of a leak, the entire panel will have to be repaired or completely replaced, while for cast-iron radiators, you can change the faulty section to another.

- The panels are connected to each other with a weld, and no matter how high-quality it is, it can leak under constant water hammer.

- Narrow channels for the coolant, on the one hand, provide a small amount of it in the device, which has a positive effect on its thermal power, and on the other hand, they quickly become clogged due to low-quality coolant in the central heating system.

- The cost of stainless steel devices is higher than cast iron devices. It is not advisable to install them in an apartment with centralized heating, but in a private house they will not only effectively heat it, but also decorate the interior.

If old cast-iron radiators are to be replaced, then heaters with either the same parameters or better ones should become an alternative to them.

Heating radiators Crimea

We sell bimetallic, steel, aluminum, cast-iron radiators in Simferopol, manufactured in accordance with strict quality and reliability requirements.

Heating radiators:

- PROVIDE a high level of efficiency and heat transfer with a small volume of coolant.

Contact us by contact phones, +7 (3652) 54 94 95, +7 (978) 71 333 47, and our managers will help you choose the models with the required technical characteristics.

- DIFFERENT in a strict, sustained design. To the attention of customers - the absolute bestsellers of the market from the series Korado 500, Korado 600, cast iron batteries Kiran, Viadrus with the original profile.

Hurry up to buy in Simferopol! The price of heating radiators is from 500 rubles per section, from 2000 rubles - per panel, depending on the standard size.

- CREATE all conditions for comfortable daily use. Heating radiators are easy to install, their adjustment is carried out using temperature regulators (an option is provided for aluminum batteries). At the same time, the minimum service life of products made of high quality materials is at least 15 years.

You can buy batteries in Simferopol with side and bottom connections. The scope of delivery includes all necessary fasteners, plugs, spacers, ventilation covers.

We also offer energy-saving convectors in Simferopol, which are a modern solution if for some reason you cannot use radiators.

Prices for batteries for heating in Simferopol

The extensive range of "Krymteploservis" allows you to buy heating radiators in the Crimea with the required set of characteristics.

About a hundred models of Korado, Viadrus, Radiatori, Mirado, AllTermo and others are in the Krymteploservice catalog!

At the same time, prices for radiators in Simferopol are determined:

- material of manufacture;

- standard sizes of heating devices and their rated power;

- a series of industrial products ("economy", "classic", "luxury");

- possibility of connection, working pressure;

- features of surface finish and design, etc.

Tubular, panel, sectional radiators are ideally adapted to work in the conditions of the Russian winter. The price of radiators in Crimea varies widely, so you will certainly find the right model for equipping residential, administrative, industrial premises. All products have certificates of conformity and a guarantee from manufacturers.

Choose and buy heating batteries and radiators in Simferopol on the site "Krymteploservis"

Difference between cast iron and bimetallic batteries

Radiators, consisting of two types of metals at once, came to the domestic market from Italy and quickly won the hearts of consumers, despite their high cost. This can be explained in one word: "reliability". If you choose which is better, cast iron or bimetallic batteries, then you should refer to a comparison of their technical indicators:

- Structure:

- Cast iron structures now look stylish, but they are also assembled from sections equipped with a fairly wide channel for the coolant. Their weight has become much less (3.5 kg versus 8 kg earlier), the appearance is presentable, and the reliability is the same. On the market there are classic sectional models and artistic, in retro style. The latter are very expensive and mostly imported.

- Bimetallic structures consist of a steel or copper core with aluminum fins and a casing. The coolant comes into contact exclusively with stainless steel, which protects the device from corrosion, and the casing provides high heat transfer. Such a heater weighs a little, it is easy to install, and additional thermostats allow you to monitor the heating of the coolant.

- Heat transfer level:

- If you decide whether cast-iron or bimetallic radiators heat better, then their indicators will be approximately equal... So the heat transfer from the cast iron section ranges from 100 W to 160 W. Many consumers think they take too long to warm up and they are right. At the same time, everyone forgets that these batteries also cool for a very long time.

- The heat transfer of one section of a bimetallic radiator is 150-200 W, which, with instant heating, brings this type of heaters to a leading position.

- Operating pressure:

- Although many years of experience in operating cast iron batteries suggests that they are strong and reliable, this is not entirely true when it comes to high-rise buildings. Even in five-story buildings, water shocks in the heating system can occur quite strong, let alone buildings of 16 floors and above. The working pressure of cast iron batteries is 9-12 atmospheres, which may not be enough with a sharp rise in pressure, for example, up to 15 atmospheres. In this case, the cast iron sections will simply burst.

- Bimetallic radiators are more reliable, since their operating pressure is 25-40 atmospheres, and in some models even 100 atmospheres. At this point, structures of two types of metal are also in the lead.

- Resistance to coolant:

- Cast iron is absolutely "indifferent" to the quality of water and its acidity. Its complete discharge for the summer period does not affect it, but the pebbles that sweep through the system gradually weaken the cast iron, exude it and disable it. This process is long, and if the walls of the radiator are of sufficient thickness, then it is completely endless.

- The bimetal radiator is weaker in this respect. He is not afraid of the acidity level of the water while it is in the system, but as soon as it is drained, corrosion begins to appear after 2-3 weeks of contact with air. In this indicator, bimetal loses to cast iron.

- In terms of temperature, both types of radiators tolerate its changes well. For cast iron, the maximum water heating is +110, and for bimetal - +130 degrees.

- Today you can find cast-iron batteries, the age of which has passed the 100-year mark, but on average they have a service life of 50 years. Manufacturers set a limit for bimetallic radiators of 25-30 years, which is less than that of cast iron.

Bimetallic heaters are the best option for replacing old batteries. In general terms, they are superior to cast iron devices, which guarantees their efficient operation in an unfriendly district heating environment. In addition, they are much easier to install, lightweight and do not require additional maintenance.

If the question is whether to change cast-iron radiators to bimetallic ones or not, then tenants of five-story buildings do not have to do this, especially since the latter devices are twice as expensive... Residents of high-rise buildings will have to abandon cast-iron batteries, since they will not withstand the load of the system and will leak. In this version, there is definitely nothing better than bimetallic structures.

Technical characteristics of cast iron radiators ms 140

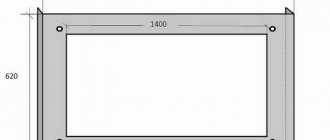

At the moment, in our country, cast iron heating radiators ms 140 can be called the most common model of heating devices. These devices are manufactured in accordance with GOST 8690–94. Depending on the distance between the axles, there are five standard sizes of batteries ms 140: 300, 400, 500, 600 and 800 mm.

Previously, all standard sizes were used quite widely, and they could be seen not only in residential apartments, but also in administrative and industrial buildings. At the moment, cast iron radiators ms 140 500 and 300 are most often used. Other modifications are extremely rare and, as a rule, are made to order.

In view of the popularity of the ms 140 500 batteries, the technical parameters of this model should be considered. For heating radiators, cast iron brand ms 140, the characteristics are given for one section, since this is a purely sectional model. Having selected the required number of sections, you can create an optimal temperature regime in the room.

The main characteristics of heating radiators ms 140 500 are as follows:

- pressure. Working pressure is up to 9 atmospheres, and pressure testing - up to 15 atmospheres;

- heat transfer is low and equal to 175 W;

- each section has two channels;

- section dimensions: height - 50 cm, width - 9.8 cm;

- the capacity of one section is 1.35 liters of water;

- the radiator is able to withstand the coolant temperature up to +130 degrees.

Comparison of aluminum and cast iron radiators

Aluminum heaters were the first to replace cast iron, but in terms of their parameters, they are more suitable for stand-alone systems than centralized ones. It is pointless to argue which radiators are better, cast iron or aluminum, since they have completely different technical parameters.

- The heat transfer of aluminum is significantly higher than that of cast iron. Heaters from it are warmed up instantly, immediately giving off heat to the room and saving energy resources. Cast iron takes time to "heat up".

- Deciding whether cast-iron or aluminum radiators are better in a city heating network is a waste of time. As a rule, the former do not tolerate strong water hammers, although there are models with a sufficient level of working pressure. But even this does not make them vulnerable in central heating conditions.

- Corrosion susceptibility at elevated Ph level of water does not allow their use in systems where it cannot be controlled... That is why aluminum batteries are installed in private houses with an autonomous type of heating. As a last resort, a filter can be installed in such a system, which cannot be done in a high-rise building. For cast iron batteries, the quality of the coolant does not matter, since this metal is resistant to increased acidity of water.

When it comes to installation, the question of which is better, a cast iron or aluminum battery, does not require an answer. It is enough to try to lift each of the radiators and make sure that the aluminum structures can be installed on their own, while for the cast iron ones, more than one pair of strong hands is required.

Summing up, we can say that in five-story buildings there are the best cast-iron batteries, while for high-rise buildings the only alternative is bimetallic counterparts.As for autonomous heating systems, both steel and aluminum radiators are suitable for them, so the consumer must himself determine which of them are more suitable for him in terms of price and quality.

Thermal inertia and efficiency - cast iron or steel radiators?

A very important criterion for those who want to make the most of the heating possibilities is the thermal inertia of radiators. This property of metal has two sides: when operating a system with room temperature control, it is necessary that the radiators quickly heat up and also quickly reduce the temperature. If you expect to "drive away" the system, for example, in the country, once, so that it retains heat for some time, then you need a high inertia.

Cast iron is characterized by high thermal inertia; it heats up and cools down longer than steel. This can significantly affect the efficiency of heating that is used continuously for a long time. For rational consumption of heat energy, that is, to save gas or electricity, it is more reasonable to install tubular steel radiators of the Harmony type from KZTO.

10-section cast iron heating radiator

10-section cast iron radiator in Simferopol

In the company "BVB-Alliance" you can wholesale a 10-section cast-iron radiator in Simferopol. You can make an application for the purchase of products, clarify the current cost and conditions of purchase by phone in Simferopol +7 (3652) 669780

or send a request by mail

.

TU 4012

Reset filter settings

Type of metalDepthLength, cmHeight, cmGOST, OST, TUMarkDescriptionPriceBuy

10-section cast iron radiator TU 4012 STI-Nova-500

10-section cast iron radiator TU 4012 STI-Nova-300

10-section cast iron radiator TU 4012 Konner-Modern

10-section cast iron radiator TU 4012 Konner-Modern-300

10-section cast iron radiator TU 4012 Konner-Modern-Style

10-section cast iron radiator TU 4012 Konner-Hit

10-section cast iron radiator TU 4012 Konner-Hit-300

10-section cast iron radiator TU 4012 Konner-Legend

* Dear Clients! The final price for products is formed based on the terms of delivery: volume, terms of payment and place of shipment. This information about the product, its price and availability is for informational purposes only and under no circumstances is a public offer determined by the provisions of Part 2 of Art. 437 of the Civil Code of the Russian Federation. Simferopol

10-section cast iron radiator - an element of the heating system of a centralized or autonomous type, consisting of ten cast iron sections, interconnected by a tie using gaskets and nipples.

Specifications

Refers to sectional models of cast iron radiators. Each section is cast from one grade of cast iron and has a given width, depth and height. Optionally, it is possible to cover the surface of the section with a primer, enamel, paints and varnishes.

The surface of the section has roughness and irregularities.

Cast iron radiators are distinguished by high corrosion resistance, biological inertness, strength, wear resistance and durability. Designed to work with various working environments (including technical water).

Withstand pressure up to 10 -15 atm, at a temperature of the heat carrier up to 150C.

Have a lot of weight. If one section fails, it can be easily replaced with a new one without the need to dismantle the entire structure.

They differ in the place of installation, the width of the battery, the method of connection to the heating system.

They keep and retain heat well, have a high level of heat transfer. Warm up slowly, but also cool down slowly.

Application

10-section cast iron radiators are used to heat large premises, industrial buildings, workshops, government and social institutions.

All questions about the supply of metal products to other regions of Russia, the availability of goods in warehouses and assortment can be asked by calling toll free 8 (800) -555-91-54 Simferopol.

The BVB-Alliance company will supply a 10-section cast iron radiator anywhere in the Russian Federation and in the CIS countries from a warehouse in Simferopol. If you have questions about the delivery time of goods, discounts and current prices for rolled metal products, you can call the manager at 8 (800) 500-45-36.

Popular products in your city Simferopol

10-section cast iron radiator in other cities