Thermal insulation work is one of the most important stages of construction. This applies to technical structures and residential buildings. High-quality insulation can significantly reduce energy costs and extend the life of walls and finishing materials.

Thermal insulation with polyurethane foam (PPU) came to the construction market recently, but quickly gained popularity among professionals and customers. This technology can significantly reduce the time spent on work. Polyurethane foam can be used as a heater on any surface, since it has high adhesion rates and has practically no restrictions.

Technical features

Wall insulation can be done in three ways:

- Spraying.

- Filling.

- Finished layers.

The method is selected based on the individual characteristics of the premises and the calculation of the cost of work. But each of the listed methods has its own characteristic nuances that must be taken into account. Spraying and insulation with plates is carried out both outside and inside the house. And the filling is carried out into the air space between the parts of the partition, which is specially left during the construction phase.

1. Spraying technology.

Due to its high adhesion, polyurethane foam instantly adheres to the base and creates a uniform layer, in which there are no cold spots inherent in most types of thermal insulation. Foam insulation by spraying is carried out using special equipment. It can be professional, and is used repeatedly, as well as one-time, which is quite suitable for work on your own.

If it is necessary to insulate a small room, for example, a loggia in an apartment, foam from ordinary cylinders is often used. It differs slightly in consistency, but contains the same polyurethane in the base. The application technology is similar to spraying with professional devices, which are used by specialists, but it is much slower due to the low pressure in the cylinder. Polyurethane foam has a higher cost, but it is compensated by the fact that you do not need to buy equipment.

Pros:

- As a result of expansion, it completely fills the area to be insulated.

- There is no need to level the walls before application.

- High speed of work performed.

Minuses:

- Relatively high cost.

2. Technology of filling.

If the house is under construction and polyurethane foam is selected, a special wall construction is required, which provides for an internal empty space, where the foam is filled. But even if the house is already fully built, thermal insulation is possible through special technological holes, which are drilled in several places, and foam is pumped through them. The device delivers insulation through hoses inserted into the wall. After the material has completely solidified, dense thermal insulation is obtained, excluding air chambers.

Pros:

- Has the highest efficiency and energy saving rates.

- The interior space is completely preserved, and additional exterior finishing is not required.

Minuses:

- Do-it-yourself polyurethane foam insulation by filling is impossible without specialized equipment.

- The injection through the holes does not exclude the formation of air bubbles inside.

- The pressure that the foam creates during expansion can damage the walls if the house is made of poor quality materials.

3. Plates.

The foam is presented not only in a liquid state, but also in the form of finished slabs.Warming is done by gluing the segments to the surface and fixing them with dowels with a wide head. Unlike spraying, this process does not require special equipment and can be done by hand.

To prevent the insulation from accumulating condensate, before installation, the surface must be treated with impregnations that prevent the appearance of mold and mildew. This should be done not depending on which side the house is insulated from. At the final stage, polyurethane foam is filled into the seams from a cylinder. Thus, the thermal insulation becomes monolithic.

Pros:

- Lowest cost among other methods.

- Ease of installation.

Minuses:

- Thermal insulation of PU foam plates is not so effective in terms of energy saving.

- The house needs decorative finishing.

- For installation, you must first level the surface, otherwise the insulation will lie unevenly.

- Foam in slabs has a lower degree of durability.

4. Penoizol.

Penoizol has a similar structure to polyurethane foam, but differs in technical characteristics. According to the standards, in rooms with increased requirements for fire and environmental safety, such as:

- Public places.

- Kindergartens and schools.

- Medical institutions.

Insulation with polyurethane foam is prohibited due to the flammability and toxicity of products emitted as a result of combustion. This applies to both the slab version and the liquid one. Fire safety rules allow the use of polyurethane only in private construction or in the construction of non-residential premises.

In turn, penoizol complies with all standards and has no restrictions on use. It is made on the basis of a complex chemical compound - urea-formaldehyde. It is a porous white material with a lot of air bubbles. The main advantage of spraying foam insulation over polyurethane is that it does not support combustion at all, and at high temperatures decomposes into carbon dioxide, nitrogen and water. The absence of toxic emissions allows this insulation to be used in any premises, regardless of their intended purpose.

Thermal insulation of the house with foam

Thermal insulation work is one of the most important stages of construction. This applies to technical structures and residential buildings. High-quality insulation can significantly reduce energy costs and extend the life of walls and finishing materials.

Thermal insulation with polyurethane foam (PPU) came to the construction market recently, but quickly gained popularity among professionals and customers. This technology can significantly reduce the time spent on work. Polyurethane foam can be used as a heater on any surface, since it has high adhesion rates and has practically no restrictions.

Wall insulation can be done in three ways:

The method is selected based on the individual characteristics of the premises and the calculation of the cost of work. But each of the listed methods has its own characteristic nuances that must be taken into account. Spraying and insulation with plates is carried out both outside and inside the house. And the filling is carried out into the air space between the parts of the partition, which is specially left during the construction phase.

1. Spraying technology.

Due to its high adhesion, polyurethane foam instantly adheres to the base and creates a uniform layer, in which there are no cold spots inherent in most types of thermal insulation. Foam insulation by spraying is carried out using special equipment. It can be professional, and is used repeatedly, as well as one-time, which is quite suitable for work on your own.

If it is necessary to insulate a small room, for example, a loggia in an apartment, foam from ordinary cylinders is often used. It differs slightly in consistency, but contains the same polyurethane in the base. The application technology is similar to spraying with professional devices, which are used by specialists, but it is much slower due to the low pressure in the cylinder. Polyurethane foam has a higher cost, but it is compensated by the fact that you do not need to buy equipment.

- As a result of expansion, it completely fills the area to be insulated.

- There is no need to level the walls before application.

- High speed of work performed.

- Relatively high cost.

2. Technology of filling.

If the house is under construction and polyurethane foam is selected, a special wall construction is required, which provides for an internal empty space, where the foam is filled. But even if the house is already fully built, thermal insulation is possible through special technological holes, which are drilled in several places, and foam is pumped through them. The device delivers insulation through hoses inserted into the wall. After the material has completely solidified, dense thermal insulation is obtained, excluding air chambers.

- Has the highest efficiency and energy saving rates.

- The interior space is fully preserved, and additional exterior finishing is not required.

- Do-it-yourself polyurethane foam insulation by filling is impossible without specialized equipment.

- The injection through the holes does not exclude the formation of air bubbles inside.

- The pressure that the foam creates during expansion can damage the walls if the house is made of poor quality materials.

The foam is presented not only in a liquid state, but also in the form of finished slabs. Insulation is performed by gluing the segments to the surface and fixing them using dowels with a wide head. Unlike spraying, this process does not require special equipment and can be done by hand.

To prevent the insulation from accumulating condensate, before installation, the surface must be treated with impregnations that prevent the appearance of mold and mildew. This should be done not depending on which side the house is insulated from. At the final stage, polyurethane foam is filled into the seams from a cylinder. Thus, the thermal insulation becomes monolithic.

- Lowest cost among other methods.

- Ease of installation.

- Thermal insulation of PU foam plates is not so effective in terms of energy saving.

- The house needs decorative finishing.

- For installation, you must first level the surface, otherwise the insulation will lie unevenly.

- Foam in slabs has a lower degree of durability.

Penoizol has a similar structure to polyurethane foam, but differs in technical characteristics. According to the standards, in rooms with increased requirements for fire and environmental safety, such as:

- Public places.

- Kindergartens and schools.

- Medical institutions.

Insulation with polyurethane foam is prohibited due to the flammability and toxicity of products emitted as a result of combustion. This applies to both the slab version and the liquid one. Fire safety regulations allow the use of polyurethane only in private construction or in the construction of non-residential premises.

In turn, penoizol complies with all standards and has no restrictions on use. It is made on the basis of a complex chemical compound - urea-formaldehyde. It is a porous white material with a lot of air bubbles. The main advantage of spraying foam insulation over polyurethane is that it does not support combustion at all, and at high temperatures decomposes into carbon dioxide, nitrogen and water.The absence of toxic emissions allows this insulation to be used in any premises, regardless of their intended purpose.

Application technique

The material is applied using special equipment. Typically, this set of technical equipment includes a pneumatic gun and a compressor. There are also forms of supply of the isolator, which are equipped with a spray can - this is the best option for home use. Initially, the mixture is in a liquid state, so during processing it easily covers the most difficult areas. By the way, it is in hard-to-reach places that work should begin. These can be ventilation passages, panel joints, underground niches and other problem areas.

It is important that the insulation with polyurethane foam is carried out under conditions of optimal temperature and humidity. In wet weather, and even more so in the rain, it is not recommended to insulate the facade. On the other hand, in the heat at 50 ° C, first apply a thin layer, and when it hardens, proceed with the full processing. After the final polymerization of the material, if necessary, its weight can be corrected, since during the expansion process the foam composition often goes beyond the boundaries of the planned insulation zone.

Penoizol

Liquid insulation usually means foam, which is used to insulate premises. One of its varieties is called penoizol. In structure, this material resembles foam, but in fact it is a urea polymer. Penoizol can be supplied not only in the form of a foam mass, but also in the form of plates. Also, granules are made from it for filling with the main material.

Penoizol is best suited for thermal insulation of frame buildings. It is designed to fill air gaps between:

- inner and outer walls;

- plastic panels and a wall;

- plasterboard and wall;

- wood flooring and its base.

Also, the material is suitable for insulating tanks and heating mains. In terms of operational properties, the foam is superior to mineral wool and expanded polystyrene. The advantages of penoizol are:

- high speed of work execution;

- undemanding to the conditions of temperature and humidity conditions;

- long service life;

- weak flammability;

- elasticity and resistance to deformation.

When hardened, the material does not form butt seams, which means it is resistant to tensile loads. In addition, it does not create a favorable environment for the development of fungi and mold, it is not damaged by rodents.

Penoizol has soundproofing properties, and can significantly reduce the level of noise in the living space. In addition, the manufacturer assures that the material is environmentally friendly.

Advantages and disadvantages of attic insulation with penoizol

Cured foam under the roof and on the floor of the attic has many advantages over other substances of a similar purpose. The obvious advantages include the following properties:

- To create a heat-insulating layer, 45 mm of foam is enough, which is similar to 75 mm of expanded polystyrene or 125 mm of stone wool.

- The coating has excellent vapor transmission characteristics that prevent condensation from forming. All wooden structures, on which penoizol is applied, retain their qualities for a long time.

- The substance is well resistant to mold and mildew. This property is especially appreciated if the attic is cold and the house is in a damp area.

- Mice do not live in the thickness of the product.

- Liquid foam is able to withstand fire. When heated, it does not melt or smoke. After prolonged exposure to high temperatures, the material evaporates. The use of this substance reduces the risk of fire in summer when the room is very hot.

- The material has sound insulating properties.

- It does not crack after impacts, only bounces and, after removing mechanical loads, restores its shape.

- It tolerates temperature changes well.

- The product efficiently fills surfaces with complex shapes. It is often used to insulate hard-to-reach places.

- The coating retains its heat-insulating qualities for a long time - up to 30 years.

- The material is very lightweight and does not overload the building structure.

- In a solid state, it is easy to handle by hand with the simplest tools.

Penoizol can create some problems during filling and during operation:

- It has a low density, so it breaks easily.

- After a while, the layer dries up and shrinks.

- For polymerization, a temperature of more than +5 degrees is required.

- In the early days, the smell of formalin will be felt in the room, but then it disappears.

- To prepare the substance and apply it to the surface, special devices are needed.

Polyurethane foam

Externally, polyurethane foam resembles ordinary polyurethane foam, but it has a closed fine-mesh structure. The material is applied in a layer from 4 to 8 cm, good adhesion to any materials is ensured. Polyurethane foam has low water absorption, so no additional waterproofing is required. Other benefits include:

- light weight;

- elasticity, the ability to fill voids of any shape;

- low vapor permeability;

- resistance to biological factors, including fungus and mold.

Polyurethane foam

When insulating premises, foam is often used, intended for installation work. There are many varieties of this material, including those that are specially designed for the purpose of warming rooms. Often, foam is used to fix boards of solid thermal insulation materials or to fill the joints between them.

Foam grades with increased adhesion have been developed for use with insulation sheets. In terms of functionality, they resemble glue: foam is applied to the surface of the thermal insulation material and pressed against the wall. Polymerization of the composition takes place within 5-10 minutes, and the board is firmly fixed.

Heat insulating paint

Insulating foam is not the only product for arranging thermal insulation that has a liquid consistency. Liquid ceramic paint is used along with it. Compared to foam, this paint has less pronounced thermal insulation properties. At the same time, the latter has the best waterproofing properties.

It is recommended to apply paint only at the junction of structural elements of a residential building, for example, between the roof and walls. Some people use this material to insulate rooms from the inside, but this is a big mistake. On the one hand, at least 10 paint coats are required to achieve the desired thermal insulation effect. On the other hand, the thermal insulation layer is never placed on the inside of the walls, as this will lead to the formation of condensation in the building due to an incorrectly calculated dew point.

Application procedure

The sequence of work depends on which liquid insulation is chosen.

If you decide to use penoizol or polyurethane foam, you need to purchase a disposable or reusable kit for spraying or pouring the mass.

Spraying involves working with open surfaces. The essence of this technology lies in the fact that the foam is sprayed on the wall in an even layer 5-10 cm thick. Before that, the wall is cleaned, and the remnants of wallpaper or paint are removed. With a step of up to 50 cm, guides are attached using self-tapping screws - wooden slats or aluminum profiles.

Usually, the guides are located vertically, strictly at right angles to the ceiling and floor, but sometimes horizontal strips are also installed. The space between them is filled with foam, while the guides themselves should protrude above the foam.They are needed in order to mount sheets of drywall on top of them when the insulation is dry.

Fill method

The fill method is more difficult to implement. It consists in filling voids with foam, which cannot be processed by spraying due to difficult access. During pouring, liquid insulation is fed into the cavity, where it is evenly distributed due to its elasticity.

The pouring technology allows you to get rid of voids in the already installed main walls, or after installing the plasterboard coating. In this case, one condition must be fulfilled: there must be access to the cavity, at least in the form of a small hole, where the nozzle of the unit for pouring the mass can fit. Sometimes the foam is poured into the mold immediately during production. This is how thermal insulation blocks are obtained, which can later be mounted inside the walls instead of spraying.

Corrosion protection

If thermal insulation of a metal pipeline is planned, then first it must be painted or protected from corrosion in some other way. Manufacturers of penoizol and polyurethane foam never warn about this, but without proper protection, the pipe will rot and crumble. Then you will have to completely remove the insulation in order to gain access to it for the purpose of repair.

Foam for insulation is fed into a gun for pouring or spraying through hoses from a container with raw materials. In the case of polyurethane foam, these are two tanks, one containing the polyisocyanate and the other containing the polyol. It is important that there is no air in containers and hoses, as it will interfere with the reaction of substances.

Seams and the principle of applying polyurethane foam

The ability to store heat is especially important when parts of a building are exposed to changing temperatures (for example, day and night). In this case, different walls will cool differently.

For example, a brick wall half a meter thick stores well, but also conducts heat well. At the same time, a wall made of insulating materials will collect about 50 times less heat. However, at the same time, it conducts heat 20 times worse and loses less heat by the same amount.

To equalize the characteristics, it is necessary to ensure the conditions in which the brick wall will warm up from the outside during the heating season. The fact is that heat is transferred from the warm parts of the wall to the cold ones. Therefore, if such a wall is cooled outside, then it will actively remove heat from the house. Both external insulation and internal insulation of the house are important.

Heat leaves the house through the walls (if they have low thermal resistance), the roof (the same reason), windows and doors to the balcony, the foundation (if there is no thermal insulation), the front door (due to wear and tear). Professionals say that with the help of wall insulation with foam, you can significantly increase the thermal insulation of the entire room.

Insulation of walls with polyurethane foam is a work of an average level of complexity that requires knowledge and skills. The spraying process should be started only after the frame for the cladding has been installed. The surface does not need to be pretreated, since this sealant has a high level of adhesion.

Popular manufacturing companies

Today in Russia there are a large number of manufacturers of foam insulation, polyurethane foam, polyurethane foam and other liquid mixtures that are used to insulate premises. Of the domestic manufacturers, the following are the most famous:

When it comes to buying a disposable construction tool, it doesn't matter what brand it is released under. Along with the Russian ones, Chinese kits are also very popular. At the same time, the choice of the material itself must be taken with responsibility. To avoid premature wear of structures, it is advisable to purchase raw materials of domestic or European production.

Features of facade insulation with polyurethane foam

Creating comfortable conditions for living in a house or apartment is the primary task of every zealous owner. Modern technologies make it possible to inexpensively organize an optimal indoor climate and save energy resources at any time of the year. Insulation of facades with polyurethane foam contributes to the extension of the life of the building's structural elements.

Types of polyurethane foam and its properties

Thermal insulation facade is a fast and reliable way to insulate a house. Due to its technical characteristics and method of application, smooth or textured facades of any geometry can be processed. Polyurethane foam (PPU) consists of polymer compounds that are foamed with an inert gas, which provides more than 85-90% of the air pockets.

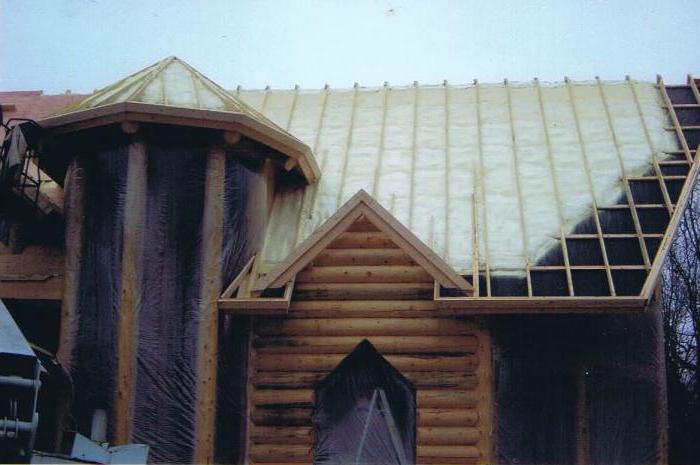

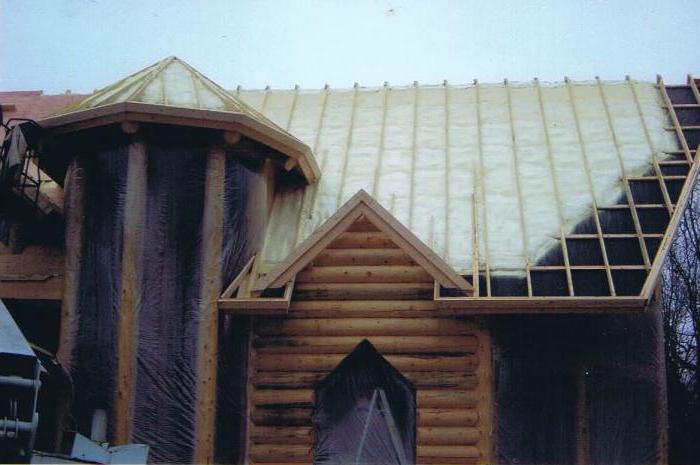

Figure 1. Insulation of the facade of the house with polyurethane foam.

Depending on the composition of the thermal insulation material, polyurethane foam structure may be:

- Semi-rigid - has a cellular and open, but rather dense, structure and is used to insulate facades with wooden base, that is, buildings made of timber, logs or plywood.

- Rigid - has a closed structure and is used for permanent structures made of concrete or brick. Due to its high density, water is not absorbed by the material.

Both types provide excellent moisture protection. PPU does not allow the walls to cool down in winter, even in the most severe frosts and heat up in summer, and with a well-thought-out heating and air conditioning system, the house will have an ideal microclimate all year round. In addition, the material also has good sound insulation properties.

Features of work on the insulation of facades with polyurethane foam

Insulation of the facade with polyurethane foam is carried out by spraying. Liquid PPU is poured into the tank and, using a pneumatic spray gun connected to the compressor, the mixture is applied to the facade under pressure. As it cools, it turns into foam, which fills in all the cracks on the facade and then hardens. To ensure good adhesion, the walls must be cleaned of dirt and dust before application. Since the foam does not form a uniform surface, after the end of the polymerization process, the master carefully cuts off the excess so that you can make the plaster facing.

Material analysis in comparison with analogues

Modern technologies offer many options for facade insulation. Compared to other thermal insulation materials, liquid thermal insulation PPU has a very high level of thermal conductivity. For example, a layer of 1 cm of polyurethane foam has the same thermal conductivity as 5 cm of mineral wool or 30 cm of reinforced concrete.

List of tools and equipment

In order to insulate a house with foam, you will need tools and materials. If the work is carried out using polyurethane foam, then you will need a spray gun, the polyurethane foam itself, a drill, a wire to check for voids and personal protective equipment for the worker (glasses, gloves, and so on). If the insulation is carried out with polyurethane foam, then the set of equipment is somewhat different. Here it is necessary to have a crate (frame) available, which is needed to divide the surface into several areas for filling with foam. You will also need a hose. You need to know that if spraying is performed on an already finished wall, then you need to do it as follows: spraying is carried out from bottom to top using a special gun.

After sprinkling to a height of about 30-40 cm, you need to stop and see how the foam is applied. It is applied in a small layer, then uniform upward movements are made. The thickness of the layer depends on the temperature conditions of the room. On average, it is 10-15 cm. It is important to remember that the useful area of the house is reduced.

Facade insulation technology with polyurethane foam

Application technology liquid heaters requires special knowledge, skills and equipment, so it is difficult to do it yourself. To carry out the work, it is best to hire a team of experienced craftsmen who will quickly take the necessary steps and will be able to provide guarantees for the quality of thermal insulation.

High quality facade insulation houses polyurethane possible only for low-rise buildings. The purpose, size, configuration and geometry of buildings are not important. The whole procedure goes through several stages:

- preparation of walls;

- application;

- reinforcement;

- finishing activities and finishing works.

Selection of equipment for spraying polyurethane foam

The equipment consists of:

- Two cylinders designed for formulationsforming foam.

- Hoses connecting cylinders to spray guns.

Figure 3. Equipment for spraying polyurethane foam. - Spray gun.

- A set of nozzles of various modifications.

- A set of keys and technical grease.

Set spraying equipment quite voluminous and expensive, so it is impractical to buy it for self-insulation of your own walls. It would be much cheaper and wiser to hire a team of equipped craftsmen.

Instructions for spraying polyurethane foam on the facade

The equipment can be household (disposable) or professional. The assembly of the entire structure is quite simple - hoses with a gun are connected to the cylinders - and you can start spraying.

The optimum temperature of the components for application is 20-30 degrees Celsius. Area theat-insulating material for thermal insulation of facades by spraying depends on the volume of the cylinders. If during the execution of liquid thermal insulation it is necessary to pause, it should be borne in mind that the duration of the operating life of the equipment does not exceed 30 days, so do not pull too long. That is why experts do not recommend purchasing cylinders with a volume open PPU more than necessary.

Preparation for the application of polyurethane foam

Characteristics and properties of polyurethane foam to work require protective clothing. It is important not to leave exposed areas of skin or hair, as after contact with the skin, the foam is extremely difficult to remove. To prevent small particles of foam from getting into the lungs, all work is carried out in a respirator or mask.

Walls must be cleaned of loose particles and old coatings. Lighting fixtures, ebbs, grilles and other elements are removed. The crate is installed with cells 20-50 cm. Installation is carried out using a level, which helps to level the walls. Next, a layer is applied polyurethane.

Facade reinforcement rules

To avoid the formation of cracks in the openings, and the finishing materials lay well, it is recommended to reinforce walls special mesh. The procedure begins with the installation of perforated aluminum corners, to which the mesh will be fixed. The corners are installed with assembly glue and gently pressed down with a spatula. Excess glue is removed.

The reinforcing mesh is made of fiberglass and is resistant to chemical and mechanical influences. It is fixed with an adhesive solution, which is sold ready-made in hardware stores.

Figure 4. Thermal insulation of facades by spraying.

To achieve good quality, polyurethane foam processed with coarse sandpaper. After removing the dust, glue is applied to the surface, into which the mesh is carefully recessed. The adhesive is evenly distributed over the surface. The mesh does not need to be pulled tightly or pressed into the heat-insulating layer. When the entire facade has been reinforced, it is recommended to apply a second layer glue with a mesh that should not show through.

Finishing works

It takes a day to dry the reinforcing layer and after that you can start finishing work.In order not to violate the integrity of the thermal insulation layer, it is not recommended to use siding or other materials that are mounted on dowels or self-tapping screws.

The best option is a simple decorative plaster for facades. This will allow you to create any effect you like and paint the house in your favorite color.

If you are looking for the most effective method of organizing ideal thermal insulation at home, PPU is the best choice. Since the procedure requires compliance with some rules, you should carefully, realistically and adequately assess your strength, and it is best to invite a team of experienced craftsmen.

Features of insulation

For self-insulation of a house with foam, a protective suit is required. Foam is usually sprayed from a cylinder onto the entire surface of the facade; it is used to fill the voids between walls, rafters, and beams.

There are many advantages to this type of wall insulation with foam in the air gap. The main ones include:

- vapor permeability;

- fire resistance;

- the ability to increase in volume;

- resistance to all kinds of mechanical stress;

- the upper temperature limit remains within +80 degrees.

Often, foam is used to seal the gaps that remain after the installation of plastic windows. Due to this, thermal insulation in the apartment also increases. A pneumatic gun is convenient to use for insulating not only windows and outer walls, but also the foundation, loggia and balcony, pipes.

The facade, after being treated with foam with insulation for the walls, turns out to be ideal - without visible joints and seams. One container contains an average of 600-700 ml of the composition, which is enough to process a square meter with a layer up to eight centimeters thick. It is very simple to work with such a gun: first, a full cylinder is inserted into it, then you need to direct it to the surface to be treated and pull the trigger. On average, the applied composition hardens within a day.

Foam insulation - definition and characteristics?

We will try to consider in detail the features of this material and its application, so that everyone who builds his own house can master the work with it. Warming up is not only fashionable now, but also necessary. Energy prices are inexorably creeping upward, maintaining comfort in a house is becoming an increasingly wasteful occupation, so apartment insulation is more relevant than ever. The same wave swept over the construction of houses, where it is possible to acquire a "reliable fur coat" at a very early stage, it remains to decide on its appearance. But if you have a ready-made structure, even with finishing, insulation will not be a problem, especially when it was decided to use foam insulation.

The class of these substances is a polymer or a combination thereof; upon reaction between the components or a single component with moisture and air, curing with preliminary foaming occurs, due to which the material successfully fills the space, sometimes increasing in volume by 20 times. The disadvantages of this group of heaters are the need for a good air flow, that is, the ventilation of the room for work. You also need to properly protect the insulation layer after the end of the work, because it is afraid of sunlight and precipitation, over time the material will simply begin to collapse.

But these moments cannot overshadow the impression of the advantages of foam materials. Biological and environmental safety allows them to be used in residential premises of varying degrees of cleanliness. Such heaters consist of pores filled with air or a gaseous reaction product between the components, due to this, good heat and waterproofing is created, therefore, additional measures to protect the room from freezing and moisture are not required.But this is provided that all external pores of the material will be isolated by finishing (internal or external, depending on the place of insulation).

Foam insulation, well closed from external influences, will serve you for an incomparably long time, moreover, with a large temperature range, even the coldest Russian winters will not destroy the material, the same applies to the natural heat.

Good insulation is also due to the fact that, expanding, the foam does not form seams or gaps through which cold could still seep, therefore the "fur coat" of these materials is the most reliable. They also adhere well to any surface, adhesion guarantees reliable service for many years. Such a layer also has antiseptic properties and protects the metal from corrosion. Yes, also, the material, as a rule, is not flammable, you see, it is also a plus.

Types of foam insulation

Foam insulation can differ in its structure and composition. The main types of material for insulating walls and windows can be distinguished:

- Penoizol. It contains aldehydes that are harmful to health, although manufacturers often claim the opposite. Dries much longer than polyurethane (complete drying time can be up to three days). It is usually used to insulate attics, load-bearing walls and structures. It can be purchased in the form of ready-made slabs or as a liquid composition.

- Ecowool and foam concrete. Can be purchased in liquid form, more often used for pouring the foundation. When finishing facades, they are practically not used due to the significant weight, which gives a large load on the walls. In addition, the high cost often speaks against this material.

- Polyurethane foam. Suitable only for sealing seams, joints, holes, since it does not allow moisture and steam to pass through, and this is a critical moment for insulating material. When interacting with air, its volume increases twenty times, while there is a minimum amount of air bubbles inside. It can be purchased in convenient small-volume cylinders with a significant shelf life.

- Polyurethane foam or polyurethane. The most common option, which is considered the most versatile. Polyurethane insulation is very effective as a thermal insulation for facades. Consists of two components, they must be mixed by a machine method immediately before application. The foam expands from the initial volume thirty to forty times, small balloons are formed inside. Due to this, high-quality insulation of the house is achieved.

Foam for wall insulation: types and features

For wall insulation, modern craftsmen use various materials and technologies for work. They have significant differences among themselves, but they are all designed for the same purpose - to make the thermal insulation of the house as productive as possible.

Liquid foam for wall insulation is called polyurethane foam (PPU).

All the necessary ingredients are mixed in the factory and the composition required for polymerization is under high pressure in cylinders. In order for the foaming and curing reaction to occur, contact of this composition with oxygen is necessary.

Should you insulate walls with foam? Of course, it's worth it for one simple reason - polyurethane foam is the ideal material for this purpose, moreover, it performs another very important function - sound insulation.

What is foam insulation? This is a special pliable mass that tends to foam when interacting with air. This composition has a fairly strong and elastic structure. To spray it, cylinders, pneumatic devices and other devices are used.

Which variety to choose

In many ways, the choice will depend on the specific situation, which area needs to be processed. You can use an example to consider the most common cases when a house needs foam insulation:

- If you need to close cracks or remove any other defects on the surface, then polyurethane will do. But such material should not be exposed to sunlight.

- If you need to fill a large volume, then Penoizol will do. But the usual cylinder will not be enough here, you will need to purchase a special high-pressure apparatus. It is not necessary to buy it at all - you can rent it or borrow it from friends, because often no one will use it.

- If you need to close up small cracks and carry out thermal insulation in small areas of the area, then you can buy a cylinder with ordinary polyurethane foam. It does not support combustion, after solidification it is particularly hard, while it has an ecological composition.

- If defects are found on the outside of the wall, then you need to apply a composition based on polyurethane. It is applied in a direct way using a special balloon or apparatus.

It is worth remembering that the foam insulation creates errors inside the layer that need to be eliminated. This requires a long hose to push the material inward. If you want to fill air layers inside the insulation, then holes are made in the wall with something sharp.

Polyurethane foam is not suitable for insulating the entire external facade - it does not have the appropriate characteristics necessary for this. Therefore, you should not choose it for these purposes, even despite its more economical cost.

Reviews about the material

Users note both the decent characteristics of polyurethane as insulation and the ease of use. In particular, many homeowners emphasize that the insulator's structure and spray technology minimizes the risk of underperforming coverage. In addition, users assure that foam insulation is very difficult to clean from surfaces. If material gets on clothing, it is usually thrown away. Therefore, during the spraying process, you should carefully limit the treatment area.

Advantages and disadvantages

Before you start insulating your home, you need to weigh the pros and cons. Of course, many are interested in what the benefits will be from this method of insulation. These include:

- fast speed of insulation, even if a large surface is being processed;

- foam is not subject to biological influences, mold or mildew is unlikely to appear on the wall;

- hardly flammable material: it can melt only at temperatures over 80 degrees;

- it is not required to pre-fix the frame to the facade - this saves both effort and time and money;

- a monolithic surface without seams is obtained, into which cold air could penetrate;

- when insulating pipes or other metal elements, a sufficiently dense layer is created through which moisture does not leak, and corrosion does not appear.

But, like any other method of insulation, it has its drawbacks. You should find out about them in a timely manner:

- should not be exposed to direct rays;

- the impossibility of frequent interaction with water;

- material cost: to insulate large areas, you will need to buy or rent special equipment;

- insufficient level of vapor permeability, you will have to install artificial ventilation inside;

- do not carry out the application procedure without a tarpaulin suit, a respirator mask with goggles and gloves. Of course, all this is unlikely to be found at home, and this is also an extra cash expenditure.

People have long begun to insulate their homes with foam, but the ideal means of insulation has not yet been invented. Of course, the effectiveness of this method cannot be disputed. The main thing is to buy high quality materials. If equipment is available for installation, the process does not take much physical effort and time.

After applying the foam and after it dries completely masters advise treating the surface of the facade with a special coating, which can be purchased at any hardware store. This is required first of all to protect human health, and only then - as protection of the insulation itself.

Where is it applied?

This type of polyurethane foam can be used for almost all building structures and surfaces that can be finished with traditional insulating agents. It can be a floor covering, a facade, a roof, walls, a ceiling, etc. Another thing is that there are different types of heat insulators, each of which is suitable for a particular area.

Under certain conditions, foam insulation can also be performed in technical areas, in storage facilities and hangars, where high humidity prevails. Car trailers are also treated with sprayed compounds, which allows ensuring not only heat preservation, but also tightness. But, as is the case with other heaters, the most widespread are basic compositions for interior decoration. Even a layman can spray them.

Foam cost

If you buy a cylinder at retail, then on average you can pay 300-500 rubles per piece. But this type of insulation is rarely bought separately. Usually its cost is included in the cost of work:

- polyurethane foam - about 100 rubles per running meter;

- penoizol - 700-2000 rubles per cubic meter;

- polyurethane - 3000-5000 per cubic meter.

The price of the material also plays a big role in its choice. But you should not save on high-quality thermal insulation if you need to insulate your home for a long time for a comfortable stay in it.

Foam insulation is suitable for most walls, including panel, block and aerated concrete. Therefore, they can be safely used as insulation for apartments and private houses. Which type of foam to choose is a purely personal matter for everyone. But first, it still does not hurt to learn more about the selected composition, read reviews, get advice from a seller in a hardware store. It is not recommended to use backfill insulation, which easily ignites, in contrast to the foam refractory version. And it is not the most convenient to use, the only exception is the floor surface.

Thermal insulation with liquid foam - better solution, because this procedure, if desired, can be carried out independently, without resorting to the help of specialists. If you do everything right and be careful, you can quickly insulate any surface that needs it.

Features of sprayed thermal insulation

Unlike most insulating materials, the foam does not acquire its complete functional structure until after installation. The basis of the composition is formed by polyurethane, which, in turn, is formed during the mixing of polyol and isocyanate. The resulting mass is applied to the working area through a spray gun. The cooling procedure itself takes only a few seconds. On the one hand, this forces the master to quickly perform work with large volumes of coating, and on the other hand, the high polymerization rate eliminates the delay in subsequent installation activities.

It is important to note another specific feature, which is accompanied by foam insulation based on polyurethane. From the moment of its application and until the final hardening of the insulator, the mass increases by tens of times. During the same period, the process of adhesive bonding takes place. It is precisely because of the possibility of organic attachment of foam to different materials that it is called a universal insulation. It is also worth noting the absence of seams and gaps in the formed structure, which also provides waterproofing qualities.