There can be no problems with cravings

Rotary deflector ready to install

The meaning of any ventilation system is to remove polluted air, excess moisture from the premises, that is, to ensure normal air exchange. This will be the case if the ventilation duct is functioning efficiently and correctly - the draft in it is excellent. If there are problems in this regard, then they are often provoked by rain, snow, wind masses falling into the channel shaft.

Ventilation deflector device

H-shaped design is effective in areas with strong gusty winds

Any type of ventilation deflectors contains standard elements: 2 cups, brackets for the lid and a branch pipe. The outer glass expands downward, and the lower one is even. The cylinders are put on top of each other, a cover is attached above the top. At the top of each cylinder are ring-shaped baffles that change the direction of air in a ventilation deflector of any size.

The rebounds are installed in such a way that the wind on the street creates a suction through the spaces between the rings and accelerates the removal of gases from the ventilation.

The device of the ventilation deflector is such that when the wind is directed from below, the mechanism works worse: being reflected from the cover, it is directed towards the gases that go out into the upper opening. Any type of ventilation deflectors has this disadvantage to a greater or lesser extent. To eliminate it, the lid is made in the form of 2 cones, fastened with bases.

When the wind is from the side, the exhaust air is discharged from the top and bottom at the same time. When the wind is from above, the outflow is from below.

Another device for the ventilation deflector is the same glasses, but the roof is in the shape of an umbrella. It is the roof that plays an important role here in redirecting the wind flow.

Ventilation deflector selection

rotary deflector

The principle of operation of the exhaust ventilation deflector is very simple: the wind hits its body, is cut by the diffuser, the pressure in the cylinder decreases, which means that the draft in the exhaust pipe increases. The more air resistance the deflector body creates, the better the draft in the ventilation ducts. It is believed that deflectors work better on ventilation pipes installed slightly at an angle. The efficiency of the deflector depends on the height above the roof level, the size and shape of the body.

The ventilation deflector is frozen on the pipes in winter. On some models with a closed case, ice is not visible from the outside. But with an open zone of the duct, ice appears from the outer part of the lower glass and is immediately noticeable.

Most often, deflectors are used in natural draft ventilation, but sometimes they reinforce forced ventilation. If the building is located in areas with infrequent and weak winds, the main task of the device is to prevent a decrease or "overturning" of draft.

deflector ASTATO

Any owner wants to choose a deflector for ventilation as efficient as possible.

We suggest that you familiarize yourself with: How to decorate a relaxation room in a bath

The best models of exhaust ventilation deflectors are:

- disc-shaped TsAGI;

- DS model;

- ASTATO.

The deflector operation during calculations is determined by two parameters:

- discharge coefficient;

- coefficient of local losses.

For example, for DS, the coefficient of local losses is 1.4.

The vacuum coefficient is influenced by wind speed.

Calculation of the deflector for ventilation type DS.

| Wind speed in km / h | 0,005 | 0,007 | 0,01 |

| Additional wind vacuum, Pa | 11 | 21,6 | 44,1 |

A method has been developed for selecting a ventilation deflector based on the total wind vacuum.

Although ventilation deflectors have been undeservedly forgotten in recent decades and have been widely replaced by umbrellas, today they are making a comeback. This is a really inexpensive and effective way to improve the performance of natural ventilation in residential and public buildings.

Please note that the hoods on the deflectors are more convex upward. This means that when bending around such an obstacle, a rarefaction is created in its lower part, and thus the formation of thrust.

Types of turbo deflectors

Varieties of deflectors in shape

Many types of deflectors have been developed to select a rotary head model that will work effectively in a specific environment. All devices differ in technical characteristics, despite the fact that the options available on the market are almost the same in appearance.

Rotary turbine models differ:

- by material of spare parts;

- by the size of the connecting ring.

Moving parts of the equipment require periodic maintenance. The cost of turbo deflectors is quite high, so many owners can make and install the structure with their own hands.

By material of manufacture

Turbo deflectors made of galvanized stainless steel and polymer coated

The choice of material depends on the buyer's preferences and budget. Some parts of the turbocharged device are made of plastic. Organic material based on natural or synthetic polymers does not react to moisture, acid precipitation.

The main materials are:

- thin sheets of chrome-plated or galvanized steel with a matte shade are presented in budget options;

- stainless steel has a double cost compared to the previous material; it is powder painted in standard colors of roofing;

- structural metal with a polymer coating does not differ in color from the facade or roof of the building.

Steel is a compound of carbon and iron, the first element gives the alloy hardness and strength, but reduces toughness and ductility. Hot-dip galvanizing is used to prevent surface corrosion and is a reliable protection method.

Chromium plating saturates the surface of steels with chromium molecules in an electric current or in an electrolyte bath. Processing increases the resistance of the metal to fracture and improves the appearance of products. Stainless steel is used uncoated or with a decorative layer, actively resists corrosion due to the addition of chromium, phosphorus, nickel, copper during production.

By the diameter of the connecting ring

The turbo deflector is selected according to the size of the base

The size of the seat is indicated in the marking and passport of the product. The diameter increment is 5 mm, sizes from 100 to 200 mm are available. More than 200 mm are made in sizes 250, 300, 315, 355, 400, 500, 600, 680 and 800 mm. Turbine diameters for extraction 1000 mm and others are made on request.

The deflector is installed on the outlet section of the ventilation pipe, which can have a cross-section of various shapes. The devices are available with a round, square base. There are turbo deflectors with a box base of the transition type. They are installed on ventilation ducts made of bricks or blocks.

The turbine retains its efficiency if the cross-sectional area of the seat ring differs from the same parameter of the pipe by no more than 15%.

What the market offers

Turbovent

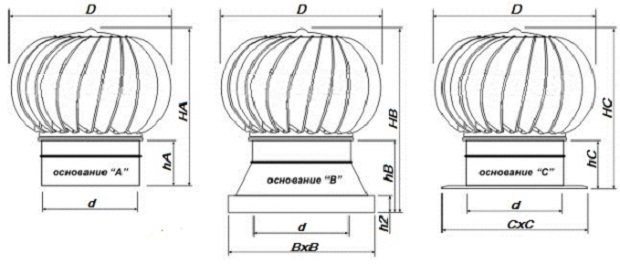

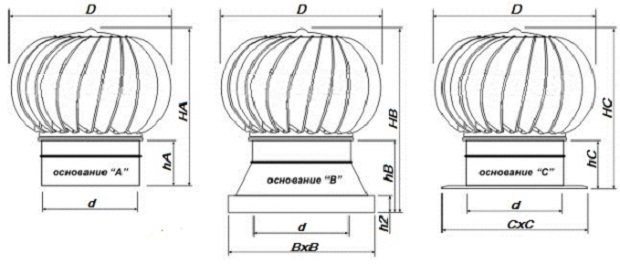

The range of rotary deflectors of this brand is represented by models of different geometric shapes, in terms of the immovable base:

- A - round pipe;

- B - square tube;

- C - square flat base.

Product marking in the assortment is presented as TA-315, TA-355, TA-500. The digital index indicates the diameter of the round or the parameters of rectangular bases.It is by them that one can judge the dimensions of the mechanism, as well as the scope of its application. For example, TA-315 and TA-355 are relevant when organizing air exchange in the under-roof space. But the TA-500 is a universal device and can be integrated into the ventilation of a residential building.

The diagrams indicate the parameters that must be taken into account when choosing a model.

The turbovent rotary deflector is produced in Russia - in the Nizhny Novgorod region, in the city of Arzamas.

Rotowent

Deflectors made of stainless steel made in Poland. Suitable for all roof configurations. Products are made of high quality stainless steel. The devices are universal - they are suitable for both ventilation systems and chimneys. The boundary indicator of the operating temperature is 500 C.

Turbomax

Rotary deflector manufactured by a company from the Republic of Belarus. The manufacturer positions its products as a rotating chimney hood Turbomax1. But it is also suitable for ventilation. It can be safely used in areas with II and III wind load zones. The company focuses the attention of consumers on the fact that they are ready to manufacture a product to order according to the parameters for a specific object.

Deflector TsAGI - "classic of the genre"

The design of old residential buildings was necessarily carried out taking into account the installation of ventilation systems with natural stimulation of air movement. This explains the dependence of natural air exchange on the whims of nature. The TsAGI deflector is a simple ventilation shaped device with an open flow path, developed by the Central Aerohydrodynamic Institute. It uses natural factors of weather changes in its work, but sometimes it works in the system and with mechanical impulse. Works both for ventilation and heating (used in chimneys). Installation options - hidden (in the channel), outdoor.

Installation features

Factory turbo deflector - one-piece design, ready for installation. It has an active movable top and a base that includes zero resistance bearings. The product is thought out in such a way that even in a strong gusty wind it will not tilt or carry it down.

Deflector with polymer protective coating

In conclusion, we would like to note that rotary deflectors in their segment are the most expensive. At the same time, the consumer is invited to choose a suitable structure made of stainless steel, galvanized or structural steel with a protective polymer coating, the color of which can be matched to the facade design. Of course, the type of material from which the deflector is made affects its cost.

Tags: ventilation, deflector, hand, your, drawing

«Previous post

The procedure for manufacturing a turbo deflector for ventilation

For manufacturing, you will need the following materials and tools:

- thick paper or cardboard;

- welding machine;

- steel bar;

- bearings on the axis of rotation;

- galvanized or stainless steel sheet;

- detailed drawing of the deflector;

- rivet gun;

- scissors for metal;

- electric drill with a set of drills;

- marker for marking.

Do not forget about personal protective equipment - glasses and gloves.

Deflector manufacturing sequence:

- Transfer the contours of the deflector parts from the drawing to the metal sheet. The reamer must contain all the details of the device. Make a structure frame with an axle and bearing seats.

- Cut out all parts of the deflector according to the pattern.

- Using a rivet gun, connect the parts together as required by the drawing.

- Connect all parts of the deflector.

The assembly is carried out at a height, so all necessary safety measures must be taken.

The video below shows the individual parts of the turbo deflector.Detailed drawings of different models can be found on thematic sites on the Internet.