Functions and types of electric ignition

The schemes of modern ignition systems are different, but they have the same basis - the use of candles powered from a household electrical network of 220 V. When you turn the switch or press a button, the electrical circuit is closed, the starting candle creates a spark on the burner with gas access. Electric ignition is divided into automatic and mechanical, which is also called semi-automatic.

The principle of operation of the igniter of gas stoves:

- The pressed button generates a voltage applied to the capacitor region.

- The capacitor charge is turned on.

- The voltage level on the thyristor rises.

- The process of discharging the capacitor starts.

- The spark gap is triggered to release a spark that ignites the blue fuel.

What does the ignition block look like for a gas stove

In order for the process to be implemented, the stove must be connected to the network, through a separate outlet from the line with a three-core wire, with a cross section of at least 1.5 mm with grounding. In the switchboard, a 16A circuit breaker is installed on this line.

Mechanical

For the operation of mechanical ignition, two types of transformers with 4 or 6 contacts are used. In the first case, the spark is cut only for the burners, in the second - additionally for the oven.

The scheme of operation of the mechanical ignition block gas for the stove:

- Includes a button on the front panel, powered by electricity.

- The process of charging the capacitor starts using the rectified voltage.

- The accumulation of charges in the farads begins, and the voltage of the main thyristor increases accordingly.

- When the voltage peak is reached, the capacitor starts discharging with the heating of the primary transformer winding, which triggers the spark gap triggering with the release of a spark that ignites the gas in the open burner.

For mechanical ignition, a piezoelectric element is required, therefore this type is often called piezo ignition. Today it is already difficult to find such a stove with mechanics in the trade network among the new products of gas equipment manufacturers. The principle of mechanical control is already becoming obsolete, since it is not entirely convenient due to the fact that in order to connect the unit, ignite the gas stove, in addition to turning the gas supply regulator, you also need to have time to simultaneously press the spark starter on the panel.

Auto

Such ignition differs from mechanical ignition in the physical process of generating a spark, it does not require an ignition button, and the gas is ignited simultaneously with the rotation of the knob. This system is more complex, since both the gas supply and the appearance of a spark occur simultaneously, and the process of spark formation is multiple and performs about 50 electrical impulses per minute, accompanied by clicks. This option is considered the most convenient, is more often used in hobs and very rarely for ovens. The control mechanism can be seen if you remove the flame cutter from the burner, it is located approximately on the side in a small niche.

The scheme of its automatic ignition:

- To generate a spark, the user slightly retracts the rotary knob of the desired burner and scrolls it to supply gas;

- at this moment, the spark plug located in the burner recess closes and ignites the gas coming out of the nozzle openings.

Conclusions and useful video on the topic

As you can see, it will not be difficult even for a novice home craftsman to build a gas stove and such a device will cost much less than the purchased option. This will require a minimum set of tools and materials, as well as some free time.

But, do not forget that homemade gas equipment is fraught with a latent threat, therefore it is important to handle it very carefully and not to forget to shut off the gas supply at the end of using the device.

If you had to assemble a gas stove yourself, please tell our readers about it. You can attach photos of the assembled device to the article and share the assembly secrets.

For heating small remote non-residential premises, a home-made heater from a gas burner and a heater from a gas stove are suitable. To provide sufficient heat for a medium-sized room, you should consider installing a gas heat gun or gas fireplace.

All considered devices can operate both from gas pipes supplied to the room, and from gas cylinders. It is worth remembering that when connecting to a gas pipe, it is necessary to install a meter and officially register the procedure with the gas control authorities. With a self-made construction device, this procedure will be much more complicated.

If you use gas cylinders, you can effectively heat your premises during the winter period. It is important to remember that compliance with safety precautions is the key to successful work with any gas devices.

Tags: gas, burner, hand, your, economical

«Previous post

—

How to turn on the oven on a gas stove manually: instructions

Gas ovens are extremely popular among housewives all over the world. The advantage of such ovens is their low cost and ease of use.

Heating in gas ovens occurs quickly enough, because the heating element is located at the bottom of the cabinet. In models of ovens working on gas, there are no unnecessary settings, various options for all types of baked goods. Many people appreciate exactly this - simplicity and reliability. The baking time is also shortened thanks to the fast heating.

Also, there is no need to worry about security, because modern models are equipped with everything necessary to ensure gas control and electric ignition.

Turning on the oven

The instructions for use seem complicated only at first glance. Switching on the oven manually is as easy as turning on an electric oven. The main thing is to follow the correct sequence:

- First, it is worth checking before turning on - the hose connection

- When turning on the gas supply, it is worth holding it open for a few seconds so as not to lead to gas accumulation

- Light the oven with matches or an electronic lighter

- Constantly monitor the gas supply

- Keep the oven clean, as gas does not completely burn out in a dirty oven

- The oven does not heat the room, it is also not recommended to keep it open for a long time

With a gas oven, you need to behave quite carefully, if problems occur, you should immediately contact a professional craftsman.

GENERAL LABOR PROTECTION REQUIREMENTS

1.1. To perform work using a gas burner, an employee must be at least 18 years old, who has passed a medical examination and has no contraindications for health reasons, who has the necessary theoretical and practical training, who has passed introductory and primary at the workplace briefings on labor protection and training under a special program, certified qualification commission and received admission to independent work. 1.2. An employee performing work using a gas burner (hereinafter referred to as an employee) must periodically, at least once a year, undergo training and testing of knowledge of labor protection requirements and receive admission to work of increased danger. 1.3.An employee, regardless of qualifications and work experience, must undergo repeated instruction on labor protection at least once every three months; in case of violation of labor safety requirements by the employee, as well as in case of a break in work for more than 30 calendar days, he must undergo an unscheduled briefing. 1.4. An employee who has not undergone timely instructions and testing of knowledge of labor protection requirements is not allowed to work independently. 1.5. An employee who performs work using a gas burner, admitted to independent work, must know: safety measures when using gas cylinders and burners. Rules, norms and instructions for labor protection and fire safety. Rules for the use of primary fire extinguishing equipment. First aid methods in case of accidents. Internal labor regulations of the organization. 1.6. An employee sent to participate in work unusual for his profession must undergo targeted instruction on the safe performance of the forthcoming work. 1.7. The employee is prohibited from using tools, devices and equipment, the safe handling of which he is not trained. 1.8. During the performance of work using a gas burner, the worker may be affected mainly by the following hazardous and harmful production factors: - the possibility of a fire when using a gas burner; - the possibility of an explosion of a gas cylinder; - the surfaces of the gas burner heated to a high temperature; - uncomfortable working position. 1.9. An employee performing work using a gas burner should be aware that during work the most likely cause of injury may be burns from an open flame from a gas burner. 1.10. To protect against the effects of hazardous and harmful production factors, the employee must use overalls, safety shoes and other personal protective equipment. 1.11. To prevent the possibility of a fire, the employee must comply with the fire safety requirements himself and not allow other employees to violate these requirements; smoking is allowed only in specially designated areas. 1.12. The employee is obliged to comply with labor and production discipline, internal labor regulations; it should be remembered that the consumption of alcoholic beverages, as a rule, leads to accidents. 1.13. If an accident occurs with any of the employees, then the victim must be provided with first aid, report the incident to the manager and preserve the situation of the incident, if this does not pose a danger to others. 1.14. The employee, if necessary, must be able to provide first aid, use a first-aid kit. 1.15. To prevent the possibility of illness, the employee should follow the rules of personal hygiene, including thoroughly washing his hands with soap and water before eating. 1.16. It is not allowed to perform work while intoxicated or in a state caused by the consumption of narcotic drugs, psychotropic, toxic or other intoxicating substances, as well as drinking alcoholic beverages, using narcotic drugs, psychotropic, toxic or other intoxicating substances at the workplace or at work. time. 1.17. An employee who has committed a violation or failure to comply with the requirements of the instruction on labor protection is considered as a violator of production discipline and may be brought to disciplinary liability, and depending on the consequences - to criminal liability; if the violation is related to the infliction of material damage, then the perpetrator may be held liable in accordance with the established procedure.

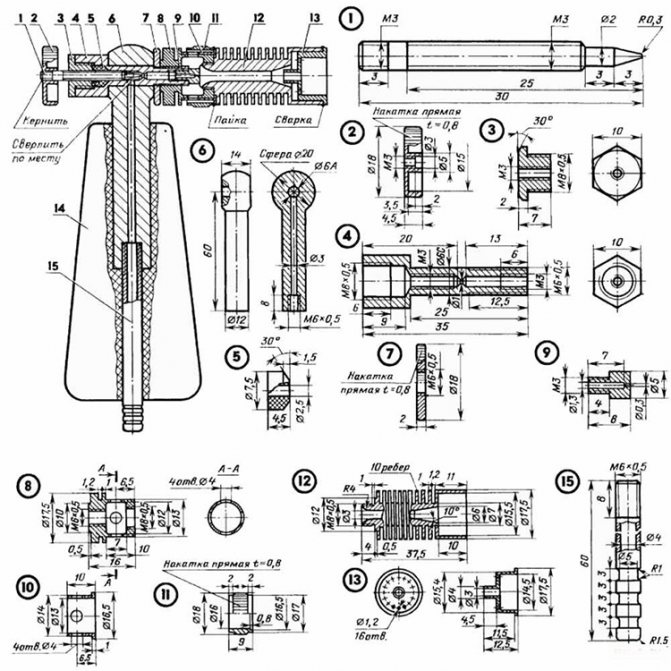

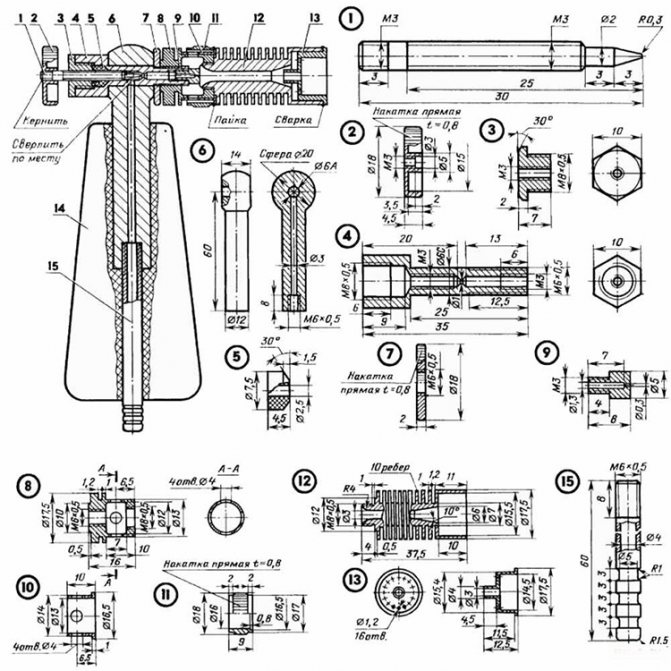

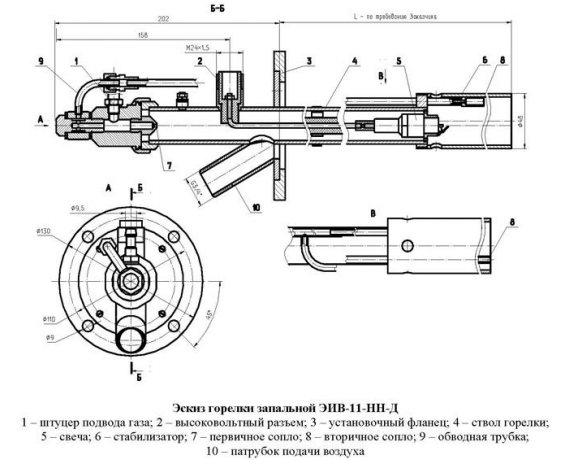

How to make a gas burner with your own hands

Here is the procedure to follow when making a burner:

- It is necessary to cut a fragment of a certain length from the brass tube, which will represent the body of the burner. We select the length for convenience of work and with a small margin for installing the handle.

- The easiest way is to use a handle from an old, worn-out electric soldering iron. In the absence of such, you can cut this element from a wooden block. A through hole must be drilled along the axis of the wooden handle, into which the burner will be installed. Use epoxy to fix it.

- To the end of the tube sticking out of the handle, you need to attach a tap, removed, for example, from an old autogen. The joint should be sealed with FUM tape or silicone.

DIY hydrogen burner

Next, you need to plug the tube-body on the other side and make a hole with a diameter of 0.1 mm here - this will be the nozzle. It is not so easy to make such a small hole, let us dwell on this in more detail.

A waste burner is a necessary device that essentially operates on waste. The burner for working off with your own hands and in our time does not lose its relevance.

You can find instructions for soldering plastic pipes here.

Do you know what an electrolyser is? In this topic, you will learn everything about this device and how to make it yourself.

—

How to turn on the grill in a gas oven?

Many buyers tend to purchase an oven with a grill function. This is one of the most useful options for preparing delicious meals. Thanks to the grill, you can enjoy crispy chicken and you don't need to travel far to cook it over the fire.

Included with the grill function, in some models, a valve is attached, perhaps even a convention function or a fan, thanks to which the cooking time is accelerated. If there is no spit, it is worth turning the dish more often so that the heating is distributed more evenly. If there is no fan function, during operation, you need to keep the oven door ajar.

Grill in a gas oven

Turning on the grill in a gas oven is very simple:

- It is necessary to put the knob of the oven burner tap on the grill designation (basically, it is a square with three triangles at the top)

- Set fire to the oven (manually with matches, or by electric ignition, depending on the type of oven)

- Monitor the constant presence of gas supply to the oven

- After completing the cooking process, it is necessary to thoroughly wash the equipment before using it again. Before using the stove, it is worth studying the instructions for use.

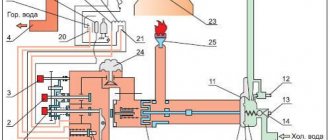

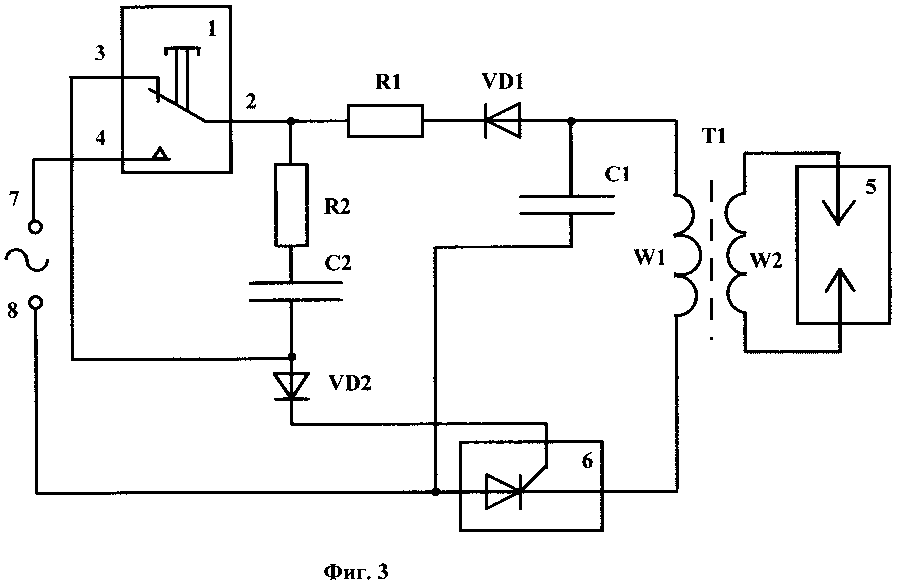

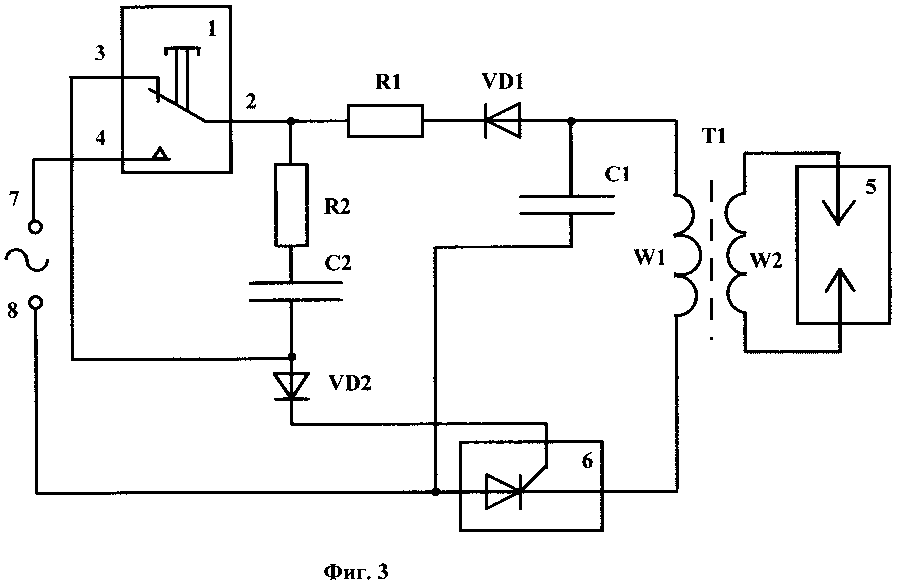

Electric ignition circuits

Depending on the type of electric ignition, two variants of the schemes of the gas stove ignition units are distinguished:

- Single spark ignition - when the ignition button is released, a single spark is generated.

- Multi-spark - by turning the knob of the burner, a spark is continuously generated.

The first scheme works like this:

- when the ignition button is pressed, the mains voltage is applied to the capacitor, it is charged;

- when the button is released, the capacitor contact is connected to the transformer;

- the reverse process is performed - the discharge of the capacitor through the primary winding of the transformer;

- a voltage of about 10 kV is generated on the secondary transformer winding;

- a spark is formed;

- pressing and releasing the button will repeat the process.

The second scheme works as follows:

- with a positive half-wave of the mains voltage, a capacitor is charged through the diodes;

- with a negative half-wave, the cathode is connected to the "minus" half-wave, and a control current is supplied to the control electrode of the thyristor through a resistor;

- the thyristor opens and the capacitor is discharged to the high-voltage transformer, which produces a spark;

- a voltage of about 10 kV appears on the secondary transformer winding;

- while holding the gas supply knob, the process is carried out at a frequency of 50 Hz (1 spark per second).

Note! There is a 4-ex or 6-electrode ignition. The number of electrodes depends on the number of secondary windings of the step-up transformer

Six-electrode ignition units are usually used in combined types of stoves in conjunction with an oven. Two of the six electrodes are located in the oven and work precisely to ignite it.

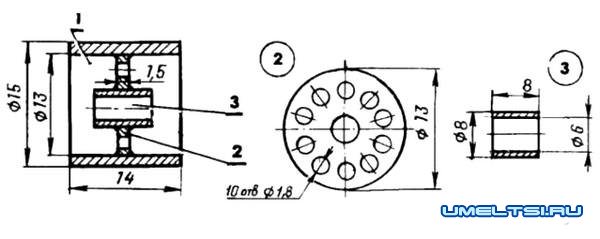

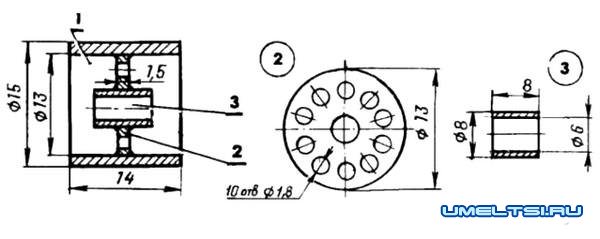

Splitter fabrication and installation

The splitter is made from a piece of brass tube slightly larger than the diameter of the burner. It is attached to the body in parallel. Now, during the operation of the burner, a vacuum is formed in the place where the gas leaves the nozzle, as a result of which air will be sucked in there.

The principle of operation of this device is the same as that of a tourist primus, only it has a smaller size and runs on a different fuel.

This burner can operate both on propane and on a mixture of propane and butane.

Rules for using a gas stove

17.09.2012 11:39

Department of construction, energy and housing and communal services

Rules for using a gas stove

Subscriber requirements

MUST:

1. It is allowed to operate gas stoves after passing the briefing in the technical office of JSC Vologdagaz.

2. Keep the gas stove clean and in good working order. Do not obstruct the stove with foreign objects.

3. Monitor the work of the gas stove.

4. To inspect and repair the gas pipeline and gas stove, allow the employees of OJSC “Vologdagaz” to enter the apartment upon presentation of their service certificate.

5. Economically use gas, timely pay for its cost and the cost of maintenance of gas equipment.

6. If the gas supply is suddenly cut off or if the smell of gas appears in the room, you should immediately stop using gas, turn off all taps on the gas stove and the gas pipeline (valve on the cylinder), open the vents or windows to ventilate the room, call the emergency gas service by phone 04 ( outside a gas-polluted room). Do not light fire, do not smoke, do not turn on electric lights and electrical appliances, do not use electric bells.

IT IS FORBIDDEN:

1. Leave a working gas stove unattended at night.

2. Use for sleeping and resting the premises where the gas stove is installed (kitchens, etc.)

3. Place objects on the gas pipeline and tie up ropes.

4. Allow preschool children to use gas appliances, persons who do not control their actions and do not know the rules for using these appliances.

5. Use a gas stove with a closed window (transom) and a grate of the ventilation duct in the kitchen.

6. Use gas for other purposes (for space heating).

7. Use a faulty gas stove.

8. Unauthorized, in addition to OJSC "Vologdagaz", to rearrange, replace and repair gas appliances and equipment.

9. Redevelop the premises where gas appliances are installed, without agreement with OJSC Vologdagaz.

TURNING ON THE GAS STOVE:

1. Before turning on the gas stove - ventilate the room and make sure that the taps on the gas stove are closed.

2. Open the valve on the gas line in front of the stove or the valve on the cylinder.

3. Bring a lighted match (electric or piezo lighter) to the burner, and then press the corresponding knob on the gas stove and turn it half a turn. When igniting, make sure that the gas ignites at all burner openings.

4. Before using the oven - open the door and ventilate it for 2-3 minutes.

TURNING OFF THE GAS RANGE:

1. Close the valve on the gas line or the valve on the cylinder.

2. Turn off the taps on the gas stove or the oven tap.

| Next> |

Advantages and disadvantages of gas ovens

The market offers consumers a wide variety of energy sources.At the present stage of economic development, gas is one of the most profitable and efficient fuel options.

The use of gas as a power source for heating equipment is beneficial in that its cost does not hit the consumer's pocket. In addition, the gas has a high efficiency. The operation of gas-fired heating devices is easy to use, economical and safe.

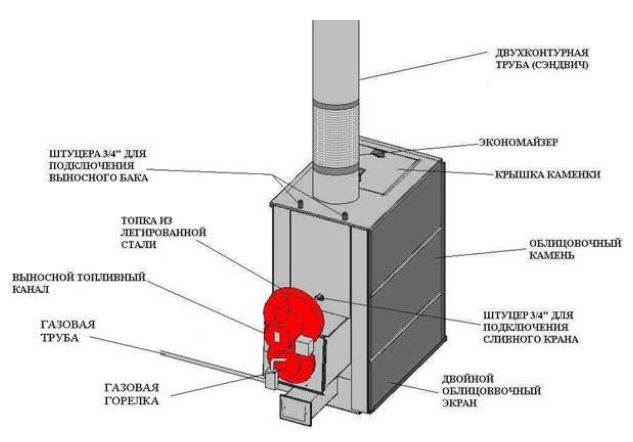

This kind of homemade heater is often used for a wide variety of purposes. It can be used to heat a greenhouse, garage, box. Due to their mobility and low assembly cost, portable heaters can be taken even on camping trips

When arranging a gas oven in a room, the best option for owners will be a situation when a gas pipeline is directly connected to the building. However, in modern realities, this is a very rare case. Many will have to purchase gas cylinders and other containers for storing and supplying fuel to the furnace.

The advantages of using gas ovens include:

- fast, efficient and high-quality heating of the room;

- mobility and compactness of gas equipment;

- the ability to quickly move the oven to the desired location;

- independence from government communications, power outages and many other factors.

Gas equipment, like any other, has its drawbacks. However, they are relative and easy to work around.

The disadvantages include:

- the use of gas is strictly regulated by regulations;

- owners of non-residential premises will have to obtain a number of agreements and permits from the gas industry and other government agencies;

- drawing up the necessary project can cost a round sum;

- the use of reduced and bottled gas requires compliance with safety measures.

In order for the gas stove to perform its function as efficiently as possible in the room, it is necessary to have protective screens. Such structures are equipped with reflective surfaces, due to which warm air does not escape, but is reflected and heats the entire area of the box.

Craftsmen are constantly improving their skills and applying new techniques to design homemade units. Some modern handmade gas heaters are equipped with special blowers to control the flow of warm air.

Open burning stoves require the design and installation of a ventilation system and provision of air humidification. When the device burns oxygen, the air becomes dry. This often leads to headaches and throat problems.

Advantages of a canister gas burner

Compared to oil burners, gas burners have many advantages. They run on environmentally friendly fuel, instantly ignite and do not leave any residual combustion products after their use.

Due to the use of gas, minimal attention can be paid to cleaning the interior of this device.

The portability and compactness of a gas burner on a small-capacity canister allows you to direct the flame stream at any angle that is necessary for the owner's comfortable work. This device can be used in various situations - when lighting raw firewood and charcoal, when soldering parts with tin-copper solders, when creating decorative patterns on wood, as well as in cooking - in order to caramelize sugar. And this is only a small part of the possibilities for using this product.

After purchasing this device, you must carefully study the instructions for use and safety. You can use the burner only strictly observing all the rules for its use. Overheating of the gas cylinder is unacceptable - it must not be left in the hot sun or near heating devices.After prolonged operation, a strong cooling of the reservoir occurs, which reduces the power of the torch. To avoid this, a special catalytic heating pad is put on the cylinder.

A gas burner will be a reliable and effective assistant for its owner. The presence of this device on the farm will be able to solve a lot of problems that may arise at any time. Its correct use will bring a lot of positive emotions, and will help to bring any ideas to life, no matter how difficult they may seem at first.

sledopyt.net

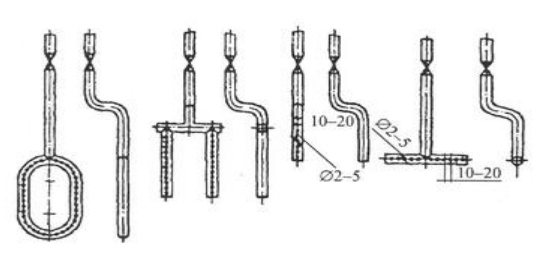

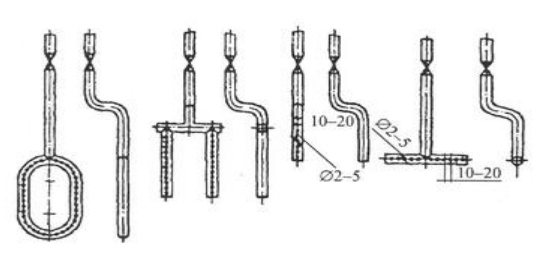

Application of torches for brazing and brass brazing

Soldering allows you to make a one-piece tight connection of two metal parts by a kind of "gluing" them with a kind of molten material - solder. The latter must exhibit high adhesion with respect to the metals being joined, that is, be very "sticky", and have sufficient strength after solidification.

The melting point of the solder must be higher than the operating temperature at which the brazed product is used; and at the same time lower than the melting point of the base material.

A gas burner is just needed in order to heat the solder and thus make it viscous enough.

Obviously, for the convenience of its operation, its torch must maintain a stable shape and temperature.

The advantage of this tool lies in the ability to process areas with a large area - such a task will not be possible for an electric soldering iron.

At the same time, a simple, low-power burner can be made without much hassle with your own hands.

With the help of a homemade burner, you can do a lot of useful things. Its capabilities will be quite enough for soldering copper and brass vessels that are part of radiators, intercoolers and heat exchangers, as well as for soldering using solid solders.

In addition, only with the help of this tool, it is possible to disassemble the radiator in order to replace its core, as well as replace the honeycomb in it.

Such a burner will also come in handy during body repair, in which a high temperature is not only unnecessary, but also very undesirable, since it can cause warpage of this part of the car.

To carry out the restoration of a small damaged area, to solder the holes with brass, to carry out "jewelry" straightening - this tool will be quite suitable for all these works.

Slight heating will also be needed if it is necessary to dismantle a part fitted with an interference fit, that is, pressed.

This could be a bearing race or some kind of bushing.

This method is especially effective if the parts included in the joint are made of materials with different coefficients of thermal expansion.

The main characteristics of gas burners on a spray can

Gas burners on a canister have different power - it depends on the composition of the gas mixture and, accordingly, on the flame temperature, which can range from 1000 ° C to 2500 ° C. The gas pressure in the cylinder also plays a significant role for efficiency.

Some models have a built-in nozzle regulator that allows you to change the diameter of the flame stream until the desired torch size is obtained. It is also possible to change the supply of the gas mixture from the cylinder. Thanks to this, the power of the device used can be increased.

Compact cylinders with liquefied gas have different types of connection to the burner - threaded or collet. The common gas mixture used to fill the tanks allows the burners to be used at ambient temperatures between 5 ° C and 45 ° C. Special gas mixtures, which include isobutane / butane / propane (the so-called "winter mixtures"), allow working even at subzero temperatures. They make it possible to create a torch with a temperature of over 2000 ° C.

On sale there are models weighing 70 grams - excluding the balloon.This greatly facilitates the use of this device by the owner.

Scheme

A homemade soldering torch is extremely simple. Its body is a tube with a nozzle at the end. At the other end, a valve will be installed with a branch pipe for connecting the gas supply hose.

For the convenience of adjusting the torch power, we will equip the nozzle with a divider.

Gas burner diagram

LABOR PROTECTION REQUIREMENTS DURING WORK

3.1. The gas cylinder must be firmly installed on a level, well-ventilated (ventilated) area and reinforced. 3.2. The use of gas cylinders for work in confined spaces is allowed provided that effective ventilation is ensured. 3.3. When working with a gas cylinder, it is necessary to take measures to prevent shocks, shocks, falls, and when working at an outside air temperature below 00 C - from freezing. 3.4. All devices connected to the gas cylinder (reducer, hoses, burner) must be in good working order and periodically checked: - burner - at least once a month for gas tightness; - gearbox - at least once a quarter, technical inspection and testing; - hoses - every day - for cracks, ties, etc. 3.5. Gas hoses must be free of cracks, ties, etc. 3.6. Before connecting the reducer to the cylinder, it is necessary to purge the reducer fitting to remove foreign particles from it. 3.7. The reducer must be attached to the gas cylinder only when the cylinder valve is closed. 3.8. After connecting the pressure regulator, slowly open the cylinder valve and set the working gas pressure. 3.9. The length of the hose, depending on the working conditions, should be in the range from 8 to 20 m. 3.10. Regardless of the place of work, the following distances from the gas cylinder to: - heat sources (for example, heating radiators) - at least 1 m must be maintained; - open fire - not less than 10 m. 3.11. When working with gas cylinders, it is prohibited to: - install cylinders in an inclined position; - install cylinders in aisles, driveways, in a place where workers are congregated, in poorly lit places; - expose cylinders to sunlight; - perform work without a gearbox; - use hoses made of separate scraps or interconnected by wire, clamps; - leave cylinders in operation with open valves unattended; - disassemble and repair the burner connected to the gas cylinder; - warm up the frozen gearbox with open fire; - smoking and eating in the workplace; - the presence of strangers. 3.12. Do not work with the gas burner near electrical appliances and other live parts that are energized. 3.13. If work is carried out near live electrical equipment, the electrical network must be disconnected before starting work. 3.14. While working with a gas-air burner, an employee is prohibited from: - moving outside the working area with a lit burner, including going up or down stairs, ladders, etc .; - hold gas sleeves under the arm, pinch with feet, wrap around the waist, wear on the shoulders, bend, twist; - smoke and approach the gas cylinder with an open flame less than 10 m. 3.15. During breaks in operation, the gas burner must be extinguished. 3.16. When working with a gas burner with an open flame in windy weather, the worker should be positioned, if possible, on the upwind side. 3.17. The cylinders must be protected from heating by sunlight or other heat sources. The maximum permissible temperature of the liquefied gas cylinder is not more than 45 ° C. 3.18

Liquefied petroleum gas is explosive, its leakage is not allowed, and when working with cylinders, care should be taken to prevent them from falling and hitting. 3.19

Complete burnout of gas from the cylinder is not allowed.A low burner flame indicates insufficient gas in the cylinder, clogged burner diffuser or cylinder capsule. 3.20. When using a gas burner, there should be no smell of gas. You can check for gas leaks by applying a soapy emulsion to the suspected gas leak. Checking gas leaks with fire is prohibited. 3.21. If the gaskets are worn out, they should be replaced with new ones from the kit. Burner and cylinder malfunctions should be repaired by specialized workshops. 3.22. Only one gas burner can be connected to one cylinder. 3.23. When working with a gas burner, it is not allowed to disassemble and repair burner and cylinder malfunctions and leave a lit burner unattended.

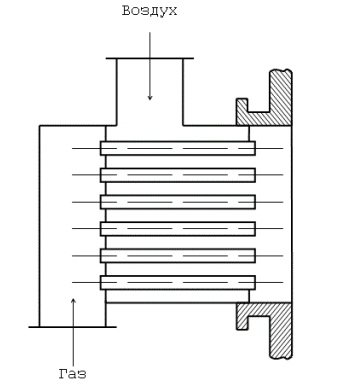

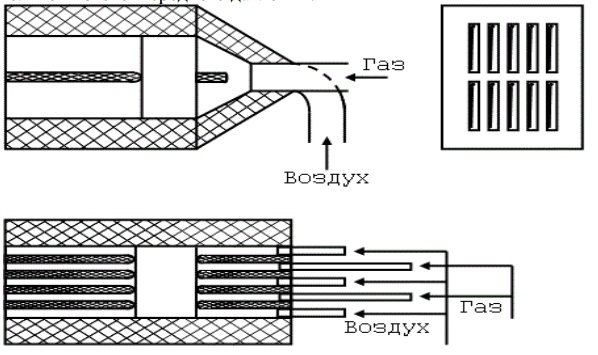

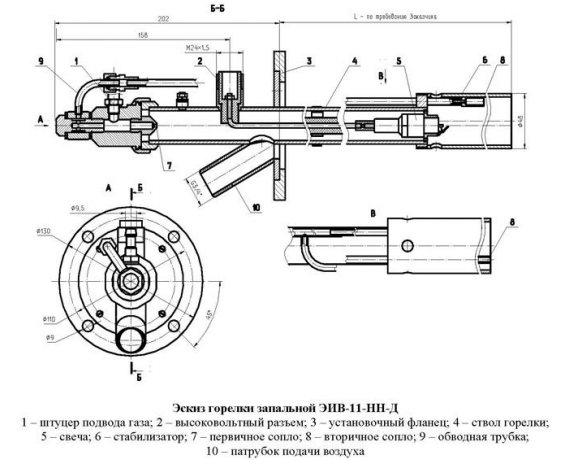

1.3. Gas burners for boiler systems

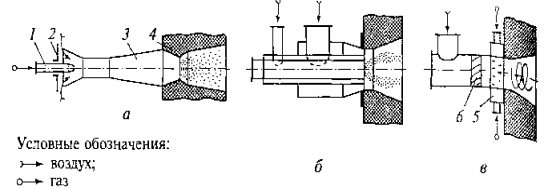

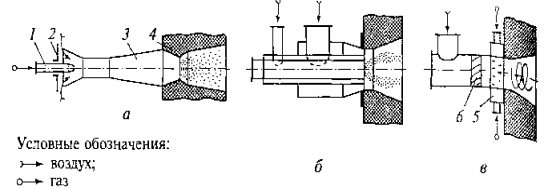

In accordance with the general provisions of the theory of combustion of gaseous fuels), gas burners are:

- complete premixing (gas and air are mixed before leaving the burner) - kinetic;

- partial premixing - diffusion-kinetic;

- external mixing - diffusion (Fig. 12).

Fig. 12. Diffusion gas burners

Gas burners are classified according to the following criteria:

- along the length of the formed torch - for long-flame and short-flame;

- according to the luminosity of the flame - to a luminous or weakly luminous torch;

- by the calorific value of the combusted gas - for burners for high-calorific and low-calorie gases;

- by pressure in front of the burner - for low- and high-pressure;

- by the number of supply pipelines for one- and two-wire, etc.

One of the essential features is the method of mixing the flared gas with the air necessary for its combustion.

On this basis, burners are of the following three types.

1. Burners without preliminary mixing of gas with air

Gas and air, in the amount required for combustion, are supplied separately through the corresponding channels of the burner. The combustible mixture is formed in the flame in the process of turbulent mixing of gas and air after they leave the burner.

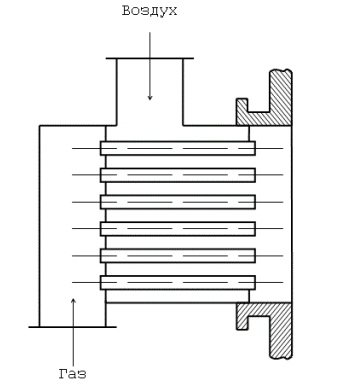

An example of this type of burner is a tubular burner for low-calorific gases (fig. 13). Gas enters through the gas manifold and pipes connected to it, and air flows through the opposite manifold into the annular space. Mixing occurs in the jet streams at the outlet of the pipes.

Fig. thirteen. Tubular burner for low calorific gases

Such burners are used for burning low-calorific gases in large quantities and in furnace technology, when it is necessary to have an extended glowing torch with a more uniform heat transfer along the length of the working space of the furnace.

2. Burners for premixing gas with air

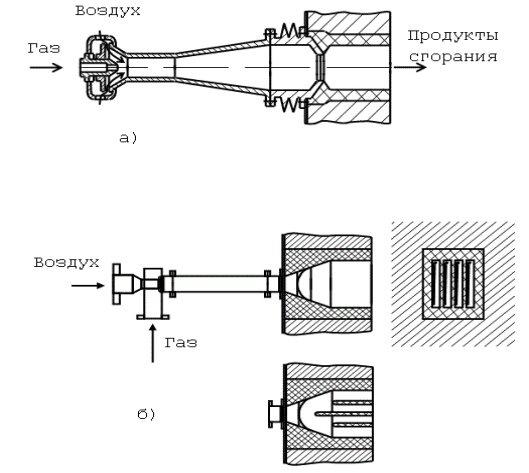

Burners operating on the principle of kinetic combustion are used in cases when it is necessary to burn gas with a high thermal stress of the volume with a minimum chemical underburning and with a short weak flame (Fig. 14). Premixing of gas with air takes place in mixers, from which the finished mixture enters the burner. This type includes tunnel and other types of burners of a homogeneous gas-air mixture obtained by premixing gas with air in mixers of various designs.

In industry, tunnel-type injection burners are widely used, which provide automatic control of a constant ratio of gas and air flow rates and allow the combustion of dusty gases. The burners are more heat-resistant and have an increased flow capacity at low resistances.

Fig. 14. Injection burners with ceramic tunnel channel: a - single-wire burner with a single-channel tunnel; b - two-wire burner with multi-channel tunnel

3. Burners with partial mixing of gas and air

These burners are equipped with short mixers in which partial mixing takes place.Mixing continues and ends in the torch during combustion.

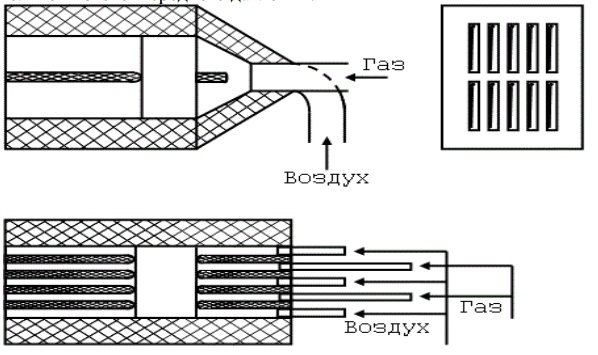

Burners operating on this principle are widely used in the power industry for burning natural gases.

In burners with partial mixing for low-calorific gases (Fig. 15), due to the commensurate flow rates of gases and air, gases and air are fed in alternating flat flows through channels to the prechamber, in the channels of which mixing and combustion begins. The mixing and combustion process continues and ends in the outlet ducts. The section of the burner tunnel is determined by the amount of combustion products and their speed, taken in the range of 30-40 m / s.

By the method of air supply, burners are divided into injection and blowing (with forced air supply). In accordance with this, burners are distinguished with low gas pressure (up to 5 kPa), medium (5 kPa - 0.3 MPa) and high (more than 0.3 MPa). Injection burners are available only for low and medium pressure.

Fig. 14. Blast furnace gas burner

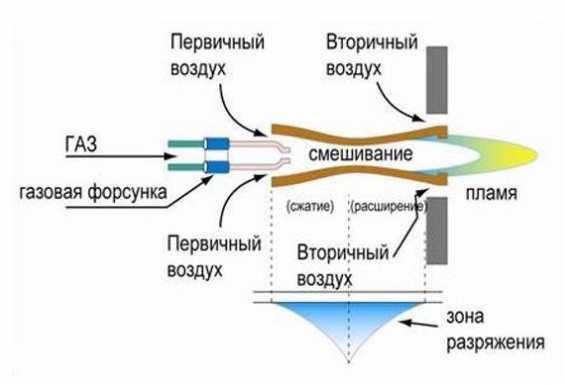

The combustion of fuel in the form of a gas is determined by the method and rate of its mixing with air (oxygen). For small heating boilers, the installation of a gas heating system usually implies atmospheric and fan burners.

The principle of operation of a gas burner is shown in fig. 16.

Fig. 16. The principle of operation and design of a gas burner

Examples of burners and their main parts are shown in fig. 17.

Fig. 17. Examples of some gas burners and their main elements

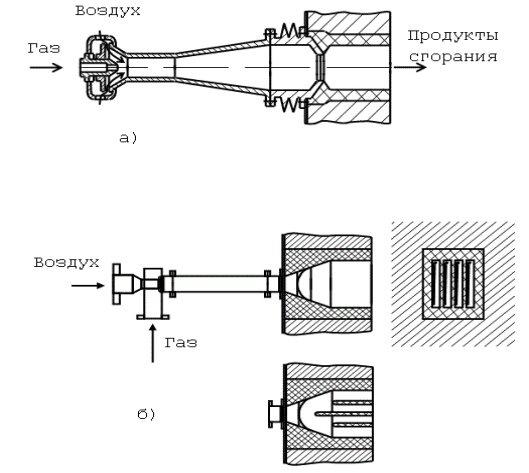

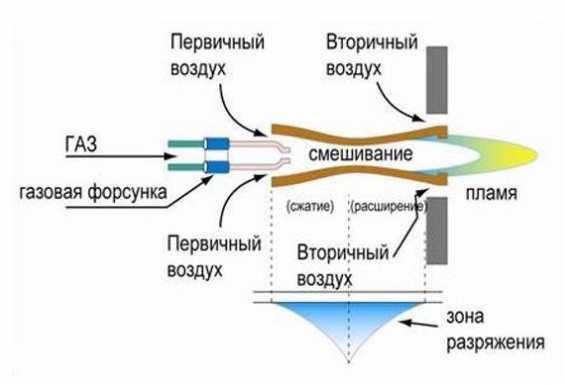

In fig. 18 shows the basic schematic diagrams of gas burners. In the injection burner (Fig. 18, a), the gas flowing out of the nozzle ejects (sucks in) air and mixes with it. The gas-air mixture in the injection burner burns in a refractory nozzle (tunnel) directly adjacent to it. Due to the high temperature of the inner surface of the packing, the combustion of the finished gas-air mixture proceeds almost instantly and ends inside the packing. For this reason, such burners are conventionally called flameless.

The volume of the combustion chamber adapted for flameless combustion of gas can be significantly reduced, and when choosing the dimensions of the chamber, one proceeds not from the need to ensure the completion of the combustion process in it, but from the condition of obtaining the largest heating surface area.

Gas flow through the burner, depending on its design, can vary within wide limits - from 0.5 to 1000 m3 / h and more. The length of the nozzle reaches 1 m, the speed of the gas-air mixture reaches 3080 m / s. Injection burners are installed under boilers with a steam capacity of less than 2.75 kg / s (10 t / h). An important advantage of this type of burners is the absence of fans for air supply, which reduces the energy consumption for boiler unit maintenance.

A diagram of the simplest forced air burner is shown in Fig. 18, b. In it, gas is supplied to the annular space between the inner pipes, and air enters the annular space between the middle and outer pipes, while the design provides for the swirl of gas and air flows. The gas is ignited through the inner tube, through which the burner is monitored. Gas mixes with air in an expanding embrasure arranged in the firebox lining.

The mixing process is significantly improved if the gas is supplied in small jets flowing from small holes (Fig. 18, c).

Fig. 18. Gas-burners: a - medium pressure kinetic injection burner; b - diffusion burner with parallel streams of gas and air; c - burner with incomplete premixing: 1 - gas nozzle; 2 - regulating air inlet; 3 - mixer; 4 - ceramic nozzle (prechamber); 5 - annular gas manifold; 6 - blade eevirhritel

Atmospheric burners are appliances that are characterized by the premixing of fuel and air. They do not require a blower fan.

Such atmospheric burners Is a set of rods into which gaseous fuel is supplied through a special ejector. The fuel-air mixture enters the combustion chamber through special holes that are distributed along the upper generatrix of the rods. Ignition electrodes are designed to ignite the fuel-air mixture, and many "torches" of relatively low temperature are formed in the combustion chamber. Usually, both wall-mounted and floor-standing boilers are equipped with such burners.

Installation of gas heating and its operation when fan burners organized differently. They differ in that they have forced air supply using a special fan, as well as precise air supply control. These types of burners are only used in boilers with a closed combustion chamber, which is often pressurized.

In fan (blower, forced draft) burners (Fig. 19) there is a mechanical mixing of gas or liquid fuel with air under pressure, as well as the supply of such a mixture to the furnace. A burner of this type provides maximum (95-98%) efficiency, is not sensitive to gas pressure drop and has a more attractive operating cost.

Fig. 19. Fan gas burners

A fan gas burner for home heating implies the following system of functioning: fuel is mixed with air after it leaves the burner. At present, fan burners are highly automated and also have a modular design. As a rule, such automated block burners are installed on autonomous boiler plants with a power of 5 kW and more. Thanks to this, the participation of the user in the control of the heating system is minimized and reduced to one thing - you need to order gas heating and configure it.

The fan burner automation switches it on and controls its safe operation. If an alarm occurs, the burner switches off automatically.

Each burner of this type has a gas multiblock. It includes the following components: a relay that turns off the burner if the inlet pressure drops below the set; gas filter; a gas pressure stabilizer, which must maintain a constant outlet pressure when the inlet pressure changes; gas flow regulator; starting pressure regulator.

Installation of gas heating with automated block burners provides compactness and convenience. Due to the design of such burners, if necessary, some parts can be cleaned without disassembling the fuel supply unit and the burner itself.

The air flow is swirled by a special vane swirler. The mixing of gas with air ends within the embrasure.

In addition to purely gas burners, some installations use burners for co-firing gas and fuel oil or combining low-calorific gas with pulverized fuel and others.

For the reliable and economical operation of the boiler unit, not only the type of burner is important, but also their number. As a rule, several burners are installed in the furnaces of boilers. This is necessary so that the torch fills the combustion volume to the maximum and it is possible to regulate the combustion processes in the required range of variation in heat output with a variable operating mode of the boiler unit. Each type of burner has a limited heating capacity regulation range. By varying the fuel consumption and the excess air ratio on each burner within the permissible limits, it is possible to achieve a certain depth of regulation and the heating capacity of the boiler unit.

Fig. twenty. Example of connecting a gas burner to a boiler

Other types of burners include diffusion-kinetic and combined burners.Diffusion-kinetic - this is an intermediate version of the main types, the principle of which is that the air for combustion of fuel enters the chamber only partially, and after that it is added to the fire.

How is an electric ignition gas stove connected?

Gas stove connection diagram.

It should be noted right away that it is best to attract specialists to connect the gas stove. Only they can do everything right and avoid very unpleasant consequences. If, nevertheless, you decide to make the connection yourself, then you need to know a few rules that you will need to apply in the process.

- So, the stove is already at your home. Do not rush to start installing it from the very first minutes. Let the technique stand at home for a while. This is necessary in order for the structure to get used to the new temperature regime. Be sure to inspect the slab for damage.

- Pay particular attention to the areas where the connection to the gas network takes place. Check all switches for proper operation. You must be sure that the gas is supplied at full capacity.

- Since we are considering an electric ignition stove, you will, of course, need electricity. For these purposes, an outlet will be sufficient, which, in turn, is grounded. Remember that incorrect connection can lead to irreparable consequences.

- You must understand that if the stove has an electric oven, then the old electrical wiring, which has cross-sections, will not work for its full and correct operation.

- The choice of gas hose is undoubtedly an important consideration. For a stove with an electric ignition function, you need to purchase a white hose with a yellow strip. Be sure to inspect the hose. You must exclude possible gas leakage. It is also important that all connections between the stove and the gas pipes are securely fastened and tightened.

- The gas stove must be level. To do this, you need to adjust the legs that are at the bottom. If you are installing a hob, it is important that it is level. Pre-measure and align the place where it will be installed.

After you have done everything that was described above, you will need to check the stove for operability in all available modes.

All of the above rules will help you quickly and correctly install an electric ignition gas stove. If after installation you have any problems or doubts, you need to immediately seek help from specialists, who, in turn, will be able to identify the malfunction and prevent a number of very unpleasant and life-threatening consequences.

In any case, will you install the equipment yourself or with the help of craftsmen, you must follow all safety rules so as not to harm yourself and others.

Possible breakdowns

Turning on the oven is not always successful. This can happen for several reasons:

- The burner may be clogged. In this case, the heat control sensor does not work, since fire does not fall on it. As a result, the flame goes out. After thorough cleaning of the part, the cooker will turn on easily.

- Severe depletion of thermocouple. The reason is that there is a great deal of interference in the gas supply to the oven.

- If the gas valve has received mechanical damage, it must be replaced. This part cannot be repaired.

- The timer very often fails. The reason is long-term use of the product. The main symptoms of such a breakdown are considered to be periodic shutdown or complete shutdown. To detect a malfunction, first check the continuity of the thermocouple. Then the condition of other parts associated with the flame detector.

- If, after heating, the oven starts to go out, it is necessary to adjust the flame by setting the minimum position. This problem arises from insufficient heating of the fire.As a result, the flame is automatically turned off.

Important! Quite often there are cases in which the flame does not completely cover the burner. In one part, it is missing. In this situation, it is required to stop the gas supply. Then ventilate the room, repeat all operations starting from the initial stage of ignition. Complete ignition is required for the oven to function properly.

Manufacturers produce different models of ovens. Some are very difficult to set on fire. However, their advantage is complete safety and great functionality. It is very important to follow the technological sequence of operations, to be attentive to such devices.

Delicious recipe! Khinkali is steamed or in water

The process of setting fire to the oven in a gas stove depends on the type and characteristics of the oven. Most modern models have automatic or semi-automatic electric ignition and the "gas control" function, which greatly simplifies the process of turning on the oven and helps prevent gas leaks.