The presence of an autonomous water heating system provides not only comfortable living, but also independence from the whims of utilities. The performance of such systems, their efficiency and safety depends on the technical characteristics of the Ariston boiler, the connection diagram and the quality of the installation.

The key to a long and trouble-free service is compliance with all operating rules and timely maintenance. Ignoring the requirements prescribed by the manufacturer can lead to premature failure of both individual parts of the boiler and the entire product as a whole. In addition, the possibility of electric shock increases many times over.

The operating manual contains all the necessary information regarding the installation, connection, conditions of use and the frequency of maintenance of the Ariston storage water heater. In addition, the document includes a list of the most common problems and a method of self-elimination, however, in order to effectively solve the problems that have arisen, knowledge of the design and basic principles of the product will be required.

The device and principle of operation of the water heater "Ariston"

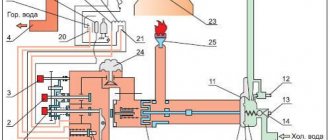

The modern Ariston boiler for 30, 50, 80 and 100 liters is a sealed structure consisting of the following parts and assemblies:

- Storage tank:

- Electric heating element (heating element);

- Magnesium or zinc sacrificial electrode;

- Setting and control unit;

- The casing.

The inner surface of the tank must undergo anti-corrosion treatment. Depending on the cost of the product, various modifications can have as anti-corrosion protection:

- Titanium sputtering;

- Glass porcelain coating;

- A layer of heat-resistant enamel resistant to aggressive compounds.

In addition, expensive premium water heater models can have all-metal welded storage tanks made of alloy stainless steel.

The air gap between the casing and the inner container is filled with a polymer heat-insulating compound (most often, polyurethane foam). Thermal insulation can significantly slow down the cooling process, thereby reducing energy consumption.

Heating elements are classified into two main types: "wet" and "dry". Wet heaters are called heating elements that come into direct contact with the heated liquid. In the process of interaction with the working environment, on the outer surface of the heating element, a persistent coating of insoluble scale is formed, which prevents normal heat transfer. A zinc or magnesium anode is used to protect the heating elements and the inner surface of the tank against corrosive destruction.

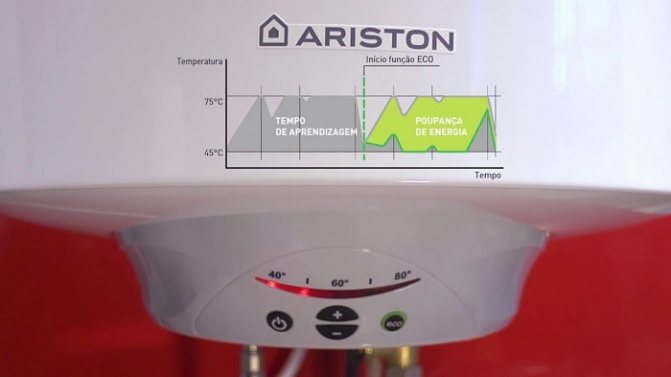

The functionality, information content and ergonomics of the water heater largely depend on the design and design of the control and adjustment unit. There are two types of control mechanisms: electronic and mechanical. Digital systems are attractive in appearance and precise in setting, but are extremely sensitive to voltage fluctuations.

The mechanical block looks "simpler", and the adjustment accuracy is not the same, but the reliability of such devices fully compensates for these shortcomings. In addition, the price of models with electronic adjustment is noticeably higher.

The casing of the unit can be made of both metal and polymeric materials.The most common is the cylindrical shape, but models of other configurations are in demand.

Overview of common breakdowns

To eliminate malfunctions that occur in refrigeration units, it is necessary to have a minimum understanding of the most common failures. Since self-repair is simply impossible without an adequate response to the problem that has arisen, study in detail the reasons why certain situations arise.

Refrigerator leaking

It can be caused by mechanical damage to the case, destruction of the thermal insulation layer and, as a result, violation of the temperature regime. In this case, condensation forms at the place of damage, which flows down the refrigerator. To fix the problem, it is necessary to restore the thermal insulation layer and patch the hole.

The refrigerator freezes and frost appears

If, when opening the door, you become a witness of a frozen layer of frost and frozen food, then such a situation could arise if:

- Cooling level set too high, adjustment required;

- Malfunctions with a temperature sensor, compressor unit, etc .;

- The door seal does not fit tightly, which could occur due to a loss of elasticity;

- Failed and requires replacement of the thermostat;

- The door does not close completely due to overcrowding in the cooling chamber.

To check the tightness of the doors at the factory, a special metal probe is used, which at home can be replaced with a strip of paper. In the place where the paper penetrates under the magnetic stripe, air is sucked in from the outside, which causes the deposition of ice and more diligent cooling.

The refrigerator turns on, but does not freeze or chill

Such a problem may occur due to:

- Malfunction of the thermostat or setting the cooling mode to a minimum;

- Failure to configure complex electronic control units in modern models;

- Accidental start of defrosting, while it is required to completely defrost the refrigerator and turn it on again;

- Abrupt loading of two-compartment refrigerators with large volumes of products that he does not have time to cool;

- Leakage of refrigerant, while you urgently need to find the place of damage and fix it;

- Compressor motor malfunction or clogging of the entire cooling system.

The refrigerator does not turn on

In case of such a malfunction, check the electrical circuit for its integrity. In this case, the following causes of breakdown are possible:

- Household appliances are not plugged into the socket, the voltage level in the mains is insufficient or the socket is faulty;

- It is necessary to check the chain of the plug and cord for continuity;

- Breakdown of the relay or electric motor.

Modern refrigerators Atlant, Samsung and others may not turn on due to failures in the control unit. It is quite difficult to find such problems at home.

Long work without shutdown

In normal mode, you hear active work for 10 to 20 minutes. Then it should turn off until the next cycle. Otherwise, there is a rapid wear of the rotating elements. The cause of the problem may be:

- Loosely closed door or hot air of the surrounding space, due to which the required temperature level is not reached in these household appliances;

- The device operates in super-freezing mode, but such work cannot last longer than the one regulated by the factory instructions;

- The thermal electronic sensor is out of order;

- Freon is leaking from the cooling system.

Increased noise level

For correct operation of the unit, its installation is carried out using a building level and on a solid foundation.If these requirements have not been met and the refrigerator is wobbling, then there will be third-party noises during operation.

If installed securely, the sound can be emitted by the compressor casing, touching the back of the tube, contacts of the protective relay, by the evaporator fan. To eliminate such situations, it is required to adjust the operation of the corresponding elements.

How to choose the volume of the water heater

Boiler capacity is one of the main criteria to consider when purchasing. Customer feedback and statistical analysis made it possible to determine the required amount of hot water depending on the number of consumers.

A 30 liter Ariston heater is enough for one person. If two people live in one apartment at the same time, "Ariston" 50 liters will fully meet the need for hot water. A family of three or four people will need 80 liters of Ariston. If we are talking about providing a private cottage or a small restaurant, the best option would be "Ariston" for 100 liters or more.

Magnesium anode

This structural element of a gas water heater is similar in appearance to a pin made of metal. If we talk about its functional advantage, then magnesium alloy should be considered as such. It is evenly applied to the surface of the part. The maximum thickness of this layer for Ariston gas boilers does not exceed 30 mm. Thanks to him the inside of the tank is protected water heater from corrosion processes. And this has a positive effect on the service life of this equipment.

Do not install the anode yourself if your boiler does not have one. It is better to seek the help of a specialist. In addition to installing the anode, he can assess the condition of your equipment, check the degree of wear, and also carry out all the necessary work to maintain the unit in working condition.

It must be said that parts such as the heating element and magnesium anode used in Ariston gas boilers have a specific shelf life. In many ways, it depends on the load that falls on the equipment during its operation. The environment also affects the shelf life. Specialists recommend replacing these important elements once every one and a half years. If you neglect this recommendation, then there is a risk of destruction of the walls of the heater. Rust will develop on the inside, which can lead to the destruction of the tank at some point.

Not in all cases, the problem of increasing the equipment life can be solved by replacing a part such as a magnesium anode. Everything due to poor quality waterthat flows from our taps. In our time, it is not uncommon for the elements of a water heater to simply not cope with poorly filtered water. In such cases, it becomes necessary to completely replace the boiler. If we talk about the average values of the service life of a device for heating water, then usually it does not exceed 7 years, provided it is continuously used with the necessary repair procedures carried out during operation.

Operating instructions for the water heater "Ariston"

The beginning of operation can be considered the installation and connection of the boiler to the centralized cold water supply system and the electrical network. The quality of installation depends on the safety, efficiency and service life of the product. If, for one reason or another, the boiler is put into operation on its own, you should pay special attention to the points outlined below.

Installation and connection recommendations

It is necessary to start work on fastening and connecting an Ariston brand water heater with a thorough study of the instructions attached to it.

- Since the power consumed by the device is quite large, it is necessary to make sure that the characteristics of the wiring used for connection fully correspond to the expected loads and has a ground loop. The best option for connecting to the mains is a separate cable from the switch cabinet or panel.

- Do not use components that have visual defects, damaged threads, etc. Particularly noteworthy is the supplied safety valve.

- Since the mass of the product is large enough, and the temperature of the water contained in it can reach + 750C, the boiler must be attached to the supporting surface on metal anchor bolts with a diameter of at least 10 mm. It is allowed to use plastic dowels of the same capacity.

- Installation of supply and discharge pipelines must be carried out in strict accordance with the diagram supplied with the heater by the manufacturer.

- The place of connection to the mains must be reliably protected from condensation, moisture and direct contact with water.

- It is possible to connect "Ariston" to the power supply only after filling the storage tank with cold water, otherwise the heating element of the water heater may fail.

- If all work is done correctly and the product is in good working order, after switching on the corresponding indicator should light up, indicating that the boiler is working.

Electrical

Instantaneous water heater Ariston Bravo M This type of water heating devices is represented by brands:

- Ariston Bravo M - equipped with mechanical controls. Complete with built-in filter and shower head;

- Ariston Bravo E - equipped with electronic regulation of the process, LED indicators for switching off / on and adjusting the temperature level of water heating.

Bravo E and Bravo M water heaters have a number of advantages:

- very compact, since there is no storage capacity (since it is simply not needed);

- small size allows you to mount devices at any convenient point, easily move and install to a new place;

- design features do not require the installation of additional equipment (chimney);

- water heats up instantly, it is possible to adjust the temperature;

- the ability to select the power of the tubular electric heater upon purchase, based on the volume of energy consumption.

It should be noted: installation of water heaters should be carried out as close as possible to the supply taps, since at sufficiently large distances of water transmission, there is a noticeable overspending of electrical energy.

Instantaneous water heater Ariston Bravo E But there is one important negative point of these units: high energy consumption - from 3 to 24 kW and above. In this case, reliable wiring and installation of an additional automatic machine and an electric meter are required.

Small-sized water instantaneous heaters with a minimum power are appropriate to install in private houses, where it is possible to set a limit on the consumed electricity. And new city apartments with improved electrical wiring can be equipped with water heaters of any capacity.

Perhaps you will also be interested in an article on repairing an Ariston water heater with your own hands. Read the article on how to replace the heating element in the Ariston storage water heater here.

Water heater Ariston: operation, maintenance and repair

To ensure efficient and safe operation, it is necessary to know and follow the basic rules for using the product.

- Do not turn on the device until the storage tank is full.

- Mechanical or other damage to electrical cables is not allowed;

- Before using the Ariston water heater, you should make sure that the grounding is working properly;

- In the event of a malfunction, the unit should be immediately disconnected from the power supply, drained and contacted for service.

Even with proper operation, timely maintenance of the system is necessary to maintain operability. First of all, this is due to the low quality of the supplied water. Despite the presence of filters, a large amount of chemical compounds and mechanical impurities enter the internal tank, contributing to the formation of scale and other contaminants. Regular cleaning of the heating element and the inner surface of the storage tank will significantly increase the service life of the boiler. Scheduled maintenance includes:

Preliminary drainage of water from the storage tank;

Disconnecting plumbing fixtures;

Dismantling the water heater body;

Cleaning the heating element and the inner surface of the tank without the use of especially aggressive detergents, if possible avoiding mechanical and abrasive effects;

Assessment of the state of the magnesium anode and, if necessary, its replacement.

Timely implementation of these recommendations will ensure long-term and efficient operation of the Ariston autonomous heating system.

The preservation and subsequent switching on of the boiler deserves a separate consideration.

Types of heating elements

An important detail in the construction of the Ariston storage gas boiler is the heating element. It is due to it that the water is heated to the desired temperature. It is located in the water tank. There are several types of heating elements:

- dry;

- wet.

Dry heating element

This heating element is located so that during operation of the equipment it does not come into contact with water in any way. This has a positive effect on its service life. Besides provides reliable protection against limescale and electric shock is excluded.

Along with the advantages, heating elements of this type also have their disadvantages. The main one is the high cost of such parts. In comparison with wet heating elements, the price tag for dry elements is 2 times higher.

Wet heating element

By the name of this element, everyone understands that in the process of work it is submerged in water. This means that there are problems with limescale, which must be removed. This is the main reason for its early failure. In addition, the formation of a white crust on its surface leads to a decrease in thermal conductivity heating element. Also, if you do not remove scale, then the cost of electricity for heating water increases.

Ariston gas boiler models with such a heating element are inexpensive. Therefore, if the consumer has made a choice in favor of such equipment, then its purchase will not greatly impact the wallet. Anyone can buy such a device for heating water.

There is another important detail in the design of storage-type gas heaters. This is a magnesium anode. With its help, the negative impact on the heating element of the incoming water is reduced. It also protects the boiler walls.

How to turn on the Ariston water heater after winter: instruction manual

If you do not plan to use the device in the cold season, you should take measures to preserve the system, and, above all, the water heater itself. This requires:

- Drain the reservoir completely;

- Disconnect the plumbing fittings from the inlet and outlet pipes;

- Clean the heating element and the inner surface of the tank;

- Liberally grease the threaded surface of the branch pipes with grease or other grease and wrap it with rags or PVC foil.

To turn on the Ariston heater after winter, you need to:

- Clean the pipes from grease residues;

- Connect the device to the main pipelines;

- Make sure that the grounding and wiring are in good condition;

- Fill the storage tank with cold water;

- Switch on the power supply.

Important!

It is strictly forbidden to connect an empty storage heater to the mains!

Due to the simplicity of design, reliability and affordable price, Ariston storage water heaters for 30, 50, 80 and 100 liters are deservedly popular. A wide range of models allows you to choose a model in accordance with the needs and financial capabilities. However, one should not forget that only full compliance with the operating instructions and timely maintenance will ensure efficient operation and prevent premature failure of the Ariston boiler.

Preventive maintenance of the storage water heater

Regardless of how water enters our house for domestic needs, whether it is a city network or an individual source of water supply (well, well), it has a certain hardness. Namely, chemical compounds of alkaline earth metals are dissolved in it. These salts are able to collect in stable forms. High temperature acts as a catalyst for the process of their crystallization. As a result, scale is formed in the water heater, plaque in the electric kettle and in other devices that use water heating using thermoelectric heating elements (TENs).

Signs indicating that the boiler has not been descaled for a long time are:

- Increasing the heating period of the water volume;

- The occurrence of extraneous noise during operation;

- The monthly energy consumption increases significantly;

- The liquid temperature does not reach the indicator set on the thermostat;

- The safety valve is often triggered, indicating unauthorized overheating.

Periodic maintenance of water heaters can be performed independently; this requires a clear understanding of the work algorithm. First, it is necessary to disassemble the device, having previously disconnected it from the power supply and the water supply system. It should be taken into account that the outlet pipe cannot provide the maximum liquid outlet when cleaning the storage water heater, this is due to the fact that hot water is drawn in the water tank from the top. Therefore, emptying is carried out through the cold water supply. The safety valve is screwed on without fail, since it performs the function of a check valve in parallel. This achieves the immersion of the heating element in the liquid and the prevention of its premature failure.

Effective flushing of boilers is only possible with complete removal of the flange on which the heating elements are fixed. Different manufacturers may use different numbers of mounting bolts, but they all use a spacer. It can be rubber or silicone. When the flange is removed, they are carefully monitored so as not to cause mechanical damage to this part. Otherwise, during assembly, it will be impossible to achieve the tightness of the tank.

Further, the cleaning of the storage water heater continues in a horizontal position. The walls are washed under the pressure of water, while a rag is used. Do not use metal nets for washing dishes, since the inner surface of the tank is enameled and such cleaning of the water heater will soon lead to the destruction of the sheet metal from which the tank is made.

Particular attention is paid to the lower part of the container. Scale usually settles to the bottom.

It clearly introduces how the Ariston boiler is cleaned by video, with a really embodied sequence.

Video:

After cleaning the boiler with your own hands, they start flushing the parts on the dismantled flange.It is quite easy to put in order a copper sleeve, into which an element is placed to take the temperature readings necessary for the correct operation of the thermostat. The heating elements themselves are much more difficult to clean, and cracks must not be allowed to appear on them. If, after flushing the heating elements, mechanical damage is found on their surface. The heating elements should be replaced with new ones that are purchased at service centers or on specialized Internet sites.

To neutralize the negative impact of stray electric charges (Foucault currents), a magnesium anode is provided in the boiler. It collapses in the course of long-term operation, taking over the discharges. When servicing the boiler yourself, you need to provide for its replacement. The anode is attached by means of M4, M6 threads. Screwed in clockwise, respectively, dismantling is carried out in the opposite direction.

After the boiler has been cleaned with your own hands, they proceed to the assembly of the water heating unit in the reverse order. The flange part is assembled in the hands, and then it is attached through the gasket to the tank. It is important to tighten the nuts firmly enough to prevent leakage. Filling the device is no less crucial moment. To do this, a hot water tap is opened at any point of consumption, and they wait until a jet appears.

Once again, having visually checked the tightness of all the investment connections and making sure that there are no drops on the bottom of the boiler, connect it to the electrical network. Thus, the routine work on cleaning the water heater of the video about which is presented allows not only to extend the service life of the device, but also to increase its productivity. With the same electricity consumption, the serviced boiler will be able to heat more water, and its thermostat will more accurately correspond to the set parameter.

Video: