Laminate flooring is in great demand due to its installation and operational advantages. Proper insulation of floors in a private house is important when laying laminate flooring, as this affects the service life of the material.

In case of poor quality insulation, condensable moisture may appear, which will lead to damage to the floor covering. In addition, energy costs for heating a house or apartment increase by 20%.

Insulation types

The basis for laying the laminate can be wood or concrete. Depending on this, insulation is chosen for the floor under the laminate. Expanded clay is used as a heater for a wooden floor. For better insulation, its layer should be at least 10 cm.

Other types of insulation are produced that can be laid on wooden and concrete floors:

- Styrofoam - insulation with a grainy texture, which is filled with air. It is very lightweight, practical, has excellent thermal and sound insulation qualities.

- Expanded polystyrene - evens out the base for laying the topcoat.

- Polyurethane foam... There are two types: jellied and sprayed. Slightly absorbs moisture, retains heat. Work on insulation with such material requires special equipment, in this case it is better to hire craftsmen.

- Mineral wool Is an inexpensive and long-lasting material. After installation, this insulation must be covered with foil or metallized film.

- Ecowool in its structure and qualities it is similar to mineral wool, but it is made from cellulose fibers, therefore it does not harm human health.

- Foil available in two forms: in slabs and in rolls. Lay with reflective side down.

- Bung - the most expensive insulation, however, environmentally friendly, reliable and durable.

- Plywood underlay, oriented strand board (OSB), gypsum fiber sheet (gypsum fiber board - in more detail: "How is the laying of gypsum fiber board on the floor - examples from practice"), fibreboard (fiberboard), chipboard (chipboard) - will allow in a short time and with this qualitatively make the floor even and warm.

Installation on a concrete base

When insulating a concrete base, it is necessary to check the quality of the floor and, if necessary, eliminate all irregularities and cracks.

If the surface quality is not satisfactory, then it should be cleaned of debris, dust and treated with a deep penetration primer.

If work is carried out on the overlap of the first or basement floor in a house with a basement, it is better to cover the base with plastic wrap before laying the foam. The strips of the film are overlapped, the seams are fastened with construction tape.

Next, the sheets of insulation are laid. Plates are mounted with a seam offset, not less than 1/3 of the size of the side of the sheet. The surface of the penoplex is covered with a film, a reinforcing mesh is laid and a screed is poured under the finishing coating.

General technology of floor insulation

First, the base is prepared. All existing irregularities on the floor should be eliminated: comb off protrusions, pits and cracks, seal up with mortar and putty. The next stage is the implementation of waterproofing. The surface is covered with plastic wrap so that the edges overlap. Scotch tape is glued to the seams. The waterproofing layer is very important: it protects the wooden elements from moisture.

If a wooden floor is insulated, then logs are laid, and heat-insulating material (expanded clay, mineral wool, polystyrene) is placed in the space between them. Then, to level the surface, boards and substrates from materials produced in sheets, for example, plywood, are used.

If the floor is uneven, then it can be leveled with a concrete screed or self-leveling mixture. Prepare such a flooring mixture according to the instructions in a container of a suitable size. Then it must be spread over the surface with a spatula.

Also, insulation under the laminate on the concrete floor can be laid between the beams, and a dry screed can be made on top and a substrate can be laid. So that the floor level does not rise very high, you can lay a thin thermal insulation film with a foil layer. This material is glued to flat floors with a special compound.

Styling nuances

In principle, there are no significant differences in laying a polystyrene foam backing compared to other types of laminate backing. An exception is the location of the polystyrene foam material in relation to the laminate:

- the roll substrate is perpendicular to the floor covering;

- the boards are laid at an angle of 45 degrees in relation to parquet or laminate.

Laying the substrate.

Otherwise, the same order of work:

- Before starting work, the substrate is brought into the room and unpacked in order for the material to take geometric dimensions for the temperature and humidity of the room where it will be mounted;

- Some of the slabs are cut diagonally from one corner to another - they are stacked near the walls;

- A strip is laid out along for the installation of several strips of laminate. It is better to play it safe here - this is one of the few types of substrate that you can walk on. But it is better not to risk it, especially since there are no problems with such a scheme of work;

- The joints are glued together with masking tape or construction tape;

- Laminate is mounted;

- The next strip of the substrate is laid out, etc.

There are some nuances when laying roll material. The problem here is the constant curling of the cut backing sheet. Attempts to straighten often lead to the fact that it crumbles and then breaks. The solution to the difficulties that arise is simple - cut the sheets to size, unfold, put something heavy on the ends and leave for a couple of days. During this time, the internal tension will ease, and the problem will disappear.

Laminate underlays

Laminate flooring should not be laid directly on concrete, even if it is perfectly leveled and insulated. Otherwise, the laminate floor will make unpleasant squeaky sounds when walking.

Where an uneven laminate floor will bend, as a result, the locks will loosen and break, and gaps will appear between the panels. All instructions for laying laminate flooring indicate that it should be laid on a substrate with a thickness of at least 3 mm, otherwise the claims arising about the quality of the coating will not be accepted.

The underlayment under the laminate prevents condensation and constant evaporation of moisture under the coating due to temperature changes. Regardless of the fact that the substrate is thin, only a few millimeters, it has high heat-shielding characteristics, attenuates resonance during sound and shock noise, there is no need to perform additional waterproofing, as it provides natural ventilation.

In a single room, different types of substrates are not used, but in different rooms of a house or apartment it is possible. For example, in the bedroom and living room, substrates from natural materials are used, in the kitchen and bathroom - from artificial ones. You should not lay the underlay on the entire floor surface at once, it is enough to put one strip, which is enough for 2-3 rows of laminate flooring, then the material will remain even and clean (about

Popular manufacturers and prices

When planning to buy expanded polystyrene for a substrate, you should keep in mind a few points:

- no manufacturer of laminate or parquet flooring recommends an expanded polystyrene underlay for their products and, therefore, does not give a guarantee for the floor covering;

- the foam polystyrene substrate successfully fulfills all the functions of the damping layer;

- a low price for many buyers is a priority over a flooring warranty.

Production of polystyrene foam backing.

Extruded polystyrene laminate pads are produced in Russia, Poland and China (in other countries of Europe and America, such products are not sold - natural materials are in priority there) for the population of the countries of the former Soviet Union.

The most popular brands are:

- Firm VTM IsoPolin (Izopolin) (Poland) - manufactures products in the form of rolls and sheets with a thickness of 2, 3 and 5 mm. The dimensions of the roll are 20 mx 1.1 mx 2 mm, the slabs are 100 cm x 50 cm.The thickness may vary. It fits not only under the laminate, but also under the wooden floor. In terms of technical characteristics, the XPS substrate occupies the middle position between the cork and the PSE. High quality is accompanied by an appropriate price - from 55 rubles / m2;

- "Izoshum" (Russia and the Republic of Belarus) - considered the best in terms of price and quality. Produced in 3 mm thickness, with an area of 0.5 m2. The package contains 20 sheets. The price starts from 25 rubles / m2 .;

- "Solid" (Russia, Aramil, Sverdlovsk region) - produced in the form of single sheets and an accordion with a thickness of 2 to 5 mm. The package contains a simple substrate 5.25 m2, accordions - 52.5 m2. Prices start at 55 rubles / m2;

- "Aberhof" (Aberhof) - a German company produces a 5 mm thick underlay for floor screed with a height error of up to 3.5 mm. Packaged 5.25 m2 (10 sheets). For 1 m2 you will have to pay, oddly enough, only 25-30 rubles. The disadvantages include fast shrinkage. However, among this type of substrates, with a high leveling ability (3.5 mm), it is the undisputed leader.

Recommended posts

Recently viewed by 0 users

No registered user is viewing this page.

The best articles on the IVD website

Are you a professional architect or designer?

IVD. Renovation and finishing

Are you a professional architect or designer?

The IVD.ru website is a leading Internet project dedicated to the reconstruction and interior design of residential premises. The main content of the site is the archive of the Ideas for Your Home magazine - exclusive author's articles, high-quality illustrations, practical advice and lessons. A team of professionals is working on the project in close cooperation with renowned designers, architects and leading experts of the publishing house.

On our site you can find complex design solutions; view detailed reviews of the market for building and finishing materials, furniture, machinery and equipment; compare your own ideas with the design projects of leading architects; communicate directly with other readers and editors on the forum.

Are you a professional architect or designer?

It is common to insulate the floor with penoplex today. offer the heat insulator is chosen because of the low thermal conductivity, to dispense with the possibility of a small thickness, as well as high compression strength, which makes it possible to dispense with additional reinforcement when installing floors. They insulate floors on the ground, floors above basement floors, rooms on floors, balconies and loggias. The material is also popular because the price of floor foam and screed is relatively affordable. As a finishing coating, tiles are mounted, veneered tiles are arranged, a screed board with a "warm floor" system, penoplex is placed under the laminate and linoleum.

Why Choose Penoplex?

Floor insulation is done in different ways. Manufacturers offer various thermal insulation materials with specific advantages. Penoplex insulation has a number of undeniable advantages. This material:

Attention! The characteristics of the foam allow it to be used for floor insulation, regardless of the thickness of the laminate.

Like many materials, penoplex has a number of features that are taken into account when choosing it for floor insulation. This material is afraid of exposure to ultraviolet radiation. When exposed to sunlight, it can lose performance. In addition, the sound insulation performance is much lower than other materials used for surface insulation. For example, fiberglass or mineral wool can provide much better sound insulation for a room than penoplex.

Penoplex - warm floor base

There are many technologies for floor insulation. This is expanded clay, mineral wool, and penoplex, of course. The latter is one of the best modern heat insulators, although, it should be noted, not the most For. cheap floor insulation is sufficient for 20-30 mm first (on the slab floors it can be up to 50 mm), while the thickness of the mineral wool is increased, for example two times more is recommended.

- The advantages of foam insulation for the floor are as follows:

- Excellent moisture insulation Good

- thermal insulation properties

- Mechanical strength

- Durability

- installation Simple

Before installing the penoplex on the laminate, you need to lay the insulation itself. This is easy enough to do. It all depends on what kind of leveling screed will be - a cement sheet made of either material (plywood, OSB boards, For). GVL one will need as smooth a rough surface as possible, for the other one will have to lay down wooden logs as the basis of the coating for.

What is Penoplex?

Penoplex is an extruded material based on polystyrene. Penoplex manufacturing technology involves the use of special extrusion machines. During the production process, special catalyst gases are added to polystyrene, increasing the material in volume. The process takes place at high pressure and temperature. Oxygen dioxide is used as a blowing agent.

The mass is squeezed out of the machine, forming the slabs of a suitable size. The gas gradually evaporates, and cavities filled with air remain inside, providing high thermal insulation characteristics of the foam. The use of extrusion in the production process ensures the formation of a uniform structure with relatively small cells.

Material structure

Manufacturers offer expanded polystyrene in boards of various thicknesses. If laminate is chosen, 20 mm sheets are used. Thicker ones (up to 100 mm) are used to insulate building facades.

When buying penoplex, remember that it is a heat-insulating material, and not a substrate on which the laminate is mounted. Taking into account the purpose of the penoplex and the usual substrate, the installation is carried out in different ways. If the substrate is laid on the base, and a laminate is on top, then this heat insulator assumes the mandatory installation of either a dry or a wet screed.

underlay and Penoplex under the laminate

As you know, when laying when covering, a substrate is used - polyethylene foam cork or. Can laminate flooring be laid on a foam backing? without Many "craftsmen", as it shows, the practice is such a temptation, how to put penoplex on the laminate without any screeds. It seems that this material is durable, why be smart with a screed? gender This will only bring problems.

Penoplex is not point-to-point for the calculated load, its strength makes itself felt under static pressure. The heat insulator, according to the rules under the screed, can withstand a huge amount of time, and at the same weight it is easy to make a hole in it with a pencil though. And most of the pieces of furniture are the same point load.

An unsuccessfully placed cabinet, caught with its foot on the lock of the laminate board, can simply fall into the floor. Penoplex under the laminate will not save from destruction - there will be little in it, it is intended to protect it from noise and moisture, and not to reinforce the base. In addition, such a coating will creak terribly.

Carrying out insulation and flooring, it is still better to abandon "folk inventions" and existing technologies to rely on. And they argue that the laminate cannot be mounted directly on the penoplex. It is better to follow the instructions and end up with a warm and beautiful floor than starting a new renovation six months later, correcting your own mistakes.

Advantages and disadvantages

Like any building material, the substrate for the laminate polystyrene (more precisely, expanded polystyrene) has its advantages and disadvantages in comparison with similar materials. The pluses include:

- the ability to maintain elasticity due to the high strength of the molecular bonds of the material during compression, as a result of which the floor covering retains its integrity and beauty for a long time;

- long service life, coinciding with the life of the laminate;

- no deformation under prolonged exposure to heavy objects (under the furniture legs, the polystyrene substrate is able to restore its size for a long time);

- high thermal insulation properties - the porous structure does not conduct heat well;

- good level of noise absorption - up to 70% or 22 dB;

- retains its properties in a wide temperature range - from -50 to +75 degrees Celsius, which allows laying polystyrene material under laminate or linoleum in unheated rooms (summer cottages);

- the ability to circulate air on the concrete surface of the screed or waterproofing material (ribbed underside), as a result of which condensation does not form under the laminate;

- environmental friendliness - safe for the environment (does not rot);

- correspondence of quality to price;

- the ability of the cellular structure to prevent the formation of condensation, and, if it occurs, to absorb moisture, which makes it possible not to waterproof the floor screed;

- accuracy of sheet dimensions in length and width, which simplifies the stacking process;

- light weight and compact packaging that allows you to transport polystyrene foam lining in cars.

There are also disadvantages, but very few:

- low leveling ability - with a thickness of 3 mm, it is not able to eliminate the effect of unevenness on the floor covering more than 1 mm, as a result of which a creak appears quickly;

- has a temporary drawdown, which will go away in 4-5 weeks;

- not sold in sheets, but only in packages, as a result of which there is quite often a large balance - loss of the family budget;

- low resistance to aggressive environments (easily soluble in gasoline, acetone, chloroform, etc.), with the exception of ammonia, alkalis, alcohol, propane;

- highly flammable due to the high content of carbon (92%) and hydrogen (8%) in the composition;

- in packages, the sheet material is constantly bent;

- fragility of the substrate at strong bending.

Heating floor

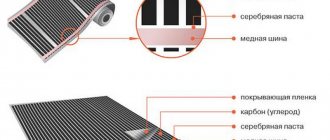

The process of installing hydraulic heated floors in residential areas is a new modern way of insulating a concrete base under a laminate. A similar floor is also suitable for a ceramic coating.

An electric cable is placed on the concrete base or water pipes are placed in the grooves cut in the concrete. They release heat energy from the operation of a gas or solid fuel boiler, or from the electrical system of a house.

Underfloor heating can change the heating system and heat the room well

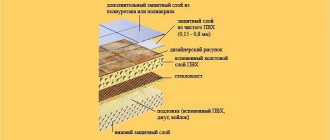

It is considered a multi-layer construction, and consists of:

- heat-reflecting material;

- protective films;

- underfloor heating itself.

During the installation of a heated floor with an electric sample, great attention is paid to the external water thermostat. Using it, it will be possible to avoid strong temperature changes and significantly increase the operational life of the heated floor system. For a couple of days before laying the laminate, the heated floor is heated.

When selecting a material for insulation under a wooden floor, a frame method of laying it is used. First of all, cross beams are installed, and between them a heat insulator. Take for work foamed polymer, mineral wool, foamed polystyrene, expanded clay concrete.

The advantage of this method is that it is not necessary to make a screed and wait for it to dry.

Insulation on floor slabs

You will need to acquire the following tools and materials:

- building level;

- polymer putty;

- primer;

- moisture-repellent film;

- insulation;

- polyurethane glue;

- self-leveling composition.

The sequence of work is as follows:

- First of all, the floor slabs are checked for flaws. Any protrusions, crevices, depressions must be removed. The protrusions can be knocked down with a perforator, and the cracks and pits are covered with polymer putty. If there are a lot of flaws, the base will have to be leveled with a self-leveling mixture. If the plates are in normal condition, devoid of damage, you can confine yourself to cleaning up debris and cleaning from dust.

- If the floor is insulated not lower than the second floor, then the penoplex is laid directly on the floor, which is pre-treated with a primer mixture. If the overlap is part of the basement or the first floor, then it is advisable to cover the floor with a hydro-repellent film. It turns out that, based on the location of the overlap, it is either primed or covered with a protective layer of moisture insulation. In the latter case, the joints of the film must be glued with tape.

- On the seamy side of the insulation, you need to apply a layer of glue, then attach it to the floor and press down well. The position of each individual slab is checked with a building level, while simultaneously controlling the horizontality of adjacent pieces of insulation so that the surface is perfectly flat. Laying of each subsequent row of plates is carried out with an offset of half the width of the segment so that the seams do not coincide.

- A layer of polyethylene film for waterproofing is laid on top of the insulation.

- A classic cement screed up to 5 cm thick, or a self-leveling compound, can be poured onto the waterproofing layer. As soon as the screed is completely dry, you can start laying the finished floor.

Recommendations and Tips

There should not be any particular difficulties with laying the insulation material. Connecting the dishwasher to the water supply and sewerage system or installing a thermostat for a gas boiler is even more difficult. In the case of thermal insulation under the laminate, the main thing is to do everything consistently and without haste.

In this case, the soundproofing substrate, insulation, waterproofing polyethylene and laminate lamellas should be laid in strips perpendicular to each other in adjacent rows. This will prevent the joints from creeping under further loads.

Advantages of Foil Cork Backing

Leveling the floor with expanded polystyrene

An example of laying polystyrene foam for leveling the surface

Thermal insulation of the floor with expanded polystyrene is a fairly simple and not particularly expensive technology. thermal insulation of floors. During the production of this material, polystyrene granules are filled with an inert gas, when a viscous liquid is foamed under high pressure and a material is obtained from fine cellular granules with micropores. Expanded polystyrene is endowed with many positive characteristics:

- has a low weight, is easily transported;

- retains its original dimensions, does not deform over time;

- repels moisture and does not swell;

- resistant to fungi and mold;

- allows you to form sheets of any size;

- easily trimmed with ordinary knives or saws;

- can be combined with various surfaces and materials;

- leaves no smell and dust during processing;

- simply and securely attached, does not crumble when attached;

- tolerates contrasting temperature effects well.

Extruded polystyrene foam (EPS) is a safe and environmentally proven material that comes in several versions depending on thickness and performance. The edges of the polystyrene foam boards can be flat and with milled grooves, which allows them to be tightly connected according to the "grooves and protrusions" system.

Important! Extruded polystyrene foam has a reduced coefficient of water absorption, therefore it is suitable for thermal insulation of the floor on the first floors, regardless of the level of occurrence of the aquifer

Extruded polystyrene sheets with grooves for even laying

Most often, polystyrene foam plates of the PSB-S-35 brand are used, but at increased loads, the PSB-S-50 brand is recommended. Some restrictions when choosing expanded polystyrene as a heater are due to the fact that the estimated service life of expanded polystyrene plates is determined within fifteen years, after which deformation and violation of the structure of the material is possible.

- To begin with, dismantle the old flooring and clean the surface of debris and dirt.

- A layer of waterproofing (roofing felt, polyethylene) is laid on the rough base.

- When insulating with wooden logs, beams are installed at a width of 50 - 60 cm, and expanded polystyrene plates are laid between them, the voids are filled with polyurethane foam.

- When laying in a docking method, polystyrene foam boards can be laid parallel to the walls, or diagonally.

- Cover the insulation with a vapor barrier (plastic wrap).

- Next, arrange a flat surface of boards or sheet materials, from the insulation to which there should be a space of 8-10 cm.

- Now you can start laying the laminate.

In the case when it is planned to fill the insulation with a concrete screed, it is necessary to install a reinforcing mesh onto which the primary screed 3-5 cm thick and the finishing layer are poured. It is recommended to add polystyrene foam granules to the solution, which are sold in the required volume.

Preparatory stage

The screed will help level the base under the laminate flooring.

Floor insulation should begin with the elimination of surface imperfections. The concrete floor needs to be leveled: fill in the existing depressions or pits, grind off the bumps, putty chips and cracks.If the floor is wooden, the boards will have to be dismantled. You can equip waterproofing so that moisture does not get into the installed insulation.

It is advisable to make sure that all the necessary tools are at hand during the work:

- jigsaw;

- screwdriver;

- drill with various attachments;

- a hammer;

- dowels, screws;

- level or rule;

- roulette;

- marker or pencil;

- construction stapler and knife.

Depending on the type of insulation chosen, the list of tools may expand somewhat. For example, for laying expanded clay you will need a shovel, and when using jellied materials, a container for their preparation. You don't have to buy the required tools. You can borrow something from friends or rent - many construction firms now provide such services.

Possible options

Thermal insulation of a concrete floor implies the presence of several different methods, each of which is performed at a certain time. Under the concrete screed, the insulation should take place "from scratch", but if the floor in the house or apartment has already been built, then it is imperative to destroy the screed down to the base. This method involves the use of durable materials that not only must be resistant to moisture and any mechanical stress, but also serve for a long time as intended.

In addition, a popular system called "warm floor", the essence of which is strong heating of the concrete over the entire surface. The system should be located on a heat-insulating layer, and then, filled with a screed. This floor can be electrical or water based. Regardless of the type, insulation implies the presence of an additional energy source. Water or electric floors are classified as active heating systems. However, they also work well as thermal insulation.

The method of incorporating special fillers into concrete is very effective. They can be: expanded clay, as well as perlite. All efficiency is based on the excellent heat insulation characteristics of the fillers, which significantly reduces the coefficient of thermal conductivity of concrete. The use of a base material with fillers is ideal for screeding or on the ground.

On the upper floors of a private house or apartment, floor insulation is carried out by creating a raised floor. This implies the use of wood logs and filling the layer between them and the thermal insulation material itself. This not only reduces the load on the foundation (if work is carried out in a private house, the parameter is important), but also eliminates the possibility of a labor-intensive screed device.

The finished concrete floor can be easily insulated using any floor covering. The main thing is that the materials have the properties of a heater. It can be warm linoleum, carpet, and appropriate high-quality laminate. You can choose from a huge number of options offered on the modern construction market: from domestically produced materials to expensive imported ones. When installing the topcoat, you can additionally apply a cork, polyethylene layer (insulation should consist of several thin layers).

The considered methods of insulation can be used separately, or in combination with each other. If shrinkage of the material acting as a heater is impossible under a concrete screed, then it is recommended to use expanded clay or crushed stone, as well as a topcoat with several layers. If the "warm floor" system is chosen, then you can do without a multi-layer coating.

Laminate has gained and became widespread due to its own versatility. Floor finishing of this type is laid in a wide variety of areas of the house - from the nursery to the kitchen.

Throughout the entire operation of such a floor covering, discomfort appears, since the laminate is cold to the touch.Moreover, it is felt during the winter. To eliminate this poor quality, a heat insulator is used under a laminate on a concrete floor.

Measures for floor insulation must be carried out correctly so that the coating will serve for a much longer period.