The supply of water to an individual house from any source of water supply is always carried out through an underground pipeline, the probability of which freezing in the winter is quite high. It is not always efficient and technically possible to submerge a water supply system deep underground; many owners of land plots with autonomous water supply have to solve the problem of how to insulate a water pipe in the ground.

To supply water to a house, no one uses underground metal pipes, which are prohibited for laying underground without waterproofing by building codes; the leader in domestic use is a low-pressure polyethylene (HDPE) pipeline with a diameter of 1 to 2 inches. Although polyethylene has a low thermal conductivity, unlike steel, and is more resistant to freezing due to its elasticity, when laying at shallow depths, it should be insulated using one of the many methods used in the construction industry.

The depth of soil freezing in the Moscow region (in centimeters)

Why is insulation necessary

There are several reasons why an underground water supply should be insulated, all of them are related to the rules for laying communications and saving financial resources - it is received after the implementation of insulation work. The main reasons for carrying out thermal protection of a water supply system:

- When laying an underground water supply line, take into account the possibility of draining water from the system; for this, the pipeline is laid with a slope of about 20 mm per linear meter towards the source. If the house or dacha is located at a great distance from the well or well, from which water is taken, for example, 50 m, then when laying the pipeline near the house at an average freezing depth of about 1.5 m at the entrance to the source, you will have to bury the pipe by 2.5 m (0.02 x 50 = 1 m). It is not economically feasible and quite difficult for technical implementation.

- To take water from wells, caisson wells are often used, in which pumping equipment is placed and the electric pump is serviced. A standard caisson tank has a submersion depth of about 2 m, while the upper casing pipe, according to the standards, is located 50 cm above the floor level.Thus, at the exit from the caisson chamber, which is an unheated room, the pipeline is placed at the lower mark of the freezing depth of 1 , 5 m, and given that when connecting to the house through the basement, a slope is needed, the entire section of the water supply system will be above the freezing point - accordingly, it must be insulated. Read more about plastic caissons.

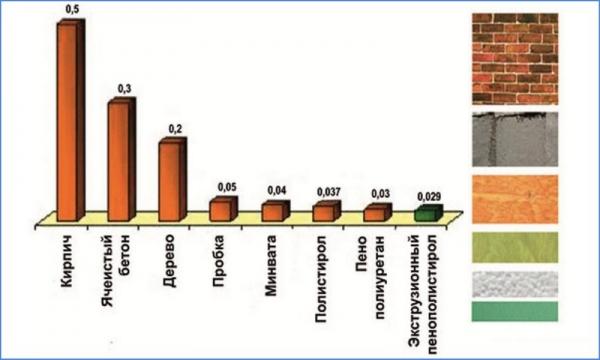

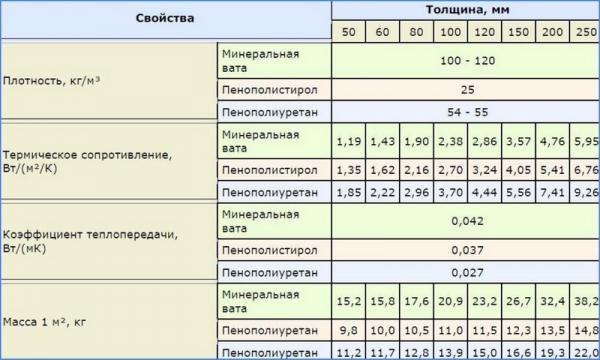

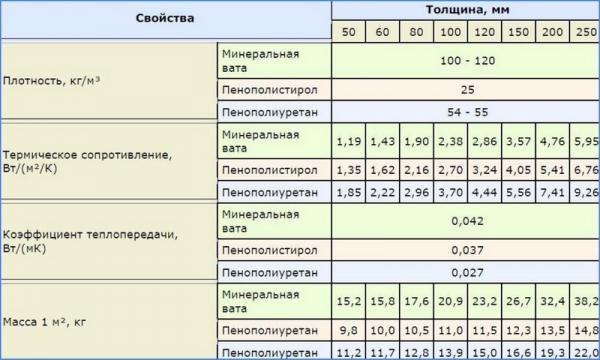

Thermal conductivity of heaters

- Insulation of water supply pipes in a private house, passing underground, allows you to save significant funds that are spent on heating cold water for household needs. It is clear that less cooled water after flowing through an insulated water supply system will require less electricity for heating than cooled water after passing through a non-insulated pipeline.

- It is known that the thermal insulation of an underground water supply system from contact with the ground does not heat pipes, but prevents heat loss, therefore, insulated pipes for a water supply system can be effectively operated in the summer - they prevent water from heating when the mains are located shallowly.

- To prevent freezing, not only the insulation of water pipes in the ground is carried out, but also on its surface at the points of exit from the well and the entrance to the house, if it is located on piles, for this, thermal insulation methods and materials similar to underground utilities are often used.

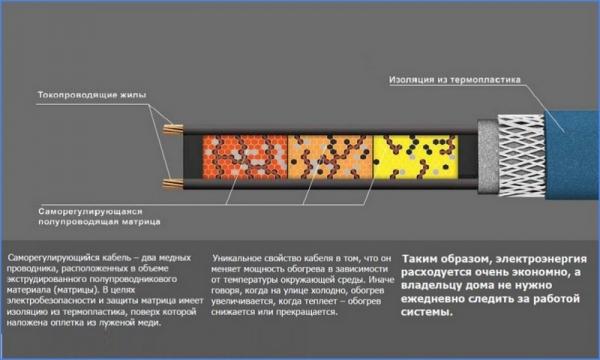

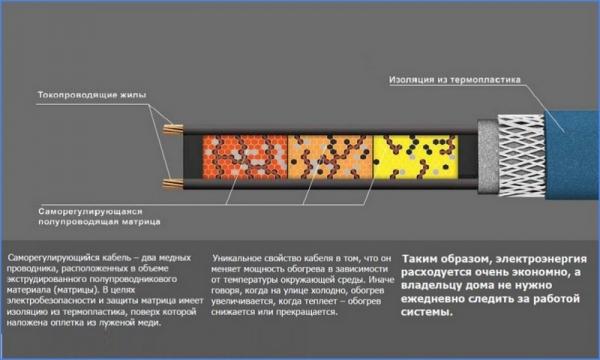

Self-regulating electrical cable device

Plot from the water source to the house

As you know, a water source can be open or closed. Open water sources will include lakes, rivers, ponds, and open springs. Sealed water sources are wells and wells.Regardless of the type of water source, pumping equipment can be used on it to organize a permanent all-season or temporary water supply.

After the equipment is installed at the source itself, it will be necessary to lay a pipeline from the pump or supply pipeline to the house. At this site, a feature will be the fact that in cold regions, with a constantly maintained pressure in the pipe, the water will freeze when there is no consumption from the consumer. As you know, flowing water cannot freeze even at very low temperatures. However, as soon as the water “stands up”, ice crystals can begin to form in the outer layers of water, those that are closer to the walls of the pipeline, even at 0C.

To avoid this, the section of the pipeline from the water source to the house is laid below the level of soil freezing for this region. As you know, the constant temperature of the earth at depths of 2-10 meters is about 4 degrees Celsius in winter. For different regions, this is indicatively slightly different. This soil temperature allows the use of year-round water pipes laid below the freezing level of the soil.

In order to reduce the amount of earthwork, the pipeline can be laid above the level of soil freezing. However, at the same time, it must be insulated and equipped with a heating cable. The power of the heating cable is selected based on the average temperatures for a given region in the winter.

Is it possible to lay a pipeline from a well, well or pond through the air, not in the ground? It is possible, but for this the pipeline must be sufficiently insulated and must be heated. The downside of such a system will be that if the heating stops, the water in the pipeline will freeze.

Insulation methods for underground water pipelines

There are several ways in which water mains are insulated, many are used in everyday life or only in the national economy, the main ones are:

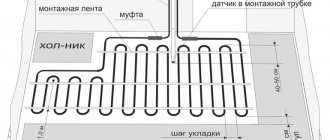

Heating cable laying options

- Continuous flow. Moving water does not freeze, therefore a small regular water consumption or circulation in a closed loop can prevent the pipeline from freezing in winter.

- Air heating. The technology is used in public utilities and the industrial sector; for its implementation, an underground water supply system is placed in a shell of large-diameter pipes, and heated air masses are injected into the space between the shells.

Note: In domestic conditions, an analogue of this method is sometimes used without the injection of warm air, for this HDPE water pipe is placed in a polypropylene PP or PVC PVC pipeline of a larger diameter from sewer pipes - the air gap between the pipe surfaces is an excellent thermalinsulator.

- Increased pressure. One of the popular Internet myths is the assertion that it is possible to lower the freezing point of water by increasing the pressure in the system. It can really be lowered by 1 ° C when a water flow is injected into a pipeline with a pressure of 132 atm., Which is incredible for a domestic water supply system with a maximum pressure threshold of about 5 atm.

Comparison of the best heaters

Requirements for insulation materials

To insulate a water pipe in the ground located at a shallow depth, building insulation is most often used, which must meet the following criteria:

- Low thermal conductivity... This is the main condition, the more the material prevents heat transfer between the pipe shell and the ground, the more efficient its use and, accordingly, the saving of financial resources.

- High chemical resistance. The soil contains a large amount of minerals that have a negative effect on the structure of the material placed in the ground, therefore, the insulation should not succumb to rapid decomposition when placed in the ground.

- Water resistance. There is always moisture in the soil, so the material should not allow water to pass through or saturate it with its shell - this sharply reduces its thermal insulation properties.

- Temperature resistance. Thermal insulation material when located underground must withstand low ambient temperatures in the cold season and high in the summer, as well as their significant differences.

Examples of pipe insulation in a caisson pit

- Biostability. There is a large amount of organic matter in the ground from microbes, bacteria, mold, the material should not be destroyed under their influence, nor should it be absorbed by underground living organisms.

- Rigidity. The material lowered under the layer of the earth experiences significant loads of the upper layer of the soil, therefore, increased requirements for strength and rigidity are imposed on it. Due to these qualities, a large number of construction pipe heaters are not suitable for underground installation.

- Long service life. It is advisable that the material lowered into the ground had to be changed as rarely as possible - this will save financial resources and save personal time.

Thermal insulation materials for underground water supply and their features

In the construction industry, a variety of insulation materials are used, which it produces in rolls or sheets, it is clear that shells having the shape of their surface are better suited for pipe insulation. Almost all materials used for thermal insulation are produced in the form of pipe shells, some of them have built-in channels for laying an electric heating cable.

Foam pipe shell

Styrofoam

Expanded polystyrene PPS (polystyrene foam), due to its physical parameters and rigidity, is the most acceptable option for thermal insulation of underground pipelines, its distinctive qualities:

- One of the lowest thermal conductivity coefficients with an average value of about 0.04 W / m · ° С.

- High rigidity (depending on the brand) makes the material irreplaceable when used in an environment with high loads on the shell, its density reaches 50 kg / m3.

- Polyfoam does not pass and does not saturate water, water absorption depends on the density of the material and does not exceed 2% on average.

- Low cost, thanks to which the foam is available to a wide range of consumers.

- The service life of the foam shell under the ground reaches 40 years.

- The temperature range for using foam is from -50 to +70 ° C.

- Expanded polystyrene is resistant to chemical and biological effects of the underground environment, does not decompose under the influence of mold, bacteria, microbes and other microorganisms.

- The foam shell is lightweight and can be easily assembled by one person in a short time without additional assistance.

An analogue of expanded polystyrene is an extruded variety (Orange Penoplex), which has higher strength characteristics, density, low water absorption of about 0.2% and thermal conductivity of about 0.3 W / m · ° C. Extruded foam is also used to make a shell for thermal insulation of pipelines; it costs a little more than conventional foam.

Tubular polyurethane foam

Polyurethane foam

Polyurethane foam PPU is the leader among all heaters in terms of the coefficient of thermal conductivity, due to this quality it is widely used in the manufacture of insulated pipes with a zinc or polymer outer shell in an industrial way. On the construction market there are polyurethane foam shells of various diameters, their characteristic features:

- Higher price compared to Styrofoam.

- The thermal conductivity coefficient is 0.025 W / m · ° С.

- Temperature range of use is from -160 to +150 ° С.

- Polyurethane foam has high rigidity and strength, its density reaches 250 kg / m3.

- The material is resistant to chemical and biological effects, does not allow water to pass through, its water absorption is 1 - 2%.

Polyethylene foam

Sheaths and foamed polyethylene PPE (Penoplex, Energoflex) are widely used for thermal insulation of external pipelines in individual houses, they can be used outdoors to seal open pipe sections located in a coffered well or entering a house on piles.

PE Foam Tubes

Due to their low stiffness, polyethylene foam tubes are crumpled during underground use without a rigid shell and, due to a decrease in thickness, they significantly lose their heat-insulating qualities, the main parameters of polyethylene foam:

- Thermal conductivity 0.31 - 0.55 W / m · ° С (depending on the brand, the indicator is lower for products made using the stitching technology).

- Temperature range -60 - +75 ° С.

- Density from 25 to 100 kg / m3.

- Polyethylene foam does not pass or saturate moisture, its water absorption coefficient does not exceed 1%.

Mineral wool

Heaters made of glass and basalt wool are very popular with consumers due to their affordability and environmental friendliness, which allows their use inside residential premises. Glass wool has low rigidity and easily crumples, basalt-based material is tougher, but due to the main drawback - high moisture absorption, quartz and basalt shells are not placed underground. Like other soft materials, mineral wool insulates the outdoor water supply in caisson wells and supply points to the house.

Mineral wool shells

Mineral wool has the following characteristics:

- Thermal conductivity coefficient 0.033 - 0.05 W / m · ° С.

- Water absorption is about 10%.

- Temperature range from -60 to +450 ° С for glass wool and -100 - +700 ° С for basalt (depends on the manufacturing technology).

- Density 30 - 225 kg / m3.

- Mineral wool is resistant to most chemicals, non-flammable and does not support combustion.

- The cost of mineral wool is 2 times higher than that of expanded polystyrene.

Heat insulating paints

This type of heat insulator is classified as a high-tech product; acrylic-based paint contains pearlite, foam glass particles, quartz fibers and microscopic granules containing a vacuum inside the shell. Heat paint is applied to the surface to be treated with a brush or spray in several layers up to 4 mm thick, it is mainly used for processing surface pipelines, containers in the national economy, in everyday life, the use of this product is economically inexpedient due to its high cost.

The use of insulating paints

In addition, many experts are not sure about the veracity of the information provided by the manufacturer on the thermal conductivity of the paint below air indicators (0.0012 W / m ° K versus 0.022 - 0.025 W / m ° K), and indicate other data in independent calculations - 0, 07 W / (m · ° K.) - this is lower than the values of any of the typical heat insulators.

Spray-on heat insulators

In industry, spraying on insulated surfaces of liquid polyurethane or polystyrene is often used, while two components are mixed and the composition is applied to the pipe shell with a spray gun. After spraying, the substance increases in volume and provides reliable thermal insulation of the object without cold bridges with high tightness.

Due to the high cost, the technology is rarely used in everyday life by individual homeowners, but in theory it is possible to use this installation to cover HDPE pipes if you agree with its owners on the price.

Spraying polyurethane foam

Special thermal insulation

The principle of operation of all types of thermal insulation materials used today is the same. The role of a heat insulator in each of them is played by air, which fills the entire inner space of the insulation. Therefore, the choice of its specific type depends only on the ease of installation and the location of the water supply line.

The insulation of the water supply system of a private house and summer cottage using tow or mineral wool is considered multifunctional. These materials, absorbing a certain amount of moisture from the air, swell significantly and acquire the ability to seal the breaks that appear in the pipes. In order for the pipeline to function in optimal conditions in winter, a five-centimeter layer of insulation of this type will be enough.

For insulation with mineral wool to be of high quality, the thickness of the material must be at least 5 cm

The service life of tow is as follows: 8-12 years. But the use of natural oil paint helps to increase this period of time by 2 times. Tow and mineral wool must be covered with waterproofing compounds or an additional layer of waterproofing. In the latter case, the same roofing material will do. Among the disadvantages of this method, experts point out the high labor intensity of the work. As a result - the high cost of the created insulation system.

How to insulate water supply pipes yourself

Before insulating a water pipe in the ground, they choose a suitable option, taking into account the financial costs of purchasing materials and carrying out work, they often stop at using cheap high-density foam shells. Some homeowners use a 110 mm sewer sheath, placing a HDPE pipeline in them - air is the best heat insulator.

Recently, the method of heating the outer or inner shell of pipes with a self-regulating electric heating cable has become popular; ready-made systems with fittings for entering an electric cable into the pipeline are being implemented in the trade network. Thus, the highest efficiency of work on heating the water supply system is achieved.

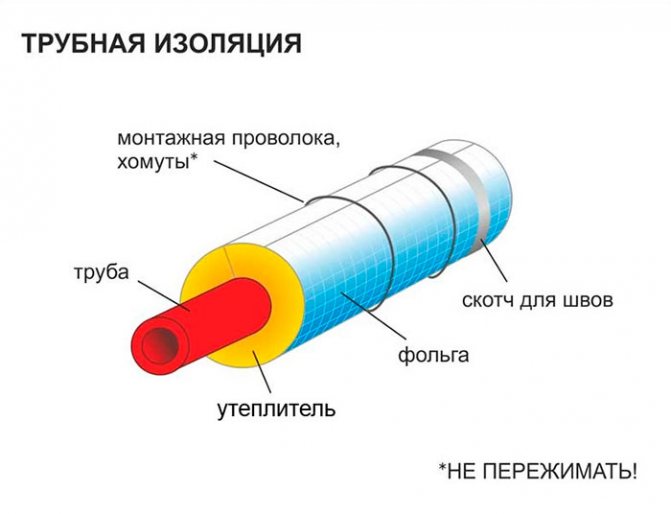

Insulation of PPP with shell

Due to the low price, availability and suitable physical characteristics, a foam shell is the best option for solving the problem of insulating an underground water pipe on the street. Do-it-yourself installation of the shell on a HDPE pipeline does not present any particular difficulties for any owner and is carried out in the following sequence:

- A foam sheath is put on the pipeline raised from the trench, snapping on the locks and shifting each segment by approximately 1/3 in relation to the opposite element. The elements are fixed on the surface with tape or plastic ties.

- After fixing the PPS segments, the pipeline is lowered into a trench on a previously prepared sand cushion with a thickness of 150-200 mm - this will prevent the heat-insulating shell from skewing with a possible break.

- Then the trench is covered with soil raised to the surface, the removed sod is laid out.

Installation of PPP shells

Water supply insulation with self-regulating electric cable

Insulation of an underground water pipeline by heating the pipe with an electric cable is one of the effective methods of combating freezing with a shallow location of the water supply main. The heating cable can be used along the entire length of the pipeline or in a separate section, it is also immersed inside the pipe shell or left outside, on the surface of the pipe. On the construction market, electric cables are sold with fittings for entering the pipeline, equipped with sealing rubber glands, the wire itself is short and usually located at the outlet of the pressure pipe from the well. In this place, the efficiency of its use is the highest - heated water will flow along the entire pipeline from the well to the house, preventing pipes from freezing. In addition, laying the cable at the junction point of the pressure pipeline from the electric pump with the water line is technically easier to implement than in any other more inaccessible place, which is usually absent throughout the entire water main.

Set with self-regulating cable for installation in a pipeline

Insulation of the pipe, when the water supply is in the ground, and you need to heat it with an electric cable from the outside, is carried out as follows:

- Place the HDPE pipeline on the surface of the earth next to the trench, clean the area in the places where the electrical cable is laid from dirt.

- They wrap the pipe surface at the point of contact with the electric cable with foil-clad aluminum tape - this increases the thermal conductivity of the shell at the point of contact. If the wire is placed in a straight line along the length of the pipe, one or more straight strips of foil adhesive tape are glued; with the spiral placement of the cable, the entire pipe is wrapped with tape.

- After laying the heating wire, screw it with the same foil tape to the pipe surface along its entire length.

- To reduce heat losses, it is imperative to use an outer shell made of PPS foam, polyurethane foam PPU, which is worn on top of the heating wire and fixed with tape or plastic ties.

Tip: If the wire runs in a straight line, it is best to purchase a shell with a cut groove in the inner sheath to accommodate the electrical cable.

- After the installation of the heating section, the cable for supplying power with electrical tape or tape is screwed to the pipeline along the entire length and the assembled structure is lowered into the trench, after which it is sprinkled with earth.

Installation of a heating electric cable on a pipe

For insulation of water pipes with individual water supply, an inexpensive foam shell and a self-heating electric cable are most often used, often both methods are combined. Carrying out installation work on the placement of the insulating shell and heating wire does not cause any particular difficulties and does not require high qualifications, with knowledge of the technology, all actions in a short time without large labor costs can be performed by one person.

How to insulate a water pipe on the street

Before approaching the installation of insulation, you need to decide on its type. Today, the market of thermal insulation materials can present a wide range of specialized heaters, different in performance, installation method, cost.

So, you can insulate water supply pipes on the street using:

- Glass wool... This is perhaps the most affordable insulation, which is used, to a greater extent, for thermal insulation of metal-plastic pipes. Glass wool is lightweight, moisture and heat resistant, not subject to mold, rotting, not edible for rodents. However, such material requires additional external insulators, and its installation requires increased precautions.

- Basalt insulation... Thermal insulation of this type is manufactured in a cylindrical shape, which makes its installation simple and easy. Basalt wool is non-combustible, durable, chemically passive and environmentally friendly. The disadvantages of insulation can only be attributed to its rather high cost.

- Styrofoam... This heat-insulating material is used both for insulation of the pipeline outdoors and indoors. The advantages of expanded polystyrene boards include affordable cost, high tensile and compressive strength, low thermal conductivity. However, the material is not classified as fireproof and environmentally friendly.

- Heat insulating paints... This method is considered the most innovative. Thermal insulating paint is a thick paste that is resistant to low temperatures and moisture. One layer of such insulation can replace insulation with glass wool and expanded polystyrene boards. In addition, paint can also be used to insulate a water column outside.

Some people use a heating cable to heat cold water pipes, which is laid both along the water supply system and wrapped around the pipes. This method of insulation is recognized as the most effective, but its installation has a lot of nuances.

Insulation of pipes with a cable in regions with extremely low temperatures requires additional hydro and thermal insulation with non-flammable materials.

In addition, for the most effective insulation, before installing the cable system, it is necessary to calculate the length, cross-section and power of the cable, to determine the pitch and number of coils.