Features of the method

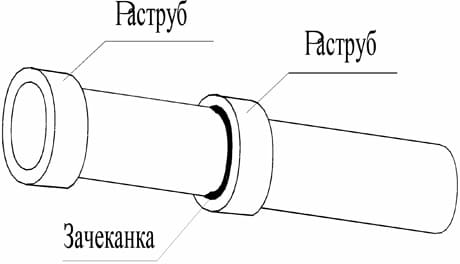

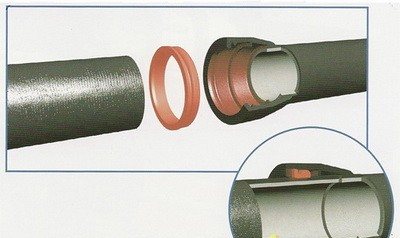

A socket is a mounting extension at the end of a pipe. This design allows you to assemble a sealed and durable flow-through interface.

To do this, the smooth edge of one pipe is placed in the socket of the other. To achieve tightness, special seals are used. A socket joint with a rubber sealing ring is one of the used methods of installing sewer and water lines.

Pipes are also glued. But in this case, the reliability will depend on the resistance of the adhesive base to water.

Flare connection options

Socket pipes can be made of various materials, small or large diameter. Considering these parameters, the most suitable connection options are applied.

Cement filling

This method is most often used for socket connection of cast iron pipes.

- The necessary measurements are made.

- The pipe is cut in such a way that the end face is free of cracks and notches.

- Then the prepared element is inserted into the socket.

- The gap inside it is closed using an oiled sealant (hemp or flax).

- Place the first layer of sealant in the pipe. In this case, the ends of the strands should not fall inside.

- Minify the seal using a hammer and screwdriver.

- Then carefully place the remaining layers of sealing material two-thirds of the depth of the socket.

- The last layer should be applied without impregnation.

- Fill the empty distance to the end of the pipe with cement mortar or asbestos-cement mixture. Also, cement can be replaced with silicone sealant, bituminous mastic or any other similar compound.

An alternative is another way of assembling cast iron structures. This is the filling of the sockets with expanding cement. Its advantages are:

- waterproofness;

- the ability to expand;

- self-sealing when hardened.

It should also be noted that the use of expanding cement significantly saves time during installation, since there is no need to caulk and stamp the joints.

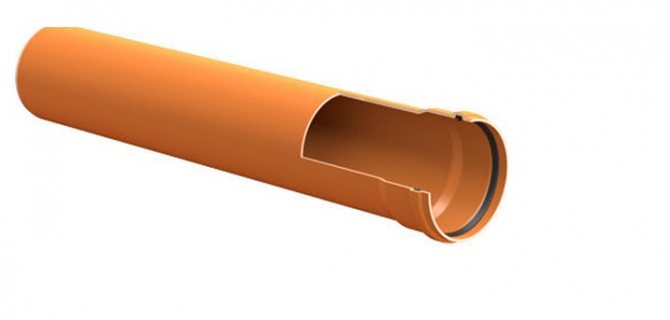

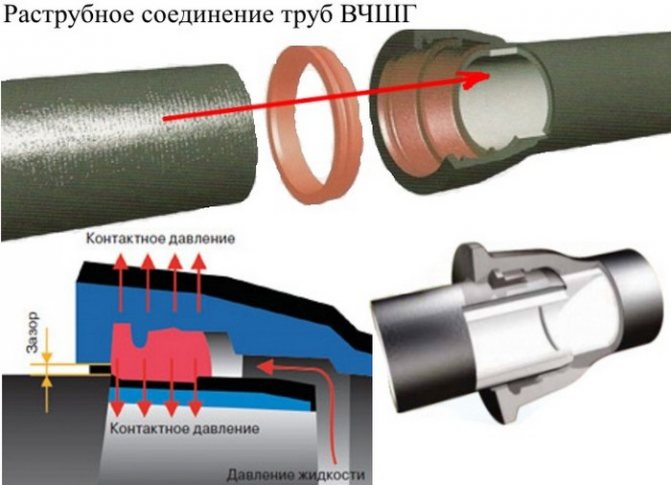

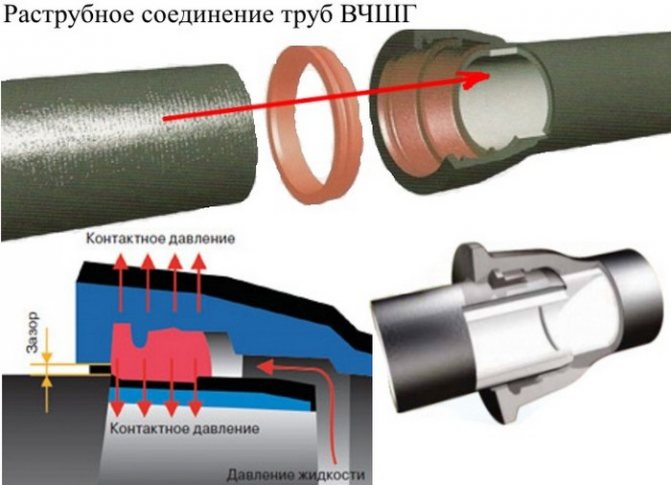

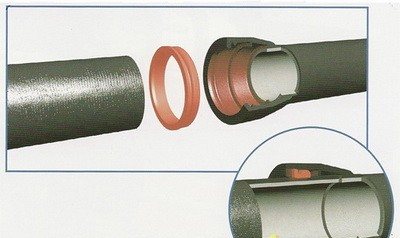

O-ring application

This is one of the ways to connect plastic pipes. The rubber ring ensures tightness. It is clamped between the straight edge of the pipe and the walls of the socket.

The seal can be with special plastic inserts. But this is optional.

It is important to avoid deformation of the sealing collar on the ring. This can cause leakage in the joint area. Curvature of the axis is allowed, but it should not exceed the thickness of the pipe wall.

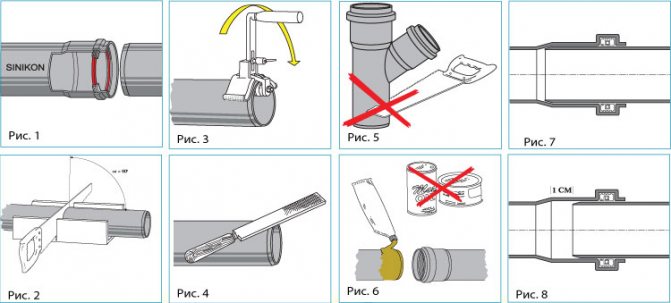

The ring may be damaged during installation. To avoid this, it must be lubricated with glycerin, silicone grease or soap. You cannot use oils for this.

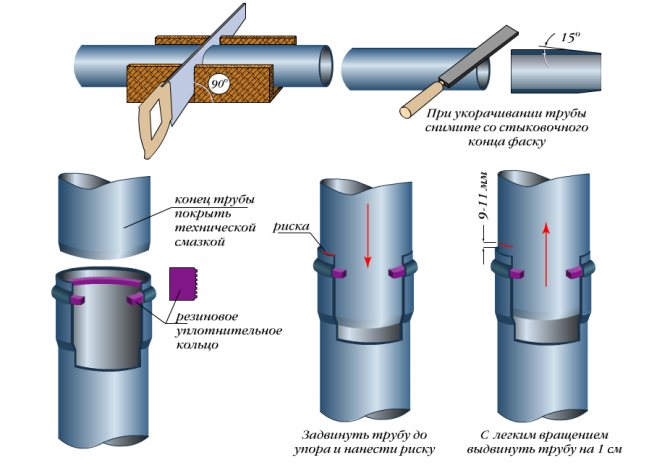

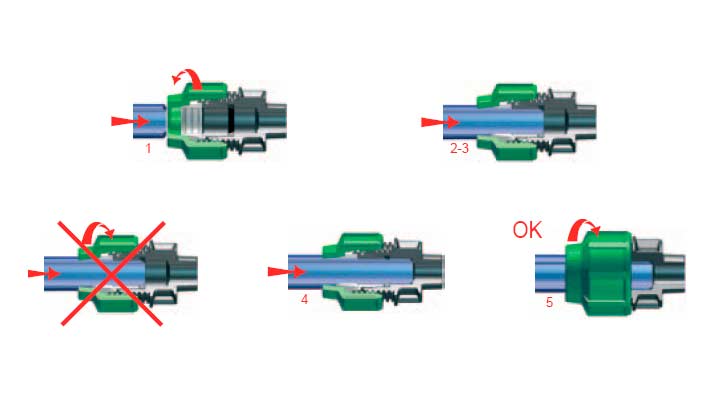

The connection sequence is as follows:

- Clean the rubber ring.

- Place it in the socket groove.

- Lubricate the beveled end of the pipe with glycerin or ordinary soapy water.

- Insert it into the socket up to the mark.

- Check for a ring in the groove. To do this, turn one of the parts to be connected.

In the case of connecting pipes made of different materials, transition pipes are used.

A special tool or a hacksaw is used to cut pipes. Saw strictly perpendicularly, laying the pipe in the miter box. After that, a chamfer is removed from the cut end with a file at an angle of 15 °. This helps prevent damage to the O-ring during installation.

Installation with glue

Glue installation is quite simple. This should be done in the following sequence.

- Prepare pipe ends.Roughen them with a sandpaper.

- Degrease with methylene chloride.

- Prepare a special glue.

- Apply a layer of adhesive to the tapered section of the pipe and to the inner surface of the socket.

- Connect the mating elements and press them together.

- After a while, the glue will harden, providing the necessary tightness.

It is important to know that lateral loads are unacceptable with such a connection. They can break the adhesive layer.

Two formulations of glue are recommended:

- First: perchlorovinyl resin (14-16 parts) and methylene chloride (84-86 parts by weight).

- Second: perchlorovinyl resin (14-16 parts), methylene chloride (74-76 parts) and cyclohexanone (10-12 parts).

It is important to know: open glue is suitable for only 4 hours due to the solvent content in its composition.

contact welding

Socket connection of pipes using resistance welding is a variant of joining parts made of various materials. It can be used for cast iron and steel as well as plastic pipes.

In this case, a manual or mechanical welding machine is used. It must be equipped with special devices for heating the elements to the required temperature.

This is a sleeve with which the outer part of the pipe is heated. And also a mandrel, which is designed to melt the inside of the part.

The sleeve-mandrel set must correspond to the diameter of the assembled structure.

Resistance socket welding is carried out as follows:

- Heat the cell with an electric current or blowtorch.

- At the same time, regulate the temperature using a thermal pencil, thermostat or pipe material - the element should melt, not burn.

- At the edges of the pipe fittings, chamfer 1/3 of the pipe wall thickness at an angle of 45 °.

- Install the stop collar on the plain end at a distance of the socket depth plus 2 mm.

- Insert the mandrel of the heater into the socket, and push the sleeve to the stop on the smooth edge. The heating period will depend on the pipe wall thickness and material.

- Remove the molten parts from the sleeve and the mandrel at the same time.

- Connect together within 2-3 seconds.

- Do not rotate parts relative to each other.

Design features

Electric-welded coupling for polyethylene pipes is a cylinder made of low-pressure polyethylene. The inner diameter of the coupling is slightly larger than the outer dimensions of the pipes to be connected. Electric-welded coupling PND 100 is designed to connect straight sections of a polyethylene pipeline of the same diameter.

Manufacturers offer a size range of welding fittings from 20 mm in diameter to 900 mm. The length of a small fitting depends on its diameter in a ratio of 1: 2.5. For example, an electrofusion sleeve for pipes with a diameter of 20 mm will be 50 mm long. The length of the maximum diameter welding fitting is slightly larger than its values. So a coupling with a diameter of 800 mm has a length of 90 cm. The length of a coupling for 900 mm is 1 m. Manufacturers offer electric-welded couplings with an elongated body.

We recommend that you familiarize yourself with: Features of choosing a hydrodynamic machine for cleaning sewers

Inside the fitting there are electric heating coils, the contacts of which are brought out in the form of terminals. The material and location of the heating elements of the electrofusion sleeve prevent heat from spreading to the outside of the part.

The welding process is provided by melting polyethylene under the influence of temperature. The molecular diffusion process affects the inner surface of the sleeve and the outer wall of the pipes. Polyethylene is melted to a specific depth and mixed at the molecular level. When solidified, a monolithic formation is formed, which has no visible interface.

The part can be equipped with a welding progress indicator.This allows you to track the connection process and simplifies the work. Fasteners on the electrowelded coupling allow you to securely fix the part on the pipes, which eliminates rejects at the joint.

The fitting has a special barcode on the tag, which is read by the scanner of the welding machine. According to the barcode information, the device sets the heating time and temperature to obtain a perfect joint.

Since the welding process is provided by molecular diffusion of molten polymer, the composition of low-pressure polyethylene in the body of the electrofusion sleeve is of great importance. The overwhelming majority of fittings are made of polyethylene of grade 100, but there are also couplings of 80. Fittings of grade 100 are considered universal. They are allowed to be used for any HDPE pipes.

Note! For a high-quality connection of HDPE pipes with electrowelded couplings, purchase pipe material and fittings from one manufacturer. This will ensure the complete affinity of the polymers.

When to apply the re-sealant

An additional seal for the socket joint of cast iron pipes is used in two cases:

- for additional sealing during installation;

- to eliminate leaks arising during operation.

As a result of a violation of the tightness and integrity of the minting, a leak is formed at the pipe joints.

The re-compactor is considered more reliable than chasing. It is suitable for sewerage and water supply networks. Consists of breakable cast iron rings, rubber gasket and long bolts with nuts.

Troubleshooting is carried out without reducing the pressure in the line in any weather.

Appointment

A funnel is a funnel-shaped expansion at one end of a sewer pipe. Thanks to this extension, the pipes can be installed correctly and quickly. As a rule, a socket joint is used on pipes made of:

For asbestos-cement and concrete pipes, such a connection is also sometimes used, but rather rarely. The essence of the installation is that one end of the pipeline is simply inserted into the funnel-shaped expansion at the end of the adjacent pipe. To make the connection tight, additional methods of waterproofing the docking point are used. The choice of this or that method depends on the material from which the pipes are made.

Important: this method of joining pipes is used when installing both external and internal sewage networks.

The main purpose of the socket and the functions assigned to it are as follows:

- With its help, the installation of the pipeline is greatly facilitated and accelerated.

- Leak-proof and leak-tight connection.

- With its help, fittings are connected to pipes.

- Thanks to the socket, elements from different materials can be connected into one system without using fittings.

- When arranging external networks, the bell acts as additional stiffeners, thanks to which the system is protected from deformation and damage.

- When dismantling, the socket connection of pipes makes it possible to do without sawing the elements.

- Flared pipes can not only be quickly assembled, but also dismantled in case of repair or replacement.

Attention: despite such an abundance of functions and advantages, socket structures are not used everywhere. For example, pipelines made of elastic materials are connected according to a different principle. The same is true for some types of pipes made of solid materials.

Installation methods

A pipe with a socket can be mounted in different ways depending on the material from which it is made. Most often, the following methods are used for the installation of plastic pipelines with a socket connection:

- mounting with O-rings;

- joint on sealant and adhesive.

As for ceramic and cast iron pipes, one of two methods is used to connect socket elements into a single system:

Types of saddles for pipes and their installation

- welded connection;

- minting.

Consider the features of performing each type of connection.

Mounting with O-rings

In some cases, socket pipes have a special groove on the side of the funnel-shaped expansion for installing an O-ring into it. As a rule, this element is made of elastic material, which has good insulating characteristics. Sometimes when buying pipes, O-rings are already installed in them.

Important: a flare with an O-ring is easy to install, but this is not the most reliable way to protect against leakage. In some cases, you have to use additional methods, for example, a sealant or waterproofing tape.

The sequence of installation of socket elements with O-rings is as follows:

- To begin with, the sealing ring must be installed in a special groove on the side of the socket. As a rule, appropriate rings are selected for pipes of a certain type and diameter. It is better to use products from the same manufacturer, which guarantees maximum size matching.

- After installing the ring, you need to check the correctness of its installation in the groove and the tightness. If the element is torn, lost its elasticity or has other defects, then it is better not to use it.

- After that, the smooth end of the other product is inserted into the prepared socket until it stops. You will not be able to advance the inserted element further than the funnel of the funnel will allow.

- To provide additional tightness of the connection, the outer joint is wrapped with several layers of sealing tape.

Attention: this type of connection is designed only for an average load from sewage drains, removed by gravity, as well as for normal atmospheric pressure. Installation with O-rings is not suitable for pressure drain systems.

Joint on sealant and adhesive

In some cases, the installation of PVC socket pipes is carried out using sanitary silicone sealant or glue. This method of connection guarantees a high tightness of the joint, and also allows you to perform work as soon as possible. But after laying the products in this way, you need to wait a certain time, which is required for the sealant to harden, before checking the system.

Advice: during work, you should be extremely careful and control so that the glue does not get inside the pipe, since in the future it can lead to blockages.

When choosing an adhesive or a sealing compound, it is worth considering the location of the pipeline. So, there are adhesive mixtures for external and internal work. You can buy glue or sealant at a hardware store or at a plumbing point of sale. This rather reliable connection method can be used when installing external and internal sewer communications.

The installation sequence is as follows:

Connection of steel and cast iron pipes - types and methods of joining

- The outer smooth end of the pipeline must be sanded with coarse sandpaper. The resulting rough surface will provide better adhesion to the walls inside the socket.

- A strip of glue or sealant is applied at a distance of 2 cm from the edge of the pipe. The width of the strip should be such that, after insertion into the socket, the adhesive is evenly distributed over the surface, but does not go beyond the edge of the element.

- After applying the sealant, you need to wait 30 seconds for it to dry a little.

- Then the smooth end of the product with glue is inserted into the socket extension and pressed for a few seconds.

- Now the adhesive or sealant needs to be given time to harden. The exact time is usually indicated on the packaging with the product used.

- After that, you can test the system.

Socket welding

This installation method is only applicable to cast iron products. In fact, welding cannot be considered a separate installation method, because it is used as an additional work when capping pipes. Welding ensures complete protection against leaks and significantly extends the service life of the cast iron system. Coating can only be performed by specialists with experience in carrying out such work.

Installation is carried out in the following order:

- The smooth end of the pipeline is installed in the socket. After that, caulking is performed using a cement mixture, which is poured so that it does not reach the edge of the pipe by 5-10 mm.

- When the cement composition is completely solidified, you can start welding. The edge of the funnel is coated with a welding compound and welded to the end piece.

- When the seam has cooled, you can start checking the system.

Methods for mounting a pipe with a socket

A pipe with a socket can be metal or polymer, of small and large diameter, designed for a gravity or pressure pipeline. In a word, pipes with an assembly extension (socket) at the end are different, but this vast assortment has one thing in common. Such pipes make it possible to assemble a strong and sealed flow-type interface literally with one movement. To do this, you just need to place the smooth end of one pipe in the socket of the other.

And in this article we will consider a socket connection of pipes made of different materials, supplementing this information with an overview of fittings with an assembly expansion (socket).

Types of socket pipes

The following types of pipes are produced with mounting thickening:

Connecting cast iron pipes with a socket

- Polyvinyl chloride fittings with a diameter of 63 to 315 millimeters (for an O-ring) or 10 to 160 millimeters (for an adhesive joint). The assortment of such products is determined in accordance with GOST 51613-2000. Moreover, pipes for a rubber sealing ring are used only in free-flow networks, but fittings for a glue socket are recommended for use even in pressure pipelines.

- Cast iron fittings with a diameter of 50 to 150 millimeters. The range of such fittings is standardized in accordance with GOST 6942.0-80. At the same time, the socket connection of cast iron pipes is used not only in the assembly of sewer pipelines. There is another type of cast iron pipes with a socket, the nominal diameter of which ranges from 65 to 1000 millimeters. Such pipes are standardized in accordance with GOST 9583-75 and are used in pressure-type pipelines.

- Ceramic fittings for sewers, with a diameter of 150 to 600 millimeters with a ribbed inner surface of the mounting bulge and the same shoulder of the bell. The range of such pipes is standardized by GOST 286-82

In a word, as you can see, socket pipes can be found anywhere - both underground and above the ground, and in structures, and in oil wells. Therefore, the methods of sealing socket joints simply cannot be of the same type. And further in the text we will consider the options for ensuring the tightness of the socket joint.

Sealing a flare connection: overview of options

The tightness of the socket joint is ensured by gaskets, adhesive bonding, additional seals and conventional welding. Moreover, the rings (sealing and retaining), as well as the slip flanges, provide for the detachable installation of the socket interface, and the welding and glue assembly - the one-piece assembly option.

O-ring mounting

Well, the details of these technological processes are as follows:

- Mounting on an O-ring is carried out as follows - an O-ring is placed in the socket, placing it in the inner groove; the smooth end of the pipe is pushed with effort through the ring into the socket.As a result, the pipe pushed into the socket expands the ring and wedges in the mounting bulge. True, such a joint will only withstand atmospheric pressure, therefore this technology is used only when assembling sewer or branch pipelines. But such a method of joining will withstand transverse deformations better than other methods of one-piece mounting.

- A special case of mounting on a seal is the fixation of cast iron pipes with tow, driven into the gap between the socket and the pipe. Moreover, after chasing (this is the name of this operation), a layer of bitumen or cement is applied to the end of the socket.

Installation of pipes with a socket on glue

- An analogue of embossing, implemented in polymer pipelines, is installation in a socket using a retaining ring. In this case, a rubber ring is moved to the joint of the pipe and the socket - an additional seal for the socket connection of cast iron pipes, which is made from a flat tape (the excess edges are cut off). Then, on both sides of the socket joint, detachable clamps are mounted, created in the form of segmental washers. By assembling these segmental washers, a semblance of a flat flange can be obtained. And one such "flange" is mounted behind the bell, and the other - butt to the rubber seal. By screwing in the mounting studs of this "flange" connection, the seal ring can be immersed in the gap between the pipe and the socket. And thanks to the elasticity of the additional seal (rubber ring), such a connection will withstand both lateral and longitudinal deformation.

- Glue installation is very simple. The first layer of glue is applied to the tapered section of the pipe, and the second layer of adhesive is applied to the inner surface of the socket. After that, the pipe is inserted into the socket and the mating elements are pressed against each other with significant effort. After some time, the adhesive layers will harden and the joint will become airtight. True, lateral loads with this method of installation are categorically contraindicated. They can destroy the fragile adhesive bond.

Resistance socket welding is carried out using special devices - soldering irons. The heating element - a tire - of such an apparatus is equipped with low-melting nozzles: a nipple, the diameter of which coincides with the internal dimensions of the socket, and a coupling, the through-hole of which coincides with the external diameter of the pipe.

By heating the corresponding parts of the socket joint of thermoplastic pipes on the nipple and in the sleeve, we achieve the destruction of polymer chains. And by pressing the heated pipe into the same socket, and leaving the connection alone for 10-15 minutes, we create conditions for the emergence of new polymer chains.

As a result, socket welding is the most reliable technology for installing polymer reinforcement.

Pipe connection technology using electrofusion couplings

The technological process of welding polyethylene pipes with electrofusion fittings is not difficult - the pipes are inserted into the fitting, fixed and supplied to the terminals with electric current.

The algorithm can be schematically described as follows:

- The pipes are prepared for connection. They are cut to size, making a cut at right angles to the pipe axis.

- The cut is cleaned, freed from dust, particles of material, moisture.

- Pipes are inserted into an electrofusion sleeve.

- Connect the fitting to an uninterruptible voltage source.

- Allow the joint to cool. The average cooling time is about half an hour.

- Check the reliability of the resulting connection. For this, the joints are coated with thick soapy foam and compressed air is fed into the system.

The nuances of the location of pipes in the coupling:

- if the fitting has restrictive protrusions, then the pipe is inserted strictly up to the mark;

- if there is no limiter, then one should be guided by the thickness of the pipe wall - the distance between the cuts of the pipes to be connected should not be greater than the wall thickness of the pipe material;

- the joint should be located in the middle of the sleeve;

- to maintain the distances, a circular mark is drawn on the outer wall of the pipe or put at risk.

Note! The electrofusion coupling is non-separable. Carelessness in the preparatory work during installation can cause damage to an expensive fitting.

The welding process takes place in automatic mode. After connecting, check the reliability of the joint. For this, the compound is coated with soapy foam and the carrier is supplied under pressure. If the joint does not begin to bubble, then the joint is sealed.

Advantages of electrofusion fittings:

- Ease of installation. Availability of work to be performed by a non-professional.

- Ability to dock the pipeline in a trench, other hard-to-reach places.

- Automation of the process eliminates the human factor during installation.

- The service life of the pipeline depends only on the materials.

We recommend that you familiarize yourself with: Features of the device and types of three-way valves, use in heating systems

The disadvantages include the high cost of fittings. However, the costs are paid off by saving on outsourcing.

Socket pipes: purpose, types, practice of application

Socket pipes are widely used in industry, urban planning facilities, where it is required to organize pipeline systems for various purposes. In modern construction, it is very important to arrange the so-called zero cycle - the foundation that prepares the site for installation work on the construction of the facility. At this stage, the construction of underground utilities is not complete without the use of structures such as a bell pipe.

Pipes with a socket make it possible in the shortest possible time to install highways for various purposes

Methods for connecting polyethylene pipes

HDPE pipes can be connected in 2 ways. The first is divided into:

- butt welding;

- electrofusion welding.

The second method provides for a connection using a coupling and fittings.

Sewer pipelines are less demanding in comparison with water pipelines. This is explained by they are free-flowing and are divided into:

- socket connection;

- fitting connection.

Coupling connection

Couplings of polyethylene pipes made by extrusion have found wide application in pipeline installation. Couplings make it possible to quickly, reliably and without any unnecessary devices connect the ends of the pipeline.

The advantages of this connection method:

- resistant to mechanical stress and temperature extremes;

- fasteners are reliable and durable;

- widespread use;

- low price of polyethylene materials;

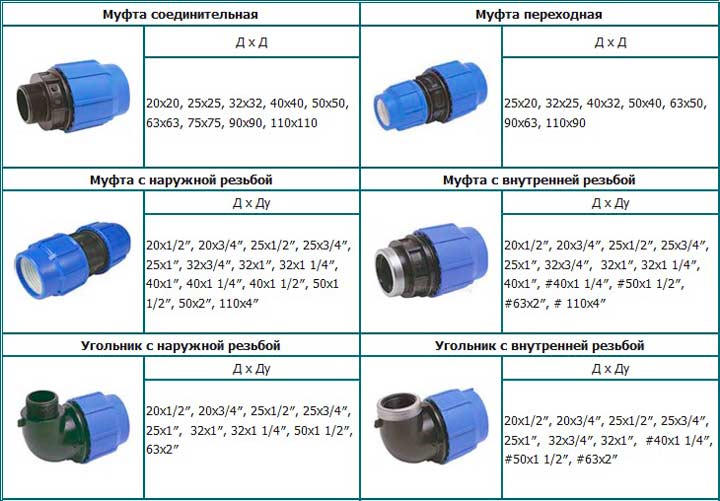

When installing the pipeline, such types of couplings:

- Compression sleeve available with both external and internal threads. These connection elements are used in the installation work of systems supplying gas and water.

- Coupling. It is the simplest, with the help of it pipes of the same diameter are connected;

- Reducing clutch. It is a transitional one for fastening pipes of different diameters.

Compression fitting connection

Compression fittings are easy enough to connect to polyethylene pipes.

This is done in a specific sequence:

- Unscrew the union nut and disassemble the fitting;

- The end of the pipe is prepared: cleaned of dirt, chamfer with a chamfer or a sharp construction knife;

- A mark is made on the pipe to what depth the pipe should enter into the fitting;

- Before the pipe is driven into the fitting, it should be rubbed with a lubricant for ease of operation;

- After inserting the pipe into the fitting, tighten the union nut back.

The nut should be tightened exclusively by hand, because using a wrench it is possible to overdo it.

Pressure pipelines are mounted with one-piece welded joints. Installation is not complicated and does not require any special qualification skills.

Butt welding

To connect HDPE pipes with butt welding, a special soldering iron will be required.

The work is performed in the following sequence:

- The ends of the pipe are fixed with the paws of the welding machine and alignment is carried out;

- The surface is heated before melting begins;

- The molten ends of the pipes are squeezed together;

- Then the seam is cooled naturally.

Electrofusion welding

This method is a little more complicated than the butt welding method and will require special couplings with electric spirals, which heats up the element, provided that the voltage is applied. The elements are welded to the coupling.

The advantage of this method is the simplicity of the work performed. The downside is the high cost of the electrical clutch. If many connecting elements are planned, then it will be more expedient to use resistance welding.

To connect polyethylene and metal pipes, two connection methods are used:

, used in pipes of small diameter. For this, it will be necessary to purchase fittings, on one side of which a thread is cut for joining with a metal pipe, and on the other - a smooth coupling for fastening to a HDPE pipe;

Threaded connection

designed for connecting pipes with a large diameter. Here, collar sleeves are welded to a polypropylene pipe.

Flange connections

Socket connection

Socket connection of HDPE pipes is one of the most economical methods. After all, there is no waste on welding. But this type is suitable only for free-flow lines. The flares are not able to properly connect the system under pressure.

To ensure tightness when immersing the sockets of one in another, it will be more expedient to use O-rings, for example rubber.

Areas of use for socket pipes

Transportation of liquids, sewerage system, stormwater system is impossible without the use of a special type of pipes. The socket design is reliable and easy to use, relatively inexpensive to manufacture and practical to operate. Its use is ubiquitous:

- industrial and civil construction;

- hydraulic engineering works in various directions;

- road construction;

- construction of railway facilities and tracks;

- Agriculture.

Pipe structures are made from various materials. The main ones that have become firmly established in the practice of application are concrete, cast iron and plastic. Each of the types has its own advantages and disadvantages. The technical characteristics of these products determine the scope of their application.

Connection types

Couplings for connecting plastic pipes made of such material are divided into: detachable and one-piece. In the first case, when docking, a crimp sleeve and a flange connection are used. In the second version, they use: welded fittings, welded and cast couplings, tees.

Let's consider in more detail.

Electrowelded. If the water supply system is mounted from small pipes, then a connecting sleeve is used. It is a heating element: two stripped pipes are placed in the fitting. The device is fixed in a special mechanism. The welding machine is connected to these contacts and heats up.

Cast and welded. If the water supply system is intended for supplying drinking water, then a cast coupling is used to combine the joints. In order for the plastic pipes and the adapter to have a sealed connection, welding equipment is required. This method is applied to pipes having a diameter greater than 50 mm.

A ferrule is used to bond areas where pipe sizes up to 110 mm can withstand light pressure. If you figure out how to connect firmly, then it becomes clear that it is better to use flange connectors, and for this:

- install the flange adapter;

- use a cast collet with a flange, using welding or electrofusion fitting.

If plastic pipes with a diameter of up to 50 mm, then a crimp coupling and collet crimp connections are used.

To carry out the joining of polyethylene materials with each other or with structures made of another material, a crimp sleeve for plastic pipes is used. The presence of a rubber seal makes it possible to make the connection tight.

Types of socket pipes, their quality characteristics

A pipe with a bell, besides all other advantages, has the main advantage - ease of installation, manufacturability in operation, relatively low costs for the installation of products.

Concrete products are especially popular. Their cost becomes lower as the produced pipe diameter increases. The bell system itself is very practical. An extension is formed at one end of the pipe, which serves as a seat for the other pipe. The joint is sealed in a manner that is most effective for this type of product.

Bell-shaped products have an extension at the end, into which the edge of the subsequent pipe is inserted

Concrete and cast-iron pipe connections are coined with sealing concrete and resin compounds with a filler, and plastic ones - with rubber O-rings that fix the installation connection. For concrete and cast iron products, special rubber seals can also be used. They improve the tightness of the connection, making them moisture-proof.

Note! The sockets in the piping system are located against the direction of fluid movement.

As a rule, cast iron and plastic socket systems are installed for sewerage and other indoor systems. Concrete products are most often used in external sewer or drainage collectors. Large diameters are usually required there, capable of freely carrying bulk liquid masses.

Socketless pipes, their connection, principles of use

Socketless pipes are also popular and practical to use, install and operate. The fundamental difference from the socket versions is that the pipes are assembled using additional devices that ensure the connection and sealing of the joint.

Socketless pipes are connected using couplings, collars and other fittings

For reinforced concrete structures, a concrete flange serves as such a connecting element, and a clamp for cast iron pipes. The absence of a socket in some cases simplifies the installation of the pipeline, reduces the construction time. Basically, such products are used in the construction of non-pressure systems. But, using special cuffs that increase the degree of sealing and strength, pipelines can perform the functions of pressure, that is, keep the pressure of the internal environment. The main application of such products is drainage or socketless sewage.

Installation tools and accessories

To install a pipeline using electrofusion fittings, you will need tools:

- for cutting pipes - a pipe cutter or a hacksaw for metal;

- sharp knife + sandpaper or beveller for cleaning the cut from burrs, irregularities;

- acetone or organic solvent, rags for removing dust and degreasing the joint.

The welding process itself requires the supply of a certain current to the terminals. For this, a professional welding transformer is used. It belongs to the expensive special equipment.For the installation of individual communications, such an electricity transformer can be rented.

We recommend that you familiarize yourself with: How to make a homemade pipe bender for a profile pipe - a complete guide with drawings

The welding machine can be easily adjusted to the required voltage. In most modern welders for plastic materials, the adjustment is carried out automatically, according to the barcode on the electrofusion fitting. Advanced models read information directly from the coupling terminals.

Assortment of concrete products. Manufacturing features

Concrete socket pipes are used in civil and industrial construction. They are inexpensive, practical, durable in use. Most often they are used in the construction of sewerage systems, urban stormwater systems, bypass pipelines for water in road construction. According to their purpose, reinforced concrete products are divided into:

- free-flow;

- pressure head;

- designed for all types of road construction.

Socket pipes made of concrete are of the pressure and non-pressure type

The industry produces three main types of socket pipes: type T, type TB and type TV. They differ in the method of production, load characteristics, and other special parameters provided for by GOSTs.

Reinforced concrete gravity pipes of type T are used for laying sewer systems, drainage systems for ground and underground waters, and other non-aggressive liquids for this product. They can withstand significant loads, are inexpensive in terms of manufacturing cost, and include available materials.

The TB type is capable of carrying an increased load during operation. They can be supplied with rubber O-rings, which simplify the installation of the connections, making them tight.

Important! Such pipelines can be used as pressure pipelines for pumping water and other liquids that are neutral to the concrete composition.

For example: the most used pipe dimensions are socket products 5 m long, 1 m in diameter and 75 mm thick. They are optimal from the point of view of the construction of the sewer collector, make up a convenient load for transportation by car - 5 pieces each on a specialized platform.

Pipes of the TV type are intended for use in road construction. These are especially durable products, complete with O-rings, capable of withstanding the pressure of the soil layers and the work of the road deck for a long time. They are divided into four groups according to their bearing characteristics:

- Group 1 - the ability to bear the pressure of the backfill soil and the roadbed up to 5 meters thick;

- Group 2 - load capacity up to 10 meters;

- Group 3 - load capacity up to 15 meters;

- Group 4 - up to 20 meters of backfill thickness.

Flared sewer concrete pipe is a rigid and reliable structure with a service life of more than 50 years. This is what makes it a special technology of using durable concrete, special structural reinforcement and high-tech manufacturing methods. The price-quality ratio of this structure is optimal, therefore, most design and construction organizations, when looking for the necessary pipes for organizing the construction of hydraulic systems, opt for concrete products.

Concrete pipes with and without socket are most often used in drainage and sewerage systems

Types of sockets for sewage

Pipes assembled from sockets are easy to install, durable and cost effective.

The most common type of socket is a concrete pipe. The larger the cross-section of the pipe, the lower its cost. The concrete socket is very durable and practical to use. One end of the socket has an extension for attaching the other part to it. The joints are sealed in the most suitable way.

Reference! The joints of pipes made of cast iron or concrete are sealed using concrete-resin compositions containing a special filler, and plastic ones are sealed using rubber gaskets in the form of rings.

To seal joints made of cast iron and concrete, a rubber cuff is sometimes used, which increases the tightness of the joints, guaranteeing the watertightness of the product.

Attention! Flared water pipes are laid against the main flow of runoff water.

Cast iron and plastic sockets are used when installing indoor water supply and sewerage systems. Concrete products are suitable for outdoor sewerage systems. External sewerage requires the use of pipes with a wide diameter, through which large flows of sewage pass freely.

Socketless pipe structures

Flared pipes are also popular, durable and practical to use. Pipes are connected using special elements that can ensure the tightness of the structure.

In railway construction, a concrete flange is used to seal joints, and a clamp is used to connect cast iron pipes. In some situations, it is better to use socketless structures to simplify installation work and save time. Such pipes have found application in free-flow sewage systems. If the connections are provided with gaskets, then the pipes can be used in pressure systems, withstanding high internal pipe pressure.

The area of wide application of the socketless design is drainage systems and sewage without the use of sockets.

Features of concrete sockets

Concrete sockets are used for the construction of houses and industrial facilities. They are distinguished by their practicality, durability, long-term use, and economy.

With the help of concrete structures, a sewerage system, storm drainage systems, and bypass pipeline systems are laid during road construction.

Concrete sockets are used:

1. in a gravity system.- 2. in the pressure system.

- 3. in all types of road construction.

In industry, sockets of the type T, TB and TV are used.

For each type of GOST provides individual parameters for the manufacturing method, for the volume of the load and the area of use.

Pipes of type T, designed for laying gravity systems, are laid in sewers, drainage of runoff water by a surface, underground method, as well as other liquids that the pipes can withstand. They provide high water permeability, are inexpensive to manufacture and install.

TB type sockets are used for sewage systems with increased load. The bells can be initially equipped with rubber rings for sealing, reducing installation time and increasing the tightness of the product.

Important! The sockets provide the passage of any liquid through the pipeline under pressure.

The most common sockets in operation have a length of five meters, a pipe section of one meter, a wall thickness of seventy-five millimeters. They are practical for the installation of sewer collectors, withstand the optimal load when driving five cars on a special platform.

TV-type sockets are used in road construction. The sockets have increased strength, are sealed with rubber gaskets, withstand increased soil pressure and road surface load.

Technical characteristics distinguish the following groups:

- 1. a group that can withstand the pressure of the filled soil and road surface with a height of no more than five meters.

- 2. a group that can withstand a load of no more than ten meters.

- 3. group with a possible load of no more than 15 meters.

- 4. a group that can withstand a backfill thickness of no more than twenty meters.

A pipe with a socket made of concrete is intended for sewerage, it is a rigid, durable structure. The term of use is over fifty years.The sockets are made using high technology from a durable material with surface reinforcement. For concrete sockets, the quality and price of the products correspond to each other, therefore, when laying the sewage system, many organizations choose these products.

Cast iron and plastic sockets

Along with concrete structures, cast iron and plastic pipes are widespread. Cast iron structures are used in the arrangement of drainage and sewer networks. As a rule, sockets are made of cast iron, plastics are mounted during the laying of domestic sewage systems, drainage systems.

Cast iron products provide good protection for cables laid underground. The sockets resist fire, protect from excessive moisture, mechanical damage. From freezing the pipes are covered with a layer of geotextile. The disadvantage of the design can be considered the fact that cast iron lends itself to corrosive changes. In order for the pipes to serve for a long time, the pipeline is subjected to anti-corrosion insulation.

Plastic sockets take out cast iron products from everyday life. The plastic elements of the sewage system are almost weightless, practical to use, have the characteristics of cast iron pipes, but are inferior to them in strength. Plastic structures are made of polyvinyl chloride, polypropylene, polyethylene of various pressures.

Also used for laying sewers and drainage, but the material limits the scope of pipes. Socket joints are sealed with a rubber seal to ensure a seal. Sometimes a welding connection of elements is used. Pipes are made in different colors, which carries information about their purpose in the pipeline system, and also increases the aesthetic appearance of the structure.

Important! Plastic resists corrosive processes.

Cast iron and plastic socket systems

The use of cast iron and plastic flared pipelines has long been rooted in construction practice. The cast iron pipe is a long-standing structure that provides a drainage system, drainage. Even in our very technological time, it is often applicable for the same purposes. Both cast iron and plastic are used in internal drainage structures and sewage systems.

A cast iron pipe is often used as a reliable protection for cable networks when laying them underground. It protects the contents from moisture and mechanical stress, is not subject to combustion. When protection from the cold is required, a special insulation is used. One of the disadvantages of a cast iron pipe is its susceptibility to corrosion. For long-term operation of such a pipeline, corrosion-resistant insulation is required.

Recently, socket types of plastic pipes have been massively used. They are very practical, lightweight and have almost the same characteristics as cast iron pipes, except for mechanical stability. In their manufacture, polypropylene, polyvinyl chloride, high or low pressure polyethylene are used.

Polymer pipes are completed with rubber bands in the socket, which greatly simplifies and speeds up their installation

The scope of application of these pipes is the same as that of traditional cast iron or concrete structures. The difference is in the technological capabilities of the pipe material. Modern fixation of the socket joint is carried out using a rubber O-ring, which ensures the sealing of the joint. Welding connection is also possible. The multicolored design gives the pipes an aesthetic appearance and indicates its purpose in the piping system. One of the important advantages is that plastic systems are not susceptible to corrosion.

Practical application of socket pipes

Socket products are widely used for organizing pipeline systems designed to transport liquids in pressure and non-pressure modes of use.Reinforced concrete structures of large diameter are used for sewerage, drainage of rainwater from city streets. Cast iron and plastic systems have the same purpose, only, mainly, inside buildings, structures, various civil objects, private estates.

Pipelines are used as protective transport systems for wiring cables, routing heating and other types of technological networks. Almost all types of socket pipes can withstand a wide range of temperatures and pressures of surface earth masses. Well-sealed structures provide the required internal pressure of the liquid composition transported through the pipeline.