Each developer has one cherished goal - to make a high-quality material in which both energy-saving characteristics and durability are harmoniously combined. As practice shows, unfortunately, these properties are opposite to each other. The solution to the problem is a symbiosis or a compromise between these characteristics. A good example of this is expanded clay concrete blocks. A house made of expanded clay concrete blocks is much warmer than a simple brick house, and besides, it is even lighter.

If we take into account the resistance to loads, then the material can be compared with foam and aerated concrete. Expanded clay concrete is even better at this. Buildings made of expanded clay concrete blocks have gained particular popularity in Europe, where heat is very important. If you are thinking of building your house from expanded clay concrete, you need to familiarize yourself with the material in more detail, find out its positive and negative sides, and also consider the technology of working with it. You will be able to see projects of houses made of expanded clay concrete blocks, as well as learn how one of them is being built.

Getting to know the expanded clay concrete blocks

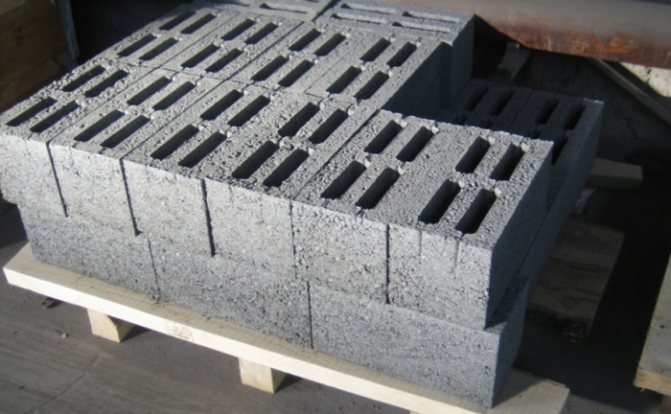

What kind of material is this? If you don't know yet, then expanded clay concrete consists of three main components:

- expanded clay (foamed and burnt clay);

- cement;

- quartz sand.

Based on the components of expanded clay concrete, it can be called an environmentally friendly material, because all the elements are of natural origin, without chemicals in their manufacture. Due to the presence of expanded clay in the composition, the weight of expanded clay blocks is much less than analogues, and its thermal insulation characteristics are at a high level. The cement in the composition makes the product durable and suitable for building houses. What are the advantages of expanded clay concrete blocks for building a house?

- Low hygroscopicity. Despite the fact that the blocks contain cement, the material is quite moisture resistant and is not afraid of liquid.

- High rates of frost resistance. Depending on the type of expanded clay concrete blocks and their purpose, the freezing and defrosting cycle ranges from 15 to 200.

- Excellent strength and density of expanded clay concrete blocks.

- Expanded clay concrete does not burn and does not interact with fire in any way.

- The combination of all the previous advantages gave rise to another one - durability. The construction of a house from expanded clay concrete blocks is done for centuries.

- The material does not rot, does not rust, insects and rodents do not eat it.

- Thanks to its bio-stability, the walls of the house will not be covered with mold and mildew.

- Low coefficient of thermal conductivity, due to which houses from expanded clay concrete are warm.

- The material, and accordingly the walls of the future house, will "breathe", since the blocks have excellent vapor permeability.

- You can even build a house from blocks yourself, while not spending as much time and effort as on brick buildings.

- A house made of expanded clay concrete will not shrink.

- The material is lightweight.

- Masonry mortar will take half as much as for brick.

- The cost of both the material and the construction of the whole house is small.

Among all these positive points, it is worth mentioning a few disadvantages of expanded clay concrete that you should know:

- despite the low weight, it will not work to save money on the foundation;

- when laying blocks, cold bridges (seams) will form, therefore, the house will have to be insulated from expanded clay concrete blocks;

- there are many low-quality fakes on the market that do not meet the declared characteristics.

If we draw a logical conclusion, then everything speaks in favor of expanded clay concrete blocks. Indeed, judging by the reviews of the homeowners, they are quite satisfied with the quality of the building, despite the years they have lived.

Nuances you need to know during construction

In order for your lightweight aggregate house to stand for a long time, be warm and reliable, it is important to familiarize yourself with the intricacies of construction technology from lightweight aggregate concrete blocks.

The first moment is to choose the type of material for work. For example, if you plan to build a low-rise house, then the best option for work will be structural and heat-insulating expanded clay concrete blocks, whose density is in the range of 700–1200 kg / m3. Less light and dense materials are suitable for insulation, but multi-storey buildings are erected from heavy (structural) blocks.

Important! The lower the density of the material, the better its thermal insulation properties, and vice versa.

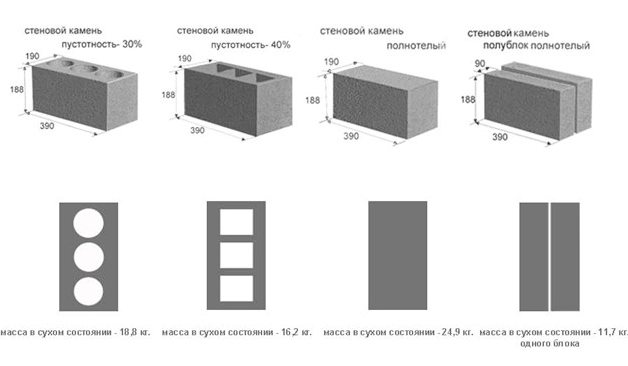

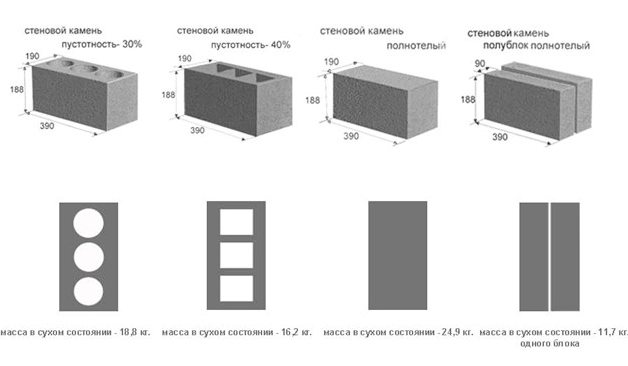

The second point is that it is important to choose the right size of the products. If you want to make your home warm while reducing energy costs, then the walls of the house should be at least 40 cm thick. One of the popular block sizes in the construction of load-bearing walls is 190 × 188 × 390. Walls made of blocks, the thickness of which is from 90 to 120 mm, serve as self-supporting partitions of the house.

The third point - the foundation for a house made of expanded clay blocks must be made strong and in-depth. The depth of the foundation is selected taking into account the type of soil, the freezing point and the location of groundwater, however, it is not less than 1 m.Make sure to make a sand cushion with a layer of 20 cm, and also fill in an armored belt of concrete of 20 cm.In this case, the frame consists of 5 or 6 rods of reinforcement Ø18 mm. If the soil settles, then the walls and foundation of the house made of expanded clay concrete will not crack.

The fourth point is that it is better to do the insulation and decoration of the building at the same time - this is beneficial in order to save money. That is why you need to choose the facing material and insulation in advance. You can sheathe the walls of the house with siding, blockhouse, facing brick or facade plaster. And as a heater, mineral wool or foam is suitable.

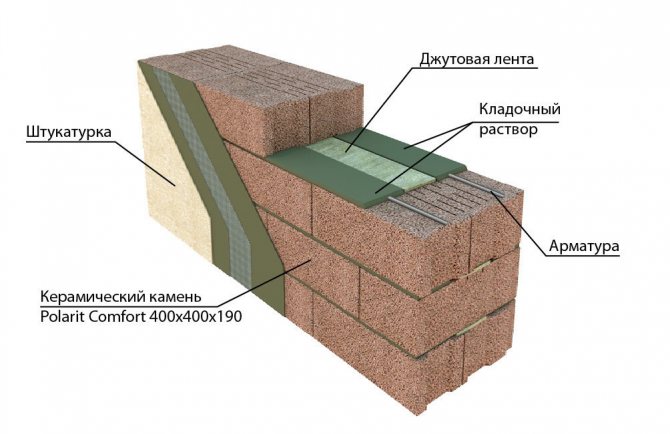

Advice! In order to prevent the formation of cold bridges through the seams, jute tape is used when laying the house. It fits in the middle of the masonry, not allowing the cold to pass through the solution.

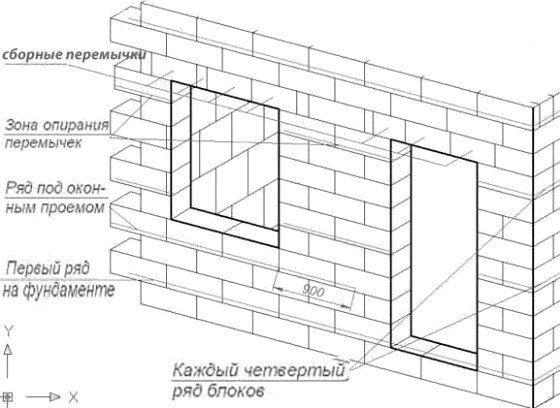

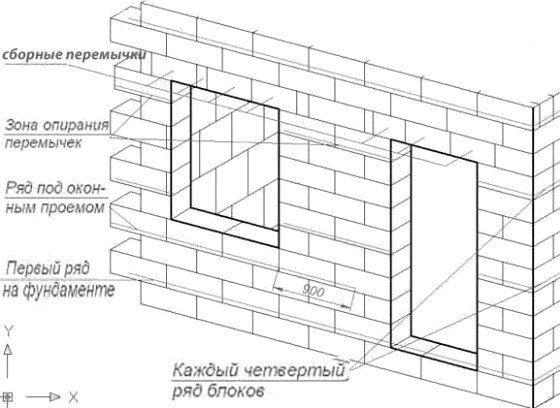

The fifth point is that the laying of blocks of expanded clay concrete must be reinforced. This is done every 3 or 4 rows using reinforcement rods, Ø12 or 14 mm. In the blocks, grooves or grooves are made, where the rods are laid. Then everything is sealed with cement mortar.

Advice! Armopoyas must be done before the installation of floor slabs, if the claydite-concrete house is two-story, as well as in front of the roof.

Choosing blocks for building a house from expanded clay concrete

Just before you start building your dream home, you need to prepare the material. The basis of construction is blocks of expanded clay concrete. Above, we mentioned a little about their varieties, but we want to dwell in more detail on the choice of products. By appointment, blocks of expanded clay concrete are:

- Heat-insulating type (500-700kg / m3)

- Construction type (1200-1800 kg / m3).

- Structural and heat-insulating type (700-1200 kg / m3)

Which one is suitable for building a house? If you want to build a cottage, then choose structural expanded clay concrete blocks. And when your goal is a small warm house, then choose structural and thermal insulation blocks. They are quite durable and have excellent thermal insulation performance. Now that you have decided on the type of expanded clay concrete blocks, let's look at how the construction work begins.

Choosing masonry for the outer wall of the house

Use thicker blocks in colder areas

Almost every owner, when building his house, is faced with the question: "How thick to make the outer wall?", It is not always easy to get an unequivocal answer to it. Since its thickness depends on the masonry, which is used in the construction of the structure. Masonry, in turn, is different in different regions of the country, depending on the climatic characteristics.

In addition, the outer wall is not always created only from expanded clay blocks. In cold regions of the country, in order to have a minimum wall thickness, combined masonry is used. In addition to blocks, they include various insulation materials (stone wool, expanded polystyrene) and bricks.

Only after the final choice of the masonry option is it worth starting to calculate the thickness of the expanded clay concrete wall.

External masonry should be 40 cm thick

There are certain postulates and rules that should always be taken into account and followed when organizing walls from expanded clay blocks. These include:

- when laying out the support wall with ordinary wall blocks, the external masonry must be at least 40 cm thick;

- if the load-bearing wall of the room is lined with large blocks of expanded clay concrete measuring 590 x 290 x 200 mm, then the outer wall is erected 60 cm thick, and the insulation is placed in special gaps.

When choosing and forming a wall cake, each owner should take into account such a parameter as the coefficient of thermal conductivity. Every building material used for the construction of walls has it.

The first necessity is designing a house

Whatever one may say, everything starts with this step. For the project you need to pay a lot to a specialist, however, without him, both expanded clay concrete and any other house cannot be built. This is the same as going from Russia to Africa without a map. And you will not be given a building permit without documents. Therefore, the first thing you should do is order a construction project from a specialized company.

Together with you, the architect will create not only the exact dimensions of the house, its structure, and other details, but will also be able to draw up an estimate. It indicates the amount of material, its type and the cost of all work. Only after that you can start building a house from expanded clay concrete blocks with your own hands.

Additional points

One of the most expensive options for external cladding, of course, is natural stone, including marble. Of course, such a house will have a very presentable look. But there is also a nuance here: each stone has its own level of resistance to frost, therefore, when choosing it, one should take into account the climatic conditions of the region where the construction will be carried out. Alternatively, you can use an artificial stone, which will cost significantly less.

If there is a desire to purchase thermal panels, then from the budget options you can use those made on the basis of polyurethane foam or clinker tiles. Their huge advantage is their low weight, which allows them to be applied to strip foundations. In addition, they have good strength and do not contain toxic components. Such panels help keep the house warm in cold weather and cool when it's hot outside. Installation of this material is easy, which allows even a beginner to cope with it. When building a house from expanded clay concrete blocks, one should not forget about ventilation systems so that it can “breathe”.

Basically, to summarize, it can be seen that such a building can turn out to be quite economical when using the right materials.

The basis of the foundations is the foundation of a house made of expanded clay concrete

When you have the required amount of materials, a detailed plan, a finished site and communications carried out, you can get to work. The foundation for the building is everything! It depends on him how durable a house made of expanded clay concrete will be and how long it will stand.It is not surprising that almost half of all funds are spent on the foundation, if not more. So what is your task? Let's walk through the process step by step. The basis will be a strip monolithic foundation, ideal for the construction of such a house. The device instruction is as follows:

- To begin with, the site is cleared of all unnecessary: garbage, vegetation, unnecessary trash.

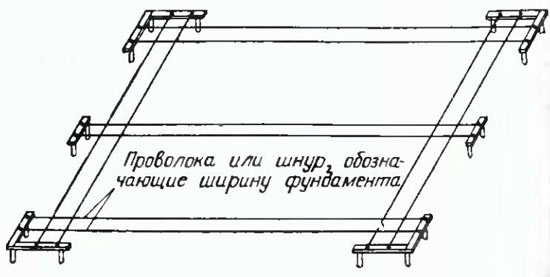

- Further, the markup is done according to the project. The twine stretched between the rods plays the role of a landmark, which indicates the place of digging a trench. It exactly follows the contours of the foundation.

- Based on the markings, you will have to dig a trench. The depth and width thereof are selected in advance at the design stage. The walls of the trench should be flat, everything is controlled by a plumb line and level.

- At the bottom, a sand cushion and an armored belt are arranged, according to the data given above.

- Removable formwork is made from boards, OSB sheets or plywood. It is strengthened and covered with a film from the inside.

- Inside the trench, you need to make a frame of reinforcement so that the concrete becomes reinforced after pouring. So, it will not crack and will become much stronger.

- At the end, it remains to fill everything with concrete. As it is poured, the composition becomes denser. It is best to do everything in one day, without leaving the concrete to dry out.

- The surface is leveled and left to dry completely.

The strip foundation for a house made of expanded clay concrete blocks will dry for about a month. For this time it is better to protect him. After 10 days, the formwork can be removed.

Advice! If the weather is hot, it can be moistened periodically to prevent cracking of the concrete.

Basic calculations

The dimensions of each element of the future structure will allow you to determine the required number of blocks for its construction.

To calculate the amount of building material, the following instruction must be followed:

- Sum the lengths of all walls;

- To this length, add the length of the load-bearing partitions of the structure;

- The resulting value, which is referred to as the length of the house, should be multiplied by the height of the ceilings;

- Further calculation directly depends on the size of the selected blocks, as well as on the thickness of the walls... The value obtained by multiplying the length of the walls by the height is multiplied by the required wall thickness;

- The final value obtained in these calculations is the volume according to which expanded clay concrete blocks should be purchased.

Advice. You should purchase this material with a margin, given the damage to some blocks.

The ease of installation and cost-effectiveness of products such as expanded clay concrete blocks has led to their popularity in the construction of private houses.

Advice. If you decide to purchase a house made of expanded clay concrete, discard the options for buildings that have been without external finishing for more than 2 years. The effect of low temperatures and precipitation on the facade of the building can be cracking of the masonry and the occurrence of chips.

We build walls from expanded clay concrete blocks

When the foundation of the house is dry, it can be waterproofed using mastic. Everything is now ready to start building the building box. What is the construction technology? It's pretty simple, here's the step-by-step instructions:

- Since the foundation has shrunk in 30 days, its surface may not always be flat. To eliminate this phenomenon, you can level the surface with mortar. The quality and evenness must be checked by the level.

- When the mortar has hardened, lay on top of 2-3 layers of waterproofing material (roofing felt). Lubricate the layers with mastic.

- Now you can start laying the material. The technology is practically no different from brick laying. You need blocks, mothers, mortar and thread with nails. It all starts with placing corner blocks. If the wall is more than 10 m, then the block is also placed in the middle. Your task is to perfectly align the expanded clay concrete blocks and pull a thread between them for orientation.The evenness of the entire structure will depend on this.

- The thread being pulled should indicate the position of the block. Based on it, you should expose the first row of expanded clay concrete blocks around the perimeter using mortar. Check if you are doing everything smoothly using a level and a plumb line. You can adjust the blocks by tapping a rubber mallet.

- When the first row of sides is ready, proceed to the second. Everything is done identically, only with blocking. The recommended wall thickness of expanded clay concrete blocks is from 40 cm. Do not forget to make doorways and windows.

- After 3 or 4 rows, reinforce the masonry around the perimeter, complementing the row of blocks with reinforcement rods in the grooves.

- The work is carried out until you reach the desired level. The last row is necessarily reinforced, since it will be the main load of the roof of the house made of expanded clay concrete blocks.

That's all, the box of the house made of expanded clay concrete sides is ready. It remains to make the roof. If before that everything was done according to technology, then you will not have any problems.