Is it possible to connect the warm floor to the boiler or not?

When constructing water heating floors, owners of apartments or private houses should:

- make a structure that will warm the air in the room to the required level;

- choose a profitable option in terms of installation and operation, which is inexpensive.

First, we suggest that you find out the structure and principle of operation of a water heated floor and the possibility of combining the system with various devices (radiators, three and two-way valves, etc.)

Gas or electric boilers are used to heat the coolant. More often, gas-fired boilers are mounted in private buildings. Such equipment cannot be installed in apartments with central heating.

In addition, a special permit is required for connection to a common heating system. Therefore, there is a need to find an alternative method - such is the arrangement of an electric boiler.

Boiler - a device for heating water from electricity for domestic purposes. But it should be noted that initially it was not intended to heat the liquid for underfloor heating. Therefore, this will be an additional load for him, as a result of which the water heater may fail.

However, it is still possible to supply the floor from the boiler, but it will not work to heat large areas in this way. This option is ideal only for a bathroom or toilet.

For your information! The correct calculation of the load on the electric heater is important.

Electric boiler

The boiler, powered by electricity, is used much more actively than the type of heating described above. It is also able to evenly heat the room using radiators connected to it.

The positive properties of an electric boiler are as follows:

- there is a possibility to control the temperature level;

- practical equipment with low cost;

- it takes a little time to fully heat the room;

- the period of operation of the electric boiler is not limited.

Types of boilers

Water heater is an electric boiler equipped with a tank in which heated liquid is accumulated. For domestic purposes, constructions up to 100 liters are used, and for industrial purposes up to 300 liters. For the arrangement of underfloor heating, an industrial type is recommended.

By their design, boilers are flow-through and storage.

Flowing

Flow-through - a compact tank with a square shaped tena, which is connected to a cold water supply. When turned on, the water heats up almost immediately. The power of such heaters is 6 - 10 kW, so they put a heavy load on the power grid.

An instantaneous water heater is not suitable for underfloor heating.

Cumulative

A storage heater is a container with two bodies, between which a protective layer of heat-insulating material (polyurethane foam) is placed. Outside body - enamelled steel.

The inside of the flask has a glass enamel coating, the process of its application is spraying, which makes it possible to obtain a smooth surface on which scale does not form. In addition, the enamel does not react to salts present in the water and does not corrode.

Some models have an internal coating not of glass enamel, but of glass porcelain - the surface is of high quality, but cracks may form upon prolonged exposure to high temperatures. However, manufacturers guarantee that the device will work without interruption for at least 10 years.

Another type of coating that is used for boilers is stainless steel with titanium, which can withstand high temperatures. A water heater with such a coating will last for more than one year.

Inside the tank there is a ten (in the form of a tubular heater), it heats the coolant. Ten is placed in a metal tube, this protects it from scale. In addition, the flask contains a magnetic anode - a rod with positively charged particles that neutralize the negative charge.

This helps to reduce corrosion build-up. The rod needs periodic replacement, as it exudes quickly enough. The water heater is equipped with branch pipes through which cold water is supplied and hot water comes out.

For your information! Today, models of electric water heaters with a volume of 250 - 300 liters have appeared on the market, which have been specially developed for use in heating systems. Their difference is in the location, and the size of the cross-section of the supply and return openings.

The standard power of storage models is 1.5 - 3 kW. The device is similar to a thermos, the water heats up and then slowly cools down, thereby maintaining a high temperature for a long time.

In addition, these types have a thermostat, which allows you to set the heating temperature required for underfloor heating. And when the required temperature level is reached, the boiler is automatically turned off, this contributes to the rational consumption of electricity.

In shape, boilers are horizontal and vertical. The vertical construction is recommended for the arrangement of underfloor heating.

It's important to know! To heat 15 liters of water to 60 degrees, you will need ten with a power of 1 kW, the heating time is 1 hour. A 100 liter tank will reach this level in 3 hours, with a power of 3 kW.

Principle of operation

Electric wall-mounted heating convectors with thermostat

By its structure, the heating element for heating has the form of a metal tube. A wire made of a special heat-resistant material is laid inside this tube. At the ends of this tube there are fastening clamps, thanks to which the spiral receives energy.

The cast iron heating elements have the possibility of thermoregulation and protection.

So that the spiral and the outer coating of the tube do not touch, they are isolated from each other using a special filler, which is also resistant to high temperatures.

The safety of the structure is guaranteed by a durable case that protects the heating element from external influences. Due to the durable case, the mechanism becomes absolutely safe, but do not immediately forget about the rules of operation. For a long service life, safety technology requires strict adherence to all regulations.

In addition to the above-described principle of operation, heating elements are often integrated into the system of gas boilers. The connection of two different devices saves a certain amount of money on heating equipment. It should also be noted that certain limits on additional equipment are not exceeded.

Teng for integration into the system of gas boilers

The principle of operation of the water heater

The principle of operation of an electric boiler is mixing cold and hot heat carrier. Heated water rises to the top, and cold water is at the bottom, where it is heated.

The work process of the water heater is as follows:

- The storage tank is filled with water through a special pipe. The inlet is equipped with a safety valve, it retains the liquid and does not allow it to flow back.

- The required temperature indicator is set on the thermostat, but not more than 80 degrees.

- The ten turns on automatically and the water starts heating.

- Hot liquid rises up, and it is released through the intake pipe located on top of the tank.

- The coolant moves along the intake pipe into the floor pipeline.

Which boiler to choose?

For the construction of warm water floors, the model of a flow-through electric boiler is practically not suitable. The main disadvantage is the significant power consumption.

The only suitable option for underfloor heating is a storage water heater. When choosing the type of shade, attention should be paid to the power of the equipment, it depends on how intensively and quickly the heating medium is heated, as well as its volume.

For your information! Devices with a power of 6 - 10 kW are specially designed for installation in combination with heating systems. Their main disadvantage is the high consumption of electricity.

When calculating the power of an electrical appliance, one should proceed from the fact that a water heater with a capacity of 1 kW is required to heat an area of 10 square meters, therefore a household boiler model for underfloor heating is not suitable. It can only be used for small spaces - bath or toilet.

The second point that you need to pay attention to when buying is the volume of the tank. The greater the amount of hot coolant obtained, the less often the water heater will be periodically turned on in order to save the resource.

Features of the design of a warm floor connected to a boiler

When designing an underfloor heating system from a boiler, it is necessary to take into account:

- the size of the pipeline and the number of branches, the longer the circuit, the slower the circulation of the liquid;

- power of the heating element - if the size of the lower threshold of the heated room corresponds to the power of the boiler, then after a while the efficiency of heating the coolant may decrease, the way out is to buy a heater with a power reserve of 20%.

In addition, the system requires constant maintenance - periodic descaling of the storage tank and shade. This procedure will help keep the underfloor heating pipes in good condition and increase their service life.

It is recommended to connect the boiler in a bath or room that is located near the heated room.

And to increase the performance of the device, the structure must be equipped with a circulation pump.

Observing all of the above points, you can build a hydro-floor, which is able to provide heating to your apartment.

Using a water heater

When installing a warm water floor, the landlord needs to solve two problems:

- get a working structure that heats the air in the room to a comfortable temperature;

- choose an economically viable option at the manufacturing stage and during operation.

For underfloor heating, electric or gas boilers are used, which ensure the operation of autonomous heating in the apartment. However, in cases where the apartment is connected to central heating, this will not work. It is forbidden to connect other consumers to the system, except for the installed radiators.

Storage water heater

In this situation, you have to look for alternative sources, and one of them is an electric boiler. Of course, this device is not designed for such use, and the TP circuit will become an additional load on it. And this can lead to failure of the drive. Nevertheless, the creation of such a structure is allowed.

It is important to correctly calculate the loads here - it will not work to heat large areas with a boiler. But for TP, arranged in the bathroom or in the kitchen, this source is enough.

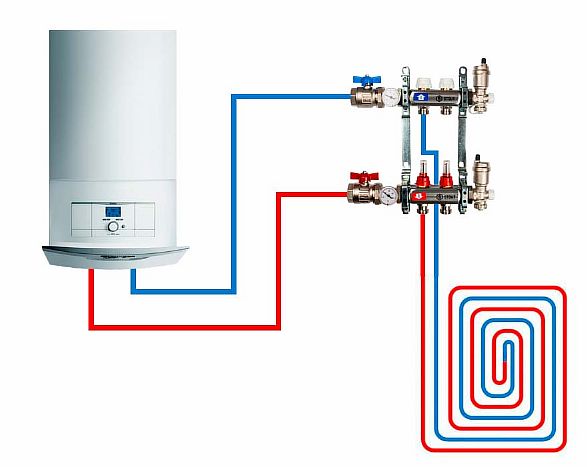

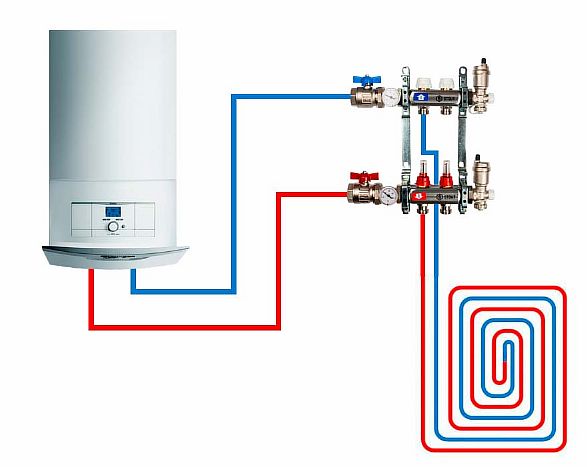

Wiring diagrams for underfloor heating and boiler

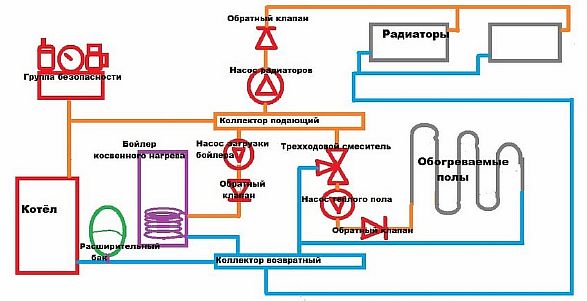

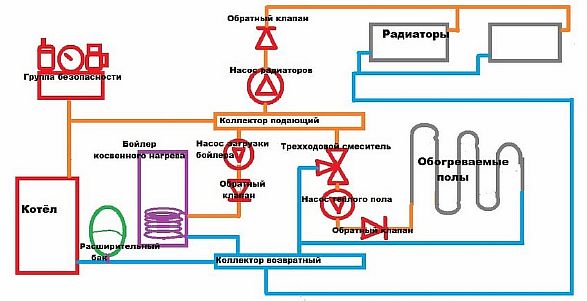

There are several schemes on how to connect a warm floor to an indirect water heater. Let's consider the simplest ones:

- With the help of a three-way valve - the essence lies in the interaction of two circuits: a warm floor and a water heater.This valve distributes the coolant between them. It is controlled automatically by a thermostat on the heater. Such a system contributes to the rapid heating of water in the boiler, while it is possible to completely turn off the DHW supply to the floor branches. And when the set temperature is reached, the valve is triggered and the flow is resumed. This method of strapping is suitable for constant use of the boiler.

- With two circulation forced pumps - this option is recommended for non-constant, seasonal use of the device. One is placed on the supply pipe in front of the water heater, and the other on the floor contour.

A thermal relay is used to power the circulation pump, therefore it functions only when the temperature drops below normal. Heating is accelerated and forced circulation is activated. In this scheme, there is no three-way valve, and the connection is made using tees.

- Using a hydraulic switch - this method is recommended for boilers with a volume of 200 liters or more, and with several heating branches. The hydraulic distributor system makes the layout simpler and there is no need to install pumps on each floor contour. The hydraulic arrow provides equal coolant pressure in all loops. However, it is difficult to do the strapping with your own hands in this way, without experience.

Gas boiler connection

To carry out the correct connection of the water heated floor for the boiler, you should choose an autonomous room. The arrangement of such a system in a standard apartment will require expert advice.

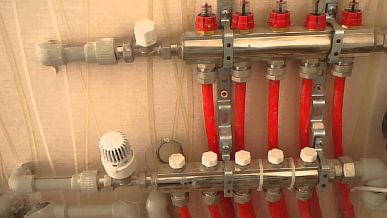

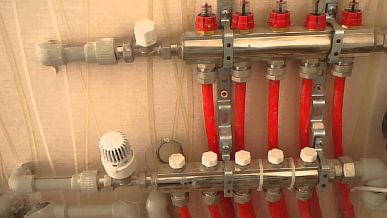

The installation algorithm includes a number of stages, taking into account the correct connection of the water collector for the underfloor heating, which serves as a guarantee of further flawless operation.

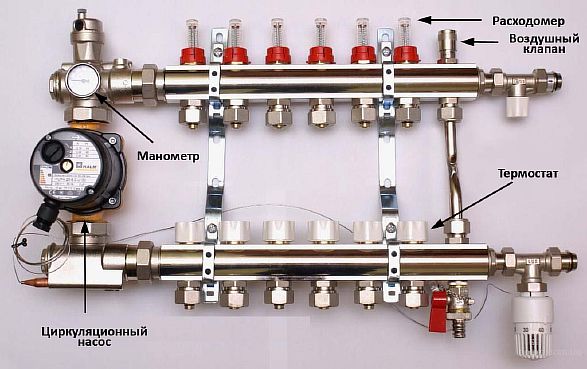

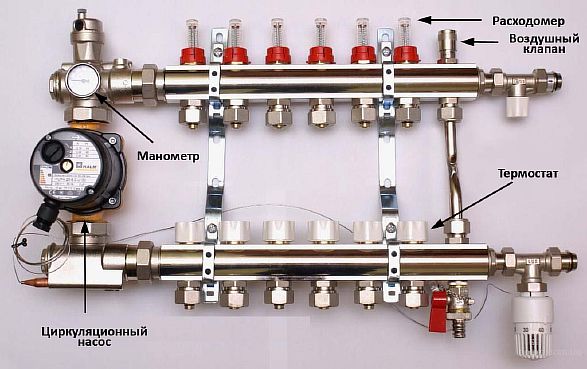

- Installation of a collector in a selected place, which serves for the important function of maintaining the water cycle in the heated floor system, as well as for combining, if necessary, with existing heating sources.

- Placement of a return pipe in the cabinet, which serves to direct the cooled heat carrier back to the boiler, and a pipe that supplies heated water directly to the system. They are equipped with a shut-off valve that allows the water to be shut off in an emergency.

- Connection to a metal valve through the compression fitting of the pipe leaving the gas boiler. The collector input is then connected to it. With the help of fittings, the contours of the heated floor are subsequently connected.

- To ensure uninterrupted circulation of liquid, a pump is mounted on the supply pipe. The most rational for flawless functioning is its version with a thermostat.

- Test run of the system.

Construction and connection of underfloor heating to the boiler

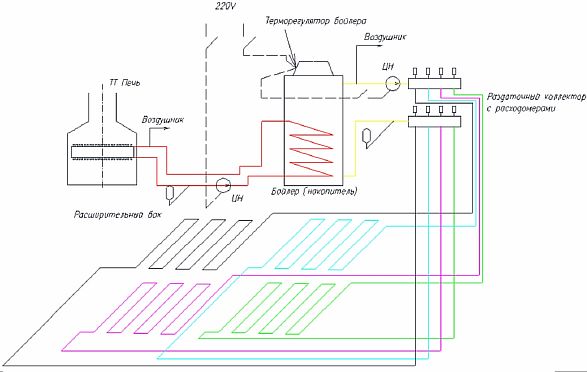

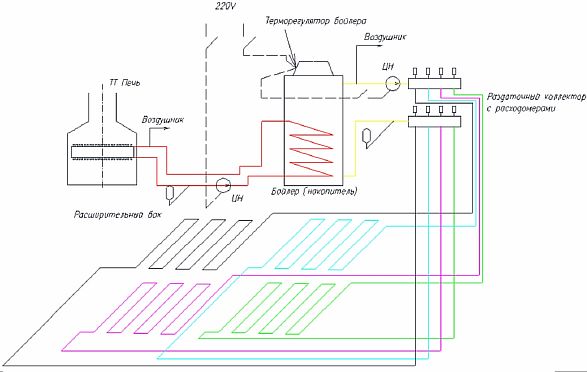

For clarity, we will consider how to make a warm floor from a water heater, using the example of using a 3 kW tena for heating an area of 30 m2, with the installation of a three-way valve.

We need a recirculation boiler with outlets to connect hoses for hot and cold water supply. The recommended diameter of the nozzles is 2.6 centimeters. In addition, you should stock up on the tools that you will need in your work so as not to be distracted during the installation process.

The sequence of construction of hydraulic floors from a water heater is as follows:

- Preparation of the rough base - it should be leveled and cleaned of debris.

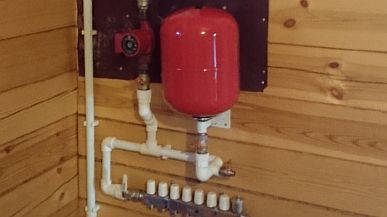

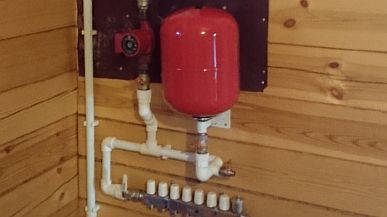

- Installation of the manifold assembly - it must be fixed on the wall, or mounted in a specially equipped metal box.

- Bonding the room around the perimeter with a damper tape - this will help preserve the integrity of the concrete screed.

- Hydro and thermal insulation - polyethylene film can be used as a waterproofing material.The choice of thermal insulation material is huge, from regular foam to expanded polystyrene mat with lugs.

- Installation of the water circuit - it can be pipes made of copper, polyethylene or heat-resistant plastic. Heating elements are laid according to a planned scheme and with a set step. The pipes can be fastened to the reinforcing mesh, which is laid on the thermal insulation, with plastic clamps, or fixed between the grooves of the polystyrene plates.

- The connection of the circuit to the distribution manifold is one end to the cold tap and the other to the hot one.

- The connection of the boiler to the distribution unit is carried out using metal pipes.

- Installation of a three-way valve with a thermal head on the manifold - to regulate the temperature level of a warm water floor.

- Connecting the circulation pump to the underfloor heating - it provides the flow and the required pressure of water in the floor pipeline.

- Installation of an expansion tank - it is necessary to remove excess water from the heating system. It should be mounted on a cold metal pipe near the outlet to the boiler. And in front of it you need to equip a tube for air outlet.

- System performance check - to identify possible leaks and malfunctions. Pressure testing is carried out within 24 hours under operating pressure.

- Pouring the screed - the floor contour is poured with concrete. The procedure is done when there is pressure in the pipes. The concrete layer must be allowed to dry well, this will take about a month.

- Laying the topcoat - it is laid only on a completely dried out concrete base.

It is possible to turn on the water system only when the screed, as well as the tile adhesive, if ceramic tiles were used as the flooring, are dry. Raise the temperature to working condition gradually, over several days.

The principle of operation of this scheme is to heat the water in the tank, then it is brought out through the collector into the floor circuit. The spent heat carrier is returned through the distribution unit to the return pipeline.

If the water temperature exceeds the required level, the three-way valve automatically shuts off the hot water supply and opens the cold water supply. The mixing process is carried out in a special chamber. When the coolant reaches the desired degree of heating, the thermal head closes the flow of cold water.

The heater and manifold are equipped with separate automatic temperature control devices. The device on the collector is responsible for the coolant in the floor line, and in the shade - for the water heating level.

It is possible to equip a warm floor from a boiler both in the house and in the apartment. Installation is not difficult, the main thing is to follow the technological process and instructions. In addition, the low cost of the installation plays an important role, because a water heater costs less than an electric boiler.

However, it should be noted that the operation of such a heating system is accompanied by a large consumption of electricity. Therefore, it is up to you to decide how to heat your house - with an ordinary radiator or underfloor heating from a boiler.

Warm floor under the tiles - heating mat.

19.01.2019

What is a heating mat?

A thin heating cable located and fixed on a 50 cm wide nylon mesh or woven into a fabric mesh with a pitch of 6 to 12 cm is called a heating mat. Designed for the installation of an electric floor heating system directly into the adhesive layer under ceramic tiles, marble, natural granite or basalt. it is these materials that have excellent heat transfer, resistance to sufficiently strong mechanical stress, insensitivity to temperature extremes.

How to choose a heating mat?

It is mainly used for additional (auxiliary) heating of premises, if the room is well insulated, it can be used for main heating, while the power of the mat should be at least 150 W / m2. There are two types of heating mats: single-core (with two-way connection to the thermostat) and two-core (with one-way connection). Single-core mats are used in non-residential premises or outdoor areas, while two-core mats have no restrictions in arranging a warm floor in residential premises, and this should be known when choosing a heating mat, in addition, in both cases, a protective reflective screen must be provided.

The reliability and performance of the heating mat.

Different manufacturers give a guarantee for their product from 10 years to a lifetime, we agree that the reliability of the heating mat largely depends on the manufacturer, but first of all, it depends on the heating core itself and the insulation in which it is enclosed. We keep in stock and offer our customers only two-core heating mats in Teflon (polytetrafluoroethylene) insulation. Also, the main factors in the durability and performance of the heating mat is the correct choice of the area of the mat, its installation and installation.

The main mistakes and recommendations for the installation of cable underfloor heating.

1. The main task is to select a heating mat of the required length

from the calculation of the heated area (taking into account the ability to cut the mesh and lay out surfaces of different configurations), because it is forbidden to reduce the length of the mat by cutting the heating cable or laying it under stationary furniture without legs less than 10 cm, household appliances, a bathroom, etc.

2. It is forbidden to use a substrate directly under the heating mat (it should not be confused with a heating cable in a coil, which fits into the screed at least 3 cm, and forget about connecting the tile to the base). If the heat loss is large, and it was not possible to insulate the floor before the screed was poured and you decided to install thermal insulation under the mats, namely foamed polyethylene foam (in this case, we used a cork backing in rolls), leave the areas free from the backing (you can even cut the backing squares 50x50 cm and lay them, leaving gaps of 5-7 cm). This method will allow the adhesive to firmly adhere to the subfloor and firmly press the cable to the subfloor.

3. When laying out the mat, do not allow the heating cable to come close to each other, that is, the strips of the mat mesh laid out on the floor should be at the same distance as the cable laying spacing on the mat mesh. The distance of the mat to the walls should be at least 10 cm, and to the battery or heating household appliances at least 20 cm. Also, the mat's coupling must lie on the floor (if necessary, make a depression in the screed).

4. For correct operation of underfloor heating, it is necessary to lay the floor temperature sensor in a corrugated tube with a plug between the turns of the heating cable of the mat without crossing it.

5. Already at the unfolded mat, before puttying (pouring) the mixture, it is necessary to check the resistance of the heating cable or connect the voltage for a short time and check its operability. Use soft shoes when doing work.

6. Make sure that the thickness of the adhesive pad is the same over the entire floor area, does not contain air bubbles and completely covers the heating cable, use special mixtures for heated surfaces.

7. When laying tiles, technological seams of 2-4 mm should be left, since when heated, excessive linear expansion of the material is possible, and if the area of the mat occupies more than 60% of the total area of the room, then a damper tape must be laid around the perimeter of the room.

8. Leave the mounted surface to harden. Grouting of tile joints should be done no earlier than a day after the completion of installation work.Operation of "warm floor" is possible after complete drying of the final mixture - depending on the glue, this process takes from 14 to 30 days.

Electric underfloor heating is simple, reliable and comfortable.

In this article, we have tried to briefly outline the basic principles and requirements for the reliable and durable operation of an electric heating mat, but this is our experience and our recommendations.

Also read: “Heating Mat Installation Instructions”.