Having made the decision to improve your home, you probably have already considered the question of how to lay a polypropylene water supply system with your own hands. Due to the low performance characteristics, metal pipes at the present stage of technology development are considered to be an atavism. At the same time, even a beginner can assemble a system using polypropylene products. The main thing is to carry out the work strictly according to the technology, and then the water supply system will serve for about 50 years.

You can assemble a water supply system from polypropylene pipes both in a city apartment and in the country.

Benefits of PP communications

Before proceeding with the installation, it is necessary to prepare a project and purchase material. And here the question arises - which is better for a water supply system, metal-plastic or polypropylene? Experts have not come to a consensus, so it would be useful to know the arguments in favor of each option. Comparative characteristics of both types of pipe products are presented in the table below.

Table 1

| Parameter | Metal-plastic | Polypropylene |

| Cold water supply system. Service life, years | More than 50 | 50 |

| Hot water supply system. Service life, years | 50 | 25 |

| Maximum temperature | + 110˚С | + 95˚С |

| Working temperature | + 95˚С | + 75˚С |

| Working pressure, atmospheres | 10 | 10 |

As you can see, metal-plastic products are more preferable in terms of technical characteristics. However, it should be noted that for domestic use, the properties of polypropylene pipes are quite sufficient, therefore, you should not be afraid of their premature breakdown and damage.

At the same time, they have the following obvious advantages:

- low cost. Arrangement of a water supply system in an apartment with your own hands made of polypropylene will cost you 25-40 percent less than if metal-plastic pipes were used;

- it has already been said above that the installation of pipes made of this polymer requires significantly less labor. So if voluminous work is performed for the first time, then when choosing between polypropylene and metal-plastic, preference should be given to the first option.

Polypropylene pipes in terms of technical characteristics are not inferior to other types of polymer products

In conclusion

Polypropylene pipes are deservedly considered almost the best choice for organizing a water supply and a heating system. Cheapness, high durability and ease of installation allow them to gradually oust competitors from the market in the face of steel or copper pipelines.

The information presented in the article will help you navigate when choosing a pipe for a specific task. The video in this article describes in detail the main types of PP pipes.

Did you like the article? Subscribe to our Yandex.Zen channel

Water supply system design

Installation of a water supply system from polypropylene pipes in an apartment will not cause any complaints, provided that a wiring diagram has been correctly drawn up, containing the requirements for connections and fasteners of structural elements. This approach involves minimizing the length of the pipeline and the absence of unnecessary bends and unnecessary details in the project.

Advice! To get the most accurate idea of the final product, namely, to find out the number of bevels and bends, the intersection of pipes, outline the laying scheme directly on the walls with a pencil.

Polypropylene "hot" and "cold" water supply can be realized in two ways: open or closed. The second, despite the fact that it is more complicated, is used more often.Here you cannot do without accurate calculation and professional execution. Most of the piping must be made without joints. Welding does not reduce the reliability of the entire system, but it is still better to leave the joints open. So you can regularly inspect your water supply system and carry out preventive work with it without difficulties.

Open wiring is another matter entirely. Choosing this option also allows you to make the pipes less "noticeable". This is achieved by laying them along the floor level in horizontal planes, and in the corners of the premises, the pipes are already placed vertically.

Open wiring has the following advantages:

- ease of installation;

- ease of maintenance;

- the ability to quickly replace part of the system in the event of a leak.

It should be noted that the wiring of polypropylene pipes in the bathroom and in the kitchen can be carried out in both open and closed ways. This is another plus in favor of tubular products made from this polymer.

Laying the system in a closed way is more laborious: it is necessary to make grooves and carefully seal the pipe joints

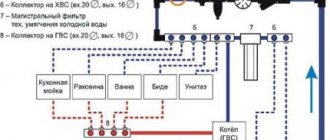

Manifold distribution system

Such a system is also called parallel and provides for the presence of a collector, which has a single input and several outputs. The number of the latter should be equal to the number of consumption points. Each individual draw-off must be connected to an individual outlet. Before you make a do-it-yourself plumbing from polypropylene, you must take into account all the advantages of the described wiring system. Among them, one can single out the absence of the need for system failure in the event of a breakdown of a separate plumbing fixture. Water will be evenly distributed to all points, this indicates that at the time of pressure drops, all devices will receive an equivalent volume of liquid. All control devices of the system are concentrated in one place, namely in the manifold cabinet. This indicates the possibility of installing metering devices at the outputs to ensure a certain pressure in a specific device.

If you will equip a polypropylene water supply system with your own hands in the country, the schemes will need to be prepared in advance. After all, you have to decide which of the types of wiring will be chosen. A significant number of streaks can be identified as the disadvantages of the collector system, which leads to a higher cost of the entire structure. Home craftsmen note the laboriousness of installation work.

Materials and tools. Getting Started

Having developed a scheme and making a drawing, you can go to a building materials store to buy the necessary tools.

- the first step is to purchase a soldering iron for working with plastic. Plumbers call it an iron. If you do not plan to constantly install water pipes, you can buy a cheap similar device, since you will not need an expensive soldering iron with a long warranty;

- polypropylene pipes will need to be cut. Special scissors are used for this. They are inexpensive. However, this operation is also allowed with a hacksaw for metal;

- corners, tees and other fittings that function as connecting elements are also purchased. They are made from the same polymer as the pipes themselves. But their diameter differs upwards, and it is recommended to purchase them with a small margin.;

- in addition, you will need a building level, a square, a measuring tape, an adjustable wrench, a marker and a rag. Don't forget about gloves too. They will prevent you from getting thermal burns while servicing the nozzles.

Before installing a new pipeline, you will need to dismantle the old one. To do this, close the main riser in the apartment. Then carefully remove the pipes.For convenience, they can be cut in suitable places. Unnecessary destruction must be avoided. Otherwise, you will be forced to deal with the restoration of the floor and walls.

Before starting work, you should prepare the pipe, fittings for it and simple tools

If you need to replace all the water supply lines in the apartment, you will have to contact the housing office, because without blocking the riser in the entire entrance, this procedure will not work. Moreover, in order not to have trouble with neighbors, they should be warned about the impending lack of water.

Preparatory stage for the installation of polypropylene pipes

At the initial stage, the question arises, where to start the installation of polypropylene pipes. Experts recommend that you first draw up a plan-diagram of the future water supply system, indicating all consumers. The most optimal location for all plumbing and household appliances should be determined.

Immediately you need to decide on the type of wiring, which is of 2 types:

- consistent;

- collector.

The first type of wiring provides for the serial connection of all water consumers. The advantage of this technology is the use of a minimum number of pipes and accessories. The disadvantage is the different water pressure (the farther from the starting point of the water supply, the worse the pressure).

With collector wiring, a distribution unit is installed that distributes water flows and directs water to a specific point of water intake. The advantage of this method is the same pressure in the entire water supply system, the disadvantage is the creation of a separate branch for each consumer (this will increase the amount of consumables).

At the initial stage, the method of pipe laying is selected. It can be either hidden or open. Naturally, the first option is more aesthetic. The purchase of pipes and accessories is carried out with a small margin.

When designing, it is necessary to shorten the length of the new water supply system as much as possible and make the number of turns and joints as small as possible. This is due to the fact that it is in these places that there is a high probability of leakage. Moreover, the presence of a large number of turns leads to a decrease in the pressure in the water supply system.

Installation features

First, pipes are selected for the assembly of water supply circuits of both types - hot and cold.

On a note! To make the right choice, you need to know the labeling of such products. For most manufacturers, it is universal.

- on polypropylene pipes for cold water there is the following sequence of symbols: PN10;

- for the organization of cold and hot water supply, universal pipe products are used, marked as follows: PN16. They do not cost much more, therefore, in this case, only such pipes should be purchased;

- if an autonomous boiler room is installed in the house, and you use very hot water, purchase PN20 products with internal high-quality reinforcement.

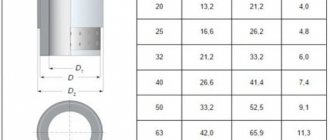

The following restrictions are imposed on the diameters of polypropylene water pipes:

- a compact pipeline with a circuit length of less than 10 meters, can be created from pipes with a diameter of 20 millimeters;

- when the total length of the contours does not exceed 30 meters, the minimum diameter should be 25 millimeters;

- contours longer than 30 meters are created from polypropylene pipe products with a diameter of 32 mm. The same cross-section should have the risers for supplying cold and hot water.

The diameter of the pipes is selected depending on the type of water supply and its length - the longer the circuit, the thicker the pipe should be

The wiring of polypropylene pipes itself can be performed in two ways:

- parallel - assumes the presence of a collector with several outputs. Each of them is connected to a separate circuit for a specific consumer. This option provides the ability to evenly distribute the pressure within the water supply system. At the same time, the implementation of such a scheme will require more financial costs. However, despite this, experts recommend making a choice in favor of this particular option;

- sequential - a horizontal branch is laid from the riser or main line, followed by cutting tees into it. From these fittings, pipes are supplied to consumers. The cost of such a design is significantly lower than the previous one, but if several taps are turned on at the same time, the head will noticeably decrease.

Installation work on laying polypropylene pipes

The laying of the water supply line begins from the places where consumers will be connected. In these places, threaded adapters and ball valves are mounted to disconnect the plumbing from the general system in case of repair work.

Depending on the type of wiring, pipes are drawn from consumers to the collector or the next consumer. When performing installation work, the distance between the pipe and the wall must exceed 2 cm. The screw-in step of the clamps is 1-1.5 m (in addition, the clamps are attached in every corner and at bends).

Particular attention is paid to laying the pipeline through walls and partitions. The pipe must be placed in a special glass, which acts as a protective barrier against mechanical stress. It is recommended that a minimum number of pipes pass through the wall (preferably one). If there are drain taps, the pipes are installed with a slight slope towards them.

Each branch of pipes is connected to a manifold with the obligatory installation of shut-off elements. Then everything is collected in one system.

An autonomous water supply system consists of such elements;

- the starting point of the tie-in is a well, well or other source of water intake;

- water meters;

- a water supply line in a trench on the street (in the northern regions it is recommended to insulate it);

- pipe entrance to a private house;

- coarse filter (mounted on the inside of the house);

- additional filters in front of plumbing and household appliances (if necessary, but always in front of the washing machine and mixer in the kitchen).

To transport warm water to the kitchen, a tee is mounted after the filter, which is designed to distribute water along two branches: hot and cold. The pipe through which cold water flows is connected to "its" collector. The hot water branch must be connected to the boiler.

Formation of pipe connections

This procedure has no difficulties. However, ignorance of how to make a do-it-yourself plumbing from polypropylene will not allow you to create a reliable structure. Installation involves the following actions:

- First, the section of the pipeline to be laid is cut off. To do this, you can use an ordinary plastic saw, but it is better to perform this operation using a special pipe cutter.

- To get a stronger connection, it is necessary to clean the pipe (its edges) from burrs.

- Then fittings are selected. All elbows, elbows, couplings, adapters should be purchased in advance.

- Then a soldering iron for pipes is taken, a pair of nozzles with a cross-section corresponding to the diameter of the fitting and pipes are inserted into it, which will be put on these nozzles.

- Next, the parts to be joined are put on the above nozzles, and after that the soldering iron is turned on. The degree and time of heating are quantities derived from the power of the device and the pipe walls.

- After the heating is completed, the parts are removed from the nozzles, and the pipe is pushed into the fitting without rotation.

- The compound is kept for 30 ... 40 seconds, after which it must be allowed to cool down.The process of complete polymerization of polypropylene lasts no more than an hour, so soon it will be possible to check the correctness of the installation of the water supply system from polypropylene pipes, primarily for the tightness of the connections.

Installation of polypropylene pipes is carried out by welding, for this you need to have a special apparatus

Advice! To eliminate errors, you need to focus on the table that comes with the soldering iron.

Varieties of wiring for water supply

Do-it-yourself plumbing in a house made of polypropylene can be installed on the basis of sequential wiring. It is also called a tee system and provides for the sequential connection of the pipeline from the main line to the points of water consumption. Two pipes should extend from the riser with an inlet shut-off device, one of which is for hot, while the other is for cold water. From them, using tees, bends are organized to all points of consumption. The main advantage of this technology is efficiency, because the minimum amount of materials will be used, in addition, the master will be able to complete the work without any problems.

Among the shortcomings, one can single out the dependence of plumbing devices on each other. This indicates that if you need to turn off one device, you will have to shut down the system. This negative factor can be neutralized by installing valves on separate branches. Among other things, pressure drops may occur when several water points are operated at the same time. The tee acts as a fairly voluminous unit, so it is not always possible to find a place for it in the bathroom. If you decide to equip a polypropylene plumbing with your own hands in the country, then you should choose exactly the sequential wiring, since this option is the most economical and will require the least amount of material.

Features of a polypropylene water supply system in the country

The problem of water supply to the dacha worries many owners of suburban real estate - lovers of gardening. After all, then it will be very difficult to organize a full-fledged watering of the personal plot, without which one can only dream of a harvest. And the implementation of an alternative option - to carry water from a well or a nearby pond, will require excessive physical costs. The most effective and realistic way out is to equip a summer water supply system at a country cottage from polypropylene pipes.

But before that, you need to decide on its location. The conduit can be of two types:

Permanent water supply. It is laid underground and, as the name suggests, does not provide for dismantling, at least until it fails. Subject to certain rules, it will be possible to use it not only in summer, but also in winter. We are talking about the implementation of methods that prevent water from freezing in the pipeline in severe frost. One of them is laying a water conduit at a depth below the freezing mark. If this is not possible, the pipes will have to be insulated. However, since the question of how to install a summer water supply system from polypropylene pipes in a summer cottage is now being considered, it will be useful to know some of the features of a permanent option.

The system is laid between trees in places of lawns at a depth of 25-30 cm. Areas passing under the beds, in order to prevent them from being damaged during digging, should be deepened by 40-45 centimeters or even more. To prevent the pipes from breaking during the winter cold, in the fall, when the irrigation season is over, the water must be drained from the system. If the slope has not been created, this can be done by blowing out with a compressor.

The plumbing system, which will be used all year round, must be laid underground, in specially dug trenches

Collapsible system. A water conduit of this type is laid on the soil surface.The advantages of this option include:

- quick installation and ease of connection to various water sources;

- all leaks that occur immediately become noticeable;

- requires a minimum of maintenance.

However, before the onset of cold weather, such a structure is recommended to be disassembled and removed from the site. Otherwise, in winter, its elements can simply be stolen.

Good to know! To create a summer water supply system, experts recommend using polypropylene pipes of the PN10 or PN16 brands.

Sequence of installation steps

Installation of a summer water supply system involves the following activities:

- drawing up a detailed network diagram with mandatory binding to the site plan. On it, not only the equipment (sprinkler heads, taps, etc.) should be marked, but also all, without exception, the details of the pipeline - plugs, tees, corners, etc. The main wiring is usually done using a pipe with a diameter of 40 millimeters. Polypropylene pipe products with a diameter of 25 or 32 millimeters are used for taps to the water intake points. The diagram should indicate the depth of the trenches. The value of this parameter is on average 30-40, and under the beds 50-70 centimeters. It is also necessary to consider the method of drainage of the system. Usually pipes are laid with a slope to the water source, and if such is the central water supply, then in the direction of the tie-in into it. There must be a drain valve at the lowest point. The location and number of water taps are calculated taking into account that short sections of hoses, the length of which does not exceed 5 meters, could be used to irrigate the entire backyard plot. If the system is installed on a standard area of 6 acres, there can be up to 10 water intake points;

- after the development of the summer water supply scheme, a specification is drawn up. The purchase of equipment and materials is made on its basis;

- if the country water supply is supposed to be connected to a centralized network, then it will be necessary to make a tie-in. The simplest method, which, moreover, does not require turning off the water, is performed using a special part - a saddle. It is a clamp with a threaded branch pipe and a seal. First, this part is installed on the pipe. Then a ball valve is screwed onto its branch pipe, and then a hole is made right through it in the pipe wall. After that, the tap closes immediately;

- the next stage is the preparation of trenches for pipe laying;

- then the system is assembled. That is, pipelines are connected to taps and other components through fittings;

- upon completion of the assembly, the finished water supply system is tested for tightness. For this, water is supplied to it and the state of the compounds is observed for some time;

- if leaks do not appear, trenches with water supply are buried.

To connect pipes, fittings of the same material as the pipes are used, they can be welded or glued

Technical parameters of pipes

Propylene pipes for water supply are connected by diffusion welding using fittings. Polypropylene plumbing, if properly used, can last about 50 years. In this case, the temperature of the liquid should not exceed 95 ° C. The service life of cold water pipes is almost 2 times longer.

Polypropylene water pipes are produced in 4 modifications.

- Pipe designed for use in cold water supply only. Nominal operating conditions: temperature not higher than +20 С; pressure - 1 MPa (10 atm). Marking - PN 10.

- A version of the pipe that allows the supply of cold and hot water. Operating mode: temperature - up to +60 C at an operating pressure of 1.6 MPa (16 atm). The accepted designation is PN 16.

- A product designed for the transportation of hot water and the installation of heating systems.Nominal parameters: temperature regime - up to +80 С; fluid pressure - 2 MPa (20 atmospheres). Pipe brand PN 20.

- Pipe reinforced with aluminum foil. The main areas of application are hot water supply and central heating. Technical operating conditions: temperature up to +95 С; the maximum allowable pressure in the pipe is 2.5 MPa (25 atm).

It should be remembered: the hot water supply system can only be installed from reinforced polypropylene pipes. There are various methods of reinforcement, in particular, with fiberglass, aluminum.

The diameter of the plastic pipes for the water supply system is selected taking into account the total length of the line. If the length is less than 10 m, pipes with a diameter of 20 mm are allowed. With a length of 10 to 30 m, pipes with a diameter of 25 mm can be used. For lengths over 30 m, 32 mm pipes are recommended. Risers are made from such pipes.

When assembling a polypropylene plumbing with your own hands, consider the following fact. The fact is that under the influence of heating, polypropylene pipes are slightly lengthened. Therefore, you need to leave a little free space for their normal elongation. Otherwise, severe deformations may occur in the line.

Devices and devices

To make summer cottage water supply systems more practical, the following devices are used:

- fitting. With it, the connection of the hose to the tap is very quick. On the one hand, it has a "ruff", which is simply inserted into the tap, and on the other, a spring grip;

- corrugated hoses. When folded, very little storage space is required;

- special accessories for the organization of drip irrigation;

- watering guns and sprayers equipped with special couplings such as aquastop.

- hoses, as well as special accessories for the organization of drip irrigation;

- watering and sprinkling heads;

- soil moisture sensors or timers. With their use, watering is carried out in automatic mode.

Good to know! When the sprinkler is replaced, these fixtures automatically shut off the water (without having to close the tap).

And in conclusion, one important piece of advice. Professionals recommend installing the line in the direction from consumers to the points of water intake.

The advantages of polypropylene

First of all, its comprehensive use is due to its physicochemical properties: low thermal conductivity and coefficient of volumetric expansion, lightness, density, lack of porosity in the structure.

Polypropylene has the following positive qualities:

- wear resistance;

- impermeability to vapor and gaseous substances;

- high rate of chemical resistance;

- electrical insulating capabilities;

- hygiene.