Classification of one-pipe heating systems

In this type of heating, there is no separation into return and supply pipelines, since the coolant after leaving the boiler goes through one ring, after which it returns to the boiler again. Radiators in this case have a sequential arrangement. In each of these radiators, the coolant enters in turn, first into the first, then into the second, and so on. However, the temperature of the coolant will decrease, and the last heater in the system will have a temperature lower than the first.

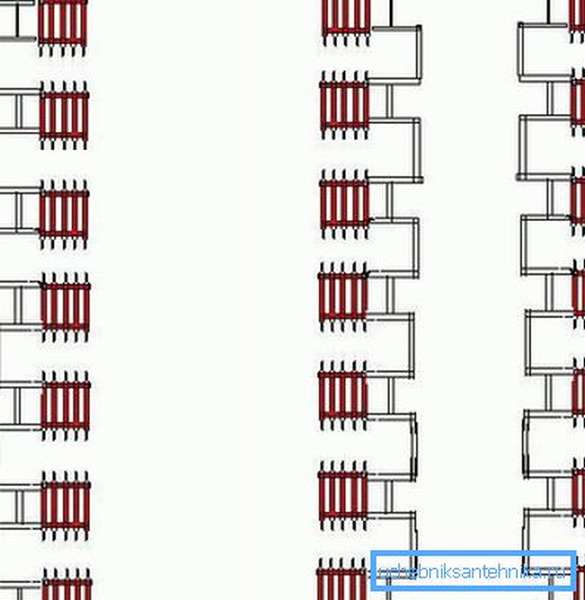

The classification of one-pipe heating systems looks like this, each of the types has its own schemes:

- closed heating systems that do not communicate with air. They differ in excess pressure, the air can only be released manually by means of special valves or automatic air valves. Such heating systems can work with circular pumps. Such heating can also have a bottom wiring and a corresponding circuit;

- open heating systems that communicate with the atmosphere using an expansion tank to dump excess air. In this case, the ring with the coolant should be placed above the level of the heating devices, otherwise air will collect in them and the water circulation will be disrupted;

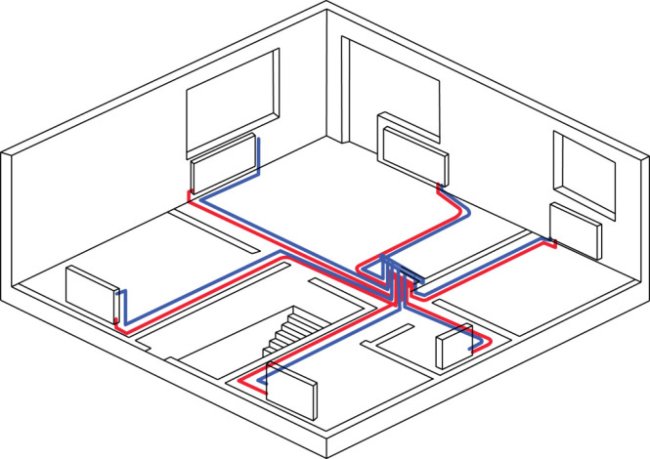

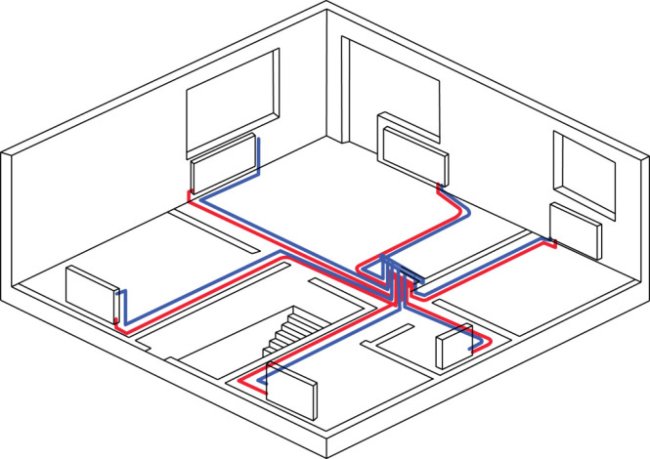

- horizontal - in such systems, the coolant pipes are placed horizontally. This is great for private one-story houses or apartments where there is an autonomous heating system. A single-pipe type of heating with lower wiring and the corresponding scheme is the best option;

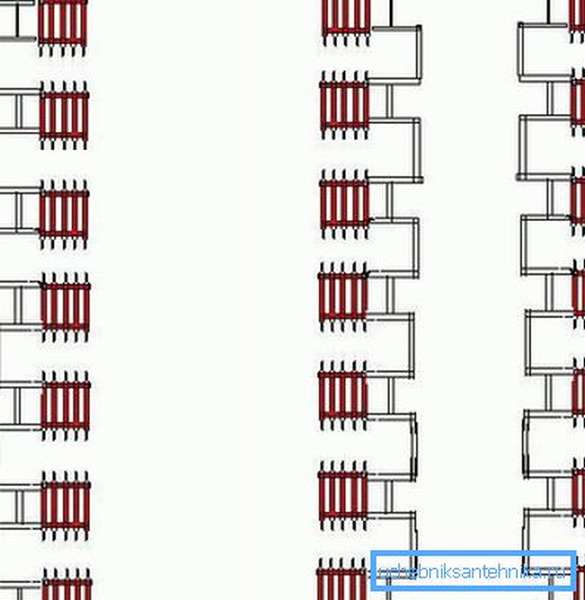

- vertical - coolant pipes in this case are placed in a vertical plane. This heating system is best suited for private residential buildings with two to four floors.

Bottom and horizontal system wiring and its diagrams

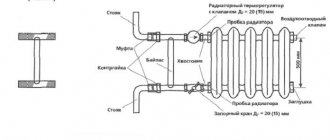

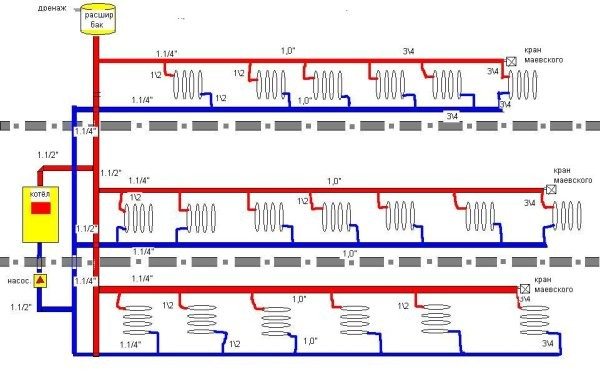

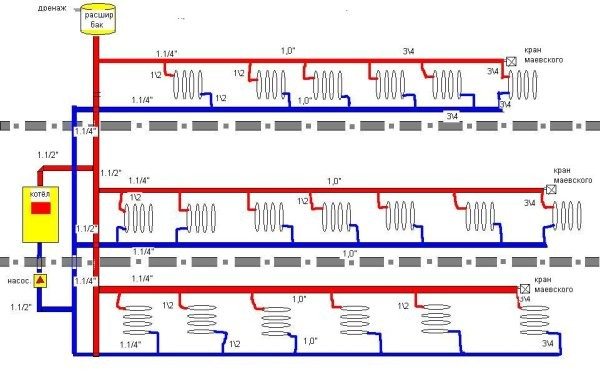

The circulation of the coolant in the horizontal pipe laying scheme is provided by a pump. And the supply pipes are located above or below the floor. The horizontal line with the lower wiring should be laid with a slight slope from the boiler, while the radiators should be placed all at the same level.

In houses with two floors, such a wiring diagram has two risers - supply and return, while the vertical scheme allows a greater number of them. During forced circulation of the heating agent using a pump, the room temperature rises much faster. Therefore, to install such a heating system, it is necessary to use pipes with a smaller diameter than in cases of natural movement of the coolant.

should be 60 degrees

On the pipes that enter the floors, it is necessary to install valves that will regulate the supply of hot water to each floor.

Consider some wiring diagrams for a one-pipe heating system:

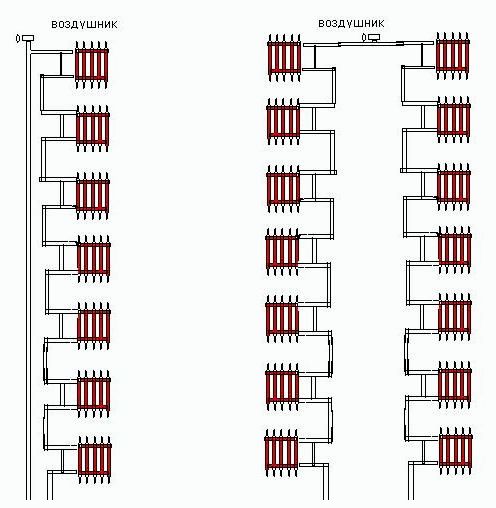

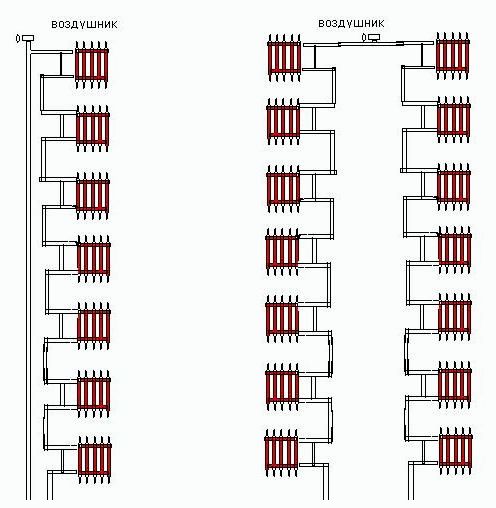

- vertical feeding scheme - can have natural or forced circulation. In the absence of a pump, the coolant circulates by changing the density during cooling during heat exchange. From the boiler, the water rises into the mainline of the upper floors, then it is distributed along the risers to the radiators and cools down in them, after which it returns to the boiler again;

- diagram of a single-pipe vertical system with bottom wiring. In a scheme with a lower wiring, the return and supply lines go below the heating devices, and the pipeline is laid in the basement. The coolant is fed through the drain, passes through the radiator and returns down to the basement through the downpipe.With this wiring method, the heat loss will be significantly less than when the pipes are in the attic. And it will be very simple to maintain the heating system with this wiring diagram;

- diagram of a one-pipe system with top wiring. The supply pipeline in this wiring diagram is located above the radiators. The supply line runs under the ceiling or through the attic. Through this highway, the risers go down and radiators are attached to them one by one. The return highway goes either along the floor, or under it, or through the basement. Such a wiring diagram is suitable in the case of natural circulation of the coolant.

Remember that if you do not want to raise the threshold of the doors in order to lay the supply pipe, you can smoothly lower it under the door on a small piece of earth while maintaining the general slope.

How to shut off a heating riser and start it after repair

To repair risers, you must first reset the system, and after completion of repair work, a restart is carried out. The implementation of these operations must occur according to a certain algorithm.

Bottom filling

First you need to find the appropriate valves. You can find them by focusing on the flights of stairs and the layout of the heating devices. If necessary, you can go up to the upper floor and see how the lintel is located. To drain the risers, unscrew the plugs or open the relief valves.

After completing this work, you can close the discharges and very slowly fill the system with water. The slowness of this process is due to the fact that when the system is quickly filled, a water hammer can occur. If there are screw valves, the water must move in the direction indicated by the arrow on the body - otherwise the valve may break, after which you will have to reset the heating system throughout the house.

Then you can open the valves completely and bleed off the air pressure on the upper floor. The Mayevsky crane is usually located in the radiator plug or at the top of the jumper. Resetting and starting will be greatly simplified if all valves installed in the system are ball valves.

Top filling

In this case, it is much easier to start heating, but much more action is required to reset the system. First, the attic riser is blocked, and after it is installed in the basement. Now you can open the reset. To prevent a possible mistake when turning off the system in the attic, it is worth starting from the number of inserts in the bottling from the located landmark.

After finishing the work, you can close the discharge and very slowly fill the riser. It is imperative to observe the direction of movement of the water. Both valves can now be opened. There is no need to bleed the air: it will move itself into the attic expansion tank.

Single pipe heating system pros and cons

Benefits

A single-pipe heating system has both advantages and disadvantages. Benefits include the following:

- the ability to cover the entire area of the building using a closed ring, which does not depend on the layout of the building;

- the ability to connect certain additional devices to the heating system, for example, warm floors, heated towel rails or equipping a built-in circulation pump;

- it is possible to direct the coolant in one direction or another. For example, in the course of circulation, you can be the first to direct colder rooms, which are often ventilated. In the same two-pipe systems, this function is reduced to the location of the boiler;

- ease of installation. There are not so many materials, and the cost of their purchase and the work itself will be much lower than when installing a two-pipe system;

- with thoughtful placement of heating devices and proper piping, the difference in temperatures in different rooms can be minimized, but it will not be possible to completely cope with this phenomenon.

disadvantages

The disadvantages of a one-pipe system are:

- the presence of special requirements for the diameter of the key pipeline;

- in the first radiator, the temperature will be the highest, and in the subsequent ones it will be lower due to the constant admixture to the coolant flow from the radiators that have already been passed;

- the last radiators should have a larger area than the first, so as not to be too cold;

- it is better not to put more than 10 radiators on one branch, since uniform heating in this way will not work.

The equalization of the temperature regime occurs due to the change in the number of radiator sections and the installation of special jumpers, thermostatic valves, valves, regulators or ball valves. It is advisable to have a circulation pump available, and in order for hot water to pass better through pipes and radiators, you need to install a special acceleration collector. In two-story houses, it is not needed.

If the wiring is of the upper type, then the supply pipe is capable of creating natural pressure, however, with such a scheme, pipes with a large diameter must be installed, and this will negatively affect the appearance of your interior. Therefore, it will be much better if it is possible to put the wiring unit under the floor covering.

We also recommend that when installing radiators in a two-story building in order to regulate heating, make a parallel connection of batteries with installation of taps at the entrances. Also, so that the temperature on the second floor is evenly distributed, instead of radiators, you can purchase a system of underfloor heating.

As you can see, a single-pipe system in terms of operation can have a number of difficulties. For example, it requires high pressure indicators, and in order for it to work normally, it is advisable to use a powerful pump, and this is not only unnecessary trouble, but also high costs. In addition, in a one-story building, a vertical spout and an expansion attic tank will be required.

However, despite this, the advantages of this solution are still greater.

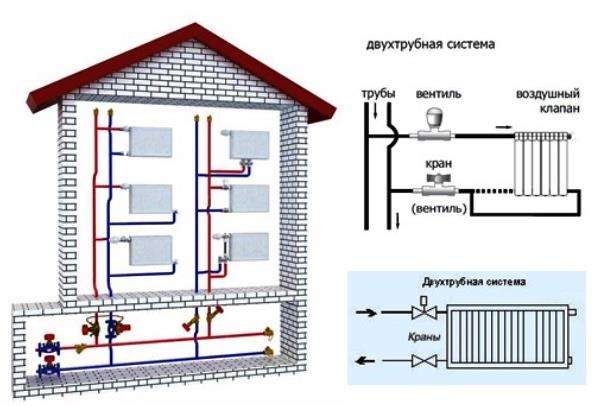

Two-pipe horizontal heating system - application features

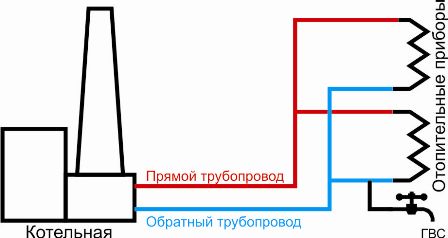

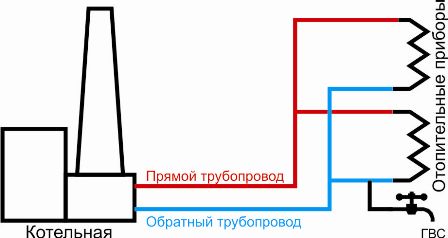

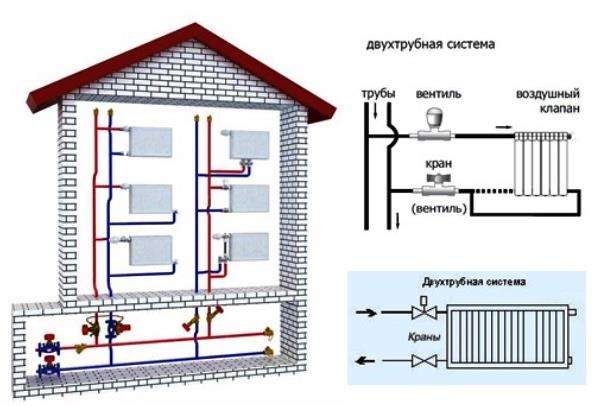

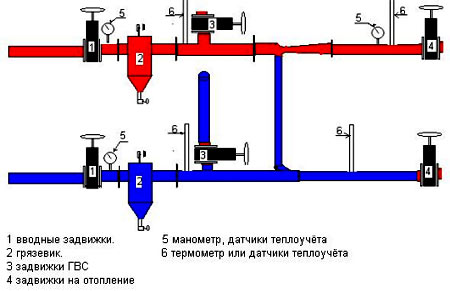

Diagram of a two-pipe heating system. Click to enlarge.

Today, not a single apartment building has a system that would calculate the water consumption constantly; naturally, no one installs throttles on separate risers.

In order to equalize the temperatures of the heat carriers at different distances from the elevator, return and supply pipelines are used, which are located in the basement (a kind of heating bed).

These pipelines have a much larger diameter than heating pipes.

It is worth noting that today in new houses, when control over construction organizations and their specifics of work has become less stringent, the use of pipes of exactly the same size and diameter on risers and stanchions has become actively practiced.

The builders began to use thin-walled pipes, which are installed for the welding of valves, which does not correspond to the previous standards and dimensions.

The result of such miscalculations is cold radiators in the residents' apartments, which are located at a great distance from the elevator unit. Very often, such apartments are exactly corner apartments that have a common wall with the street.

The two-pipe horizontal heating system in apartment buildings has one distinctive feature. For its normal functioning, water must circulate through the risers, constantly rising and falling through the pipes. In the event that something interferes with this movement, the batteries will remain cold.

Many are interested in the question: "What should be done if the system at home is running, and the radiators do not heat up or have room temperature?"

The first step is to make sure that the valves on the riser are open. If all the lambs and flags are in the "open" position, you need to shut off one of the paired risers (these tips are valid only for houses with a two-pipe heating system).

In order to block it, you need to go down to the basement (this is where both beds are usually located) and open the vent located next to them.

Next, you need to follow: if the water comes with absolutely normal pressure, then there are no obstacles to normal circulation, not taking into account the presence of air at the upper points.

To eliminate the room temperature of the batteries in the apartment, you need to drain as much water as possible from the system. It is necessary to drain until the characteristic "snorting" of air and water in the pipes is heard, and a powerful jet of hot water comes out of the tap.

In this case, you will have to go up to the highest floor and bleed the air there. After all the manipulations carried out, the circulation should be restored.

If water still does not flow, it is imperative to restart the riser in the opposite direction. Maybe a small piece of scale or slag is stuck in some place. The countercurrent can easily take it out.

It is worth noting that if, after all such actions, the riser, nevertheless, does not go to discharge, it is necessary to start looking for the room in which the renovation was recently carried out, and there, perhaps, the heating devices were changed.

In this case, you should be prepared for any turn of events: a muffled and removed radiator without a jumper, blocked for some unknown reason by the throttle, or completely cut risers with plugs at both ends.

In any case, you will find confirmation that human stupidity has no boundaries.

What is heating

Bearing in mind the heating of an apartment building, one cannot boast of a large selection. All houses are heated in approximately the same way. In each room there is a cast-iron heating radiator (its dimensions depend on the size of the room and its purpose), which is supplied with hot water of a certain temperature (heat carrier) coming from the thermal station.

example of a cast iron radiator

However, the entire water supply scheme may differ depending on what kind of heating distribution is provided in a particular building - one-pipe or two-pipe. Each of these options has certain advantages and disadvantages. To better understand this issue, you need to know exactly everything about the former and the latter. So let's briefly describe them.

- One-pipe heating system. Its design is simple, and therefore reliable and cheap. But still it is not too much in demand. The fact is that, getting into the heating system of a house, the coolant (hot water) must pass through all the heating radiators before it enters the return channel (it is also called the "return"). Of course, by heating all the radiators one by one, the coolant loses its temperature. As a result, when reaching the last user, the water has a relatively low temperature, due to which in the last room it can differ significantly from the temperature in the one to which it first comes. This often causes dissatisfaction among residents. Therefore, the described heating system of a multi-storey building is used relatively rarely.

- Two-pipe heating system. Devoid of those disadvantages that are inherent in the heating system described above. The design of this system is significantly different. Hot water, passing through the heating radiator, does not enter the pipe leading to the next radiator, but immediately into the return channel.From there, it immediately goes back to the heating station, where it will be heated to the desired temperature. Of course, this option requires significantly higher costs both for installation of the system and for maintenance. But this scheme of the heating system device allows you to ensure the same temperature in all heated buildings. Example of a two-pipe heating system

It also makes it possible to install a heating meter. By installing it on a heating radiator, the owner can independently regulate the level of its heating and, accordingly, reduce the cost of paying heating bills. In a one-pipe heating system, this option is not possible. By reducing the amount of hot water passing through your radiators, you can thus bring a lot of trouble to the neighbors to whom the coolant gets through your apartment. That is, the heating rules in this case will be frankly violated.

Of course, it is impossible to change the type of heating system in an apartment; it requires titanic efforts and enormous work that will affect the entire house. But still, it will be useful for every apartment owner to know about the pros and cons of different types of heating systems.

This video provides a broad overview of various heating systems.

Bottling

Depending on their location, there are two heating wiring schemes.

Lower

Bottom filling or heating system with bottom piping is used in most modern buildings. Both the dispenser and the return dispenser are located in the basement. The risers are connected in pairs by jumpers located in the apartment of the upper floor or in the attic, at the top of each lintel there is an air vent (Mayevsky's crane).

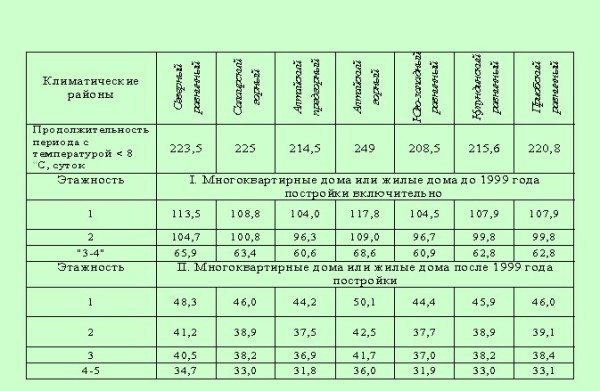

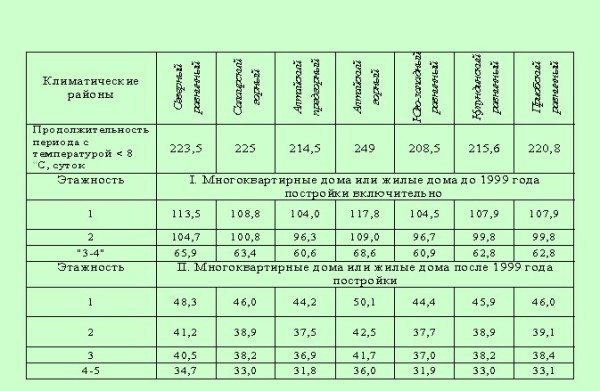

Any riser is a bridge between dispenses. The inevitable imbalance between the risers closest to the elevator unit and the risers farthest from it is compensated by the difference in the cross-country ability and the size of the pipes. Here are the usual values of the remote control for the heating circuit serving the entrance in a modern ten-story building.

| Plot | DN pipes |

| Filling near the elevator unit | 50 |

| Filling at the end risers | 40 |

| Uprights | 20-25 |

What are the specific advantages of the lower heating pipe routing?

- All valves on paired risers are concentrated in one place. You do not need to go to the attic to disconnect.

- Dumping the coolant into the technical basement during repairs does not imagine any trouble.

But: often basements are used for storage or utility rooms of stores. In this case, there is no need to say about any advantage, you yourself realize: you will have to dump the risers through a hose into the sewer.

The main drawback that the lower wiring of heating systems owns is the laboriousness of starting them at the end of the reset. In order for circulation to begin through all the risers, it is necessary to bleed off the air space. At the same time, not all the inhabitants of the upper apartments can do this, and one should not forget about the empty premises.

Upper

Top filling, or heating with top flow distribution is predictably different in that the filling thread is taken out to the attic. The return flow remains in the basement. Any riser is a separate element, free from other risers.

In the attic, in addition to pouring the filing, in this case there are:

- Shut-off risers from the valve supply.

- Plugs for their discharge (more correctly, for the suction of air necessary in order to completely drain the group of heating devices).

- Expansion tank. Regardless of the name, it does not compensate for the increase in the volume of the coolant during heating (the system is not autonomous, but connected to the heating main). The tank, located at the top of the supply fill, laid with a minimum slope, helps to collect the air that is removed from there through the relief valve.

Such a layout of the heating system was massively used until about the 80s of the last century.

How does it look against the background of the bottom filling?

- The main trouble here is the laboriousness of resetting the launch of a separate riser. To completely drain it, you need:

- Close the valve in the attic.

- Close the valve in the basement and unscrew the plug.

- Unscrew the cap in the attic.

It is curious: the whole house has a heating system with an upper supply wiring is reset and started up much more easily, especially if the discharge from the heating expansion tank is brought out to the elevator unit. Alas: dumping a house is associated with the loss of a huge amount of coolant, which is undesirable from the standpoint of saving thermal energy.

- The main advantage of the top filling is that the launch is extremely simple and does not depend on the residents of the house. It is enough only slowly (so that there is no water hammer) to open the house valves on the supply and return, after which it remains only to throw off the air space from the expansion tank.

Features of gravity systems

Due to the fact that turbulent flows are formed, accurate calculations of the systems cannot be carried out, therefore, when designing them, averaged values are taken, for this:

• maximally raise the acceleration point;

• use wide delivery pipes;

Further, from the beginning of the first divergence to each subsequent one, a pipe of a smaller diameter is connected by a step equal to it, which involves inertial flows.

There are also other features of the installation of gravity systems. So, pipes should be laid at an angle of 1-5%, which is affected by the length of the pipeline. If the system has a sufficient difference in heights and temperatures, you can use horizontal wiring.

It is important to ensure that there are no areas with a negative angle, since they cannot be reached by the movement of the coolant, due to the formation of air jams in them.

So, the principle of operation can be based on the open type or be of the membrane (closed) type. If you make the installation in a horizontal orientation, it is recommended to install Mayevsky taps on each radiator. because with their help it is easier to eliminate air congestion in the system.

Watch a video in which a specialist talks about the conditions for the possibility of using a gravity, pumpless, gravitational heating system:

Classification of district heating systems

The variety of schemes for organizing central heating that exists today makes it possible to rank them according to some classification criteria.

According to the mode of consumption of thermal energy

- seasonal, heat supply is required only in the cold season;

- year-round, requiring constant heat supply.

By the type of coolant used

- water - this is the most common heating option used to heat an apartment building; such systems are easy to operate, allow transporting the coolant over long distances without deteriorating quality indicators and regulating the temperature at a centralized level, and are also characterized by good sanitary and hygienic qualities.

- air - these systems allow not only heating, but also ventilation of buildings; however, due to the high cost, such a scheme is not widely used;

Figure 2 - Air heating and ventilation scheme of buildings

- steam - are considered the most economical, because small diameter pipes are used to heat the house, and the hydrostatic pressure in the system is small, which makes it easier to operate. But such a heat supply scheme is recommended for those objects that, in addition to heat, also require water vapor (mainly industrial enterprises).

By the method of connecting the heating system to the heat supply

- independent, in which the heat carrier circulating through the heating systems (water or steam) heats the heat carrier supplied to the heating system (water) in the heat exchanger;

Figure 3 - Independent district heating system

- dependent, in which the heat carrier heated in the heat generator is supplied directly to the heat consumers through the networks (see Figure 1).

By the method of connection to the hot water supply system

- open, hot water is taken directly from the heating network;

Figure 4 - Open heating system

- closed, in such systems, water is taken from the common water supply, and its heating is carried out in the network heat exchanger of the central unit.

Figure 5 - Closed central heating system

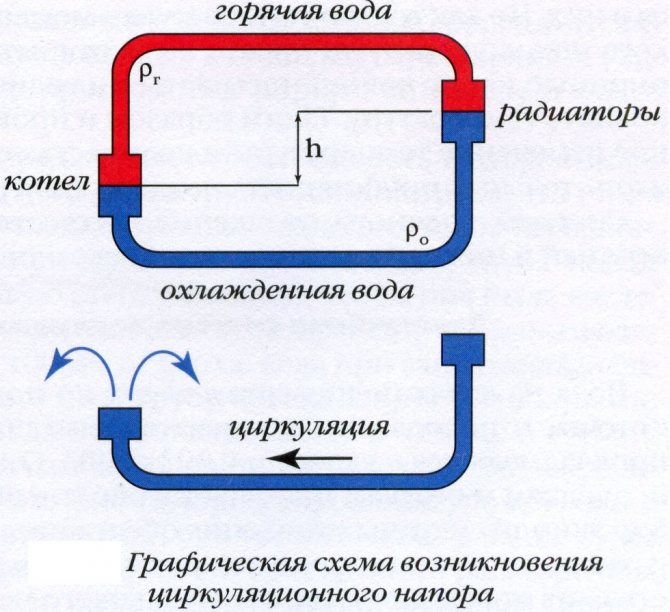

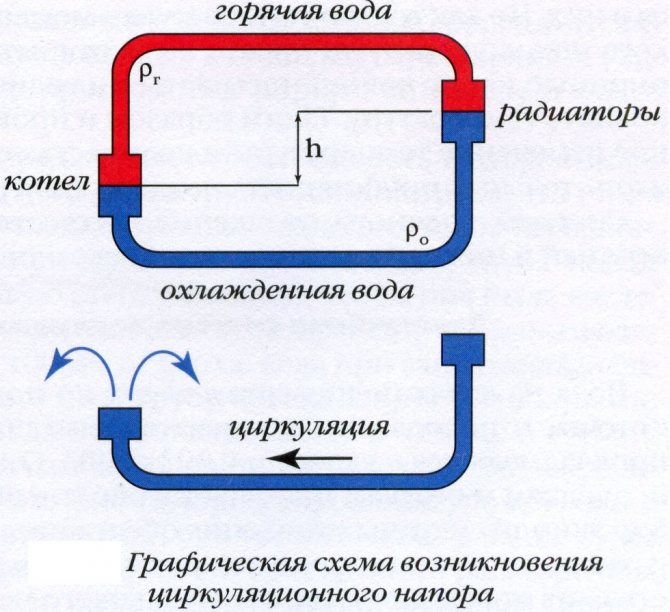

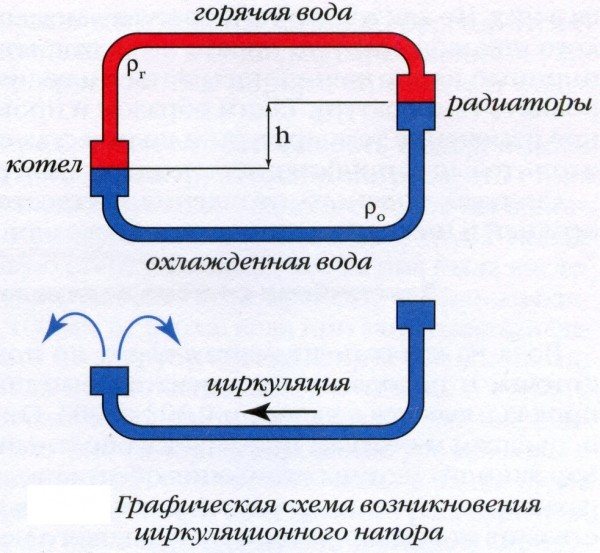

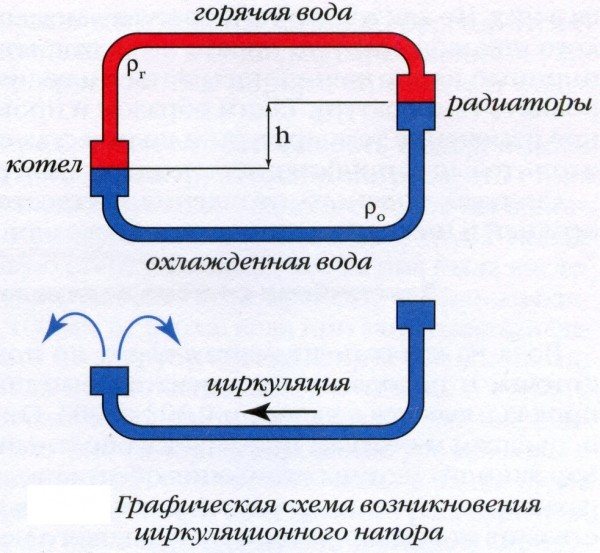

The principle of operation of a gravity heating system

The principle of operation of heating looks simple: water moves through the pipeline, driven by the hydrostatic head, which appeared due to the different mass of heated and cooled water. Such a structure is also called gravity or gravity. Circulation is the movement of the cooled liquid in the batteries and the heavy liquid under the pressure of its own mass down to the heating element, and the displacement of the light heated water into the supply pipe. The system works when the natural circulation boiler is located below the radiators.

In open circuits, it communicates directly with the external environment, and excess air escapes to the atmosphere. The volume of water that increased from heating is eliminated, the constant pressure is normalized.

Natural circulation is also possible in a closed heating system if it is equipped with an expansion vessel with a membrane. Sometimes open-type structures are converted into closed ones. Closed circuits are more stable in operation, the coolant does not evaporate in them, but they are also independent of electricity. What affects the circulating head

The water circulation in the boiler depends on the difference in density between the hot and cold liquid and on the height difference between the boiler and the lowest radiator. These parameters are calculated even before the installation of the heating circuit is started. Natural circulation occurs because the return temperature in the heating system is low. The coolant has time to cool down, moving through the radiators, it becomes heavier and, with its mass, pushes the heated liquid out of the boiler, forcing it to move through the pipes.

Boiler water circulation diagram

The height of the battery level above the boiler increases the pressure, helping the water to more easily overcome the resistance of the pipes. The higher the radiators are in relation to the boiler, the greater the height of the cooled return column and with the greater the pressure it pushes the heated water upward when it reaches the boiler.

Density also regulates the pressure: the more the water heats up, the less its density becomes in comparison with the return. As a result, it is pushed out with more force and the pressure increases. For this reason, gravity heating structures are considered self-regulating, because if you change the temperature of heating the water, the pressure on the coolant will also change, which means that its consumption will change.

During installation, the boiler should be placed at the very bottom, below all other elements, in order to ensure a sufficient head of the coolant.

What it is

Let's start by describing the general principles of the heating system.

Heating of heating devices is ensured by the circulation of a heat carrier through them (industrial water, antifreeze, ethylene glycol, etc.). Circulation requires a differential created between the inlet and outlet of the device.

This drop can be provided in several ways:

- Connection through an elevator unit to a heating main, where a pressure difference of 2 - 3 kgf / cm2 is maintained between the supply and return lines.

Nuance: after the elevator, the difference between the mixture and the return is much less - 0.2 - 0.3 kgf / cm2. Exceeding this value would make the circulation excessively fast. Consequences - noise in pipes and high temperature of the return pipe.

- Circulation pump.

- The difference in the density of the hot and cold coolant in the so-called gravitational (gravity) systems.

Obviously, in all cases it is necessary to ensure that each heater is connected to the common system with two connections. This can be done in several fundamentally different ways.

| Scheme | Short description |

| Single pipe | The heaters are connected to a common ring circuit |

| Two-pipe | Heating devices are connected between the supply and return pipelines that run along the entire perimeter of the heated premises |

| Collector | Each heater is equipped with its own pair of connections connected to a common manifold |

It is curious: mixed schemes for connecting radiators prevail in apartment buildings. The presence of a dedicated supply and return heating filling makes the system two-pipe; at the same time, batteries are often combined in series within the riser.

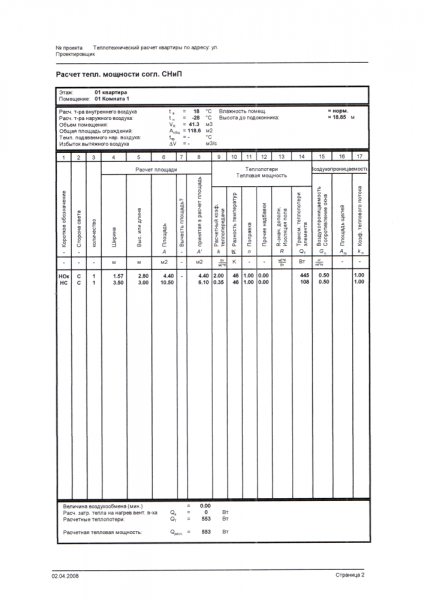

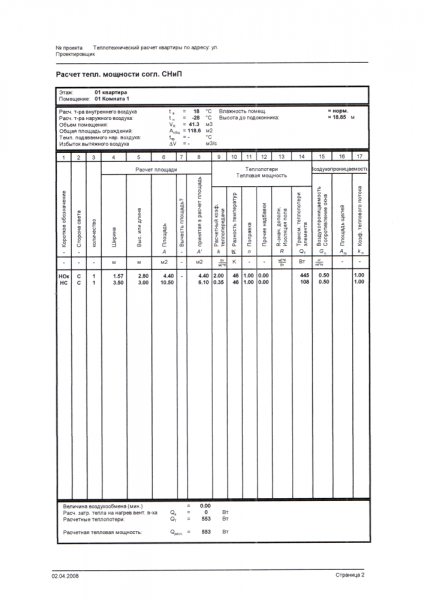

Power calculation

The effective heat output of the boiler is calculated in the same way as in all other cases.

By area

The simplest way is the calculation of the area of the room recommended by SNiP. 1 kW of thermal power should fall on 10 m2 of the area of the room. For the southern regions, a coefficient of 0.7 - 0.9 is taken, for the middle zone of the country - 1.2 - 1.3, for the regions of the Far North - 1.5-2.0.

Like any rough calculation, this method neglects many factors:

- The height of the ceilings. It is far from being the standard 2.5 meters everywhere.

- Heat leaks through the openings.

- The location of the room inside the house or against external walls.

All calculation methods give large errors, therefore, the thermal power is usually included in the project with a certain margin.

By volume, taking into account additional factors

A more accurate picture will be given by another calculation method.

- The basis is a thermal power of 40 watts per cubic meter of air volume in the room.

- Regional coefficients apply in this case as well.

- Each standard size window adds 100 watts to our estimate. Each door is 200.

- The location of the room against the outer wall will give, depending on its thickness and material, a coefficient of 1.1 - 1.3.

- A private house with a street below and above is not warm neighboring apartments, is calculated with a coefficient of 1.5.

However: this calculation will be VERY approximate. Suffice it to say that in private houses built using energy-saving technologies, a heating capacity of 50-60 watts per SQUARE meter is included in the project. Too much is determined by heat leaks through walls and ceilings.

Features of the top wiring

Water heating with top wiring is used when there is no possibility of laying the supply and return lines with the coolant in the screed, at floor level or in the basement. Such an option for supplying the working medium is also in demand when installing a heating system with natural circulation.

The advantages of a top-wired heating circuit include:

- ease of installation... The pipeline can be hidden in ceiling structures or in the attic, which improves the aesthetic perception of communications. When installing highways with a coolant under the ceiling, the placement of furniture should be taken into account, avoiding closing the pipes;

- low heat loss... The heated air in the room rises up and compensates for the heat transfer of the pipes, therefore, a significant part of the thermal energy enters the heating devices;

- good hydrodynamic performance... Using axonometry and hydraulic calculation methodology, it is possible to design a heating system with a minimum number of corner turns and branches.

The main disadvantages of a network with an upper wiring are the increase in the cost of purchasing materials. In addition, it becomes necessary to install more powerful heating equipment due to an increase in the volume of the coolant.

Depending on the design features, the network with the upper supply of the working medium can be one-pipe or two-pipe.

Heating system project development

The heating device, starting from the introductory system and ending with heating radiators, is created immediately after the framework of an apartment building is built. Of course, by this time, a heating project for an apartment building must be developed, tested and approved.

And it is at the first stage that a number of difficulties often arise, as in the performance of any other, very complex and important work. In general, the heating system of an apartment building is complex.

The power of a heating system may depend on the strength of the wind in your area, the material of which the building is built, the thickness of the walls, the size of the premises, and many other factors. Even two identical apartments, one of which is located on the corner of a building and the other in its center, require a different approach.

After all, a strong wind in the winter season cools the outer walls rather quickly, which means that the heat loss of a corner apartment will be much higher.

Therefore, they must be compensated by installing larger heating radiators. Only experienced specialists who know exactly how all the equipment works and how they work can take into account all the nuances, choose the best solutions.

A beginner who decides to calculate the heating system in an apartment building will be doomed to failure from the very beginning. And this will not only lead to a significant waste of resources, but also put the lives of the inhabitants of the house in danger.

Uprights

The distribution of the coolant for heating devices in a private house is possible horizontal and vertical (standing). In multi-apartment buildings in different areas, these schemes coexist: if the filling is always a horizontal wiring, then the riser is a vertical wiring.

What is useful to know about risers in an apartment building?

- Not on a single floor, except for the top one in a house with a bottom filling, should the radiator tie-ins be connected to the paired risers. If you insert a heating device between the supply and return risers on the fifth floor of a ten-story building, the inhabitants of the upper floors will freeze: the circulation above the inset will actually stop.

- In buildings of new projects, one of the paired risers is often idle (in other words, it is not connected to the batteries). The heating wiring diagram with idle risers allows paired risers to be bypassed from the basement, without the participation of residents. It is enough just to install a vent on the idle line instead of a plug and overtake it for a discharge: the air lock will completely fly out at the water front.

- In stalinkas, two radiators are often connected to one riser in parallel, without changing the diameter. Along with this, the riser itself is a jumper between their liners. Such

the wiring of the heating system is fully operational, but only with a huge (DU25) diameter of the connections.

Practical consequence: if you want to replace the inter-apartment wiring with your own hands, or use pipes for heating of the same diameter, or throttle the jumper. The instruction is due to the fact that with a jumper diameter of 25 mm and connections with a nominal bore of 15-20, the batteries will simply be cold.

Centralized heating system

No one will argue that the centralized system for supplying heat to apartment buildings, in the form in which it now exists, to put it mildly, is morally outdated.

It is no secret that losses during transportation can reach up to 30% and we have to pay for all this. Avoiding central heating in an apartment building is a tricky and troublesome process, but first, let's figure out how it works.

Heating a multi-storey building is a complex engineering structure.There is a whole set of drains, distributors, flanges that are tied to a central unit, the so-called elevator unit, through which the heating in an apartment building is regulated.

Two-pipe heating scheme.

Now it makes no sense to talk in detail about the intricacies of the operation of this system, since professionals are engaged in this and the ordinary person simply does not need this, because nothing depends on him here. For clarity, it is better to consider the scheme for supplying heat to an apartment.

Bottom filling

As the name implies, the bottom-filling distribution scheme provides for the supply of the coolant from the bottom up. Classic heating of a 5-storey building, assembled according to this principle.

As a rule, the supply and return are installed along the perimeter of the building and run in the basement. The supply and return risers, in this case, are a jumper between the lines. It is a closed system that rises to the top floor and descends back into the basement.

Two types of filling in comparison.

Despite the fact that this scheme is considered the simplest, putting it into operation is troublesome for locksmiths. The fact is that at the top of each riser, a device for bleeding air is installed, the so-called Mayevsky crane. Before each start, you need to release air, otherwise the air lock will block the system, and the riser will not be heated.

Important: some residents of the extreme floors are trying to move the air relief valve to the attic, so as not to collide with housing and communal services workers every season. This conversion can be expensive.

Attic - the room is cold and if you stop heating for an hour in winter, the pipes in the attic will freeze and burst.

A serious disadvantage here is that on one side of the five-story building, where the input passes, the batteries are hot, and on the opposite side they are cool. This is especially true on the lower floors.

Radiator connection option.

Top filling

The heating device in a nine-story building is made according to a completely different principle. The supply line, bypassing the apartments, is immediately carried out to the upper technical floor. An expansion tank, an air relief valve and a valve system are also based here, which allows you to cut off the entire riser if necessary.

In this case, the heat is more evenly distributed over all radiators of the apartment, regardless of their location. But here comes another problem, the heating of the first floor in a nine-story building leaves much to be desired. After all, after passing through all the floors, the coolant comes down already barely warm, you can fight this only by increasing the number of sections in the radiator.

Important: the problem of freezing water on the technical floor, in this case, is not so acute. After all, the cross-section of the supply line is about 50 mm, plus in the event of an accident, you can completely discharge water from the entire riser in a few seconds, you just need to open the air vent in the attic and the valve in the basement

Temperature balance

Of course, everyone knows that central heating in an apartment building has its own clearly regulated standards. So during the heating season, the temperature in the rooms should not fall below +20 ºС, in the bathroom or in the combined bathroom +25 ºС.

Modern heating of new buildings.

In view of the fact that the kitchen in old houses does not differ in a large square, plus it is naturally heated due to the periodic operation of the oven, the permissible minimum temperature in it is +18 ºС.

Important: all the above data are valid for apartments located in the central part of the building. For side apartments, where most of the walls are external, the instruction prescribes an increase in temperature above the standard by 2 - 5 ºС

Heating standards by region.

How it works

First, some general information.

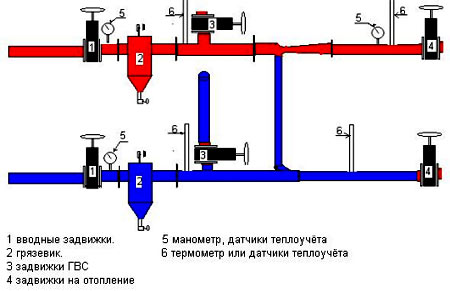

Hot water supply and heating of an apartment building begins with the introduction of the heating main into the house.Through the foundation, two lines are started from the nearest heat chamber - supply (through which industrial water, it is also a heat carrier, enters the building) and return (water, respectively, returns to the CHP or boiler house, giving off heat).

In the thermal chamber at the entrance to the house (as an option - at the group entrance to several houses located in close proximity to each other) there are cut-off valves or taps.

Heat chamber at the stage of installation

The heat point, also known as an elevator unit, combines several functions:

- Provides a minimum temperature difference between the supply and return of the heating system;

Reference: the upper peak of the supply temperature is 150 degrees, while, according to the temperature schedule, the return flow must return to the CHP plant cooled down to 70 ° С. However, such a difference would mean extremely uneven heating of heating devices, therefore, water from the elevator enters the heating circuit with a more modest temperature - up to 95 degrees.

Temperature graph of the supply and return lines of the heating main depending on the outside temperature

- Organizes the supply of hot water to the hot water supply system and its shutdown on a scale of the house in case of accidents and current repairs;

- Allows you to stop and reset the heating system;

- Allows you to take control measurements of temperature and pressure;

- Provides cleaning of the coolant and water for hot water supply from large contaminants.

The heating system can be organized:

- With top filling: the filling of the supply takes place in the attic or technical floor under the roof of the house, and the return filling is located in the basement or underground. Each heating riser is disconnected independently of the others by two taps at the top and bottom of the house;

Top filling: heating supply is distributed in the attic

It is curious: there is also a reverse scheme - with feeding in the basement and pouring the return in the attic. However, it is much less popular and, as far as the author knows, is used mainly in small buildings with their own boiler rooms.

- With bottom filling: supply and return are bred in the basement; heating risers are connected to the filling one by one and are connected in pairs by jumpers on the top floor or attic. Each jumper is supplied with an air vent (Mayevsky valve or a conventional valve) to bleed the air lock.

The DHW system in buildings built in the 70s and in older houses is usually dead-end - completely identical to the cold water supply system. From a practical point of view, this means that hot water has to be drained for a long time during the drawdown before it is heated, and heated towel rails installed on the hot water supply pipes are heated only during the drawdown.

Dead-end DHW system: water needs to be drained for a long time before it heats up

In newer buildings, hot water supply and heating of a residential building function according to the general principle - water circulates continuously through the circuits, ensuring a constant temperature of heated towel rails and instantaneous heating of water during parsing.

To learn more about how the heating and water supply system of residential buildings is arranged, the video in this article will help you.

Top-piped two-pipe heating system

Installing a two-pipe top-wired heating system minimizes or eliminates many of the above disadvantages. In this case, the radiators are connected in parallel.

For its installation, much more materials are needed, since two parallel lines are installed. A hot coolant flows through one of them, and a cooled one through the other. Why is this top-drawer heating system preferred for private homes? One of the significant advantages is the relatively large area of the room. The two-pipe system can effectively maintain a comfortable temperature level in houses with a total area of up to 400 m².

In addition to this factor, for a heating scheme with top filling, such important performance characteristics are noted:

- Uniform distribution of hot coolant over all installed radiators;

- The ability to install control valves not only on the piping of batteries, but also on separate heating circuits;

- Installation of a water underfloor heating system. The hot water distribution manifold is only possible with two-pipe heating.

For the organization of forced top filling in the heating system, it is necessary to install additional units - a circulation pump and a membrane expansion tank. The latter will replace an open expansion tank. But the place of its installation will be different. Diaphragm sealed models are mounted on the return line and always in a straight section.

The advantage of such a scheme is the optional observance of the slope of the pipelines, which is characteristic of the upper and lower distribution of heating with natural circulation. The required head will be generated by a circulation pump.

But does a two-pipe forced heating system with an overhead wiring have any drawbacks? Yes, and one of them is dependence on electricity. During a power outage, the circulation pump stops working. With a large hydrodynamic resistance, the natural circulation of the coolant will be difficult. Therefore, when designing a single-pipe heating system with an upper wiring, all the required calculations must be performed.

You should also take into account the following features of installation and operation:

- When the pump stops, the reverse movement of the coolant is possible. Therefore, in critical areas, it is necessary to install a check valve;

- Excessive heating of the coolant can cause the critical pressure to be exceeded. In addition to the expansion tank, air vents are installed as an additional measure of protection;

- To increase the efficiency of the heating system with an upper piping, it is necessary to provide for automatic replenishment of the coolant. Even a slight decrease in pressure below normal can lead to a decrease in the heating of the radiators.

The video will help you to clearly see the difference for different heating schemes:

Most of the heating systems in apartment buildings and private houses are built according to this scheme. What are its advantages and are there any disadvantages?

Can a do-it-yourself two-pipe heating system be installed?

Convector in a two-pipe heating system

Classification

Let's start with an overview of the properties that differentiate the different schemas.

Serial and ray wiring

In the first case, the radiators are mounted to a common pipeline. Consecutive wiring does not mean that each radiator breaks the main fill. On the contrary, very often a bypass is mounted between its inserts, which makes it possible to regulate the temperature regime of the heater independently of others.

Important: when installing any throttling valves, a bypass is required. Otherwise, we will begin to regulate the patency not of the radiator piping, but of the entire circuit.

Radial (collector) wiring means that combs with throttles or valves are mounted on the supply and return pipelines, from which the coolant is diluted with a pair of connections to each heating device. The disadvantage of this solution is obvious: the pipe consumption increases many times over.

Why, then, is the radiant heating system (wiring) so popular?

- Temperature control is very convenient. From one point, the owner of a house or apartment can regulate the heat transfer of each radiator.

- Each pair of pipes leading from the collector serves only one heater. If so, you can get by with a smaller pipe diameter, which, in turn, allows you to lay the eyeliner in the screed or the space between the sub-floor logs. The pipes will not remain in sight and spoil the design of the room.

The photo shows a heating manifold.

One-pipe and two-pipe schemes

The difference between the two is easier to explain with examples.

A typical one-pipe heating system is Leningradka, a simple wiring, which is a filling ring laid along the perimeter of the house. Heating devices break it or, more correctly, are connected in parallel.

What does such a realization of heating give?

- Cheapness. It is clear that one pipe will cost less than two.

- Exceptional resiliency. While the coolant circulates in the circuit, stopping its movement in a separate heating device and defrosting it is impossible in principle.

The price of these qualities is a wide range of temperatures on radiators, as close as possible to the heat source and far from it. However, heat transfer is easy to equalize with chokes or by varying the number of battery sections. In addition, the contour should be continuous: a door or panoramic window will have to be encircled by pouring from below or from above.

Horizontal single-pipe options.

In the case of two-pipe heating, we lay two independent filling lines - supply and return. Each radiator is a jumper between them.

Important: balancing of two-pipe heating with throttles is mandatory. Otherwise, the entire volume of the coolant will go through nearby heating devices; distant ones can be thawed. There were precedents.

Dead-end and passing schemes

In a dead-end wiring, the supply filling reaches the far point of the contour, after which the coolant returns to the starting point along the return, moving in the opposite direction to the original direction.

However, in the event that the heating circuit surrounds the entire house or apartment around the perimeter, the coolant can return to its starting point and continue moving in the same direction. In this case, the scheme is called passing.

Of course, subdivision on this basis is possible only for two-pipe schemes.

Top and bottom filling

A typical scheme for five-story Soviet-built buildings is when, in a two-pipe heating system, both dispenses are located below, in the basement. Each pair of risers connected on the upper floor serves as a jumper between them. This is the so-called bottom filling.

A nuance: by professionals, bottling means both the direction of movement of the coolant, and the pipe along which it moves to the risers.

In houses with an overhead filling, the supply pipe is taken out to the attic. EACH riser serves as a jumper between the supply and return pipelines.

Which circuit is better? It's hard to say unequivocally.

- For bottom filling, all valves and fittings are located in the basement. Leaks won't flood apartments.

- On the other hand, starting circulation in the heating system becomes more complicated. After all, the jumpers between the paired risers are airborne; and they are in apartments, access to which is often problematic.

In the case of top filling, all air locks are forced into the expansion tank located at the top of the supply pipeline, from where the air is vented through a valve or an automatic air vent.

One of the top filling schemes.

Natural and forced circulation

Let's imagine a certain closed volume filled with water. Now let's place a heating element of any type in it. What will happen to the liquid?

Having heated up, the water in full accordance with the laws of physics will expand, reduce its density. Then it will be forced out by the colder and denser masses surrounding it into the upper part of the vessel.

It is this effect that underlies the operation of a gravitational heating system. How does it work?

- After the boiler, the filling rises vertically upward, forming a booster manifold. An air vent is mounted at its upper point (in the case of an open system without overpressure, an open-type expansion tank).

- The rest of the contour runs with a slight constant slope along the contour of the house.The cooling water makes its way through the filling by gravity, giving off heat to the heating devices. Having reached the boiler, it heats up again - and then in a circle.

Such a scheme is fault-tolerant and non-volatile, however, it has a number of disadvantages:

- The head in the gravity circuit is small, and to ensure circulation, it is necessary to minimize the hydraulic resistance of the filling, overestimating its diameter. This means a lot of money and… please, come up with an antonym for the word “aesthetics” yourself.

- A pipe laid not on a level, but with a slope also does not add sophistication to the design of the room.

- Finally, a system with natural circulation heats up the house for a very long time and after warming up has a wide range of temperatures at the beginning and at the end of the circuit.

Forced circulation in autonomous circuits is provided by a low-power circulation pump. In houses connected to central heating, it is not needed: the pressure difference between the supply and return pipelines of the heating main is usually at least 2 kgf / cm2.

An interesting solution is a circuit built like a gravitational one, but with a pump embedded in it. Moreover, the latter does not break the main contour, but cuts parallel to it. Between the inserts, the filling is equipped with a valve or a check valve (exclusively ball, with a minimum hydraulic resistance and not requiring a large differential to operate).

It is possible to work with both forced and natural circulation.

The proposed scheme is capable of operating in two modes:

- In the presence of electricity, the pump provides quick and even heating of all heating devices. In this case, the bypass is closed (by a valve or a triggered check valve).

- Without electricity, the bypass opens, after which the system continues to work with natural circulation.

Such an implementation will allow you to heat your home and not be afraid of heating equipment failure due to lack of power supply.

Types of gravity circulation heating systems

Despite the simple design of a water heating system with self-circulation of the coolant, there are at least four popular installation schemes. The choice of the type of wiring depends on the characteristics of the building itself and the expected performance.

To determine which scheme will work, in each individual case it is required to perform a hydraulic calculation of the system, take into account the characteristics of the heating unit, calculate the pipe diameter, etc. Professional help may be required when performing calculations.

Closed system with gravity circulation

In the EU countries, closed systems are the most popular among other solutions. In the Russian Federation, the scheme has not yet been widely used. The principles of operation of a closed-type water heating system with a pumpless circulation are as follows:

- When heated, the coolant expands, water is displaced from the heating circuit.

- Under pressure, the liquid enters the closed diaphragm expansion tank. The design of the container is a cavity divided into two parts by a membrane. One half of the reservoir is filled with gas (most models use nitrogen). The second part remains empty for filling with a coolant.

- When the liquid is heated, enough pressure is created to push the membrane and compress the nitrogen. After cooling down, the reverse process takes place, and the gas squeezes the water out of the tank.

Otherwise, closed-type systems work like other natural circulation heating schemes. The disadvantages are the dependence on the volume of the expansion tank. For rooms with a large heated area, you will need to install a spacious container, which is not always advisable.

Open system with gravity circulation

The open-type heating system differs from the previous type only in the design of the expansion tank.This scheme was most often used in older buildings. The advantages of an open system are the ability to independently manufacture containers from scrap materials. The tank usually has a modest size and is installed on the roof or under the ceiling of the living room.

The main disadvantage of open structures is the ingress of air into pipes and heating radiators, which leads to increased corrosion and rapid failure of heating elements. Airing the system is also a frequent "guest" in open-type circuits. Therefore, radiators are installed at an angle; Mayevsky taps are required to bleed air.

One-pipe system with self-circulation

A single-pipe horizontal system with natural circulation has a low thermal efficiency, therefore it is used extremely rarely. The essence of the scheme is that the supply pipe is connected in series to the radiators. The heated coolant enters the upper branch pipe of the battery and is discharged through the lower branch. After that, the heat goes to the next heating unit and so on until the last point. Return flow is returned from the extreme battery to the boiler.

This solution has several advantages:

- There is no pair piping under the ceiling and above the floor level.

- Funds are saved on installation of the system

The disadvantages of this solution are obvious. The heat transfer of heating radiators and the intensity of their heating decreases with distance from the boiler. As practice shows, a one-pipe heating system of a two-story house with natural circulation, even if all slopes are observed and the correct pipe diameter is selected, is often altered (by installing pumping equipment).

Self-circulation two-pipe system

The two-pipe heating system in a private house with natural circulation has the following design features:

- The supply and return pass through different pipes.

- The supply line is connected to each radiator through an inlet branch.

- The second line connects the battery to the return line.

As a result, a two-pipe radiator-type system offers the following advantages:

- Even distribution of heat.

- No need to add radiator sections for better heating.

- It is easier to adjust the system.

- The diameter of the water circuit is at least one size smaller than in single-pipe circuits.

- Lack of strict rules for installing a two-pipe system. Small deviations with respect to slopes are allowed.

The main advantage of a two-pipe heating system with lower and upper wiring is simplicity and, at the same time, efficiency of the design, which makes it possible to neutralize errors made in calculations or during installation work.

Bottom wiring

This scheme is a classic two-pipe wiring. In the basement, the supply and return are installed, and the heating devices are connected to the jumper, which is located between these circuits. The jumper in this case is two risers that are connected to each other at the highest point of the heating system. Heating elements taken out to the attic must be insulated, otherwise the very first frost can provoke stagnation of the solidified liquid or a breakthrough in the pipeline. It will be possible to solve such a problem with a blowtorch, and in the worst case, you will need to weld the heating pipes.

In theory, such a connection requires a good balance of risers so that distant risers can work as efficiently as those nearby. In practice, such balancing is not performed, but the heating is still functioning stably. This is due to the fact that the diameter of the heating risers is different.

The length of the filling from one elevator unit should be minimal in order to ensure the minimum temperature difference on the near and far risers.In the case of a pairwise installation of risers, one of them can work without load, but the heating devices must be connected to both.

general information

Basic moments

The absence of a circulation pump and generally moving elements and a closed circuit, in which the amount of suspended matter and mineral salts, of course, makes the service life of a heating system of this type very long. When using galvanized or polymer pipes and bimetallic radiators - at least half a century. The natural circulation of heating means a fairly small pressure drop. Pipes and heating devices inevitably provide a certain resistance to the movement of the coolant. That is why the recommended radius of the heating system of interest to us is estimated at about 30 meters. Obviously, this does not mean that with a radius of 32 meters the water will freeze - the border is rather arbitrary. The inertia of the system will be quite large. It may take several hours between the kindling or starting of the boiler and the stabilization of the temperature in all heated rooms. The reasons are clear: the boiler has to warm up the heat exchanger, and only then the water will begin to circulate, and rather slowly. All horizontal sections of pipelines are made with a mandatory slope along the direction of water movement. It will provide free movement of cooling water by gravity with minimal resistance.

What is equally important - in this case, all air locks will be forced out to the upper point of the heating system, where the expansion tank is mounted - sealed, with an air vent, or open.

All the air will collect at the top.

Self-regulation

Heating of a house with natural circulation is a self-regulating system. The colder it is in the house, the faster the coolant circulates. How it works?

The fact is that the circulating head depends on:

Differences in height between the boiler and the bottom heater. The lower the boiler is relative to the lower radiator, the faster the water will flow into it by gravity. The principle of communicating vessels, remember? This parameter is stable and unchanged during the operation of the heating system.

The diagram demonstrates the principle of heating clearly.

Curious: that is why it is recommended to install the heating boiler in the basement or just as low as possible inside the room. However, the author has seen a perfectly functioning heating system, in which the heat exchanger in the furnace firebox was noticeably higher than the radiators. The system was fully operational.

Differences in density of water leaving the boiler and in the return pipe. Which, of course, is determined by the temperature of the water. And it is precisely thanks to this feature that natural heating becomes self-regulating: as soon as the temperature in the room drops, the heating devices cool down.

With a drop in the temperature of the coolant, its density increases, and it begins to quickly displace the heated water from the lower part of the circuit.

Circulation rate

In addition to the pressure, the rate of circulation of the coolant will be determined by a number of other factors.

- The diameter of the distribution pipes. The smaller the internal section of the pipe, the more resistance it will exert to the movement of the liquid in it. That is why pipes with a deliberately overestimated diameter - DU32 - DU40 are taken for wiring in the case of natural circulation.

- Pipe material. Steel (especially damaged by corrosion and covered with deposits) has several times more resistance to flow than, for example, a polypropylene pipe with the same cross section.

- The number and radius of turns. Therefore, the main wiring is best done as straight as possible.

- Availability, quantity and type of valves. a variety of retaining washers and pipe diameter transitions.

Every valve, every bend causes a drop in head.

It is because of the abundance of variables that an accurate calculation of a heating system with natural circulation is extremely rare and gives very approximate results. In practice, it is enough to use the recommendations already given.

Terminology

First, to avoid confusion, let's define the terms.

- Elevator or heating unit - the place where the control of the heating system and hot water supply of the house or part of it is concentrated.

In addition: the elevator unit brings the pressure and temperature of the heating agent to the optimal indicators for the operation of the heating system. So, the difference between the supply and return lines of the highway reaches 4 kgf / cm2, at the same time, a difference of 0.2 kgf / cm2 is enough for the circulation of water through the batteries.

- Water jet elevator - the main element of the elevator unit, the mixing chamber, in which the warmer water from the supply is mixed with the return water drawn into the re-circulation.

- Suction - a pipe connecting the supply and return in the elevator unit. Through it, the colder water of the return pipeline enters the repeated circulation cycle.

- Bottling (bed) - a horizontal pipe supplying the heat carrier from the elevator unit to the risers.

- Uprights - vertical sections of the heating system, supplying water specifically to heating devices.

- Eyeliners - pipes connecting the riser to the battery.

So, what specific wiring diagrams of heating systems can be used in multi-apartment buildings? What specific elements do they include?

House heating scheme

As mentioned above, most modern houses in cities are heated with a centralized heating system. That is, there is a heating station where (in most cases with the help of coal) heating boilers heat water to a very high temperature. Most often it is more than 100 degrees Celsius!

Water is supplied to all buildings connected to the heating main. When a house is connected to a heating plant, input valves are installed to control the process of supplying hot water to it. A heating unit is also connected to them, as well as a number of specialized equipment.

heating unit operation scheme

Water can be supplied both from top to bottom and from bottom to top (when using a one-pipe system, which will be discussed below), depending on how the heating pipes are located, or simultaneously to all apartments (with a two-pipe system).

Hot water, getting into the heating radiators, heats them up to the required temperature, providing it with the required level in each room. The dimensions of the radiators depend both on the size of the room and on its purpose. Of course, the larger the radiators are, the warmer it will be where they are installed.

Useful little things

- When balancing with throttles, the time interval between the change in the throttling mode and the stabilization of the temperature of the heating devices reaches 6 - 8 hours.

- For a cottage with an area of up to 100 m2 with forced circulation of the heat carrier in a two-pipe system, a reasonable minimum of the filling section is DN2, up to 200 m2 - DN25.

- In a gravitational system, filling cannot be made thinner than DU32 when using polymer pipes and DU40 - steel... In addition, gravity systems are used on an area of no more than 100 m2: in a large room, the hydraulic resistance of a long circuit simply will not provide the minimum required circulation rate.

Gravitational two-pipe scheme.