Autonomous heating of a private house up to 500 m2

Autonomous space heating over 500 m2 (roof-top boilers)

Centralized heating in apartment buildings or non-residential premises of any size.

Why these three types?

Each version of this type of heating works according to different parameters and composition of the coolant in the pipeline and radiators. Autonomous systems up to 500 m2 - the pressure in the system cannot be more than 3 bar (kilogram) and the coolant, if desired, can be filled without unnecessary chemicals that accelerate the aging process of the equipment.

Autonomous systems of more than 500 m2 - a roof boiler room for residential apartments in a multi-storey building, the pressure depends on the height of the building, but not more than 6 bar (kilogram) with a conventional heat carrier (tap water).

Centralized heating of apartment buildings and non-residential premises is the most problematic heating system throughout our homeland, the pressure in such systems reaches 9 bar (kilogram) with a coolant in which there are chemicals and a lot of dirt.

All of the above affects the durability of your batteries and supplies (pipes and taps) to them. Knowing the system and the factors of their problems, consider the heating devices themselves, and in the next article we will decide which pipes and taps to install. These devices are available to choose from: Cast iron - irrelevant, ugly and ineffective in terms of heat transfer 160 W per 1 m2. Aluminum - modern, beautiful, efficient 199 W per 1 m2 for breaking up to 25 Bar. Bimetallic - modern, beautiful, 187 W per 1 m2, but with a breaking power reserve of up to 40 Bar. Steel panel radiator - modern, efficient, reliable, but not always affordable. Cast iron batteries need no discussion! Aluminum radiators: The most common type of heating equipment today, so much has been said and written about them, but aluminum radiators are still worthy of attention. Their technical data, for all manufacturers, is almost the same if we consider the 500/100 model, since the property of aluminum is unchanged. A good manufacturer improves the design and convection of the appliance for more heat dissipation in each section. The working pressure of the radiators is 16 Bar (kilogram), the burst pressure is 25 Bar.

The heat dissipation of the battery and the price depends on three factors:

- Manufacturer.

- Model.

- Weight of one section.

The price is most influenced by the manufacturer, since goods from Europe are more expensive than ours or from China. The radiator model is 500/100, 500/85, 500/80, 500/70 as well as 350/100 and 350/80 and the smallest 200/80.

What does 500/100 mean - these are dimensions, where 500 is between the axial distance, and 100 is the depth of the product

... See dimensions in millimeters from the photo:

- Total height under the letter, A

- Distance between the axes of the connection holes, B

- Section depth, C

- Front section width, D

The standard in our country is 500/100, cast-iron batteries 500 mm along the axes of the pipeline. Other models 500/85 and so on, are made mainly to reduce the cost per section, due to less aluminum in it, and in appearance they look exactly the same, the manufacturer is disingenuous, visually passing off as a standard radiator.

And so we know that we need 500/100 with a heat transfer of 199 W per meter of heating area, with ceilings in a house no more than three meters in height and it is suitable for replacement in an apartment without additional parts, and then models 500/85, 500 are also suitable for us / 80 and 500/70, but their heat transfer is much less due to the reduced area of the radiator section, you need to look at the product data sheet, the price of such sections is cheaper than that of a standard 500/100 radiator. An important factor when choosing a heating radiator is production, cast aluminum radiator or extrusion. Cast radiators naturally pour into molds under high pressure and are a one-piece piece, which means maximum reliability.Extrusion - the radiator is welded by welding and three parts, which reduces the cost of the production process, worsens the quality of reliability, this will definitely not withstand the pressure testing of the system in apartment buildings. Today, extrusion is rarely found in stores. The third factor is the weight of one section, good and at the same time real Italian or, so to speak, real aluminum radiators 500/100 have a weight in one section from 1.2 to 1.4 kg. Less weight affects heat dissipation, service life, withstands lower working pressure.

Each person wants to buy at a cheaper price and sell at a higher price, see the product passport, there is indicated the manufacturer, model, power and all other technical data for the heating equipment that you want to purchase. For example, you need a heating device for an apartment where there is a high operating pressure and the pressing pressure and the coolant does not always correspond to the standard temperature, it is preferable to purchase a real heavy radiator with a standard size. It's another matter if you need to heat a private house with the available minimum pressure and constant heat flow from your own boiler, here you can save on the quality of devices, in a private house there are practically no factors for the rapid destruction of sections of the device. I hope you will be able to choose the most profitable variant of the heating device for yourself.

Bimetallic radiators - This is an outwardly ordinary aluminum battery, the difference is in the inner steel tube through which the heating liquid flows, that is, water, the tube consists of three parts, welded together to form a through channel and is filled with aluminum on top using a special technology. The coolant flows through the steel tube without touching the aluminum and without producing a chemical reaction that destroys the aluminum. All chemical reactions in pipelines occur very slowly, the time of destruction by a harmful chemical reaction for aluminum has not been investigated and the service life can be even 20 and 30 years. Bimetallic batteries are very good, they have a huge margin of safety in terms of a burst pressure of 40 bar and a constant working pressure of 25 bar. The reliability of such radiators in the heating systems of an apartment building is undeniable, but all these data refer to radiators produced at a plant in Europe, and their cost is two, three times higher than that of an aluminum radiator of the same brand (brand) for example GLOBAL.

Heat dissipation of a bimetallic radiator up to 180 W and an aluminum radiator up to 199 W. With all the laudatory reviews of bimetallic radiators, the advisability of installing it is money down the drain or full awareness of an impenetrable heating device in the form of a battery. Rather, the pipes will burst. Let's compare the parameters of heating systems and radiators:

Autonomous heating system:

| Technical data | Aluminum | Bimetallic |

| Working pressure in heating systems 3 - 6 bar (kilogram) | ||

| System pressure test maximum 12 bar | ||

| Temperature range maximum 85 degrees |

District heating in apartment buildings:

| Technical data | Aluminum | Bimetallic |

| Working pressure in heating systems 14 Bar (kilogram) | ||

| System pressure test maximum 9 bar | ||

| Temperature range maximum 90 degrees |

The heat carrier is water, the chemical reaction is unknown.

Aluminum is interesting in that it opens up wide opportunities for energy saving due to the high thermal conductivity of the metal. Aluminum batteries heat up the room faster than steel radiators. This means less hot water consumption and faster response to changing room temperature requirements. Radiators of this type can reduce up to 10% of the annual heating consumption.

The main technical characteristics of aluminum heating batteries include:

- heat transfer (power);

- working and pressure testing;

- dimensions;

- center distance;

- mass and capacity (internal volume) of one section;

- the maximum permissible temperature of the heating medium.

In this article:

Medium size

This parameter characterizes the distance between the manifolds (the centers of the upper and lower holes) of the device.

The standard provides for three standard sizes for the center distance:

- 500 mm;

- 350 mm;

- 200 mm.

But on the market you can also find non-standard radiators, the center-to-center distance of which can vary from 200 to 800 mm.

The distance between the axes of the collectors plays an important role when choosing a heating device: the overall overall size of the radiator depends on it

.

Why know the amount of coolant in the battery

The calculation of the volume of the coolant in the battery is done in order to:

- choose the correct radiator mount. It must withstand not only the weight of the product, but also the weight of water, which fills the entire interior space. The weight of the liquid is equal to the volume;

- select a boiler of the required power. If it is weak, it will create little pressure and the water will move slowly;

- select an expansion tank of the required volume. Many are rejecting this element. However, it is better to use it, since it compensates for the pressure created by the heated coolant increased in volume. For example, when heated, the volume of liquid increases by 4%. If she has nowhere to go, then the pressure on the batteries and pipes increases. Sooner or later, thermal expansion will "please" with a leak;

- determine the total need for a coolant. To do this, it is necessary to take into account the internal volume of pipes with low hydraulic resistance, as well as the volume of the heating boiler, capable of creating the required pressure;

- maintain the correct concentration of antifreeze. This applies to cases where water will mix with antifreeze. This can be done, and in some cases the formed liquid for heating radiators freezes at lower temperatures than 100% antifreeze;

- select the type of circulation. The coolant can move naturally (from top to bottom) or move under the pressure generated by the pump. The natural type of circulation is chosen in the case of batteries with a large internal volume and low resistance to the heated liquid. As for the second type, the size and weight of the batteries does not matter.

Operating pressure

This parameter indicates at what coolant pressure the radiator can be operated.

- There are two types of aluminum radiators available:

- up to 6 atm (normal);

- up to 16 atm (reinforced).

In private houses equipped with an autonomous heating system, the average value of the coolant pressure in the network usually does not exceed 1.4 atmospheres. In houses with central heating, this parameter is in the range of 10 - 15 atm. But in the heating main, the working pressure is much higher: it can reach 30 atm.

Obviously, for the installation of aluminum radiators on central heating, devices with a higher working pressure should be chosen.

Some manufacturers indicate in the passport the working pressure not in atmospheres, but in MPa. To convert mega Pascals to atmospheres, multiply the parameter by 10 (for example, 1.5 MPa corresponds to 15 atm.).

How much water is in one section of a bimetallic radiator

As with aluminum, there are many options for manufacturers and brands of bimetallic radiators. In the same way, their structure, appearance, and channel diameters differ.

The volume of water in a bimetallic radiator depends on its height and is (in liters):

- 35 cm - 0.1-0.15;

- 50 cm - 0.2-0.3;

- 60 cm - 0.25-0.35;

- 90 cm - 0.3-0.5;

- 120 cm - 0.4-0.6.

To calculate the volume of a section of a bimetallic radiator with a non-standard height, use the formula (V - volume in liters, h - height in meters):

V = h x 0.35

This will give you an approximate value, which can fluctuate within 20%.

vteple.xyz

Pressure test

Heating system pressure testing

Before the start of the heating season, the central system is checked for leaks - that is, pressurized. This operation consists in supplying a coolant at a pressure 1.5 - 2 times higher than the operating pressure.

Standard values of the pressure test are from 20 to 30 atm.

If the radiator is not designed for such a pressure, it may fail during testing of the heating system.

If you have central heating in your house

, be sure to pay attention to this parameter when buying a battery: according to the passports of many models, it is only 18 atm. Such models are only suitable for autonomous heating systems.

Heat carrier temperature

When calculating the parameters of the thermal power of the heating system, it should be remembered that the heat transfer of the radiator directly depends on the temperature of the coolant. That is why you should focus on the actual temperature.

Most often, the nominal heat transfer of the radiator is possible at a coolant temperature of 90 ° C. It is this limit value that manufacturers indicate in the technical characteristics of their products, and only some models are designed for a temperature of 110 - 120 ° C.

In reality, the temperature in heating systems rarely exceeds 70 ° C, therefore, the heat output of the radiator will be lower than the values specified by the manufacturer. The increased temperature of the coolant, on the one hand, increases the efficiency of using aluminum batteries, and on the other hand, reduces the service life of all elements of the heating system, including the heating boiler, therefore it is better to increase the number of radiator sections to achieve the required thermal power.

Other parameters

Aluminum radiator in the interior of the room

The weight

matters when choosing the mountings for the heater.

The passport indicates the mass of one section. To determine the total weight of an unfilled radiator, this parameter must be multiplied by the number of sections. Depending on the dimensions, the weight of one section can be from 1 to 1.47 kg.

Water volume

in the radiator is also calculated from the parameters of one section, which must be multiplied by the number of sections.

The capacity (internal volume) of a section depends not only on its dimensions, but also on the thickness of the shell. The average value of the capacity of one aluminum section is in the range of 250 - 460 ml. The internal volume of the radiator is taken into account when calculating heating systems and has the most direct effect on the volume of the coolant required to fill them.

Maximum allowable coolant temperature

for aluminum radiators it is standard and is 110 degrees.

Section volume and coolant flow

Today, not all autonomous heating systems are filled with water.... This is due to two factors.

Section size

- A situation arises when the owners need to leave the house without heating for a long time, since due to a long absence there is no need to heat the premises.

- Water tends to freeze even at zero temperature. When water freezes, expanding, it turns into ice, that is, it passes from one physical state to another. During this process, the intermolecular bonds of water are released and changed, as a result, a huge force develops that breaks radiators and pipes made of any metal.

To avoid such situations, to fill the heating system, instead of water, another coolant is used, devoid of the problem of freezing. These can be household antifreezes such as:

- ethylene glycol;

- saline solution;

- glycerin composition;

- food alcohol;

- petroleum oil.

Thanks to the special additives that are introduced into these components, the coolant compositions retain their state of aggregation in liquid form even at low temperatures.

Calculation of the coolant

Determining the volume of the flow rate of the coolant required for an autonomous heating system requires an accurate calculation. For an easy way to find out how much antifreeze is needed to fill the heating system, there are various calculation tables.

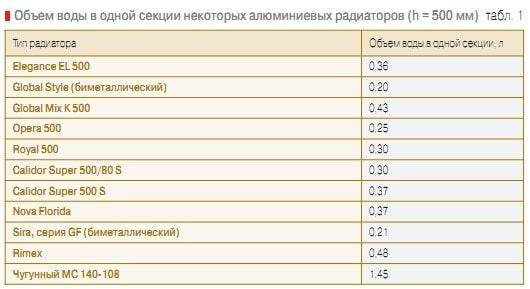

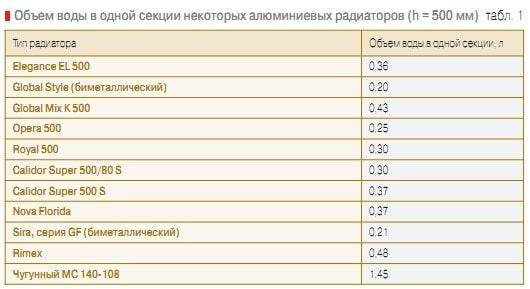

Water volume in one section

For basic calculations, you can use the information that is set out in thematic reference books:

- The standard section of the aluminum battery contains 0.45 liters of heating medium.

- A running meter of a 15 mm pipe contains 0.177 liters, and a pipe with a diameter of 32 mm contains 0.8 liters of coolant.

Information on the characteristics of the booster pump and expansion tank can be taken from the passport data of this equipment.

The total volume of the heating system will be equal to the total volume of all heating devices:

- radiators;

- pipelines;

- boiler heat exchanger;

- expansion tank.

The refined formula of the basic calculation is corrected taking into account the coefficient of expansion of the coolant. For water it is 4%, for ethylene glycol it is 4.4%.

Table with characteristics of some models

| Specifications | GREEN HP 350 (Faral, Italy) | Alux 200 (ROVALL, Italy) | Alum 350 (Rifar, Russia) |

| Distance between axles, mm | 350 | 200 | 350 |

| Working pressure, bar | 16 | 20 | 20 |

| Power (coolant temperature - 70 degrees), W | 136 | 92 | 139 |

| Section capacity, l | 0,26 | 0,11 | 0,19 |

| Weight, kg | 1,12 | 0,83 | 1,2 |

| Dimensions (H / W / D), mm | 430/80/80 | 245/80/100 | 415/80/90 |

The data given in the table are taken from the official sources of the manufacturers.

In the process of replacing and repairing the heating system in an apartment or house, you have to solve a lot of various issues of a rather specific nature. One of them: the selection of heating devices or, more simply, batteries. That is, first of all, you need to figure out if these are aluminum heating radiators, then which ones are better to choose? And in what cases will their installation be more justified and rational? Or is it better to prefer more expensive bimetallic options or standard cast iron ones?

On the modern construction market, there are several types of these products made from various materials, for example:

Steel radiators

There are two types:

- panel radiators, which are heat-conducting surfaces of a solid type.

- tubular radiators, consisting of sections in the form of vertically arranged pipes and produced in various design options.

Production material: low-carbon steel with high anti-corrosion resistance, coated with powder-type enamel.

Cast iron

Classic "accordions" with a long service life of up to 50 years, notable for their low cost and good wear resistance.

Aluminum radiators

Lightweight, compact and elegant batteries with improved heat dissipation.

Bimetallic radiators

They are made in two ways:

- Coated steel frame with aluminum.

- Steel reinforcement of the vertical ducts for better resistance to pressure within the system. The connection of the radiator sections is made using steel nipples.

Types of aluminum radiators

In turn, aluminum heating batteries are divided into two types, depending on the technology used in their production:

Cast

For their manufacture, all sections of the device are cast from a special alloy based on aluminum with the addition of silicon, which gives the material special strength under high pressure conditions. The individual parts of the radiator structure are interconnected by welding in an inert gas atmosphere.

Their strengths:

- Durability and tightness of the joints, guaranteeing high quality and efficiency of products.

- The ability to create radiators of various lengths and capacities by changing the number of sections.

Disadvantages:

- High cost compared to extrusion type radiators.

Extrusion

In the production of radiators of this type, parts are not cast, but are squeezed out under conditions of increased pressure, and then pressed with upper and lower manifolds made by casting.In some cases, composite glue is used to mount individual parts of the battery, which makes these products even cheaper.

Their advantages:

- Slightly higher heat dissipation compared to cast batteries.

- Less volume of sections, due to which they require less heating medium.

- Less weight of the radiator due to the thinner fins.

- Low cost.

Disadvantages:

- Impossibility of repair and disassembly of the radiator.

- The likelihood of a leak in the area of the collector-section junction. This may be due to insufficient quality of the adhesive or wear of the O-rings made of rubber or Teflon.

- The presence of crackling sounds arising from temperature differences during the operation of the devices.

Useful advice - when choosing radiators made of aluminum, it is better to opt for options made by casting. They have thicker walls and are better able to withstand high operating pressures in the system. If, when purchasing, the low weight and cost of these products is of decisive importance, then it makes sense to choose extrusion aluminum heating radiators, the price per section of which is much lower than injection-type batteries.

How much water is in one section of a cast-iron heating radiator

Cast iron batteries differ in section height, depth, power and weight. For example, the MC 140-500 model has a height of 50 mm and a depth of 140 mm. Basically, the height of the radiator affects the volume of water in the cast-iron section of the radiator.

The most common is the MC series. Depending on the manufacturer, the volume of the coolant may vary, so there is a small variation.

Volume of one section of MS brand (in liters)

- MS 140-300 0.8-1.3;

- MS 140-500 1.3-1.8;

- MS-140 1.1-1.4;

- MS 90-500 0.9-1.2;

- MS 100-500 0.9-1.2;

- MS 110-500 - 1-1.4.

The cast iron batteries of the ChM series are very popular. Model markings indicate the number of channels, the height and depth of the section. For example, ChM2-100-300 has a height of 300 mm, a depth of 100 mm, and water circulates in it through two channels. "Alt =" "width = 707 height = 593 data-layzr =" https://vteple.xyz/wp-content/uploads/2018/04/chugunnyj-radiator-ms-140-500.jpg ">

The volume of water in one section of the CHM brand (in liters)

- ChM1-70-300 - 0.66;

- ChM1-70-500 - 0.9;

- ChM2-100-300 - 0.7;

- ChM2-100-500 - 0.95;

- ChM3-120-300 - 0.95;

- ChM3-120-500 - 1.38.

Pros and cons of aluminum radiators

As an indisputable argument in favor of buying and using aluminum batteries, you can cite their positive characteristics, including:

- Light weight, not more than 1.5 kg per one section of the device, and compact dimensions, allowing aluminum batteries to fit well into rooms of any area.

- Good thermal conductivity and fast heating period (1.5 times faster than cast iron radiators).

- Excellent heat dissipation, making these devices as efficient and economical as possible.

- Possibility to change the number of working sections if necessary.

- Temperature control function (on batteries equipped with thermostats).

- Attractive radiator design and aesthetics.

At the same time, aluminum radiators also have some disadvantages, for example:

- Sensitivity to the pH level of the heating medium. It is desirable that it be in the range of 7-8 units, since if it is exceeded, aluminum can corrode, which over time will lead to damage to the battery.

- The need to install an air vent to prevent rupture of sections due to the threat of gas formation.

- The need to connect an aluminum radiator to pipes made of the same material or to plastic, since otherwise (in particular, in contact with copper pipes) it may be damaged as a result of the resulting electrochemical corrosion reaction.

- The ability of the radiator to withstand relatively low operating pressure.

Thermal characteristics of an aluminum heating radiator

Convection is the natural, independent transfer of heat that occurs when liquids and gases are stirred when heated. Natural convection is ineffective, therefore, in order to increase the heat transfer coefficient in modern heating systems, forced convection is most often used. This process is carried out using a circulation pump.Thus, the air masses in the immediate vicinity of the radiator surface are heated and rise upward, and cold air enters their place. This is how convection heating of air occurs in a separate room.

Radiation is the transfer of thermal energy by infrared radiation, which is carried out through the air. Radiation is typical for heating processes, including heating from a fire (fire or fireplace), from spiral electric heaters, and also from the surface of a heating radiator. The transfer of heat by means of radiation directly depends on the heating temperature of the heater itself (battery).

Aluminum heating radiators - types, performance, volume, power, heat transfer

A thermostat can be installed to an aluminum radiator and heat flow can be controlled.

Aluminum radiators have 2 types - radiators from primary aluminum and secondary, that is, the first type is made from pure raw materials, and the second type is remelted from secondary raw materials (scrap, dirty alloys). Naturally, pure alloy batteries are more expensive, but they are more reliable, of better quality, and have a longer lifespan.

Aluminum radiators, regardless of manufacturers, have a sectional structure and 2 main design options - cast and extrusion. In cast models, each section is made separately, and the extrusion ones are made according to the technology of joining 3 parts, and instead of welding individual sections, gluing or twisting with bolts is used.

Performance is one of the most important criteria when choosing a radiator model. The performance characteristics include the operating pressure and the heat output of the heater. Working pressure is an indicator of the pressure of the heating water that the device can withstand without the risk of rupture and damage. Modern manufacturers indicate operating pressures from 6 to 16 atm. Batteries with a low pressure indicator can be used in heating systems where the coolant pressure is controlled by the user himself, and the risk of pressure surges is reduced to zero (private house, apartment, summer cottage, cottage). The higher the operating pressure, the more reliable and durable the radiator, so when installing a radiator in a communal heating system, where the risk of a sudden increase in pressure (water hammer) is quite expected, it is better to take devices with a high operating pressure.

Installation examples of radiators

Heat transfer characterizes the amount of heat that can be given off by one section of the radiator. The section of an aluminum radiator has a standard size of 110-140 mm in depth, a height of 350-1000 mm, a wall thickness of 2-3 mm, a volume for a coolant of 0.35-0.5 liters, a heating area of 0.4-0.6 sq. .;. The heat transfer of an aluminum radiator is 50-60% radiation, 40-50% convection.

The high heat transfer of such a battery is ensured by the fact that aluminum has a high thermal conductivity, which is 3 times higher than that of steel and cast iron, as well as the design of the radiator.

The use of thin transverse ribs in the inner part of each section is designed to increase the already high heat transfer rates of the device in the heating system. Such a device of an aluminum battery can increase heat transfer by 80%. Also, the advantage of the design of aluminum batteries is the wide water channels, which provide excellent and reliable heat transfer, even with low quality coolant. The maximum temperature of the coolant (water inside the heating system) that aluminum radiators can withstand is 130 ° C.

Technical and consumer qualities and features

In addition to its practicality, visual appeal and low cost, the technical characteristics of aluminum heating radiators are a very decent set, which includes:

| Options | Indicators |

| Working pressure level | 6-25 atm. |

| Heat transfer of one section (heat output) | 150-212 W |

| Maximum allowable coolant temperature | 110 ⁰C |

| Section volume | 250-460 ml |

| Section weight | 1-1.47 kg |

| Center distance (the gap between the upper and lower manifolds) | 200-800 mm |

| Life time | 10-15 years old |

Please note that the most common sizes for aluminum radiators are:

350, 500 and 200 mm. They indicate the value of the center-to-center distance between the collectors. But on sale there are models with a distance between the axes that differ from the standard. It can be from 200 to 800 mm. And in order to calculate the height of the aluminum radiator, you need to add 80 mm to this value.

One of the most important indicators characterizing the quality and efficiency of aluminum batteries is their operating pressure. However, in the passport of these devices, the pressure test is also indicated, which has a slightly increased value. This characteristic of radiators is very important, since it is used in tests when starting the heating system after draining it. The standard value of the pressure test is 20, 25 or 30 atm.

In our separate article, you will learn to use. There you will find their characteristics, prices and the names of reliable manufacturers.

Pros and cons of flow and storage type water heaters

Instructions for making a shower tray yourself can be studied by following the link

Design features and classification

The material for the manufacture of the aluminum radiator section is not pure aluminum, but its alloy with silicon additives. This gives the new appliance greater strength and resistance to corrosion, extending its service life. The initial raw material undergoes special processing, then passing through a high-pressure press to obtain the elements of future apparatus.

Aluminum radiators offered in heating equipment stores have different external characteristics. They are distinguished:

1. In general appearance:

- panel,

- tubular.

2. By the structure of one, separately taken section:

- one-piece, ready-to-use (cast),

- extrusion, which are composed of individual elements using internal bolting with silicone and paronite gaskets.

3. By dimensions:

- Having standard dimensional characteristics. The dimensions of standard aluminum radiators are as follows: width - about 40 cm, height - about 58 cm.

- Low aluminum radiators can be as little as 15 cm high to fit even in very confined spaces. Now some companies even offer so-called "plinth" aluminum batteries with a height of only 2-4 cm.

- Tall, or vertical. With a small width in height, they can reach 2 - 3 meters. Their working position in the height of the room makes it possible to heat a large volume of air, and the original look also adds a decorative function to them.

Tubular instrument

Attention! The service life of the aluminum heating radiators you bought does not depend on how many elements the device contains, what its dimensions and internal volume are. The quality of the device is determined only by the quality of the raw materials and the conscientiousness of the manufacturer.

Review of popular models and manufacturers

Another question that worries consumers who choose aluminum heating radiators: which are the best companies? Traditionally, it is believed that the best quality and reliability are aluminum batteries from Italian manufacturers, although many domestic models are not inferior to them in many respects. Reviews on aluminum radiators of these brands also speak of their quality and reliability.

The most famous brands include:

| Brand | Model | Center distance, mm | Dimensions (height / width / depth) of the section, mm | Max. Working pressure, bar | Thermal power, W | Section capacity, l | Weight, kg |

| Faral, Italy | GREEN HP 350 | 350 | 430/80/80 | 16 | 136 | 0,26 | 1,12 |

| GREEN HP 500 | 500 | 580/80/80 | 180 | 0,33 | 1,48 | ||

| TRIO HP 350 | 350 | 430/80/95 | 151 | 0,4 | 1,23 | ||

| TRIO HP 500 | 500 | 580/80/95 | 212 | 0,5 | 1,58 | ||

| Radiatori 2000 S.p.A., Italy | 350R | 350 | 430/80/95 | 16 | 144 | 0,43 | 1,4 |

| 500R | 500 | 577/80/95 | 199 | 0,58 | 1,6 | ||

| ROVALL, Italy | ALUX 200 | 200 | 245/80/100 | 20 | 92 | 0,11 | 0,83 |

| ALUX 350 | 350 | 395/80/100 | 155 | 0,11 | 0,82 | ||

| ALUX 500 | 500 | 545/80/100 | 179 | 0,23 | 1,31 | ||

| Fondital, Italy | Calidor Super 350/100 | 350 | 407/80/97 | 16 | 144 | 0,24 | 1,3 |

| Calidor Super 500/100 | 500 | 557/80/97 | 193 | 0,30 | 1,32 | ||

| Rifar, Russia | Alum 350 | 350 | 415/80/90 | 20 | 139 | 0,19 | 1,2 |

| Alum 500 | 500 | 565/80/90 | 183 | 0,27 | 1,45 |

That is, the main criteria by which aluminum heating radiators are assessed: technical characteristics and price.

And in accordance with these criteria, one of the best in the middle price range can be called domestic brands Rifar and Thermal, which have excellent physical and technical qualities and have a cost that is 1.5-2 times lower than their foreign counterparts.

Water volume in one section of an aluminum radiator

There are dozens of manufacturers of aluminum radiators, the products of each of them differ in the design and dimensions of the internal channels. Therefore, one can only roughly say how much water is in one section of an aluminum radiator.

The main difference between the models is in height, therefore, we provide a list of the most common sizes (data are indicated in liters):

- 350 mm - 0.2-0.3;

- 500 mm - 0.35-0.45;

- 600 mm - 0.4-0.5;

- 900 mm - 0.6-0.8;

- 1200 mm - 0.8-1.

For non-standard sizes, you can use the formula (V - volume in liters, h - height in meters):

V = h x 0.8

The result will be approximate, but if there is no specification for the equipment at hand, you can use the obtained value.

Note that this capacity of an aluminum heating radiator may decrease over time due to the appearance of corrosion. It is formed from water with poor alkalinity or acidity. Also, the volume of liquid in an aluminum radiator can be reduced due to silting.