A lot of cheap counterfeit products have appeared on the construction market, unscrupulous manufacturers care little about compliance with GOST standards, the goods do not meet either technical specifications or environmental safety standards. More expensive samples from reliable manufacturers are not available to many consumers in this time of economic downturn.

The population of the country, looking for cheaper solutions in the field of insulation of their houses, and, more importantly, more environmentally friendly for health are increasingly beginning to make insulating mixtures with their own hands, one of the components of which is sawdust.

Sawdust as a reliable insulation of the surface of the walls of frame houses

Why is sawdust not used for insulation in its pure form?

Clean, only received sawdust for insulation of premises is categorically impossible to use for the following reasons:

- sawdust walls are a wonderful place for arranging dwellings for rodents, as well as the appearance of various kinds of microorganisms;

- after a while, the wood raw material cakes, voids appear in its mass, it begins to rot and a greater amount of thermal insulation properties disappear.

Undoubtedly, sawdust is a good solution in the issue of insulation - they have a low heat transfer value. However, they must be used wisely, correctly, and only in combination with other astringents. This will avoid the appearance of the negative consequences discussed earlier, and then such a heater will compete with industrial means.

How to choose the right sawdust?

When choosing a material, the quality of sawdust depends on their cost. That is, sawdust can be made from toxic trees, and their price is much lower. When purchasing sawdust, it is necessary to demand from the company documentation for the material, so you can make sure that it is environmentally friendly.

To insulate a house, it is necessary to choose sawdust of a medium-sized fraction. If the sawdust is large, then they lose some of the thermal insulation properties, and if the material is too small, it becomes inconvenient to work, since they emit a lot of dust and can fly away.

If materials with natural moisture are purchased, then they must be pre-dried. To insulate living quarters, it is better to use sawdust from a coniferous tree, they contain resin, and repel rodents and pests. In order to insulate the bath, you can use sawdust of deciduous trees, they are mixed with ash or lime, otherwise they will rot.

Before use, the material is kept from six months to a year, so that substances that contribute to decay are reduced in the sawdust. Sawdust should be free of debris and other inclusions, so they can be sieved through a construction sieve.

The use of sawdust and lime as insulation saves costs, since the cost of materials is not high. Sawdust has high heat-insulating and sound-insulating properties, but they cannot be used in pure form, without impurities, as they are prone to rapid combustion. Thanks to the use of sawdust and lime in a wet form, high-quality insulation blocks are obtained that are not subject to combustion, decay, and damage by rodents. Such materials can be used to insulate the ceiling, walls, floors, roof and attic.

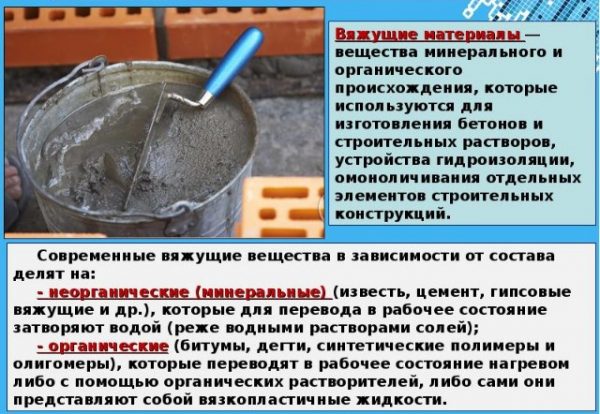

The most popular types of binders

Known to many, such substances as Portland cement, clay, gypsum mixtures, PVF glue, and cow dung can act as binding connectors for wood chips.

Astringents in construction

- Clay is the most inexpensive material, and with access to nature, it is completely free. It is a completely natural substance, therefore it is environmentally friendly - no chemical reactions are present during the drying process, only moisture evaporates. Clay is lightweight, strong enough, but fragile, durable. The only drawback is the fact that unbaked clay is not resistant to excessive moisture - it starts to deteriorate.

If we compare the clay composition with sawdust with others: gypsum, cement, then it is practically not inferior to them.

- Portland cement is the most common binder used in professional construction. The only drawback is a long time to set hardness (standing up).

Cement with the use of wood shavings is excellent for thermal wall plastering, both indoor and outdoor. The embedded cement is excellently resistant to high humidity. Backfill walls are a profitable and reliable way to keep your home warm.

- Gypsum - for interior wall decoration, ideal for “speedy” construction. Such a composition rises almost instantly, and gains strength similar to cement. The cured mixture is durable and environmentally friendly.

- Polyvinyl acetate - hardened PVA glue, insoluble in water, very strong, even tough.

For this reason, PVA is used in places with high humidity, as well as in places with direct contact with water. The hardened glue has one remarkable property - it allows water vapor to pass through - so that the treated walls will not only be insulated, but will also “breathe”. It should be noted that with strong heating of the insulation, moisture will come out of the sawdust, and they will dry out, but PVA deformation is sufficient to hold the shrunken wood particles, without losing shape and overall strength.

- For lack of anything better, cow dung will do. It was widely used until the 19th century. The house was insulated using this natural glue. Today, few people insulate their homes with them, but it is quite suitable for a barnyard. Its strength is certainly lower than that of all of the above means, but placed in the inter-wall space of an outbuilding, it will work for many years.

Other questions on this topic

how obligatory def. seam in the apartment? can it be made of "SUBSTRATE", which is usually laid under the laminate? The representative of the developer assures that the seam in our apartment is arranged as follows: the walls of the tongue and groove stand on a substrate (edges.

Hello! After the renovation of one room, there are still many bags of the self-leveling floor "Prospectors". work was planned in the entire apartment, it was decided not to return to the store. More than three years passed, but the repair could not continue for good reason.

Yesterday we went to buy mixes for wall decoration - rotband, füller. The seller in Leroy highly recommended a novelty - the superelastic gypsum plaster weber.vetonit easy gyps. According to his explanations, it is something two in one plaster and putty.

I really liked 2 types of decorative plaster, I want to do it myself, but I don't know the name, please tell me

SEARCH DOES NOT WORK. URGENT QUESTION (ACTUAL TODAY, September 1): What is the best glue to choose for floor porcelain stoneware and wall tiles? ceresit (which number) or UNIS PLUS or whatever? in some places there will be a warm electric floor devi

Gypsum plastering of walls has been known for a long time. Then all kinds of Vetonites and Rotbands had not yet been invented. This building material was mainly used by Armenians, as a result of which it got the name - "Armenian plaster". It should be noted that only very rich people could afford to plaster walls and ceilings in a house using this technology.

And to this day, despite the huge variety of all kinds of plaster mixes, "Armenian plaster" remains quite in demand.

Armenian plaster technology: preparing the mixture

First you need to mix gypsum with sawdust in a 3: 1 ratio. The ingredients should be dry mixed directly on the floor. There is also a second option: add sawdust to the already shaken gypsum. The finished mixture should resemble sour cream in density.

Sawdust is the only filler that improves the sound and thermal insulation of Armenian plaster. In addition, they greatly simplify the application of the ready-made solution to the wall surface. It is unacceptable to use shavings from under the planer or jointer instead - only from under the circular (and then sifted through a sieve with five-millimeter holes).

Armenian plaster: application on the wall

Once the mixture is ready, builders only have five minutes to fully apply it. This does not mean that you need to cook very little at a time. As a rule, one small bucket of plaster can be used up within the specified period of time.

First, the solution is sprayed onto the wall. As soon as it begins to "set", you can apply the base coat with a scoop or simply with your bare hands.

You need to work quickly, but carefully. Everything that falls to the ground can no longer be used for its intended purpose. As for the thickness of the applied layer, there are no strict restrictions: you can put as much as the base can withstand.

When the plane is brought out, it is necessary to gloss it over (putty on the walls). To do this, clean gypsum should be mixed with some kind of retarder (milk, CMC, etc.), apply the resulting solution with a trowel or spatula and smooth with strong pressure. You will get a smooth and shiny surface.

The main advantages of Armenian plaster:

1. Availability. 2. Environmental friendliness (the base consists of milk, gypsum, sawdust and water). 3. Speed of application (up to twenty square meters per day).

Unfortunately, it is almost impossible to learn the technique of Armenian plaster on your own (from books). Here you need a lot of experience working together with a highly qualified master. It remains to add that the price of plastering work "according to Armenian technology" ranges from 400 to 500 rubles per m2.

If you need a master in Rostov-on-Don to perform this or any other work, as well as advice from our managers, you can contact us by phone, + 7-903-401-04-26 or call the master at home

Call the master

Share the link to this article on social networks and get a guaranteed discount on the services of the masters!

You can also use the following types of services in Rostov-on-Don:

Most people for the construction of a fence are increasingly choosing a profiled sheet, for its durability, reliability, sufficient strength, and also low cost.

The cost of plastic double-glazed windows is quite high, and not everyone can afford to install them at home, but there is a way out - you can simply restore old wooden windows yourself.

The use of various auxiliary components

The principle of operation of heaters is the same - the wood base, which contains small inclusions of air in its structure, is mixed with a binder mass, which, after drying and gaining strength, forms a monolith.

Each composition has its own properties: getting up time, viscosity, elasticity, which can be transformed with the help of additional substances. Each team has its own nuances and solutions for specific tasks.

- So for floor insulation, sawdust is used instead of mineral wool. To increase the service life and reduce the decay process, they are knitted with PVA glue with the addition of an antiseptic solution.

- A small amount of Rotbant or TG is added to the cement-bonded mixture, if it needs to be poured into a mold, to speed up getting up, so if you add a glass of gypsum to the bucket of the mixture, the cement will rise within 1-2 hours.

- The same method works with lime compounds.

Astringents and their proportions

To prepare the sawdust mixture, there is no need to experiment, all the recipes have been known for a long time, the proportions are selected.

Gypsum

To fill, do the following:

- sawdust is placed in the prepared container (no more than 1/5 of the container);

- in a ratio of 1:10 or 1: 5, gypsum grade 1 and gypsum grade 2, respectively, are added to the base and mixed;

- add water at the rate of 1 liter per 1.4 kg of gypsum and mix;

- the mixture does not need to stand, it is immediately poured into a prepared mold.

For plastering work, the preparation of the working solution differs only in the amount of water: 1 part of water for 2 parts of gypsum.

It is necessary to prepare the solution in small quantities, since it rises quickly, and the finished solution cannot be diluted. However, a retarder can be used; casein (carpentry) glue is used as the latter.

As an analogue of the casein retarder, you can use scabbard glue with lime. Retarder recipe: 1 kg of glue is soaked for 24 hours, 2 kg of lime is added and boiled in a steam bath for 4-5 hours. The resulting retarder is added to the mixing water at a rate of 1 to 50. The setting time of the solution is increased by 20-30 minutes.

Super insulation video:

Cement

For novice plasterers, the preferred option is “mud” with Portland cement. The solution lives infinitely long up to 2-3 hours - you can plaster slowly. It can also be reanimated, the main thing is not to let it dry completely or lie down. A small amount of water is added to the prepared mixture as it thickens and mixed. Sometimes the unused solution is left overnight, flooded with water, but that's how lucky.

To improve (preserve) the thermal insulation properties of the wood base, various plasticizers are added to the cement, which increase the plasticity of the composition. As the latter, use liquid soap, shampoo or an inexpensive dishwashing detergent. The addition of a soap additive can also reduce the amount of water used. The amount of additive is measured by eye: there will be enough cap for a bucket - after a couple of batches, even a child will figure out the amount of additive.

Warming with a solution with sawdust and cement, as well as soapy water, is not recommended, because after getting up, the mixture does not allow moisture to pass through - as a result, you will get damp walls, ceiling and floor.

For indoor work, it is better to use industrial additives such as polyplast, fort or superplast - they are more effective than soap or milk.

Milk is used in the same capacity as other plasticizers, but it should be remembered that, using it, the cement will lose strength.

Plastering walls with a solution with the addition of sawdust

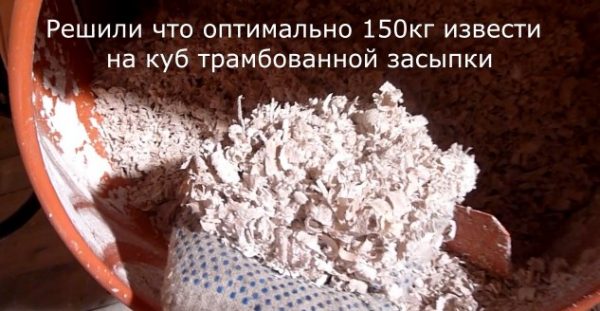

Lime

A very necessary and useful substance in the household. Lime is an alkali that is a natural antiseptic. However, she can wash not only linen, but also disinfect shavings from various microorganisms and their larvae. In addition, the alkali will relieve the base for the solution from rot and protect it for a long time from the appearance of unnecessary organisms, including rodents (they are afraid of it like fire).

For use, only slaked lime is needed (so as not to injure yourself). You need to mix lime with sawdust in the following proportion: 1 part of lime to 10-15 parts of sawdust.

Important! Timber frame walls treated with lime mortar will be more durable. Neither bark beetles nor all kinds of aphids will start in them.

Any other astringent can be added after the sawdust has been treated with lime.

It is possible to use lime as an adhesive composition, but the indicators will be unimportant, and besides, it is better not to use it inside the dwelling.

Lime works too

Clay

Another folk material forever young. It has been used throughout the history of mankind. By mixing clay with straw, you can build a hut. Clay has unique properties and is also very affordable.

Clay as insulation for the walls of the house

For home insulation, the following proportions are recommended:

- For the ceiling and floor - 1 part of diluted clay and 10 parts of wood waste;

- For wall insulation, for filling internal cavities, - 1 to 5;

- For plastering walls, a more viscous mixture is needed - 1 to 2.

The readiness of the clay solution is determined by touch, it should be a little greasy and elastic. If the pieces stick strongly to the trowel, then the mortar must be combined with the shavings.

Clay compositions are the most suitable for human life. They are environmentally friendly, durable, the main thing is to protect products made of unbaked clay from direct exposure to water. Warming with clay with sawdust is a common phenomenon.

The life of the prepared composition is endless, if the clay is dry enough to add water, and it will be fine again.

You can buy clay at any hardware store, but you can get it yourself. You should know that the best clay is at a depth of at least 1.5 meters, since its upper layers may contain particles of plant roots, and this is not welcome.

To fill the walls with clay, the composition should not be liquid and even creamy, otherwise drying will last indefinitely. Clay lumps with sawdust should be moist and slightly crumbly so that they stick together when tamped.

PVA glue for walls

To prepare heat-insulating material, you need a universal or construction PVA, other brands of glue for thermal insulation will not work.

The wood raw material for the mixture needs to be dry and as fresh as possible. There are no clear proportions, the solution is prepared by eye, about 1 to 5-10. The less glue is used, the lower the heat transfer will be. But you should not be greedy either, because poorly processed shavings will rot and rot.

Why do you need sawdust processing

To create thermal insulation, sawdust is used, previously prepared in a special way. Without antiseptic treatment and the addition of impurities, sawdust has two significant drawbacks:

- They become very flammable

- Rodents and other pests grow in them.

Therefore, before starting work, sawdust is mixed with lime, cement or gypsum, and then moistened with an antiseptic solution. The resulting mixture becomes fireproof and unattractive to pests.

Without special treatment, sawdust and careless handling of fire can burn your house to the ground, especially if it is wooden. Therefore, before you build a frame or timber house - think about it!

Scared? Have you changed your mind? But do not give up so immediately! There is an excellent material for insulating wooden houses - ecowool. Of course, ecowool has disadvantages, which are described in this article, but they are relative. All shortcomings can be easily leveled by the competent use of this material.

Do-it-yourself sawdust insulation

Sawdust is mainly used to insulate a one-story house. If you decide to make insulation from sawdust with your own hands, then you need to prepare:

- Sawdust

- Cement

- Leica

- Shovel or stirrer

- Lime

- Wood preservative (boric acid, copper sulfate)

- Mixing container

The thickness of the thermal insulation layer depends on two factors:

- Local climatic conditions

- The functional purpose of the insulated room

If the building will be used exclusively in warm weather, then a layer of insulation 25 cm thick for the ceiling and 15 cm for the walls is quite enough. If you plan to permanently live in the room all year round, then you should increase the layer thickness to 30 cm. To do this, you need to add racks to the main frame, which will create additional space for backfill.

Competent performance of insulation with sawdust requires knowledge of the following points:

- Objects with a high risk of fire (switches, sockets, heating wiring) and the places where electrical wiring and chimneys are laid must be insulated with a non-flammable material. It is most convenient to hide electrical wires in 3 mm metal pipes.

- No vapor barrier is required, as the cement in the mixture will absorb excess moisture and the wood block will become much stronger.

- It should be borne in mind that fresh sawdust contains specific substances that prevent the adhesion of cement with water, so the solution may turn out to be fragile. To prevent this problem, it is necessary to withstand the sawdust for at least two months or moisten them with water glass before use.

Sawdust with cement as home insulation

How to make insulation from sawdust with cement? To create the mixture, we need the following:

- 10 buckets of sawdust

- 1 bucket of cement

- 1 bucket of lime

All components are thoroughly mixed so that the sawdust is well enveloped and saturated with cement and lime. After that, the antiseptic is diluted in water, the solution is poured into the garden watering can and the previously obtained mixture is irrigated.

To check, you need to take a little mixture in your hand and squeeze it - if water does not appear, and the lump does not crumble, then everything is done correctly - the mixture is ready.

The next stage is filling the mixture and its layer-by-layer compaction. It will take at least two weeks for the blocks to fully mature.

The room where the work was carried out must be constantly ventilated.

After a couple of weeks, the covered areas are carefully examined for voids that form during the drying process. If any, they are filled in as described above.

Warm plaster - clay with sawdust

On the basis of sawdust, you can prepare a solution for warm plaster. To do this, they are mixed with cement, clay, water and old newspapers.

Clay and sawdust plaster is used as insulation through interior decoration.

Also, slabs can be made from the finished solution, tamp them well and dry. Such sheets are a good thermal insulation material and are used at your discretion.

Sawdust for floor insulation

Pure, uncontaminated sawdust is not used today, since they are highly flammable and burn quickly. On their basis, various insulation materials are made: ecowool, wood concrete, pellets.

For insulation of floors with ecowool, a manual method or spraying is used. In the second case, you will need a professional blow molding machine and specialist services. The purchase of such a device is impractical, since it will be used one-time, and manual processing consumes 40% more material than spraying.

When insulating the floor in climatic zones where the air temperature does not fall below minus 20 ° C, a thermal insulation layer 15 cm thick is sufficient.If lower temperatures are possible, then for every 5 ° C of frost, it is necessary to add 4 cm of a layer of insulation.

If you do not have the opportunity to hire specialists to insulate your house with sawdust using spraying, we recommend that you carry out wall insulation with foam plastic with your own hands. This material can be used to insulate all types of houses, except for wooden ones.

It is recommended to use foam insulation of houses made of brick, foam concrete, aerated concrete, etc. You can familiarize yourself with the construction of country houses from foam blocks in this article.Due to the large dimensions of the blocks and the precise dimensions, construction is carried out at a high speed.

However, if you are just thinking about building such a house, we recommend that you familiarize yourself with the cons in this article.

Sawdust with lime as insulation for walls and partitions

For insulation of walls and partitions, a mixture of lime with clean dry sawdust is used in a ratio of 1:10. If gypsum is used instead of lime, then the ratio of 1: 8 must be observed.

A small amount of an antiseptic solution (25 g per bucket) is introduced into the finished mixture, poured into the walls and tamped. With this treatment, sawdust does not sag and is not damaged by pests.

Blocks can be made from sawdust by adding cement and copper sulfate to them as an antiseptic. First, the sawdust is moistened with a solution of copper sulfate, and then cement is added to them in the same ratio as lime (1:10). This amount of cement will provide an even coating of the chips.

Water should be added as much as the solution requires so as not to disintegrate in the hand when squeezed. The water should not be squeezed out.

The finished mixture is laid out in ceilings or walls, and after each layer, the backfill is carefully tamped. The shrinkage of the insulation depends on how well the mixture is rammed.

Cement, when interacting with wet sawdust, immediately begins to set and forms a block. After complete drying, a solid hard layer is formed, which practically does not sag, but only crunches underfoot. Thus, at the end of this technological chain, a material with high sound and heat insulation characteristics is obtained at the exit.

We insulate the ceiling with sawdust

The issue of thermal insulation of the ceiling is very important, since about 20% of the heat in the room is lost through it.

The process of insulating the ceiling with sawdust consists of the following stages:

- The rough ceiling is covered with glassine

- Boards are processed with fire protection

- Sawdust is added to the water-cement mortar in a ratio of 1:10. The mixture must be moist. To do this, for 10 buckets of sawdust, you need to take 1.5 buckets of water

- The finished mixture is covered with a layer of 2 cm over the floor surface and tamped. It is better to do this kind of work in the summer so that everything dries quickly. The dried mixture does not crumple, but crunches slightly under the foot

If, when insulating with sawdust, take into account all the specific nuances and carry out the work in accordance with technological requirements and rules, then the result will be a dry and warm room that will remain so for many years.

Advantages and disadvantages of sawdust

Sawdust, considered as a raw material for construction, has its own advantages and disadvantages.

Wall insulation with sawdust pros and cons:

- Cost. This is the first thing for which this multifunctional raw material is valued. For many, the price is zero at all, whether financial costs for delivery are necessary.

- An environmentally friendly material that, when used correctly, does not emit any harmful substances. Chemical contamination is generally excluded.

- Durability in use. This fact is proven by human history - many generations of our ancestors used it and did not complain.

- Installation. In order to perform any kind of manipulation with these materials, qualifications are not needed, the work can be performed even by a person of mental labor who is far from construction.

- Thermal conductivity. A very low indicator for this parameter. The wood structure itself has the smallest air cavities, which is already a universal insulator, plus the fine fractional component of the sawdust themselves.

House of waste from shavings and clay

Disadvantages of woodworking:

- Combustible. It is necessary to observe increased measures for fire safety.

- Rotting.

It should be noted that the existing disadvantages can be solved in various ways, including those discussed in this article.

Pros and cons of sawdust insulation

Sawdust as insulation can be used to work with any elements of the house, including attic floors, floors, walls, cellars and much more. This material must undergo special processing, only in this case it will fit into the complex of construction work. All electrical cables crossing the insulation layers must be insulated, and great attention is also paid to the thermal insulation of chimneys in those places where they pass through the ceiling of the attics.

Sawdust, used as insulation for the ceiling or for other parts of the room, are divided into several varieties depending on the type of wood. The best choice is oak sawdust, which has low hygroscopicity when compared with analogues of other wood species. They are the least susceptible to the spread of rot and are not able to swell when exposed to water. In addition to oak, coniferous waste, for example, larch, pine or spruce, is suitable for thermal insulation.

The list of the main advantages of the material includes:

- increased level of environmental friendliness, since sawdust does not emit toxins;

- very low price;

- the ability to use the material in a free-flowing or other state, for example, in combination with natural or synthetic materials.

The main disadvantage of sawdust or sawdust concrete is a high level of flammability. If the material is used in combination with clay or concrete, its flammability is sharply reduced.

Wall insulation technology

With regard to technology, the following should be noted:

- backfill method. The mixture is poured onto a solid base or placed inside two surfaces where it is rammed;

- filling. A relatively liquid solution is poured into a prepared form, where, as it dries, it acquires the property of a solid monolith;

- plastering. If the walls are plastered with a sawdust mixture, then they acquire thermal insulation properties.

Thermal insulation blocks