Information about the manufacturer Izoroc

Izoroc products are manufactured in compliance with European standards

The date of the appearance of the Russian brand "Izorok" is considered to be 2000, when a large association was created on the basis of the Tambov Mineral Insulation Plant. Further development of this production was supported by investments from a number of foreign companies.

Over time, Izoroc mineral wool has become a very popular product in demand in most areas of construction technology.

To expand the production of mineral wool, the association required:

- significantly expand their production areas;

- acquire modern equipment to automate the workflow;

- to master new technologies of waste-free production of insulation products.

Izorok thermal insulation is made on the basis of the finest fibers from a melt of mineral rocks, the individual components of which are held together by a special binder. The need to comply with all the intricacies of the technological chain stimulated the engineers of the concern to improve this process all the time. Today it belongs to the undisputed leaders of the Russian market of insulation materials.

All samples of Isoroc mineral wool insulation are manufactured in compliance with European standards. Since its production is organized in Russia, the prices are attractive for domestic consumers.

Isolite Isoroc

In Tambov, on three modern production lines, a wide range of thermal insulation materials for various types of insulation is produced. The total productivity of the plant is 110-120 thousand tons of finished products per year, which is in demand in all regions of Russia. ISOROC products have proven themselves from the best side, and are in wide demand among contractors. For a private developer, Isolight Izorok slabs are an example of high quality that meets all modern construction requirements.

Non-combustible ISOROC slabs are produced on the basis of basalt rocks. The manufacturing process involves many manufacturing steps to achieve fiber durability products. The acidity modulus is responsible for the durability of mineral wool, which during the production process must be in a certain range of values of at least 1.8 Mk. In Izorok materials, one of the best indicators of the acidity modulus, which characterizes the chemical composition of the fiber, where the decisive factor is the ratio of acidic to alkaline oxides. Isolite Izorok is produced in slabs with dimensions 1000 * 600 mm and in rare cases 1000 * 500 mm. Speaking of geometric dimensions, this is one of the manufacturers that offers a choice. All products are supplied in bright red and white polyethylene packaging with the manufacturer's logo.

Isolight brands and their distinctive features ♦ Isolight-L - light slabs with an actual density of 40 kg / m3; ♦ Isolight - soft slabs with an actual density of 50 kg / m3; ♦ Isolight Lux - soft boards with an actual density of 60 kg / m3; All of these brands have important characteristics - they are low thermal conductivity, water repellency and incombustibility. The grades differ in their actual density and are in demand for the most part - “Isolight-L” and “Isolight” boards.

Factory label with technical information about the material and its production date ...

Technical characteristics of plates - "Isolight", "Isolight-L" and "Isolight Lux"

| Material characteristics | Isolight-L | Isolite | Isolight Lux |

| Density, kg / m3 | 40 | 50 | 60 |

| Thermal conductivity at 10 С, W (m.K) | 0,036 | 0,034 | 0,033 |

| Thermal conductivity at 25 С, W (m.K) | 0,038 | 0,036 | 0,036 |

| Thermal conductivity under operating conditions A | 0,040 | 0,038 | 0,038 |

| Thermal conductivity under operating conditions B | 0,042 | 0,040 | 0,040 |

| Water absorption at short-term and partial immersion, kg / m2 | 1,0 | 1,0 | 1,0 |

| Organic matter content,% by weight, no more | 2,5 | 2,5 | 3,5 |

| Compressibility%, no more | 15 | 10 | 7 |

| Slab length, mm | 1000 | 1000 | 1000 |

| Slab width, mm | 600 | 600 (500) | 600 |

| Insulation thickness, mm | 50-200 | 50-200 | 50-200 |

| Water vapor permeability, mg / (m • h • PA), not less | 0,55 | 0,55 | 0,55 |

| Flammability group | NG | NG | NG |

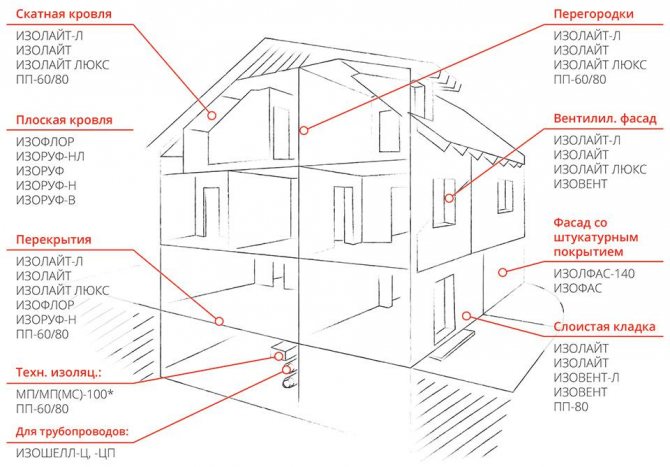

Application of non-combustible plates Isolite Izorok

√ Thermal insulation in layered and well masonry; √ Insulation of internal partitions; √ Insulation of frame walls with siding cladding; √ Thermal insulation of attic rooms; √ Insulation of pitched roofs; √ Insulation of three-layer walls with brick cladding; √ Insulation of interfloor ceilings; √ In systems, a ventilated facade as an inner layer.

The products are used in horizontal and vertical building structures and are the best in their class for a long time!

You can send an application by e-mail

It might be interesting:

| |

| |

| |

| |

|

LLC GK "TEPLOSILA" - together with you since 2005!

Product line

The density of Isoflor allows it to be laid under a concrete screed or decorative floor

The line of insulation materials for Izorok walls contains several subspecies focused on the characteristics of the protected surfaces and various areas of application. It includes the following names:

- Isolight-L;

- Isovent;

- Isofrol;

- Isoruf in packs;

- Izorok in slabs (in cylindrical shapes).

Samples of Isolight-Lux products have a density of 60 kg / cu. meter and are used to insulate surfaces of various orientations. At the same time, large loads and deformation stresses in the layers of products of this type are unacceptable. The next model in the series Isovent-L is distinguished by a significantly higher density (up to 90 kg / cubic meter) and is used for arranging ventilation of building facades.

In the Isoflor modification, the density indicator declared by the manufacturer is close to 140 kg / cu. m. This insulation is used as an intermediate link in three-layer reinforced concrete structures. It is allowed to be used in sandwich panels. For thermal insulation of roofs and concrete floors, another type of insulation material is used, called Isoruf. It is produced with marks H, B or NL, and its average density is 110 kg / cu. meter. Billets of this material or mats without a broaching shell are marked as "MP", and if available - "MP (ST)".

Insulation Izorok in slabs has two modifications with a material density of 75 and 100 kg / cu. per meter, respectively. They are ideally suited for the protection of any horizontal surfaces, but do not allow the load to be exceeded above the limit level. Izorok Cylinders bearing the CF marking are considered as a separate category of heat insulators. Various samples of these products differ in the diameter of cylindrical billets (within 18-273 mm) and are used for insulation of cold water and hot water supply pipes.

Description of the types and characteristics of Isoroc wool

1. Light series Isolight.

The manufacturer recommends using such plates for insulating all the main elements of residential buildings. However, do not forget that due to their low weight, they do not have sufficient rigidity, therefore, on vertical and steeply inclined surfaces, soft mats will inevitably slide during operation. Yes, any low-density Izorok mineral wool insulation is effective, but over time this plus will be practically reduced to zero due to the gaps that have appeared in the general layer of thermal insulation.

Isolite lightweight basalt mats are divided into separate weight categories:

- Izoroc Ultralight is a relatively new thermal insulation in this line with a minimum density (only 33 kg / m3). Available in two sizes: 50 and 100 mm.

- Isolite and Isolight-L (50 and 40 kg / m3, respectively) - may well be called universal heaters, since their rigidity is sufficient for most basic operations: from insulating floors and roofs to creating an inner layer under dense slabs in ventilation facade systems.

- Isolight-lux is a fairly dense insulation of Izorok, which is really suitable for steep roof slopes and interior partitions. Its weight reaches 60 kg / m3, while the thermal conductivity is one of the lowest in this group - from 0.033 to 0.04 W / m · K, and the compressibility does not exceed 7%.

2. Isoroc for facade work.

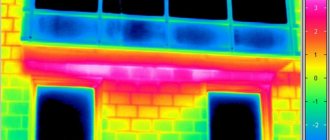

Here, traditionally, thermal insulation is divided into slabs for ventilated facades and external walls for plastering. Both types are characterized by very low water absorption - only 0.5%, however, this is achieved by an increase in the content of organic resins connecting the fibers of Izorok basalt wool. However, when used outside residential premises, this no longer matters.

Isovent - comes in two density options 90 and 80 kg / m3 (modification L). The difference seems small, but in fact, the technical characteristics of Izorok's products change noticeably from this. Although the thermal conductivity remains at about the same level, the compressive strength doubles with increasing specific gravity - from 10 to 20 kPa. With such indicators and sufficient density, Isovent can be used even in three-layer brick structures. The dimensions of the insulation are somewhat non-standard - 500x1000 mm, the thickness, depending on the modification, is selected from the range of 40 (50) -160 mm.

For plastering, you can buy Isofas miniplates with a density of 90-160 kg / m3 (4 varieties in total). Heavier basalt wool allows finishing work even without mesh reinforcement, since its peel strength is three times higher than that for slabs 90/110 (15 kPa versus 5). Isofas insulators can withstand compression from 15 to 55 kPa.

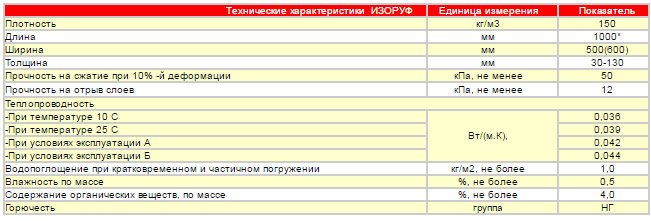

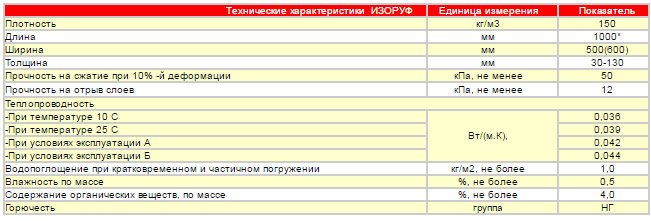

3. Isoroc for flat roofs.

This type of thermal insulation is more in demand in industrial and multi-storey construction, since the Isoruf series was developed directly for flat roofs. Depending on the method of laying and the position of the slabs, one of the following types is chosen:

- Isoruf (base product).

With a density of 150 kg / m3, it shows strength at the level of 50 kPa and an efficiency of 0.036-0.044 WmK. This thermal insulation is suitable for the subsequent installation of roll roofing and does not require additional reinforcement with a cement screed.

- Izoruf-N.

Bottom, it is also the inner layer of double thermal insulation of flat roofs. It has a lower weight (130 kg / m3) and minimum thermal conductivity, thereby providing the necessary protection for the structure. In compression, Izorok can withstand up to 35 kPa, but if such indicators seem too high, you can use an analogue from the NL series of heaters - here the density is only 115 kg / m3, and the strength reaches 30 kPa.

- Izoruf-V.

This is already the top layer, from which a high strength is required (65 kPa for compression and 15 for peel), since it is this layer that carries the main load of the roofing. The density of rigid slabs is 175 kg / m3, but the choice of sizes is small: only Isoroc with a thickness of 50 mm or an even rarer version - 40 mm, which can be purchased on request. However, the main function of this insulation is to hold the weight of the roofing and prevent deformation of the lower substrate under point loads.

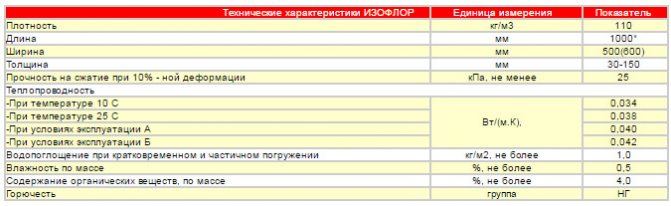

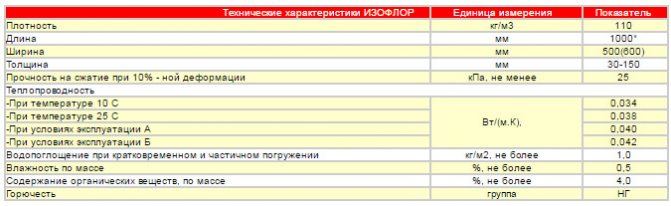

4. Isorok for floors and ceilings.

Isoflor is used for all types of floors that are under stress, including as insulation for concrete floors. Although the density of these slabs is only 110 kg / m3, which casts doubt on their ability to withstand the weight of the screed. Compressive strength - 25 kPa, water absorption is also not the lowest - 1%. But the thermal insulation characteristics are really good - 0.034-0.042 W / mK.

5. Special types.

The Izorok company produces stitched mats of the MP and MS series, quilted with steel wire, glass roving or reinforced with a metal mesh.The operating temperature range for these heaters is quite wide (-180 .. + 700 ° С), since there are no resins that bind fibers, which in other types of insulation limit the scope of its application to +400 ° С.

The main purpose:

- protection of production equipment;

- insulation of pipelines and chimneys;

- the device of fire-prevention scatterers.

If the heating temperature of the pipes does not exceed +400 ° C, the Izorok technical insulation in the form of 1 m shells made of basalt fiber will cope with the task. These are hollow cylinders with water-repellent impregnation Izoschell-Ts, as well as products of the ZF brand, lined with aluminum foil. Both types of heaters are available for 22 different pipe diameters (from 18 to 273 mm) with a wall thickness of 3-9 cm.

Scopes of insulation

Stone wool cylinders are used in engineering communications

Insulation materials of the Izorok brand are characterized by the fact that they are used not only in construction, but also in other areas. In their classic form, they are used:

- for internal thermal insulation and warming of floors (interfloor floors);

- in order to protect attic rooms and roofs of buildings;

- for sound insulation of premises in apartment buildings.

When choosing products suitable for specific purposes, the density of the insulation material used must be taken into account.

Due to their ability to retain heat well, they are used for thermal insulation of various utilities, including centralized water supply and heating systems.

Tips for choosing ISOROC thermal insulation

Thermal insulation ISOLIGHT from basalt wool slabs is used in residential and industrial premises as thermal insulation for non-stressed structures. ISOLIGHT field of application - interior partitions, exterior and interior walls of premises, attic floors. The technology of installation of plates depends on the type of insulated structure; before installation, read the manufacturer's instructions.

Universal insulation ISOVENT Are non-combustible stone wool slabs. Thermal insulation is used for thermal and sound insulation of all types of enclosing structures (horizontal, vertical, inclined). A prerequisite is the use of vapor barrier membranes to protect the material from moisture, as well as the presence of an air gap between the waterproofing film and the cladding.

Insulation ISOFLOOR from the ISOROC company presents non-combustible mineral wool in the form of semi-rigid slabs. The material perfectly reduces heat loss in reinforced concrete structures. It is also used in the construction of electric and water self-leveling floors and other structures in residential buildings. Insulation ISOROC meets all building codes, which is confirmed by the necessary certificates.

Main advantages

The Izorok line of heaters, which has a large number of varieties, is characterized by the following indicators:

- low level of thermal conductivity, which reduces the cost of heating the object;

- good sound insulation;

- high strength indicators;

- resistance of insulation boards to deformations and other mechanical influences;

- good water-repellent qualities;

- fire resistance and environmental friendliness of the product.

Another attractive aspect of this material is its resistance to aggressive environments.

Resistance to fungal formations is explained by the inorganic origin of the starting material, and fire resistance is due to the presence of flame retardant additives in it.

Characteristics

| Size, mm | Packaged | ||||

| length | width | thickness | pieces | m2 | m3 |

| 1000 | 500 | 50 | 8 | 4,0 | 0,2000 |

| 1000 | 500 | 100 | 4 | 2,0 | 0,2000 |

ISOLAYT - a versatile medium density insulation

In modern construction, universal thermal insulation materials are often used, which allow to reduce the cost of purchasing materials and their installation, as well as to avoid mistakes that often arise when using different types of heaters. Therefore the company ISOROK, which has been working on the Russian market for fourteen years, has released a heater ISOLIGHT, with which you can insulate the outer walls of three-layer masonry, interfloor ceilings, partitions, attic floors and frame walls.

Key Features

ISOLAYT is a mineral fiber insulation. For its production, natural, environmentally friendly raw materials are used - basalt rock, which is converted into fibers under the influence of high temperatures. The obtained mineral wool is pressed, adding a small amount of a synthetic binder, and shaped into slabs with dimensions of 600x1000 mm. The thickness of the slabs can vary from 50mm to 200mm, so you can buy ISOLIGHT with optimal characteristics to insulate the house in one layer and thereby save on the installation of thermal insulation.

By purchasing this insulation, you will make your home safe for living - after all, ISOLIGHT belongs to the class of environmentally friendly non-combustible materials. It retains heat well in the house, reduces noise levels, does not rot or decompose, and retains its performance characteristics for more than fifty years. Its only drawback is not too high density (50 kg / cubic meter), therefore, this insulation is not used in loaded structures.

| Technical characteristics of ISOLIGHT | unit of measurement | Indicator |

| Density | kg / m3 | 50 |

| Length | mm | 1000* |

| Width | mm | 500 (600)* |

| Thickness | mm | 50-200 |

| Thermal conductivity | ||

| -At a temperature of 10 C | W / (m.K), | 0,034 |

| -At a temperature of 25 C | 0,036 | |

| -Under operating conditions A | 0,038 | |

| -Under operating conditions B | 0,040 | |

| Water absorption during short-term and partial immersion | kg / m2, no more | 1,0 |

| Moisture by mass | %, no more | 0,5 |

| Organic matter content, by weight | 2,5 | |

| Compressibility | %, no more | 15 |

| Flammability | ||

Isolight price in our company is one of the most affordable on the Moscow market. We sell at wholesale cost and others heaters for homeorganizing their delivery to the construction site.

Material specifications

Insulation is produced in the form of plates of various sizes or rolls, differing in a number of operating parameters. The following technical characteristics of Isoroc insulation are especially important for the user:

- The density of the starting material reaches 150 kg / cubic meter.

- Compression resistance up to 55 kPa.

- Inverse or tensile strength within 15 kPa.

- Thermal conductivity, expressed as 0.075 W / (m K).

- Moisture absorption - no more than 5%.

The last characteristic is understood as the ability of the fibers of the substance to absorb moisture - hygroscopicity.

Application of ISOROC mineral wool

Areas of application of Izorok roll insulation - thermal insulation of horizontal surfaces without load, thermal insulation of inclined roofs, pipelines and equipment. Izorok surpasses expanded polystyrene in vapor permeability, fire and environmental safety, slightly inferior to foam in thermal conductivity and resistance to moisture. The materials have sufficient durability.

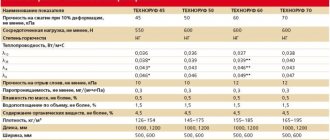

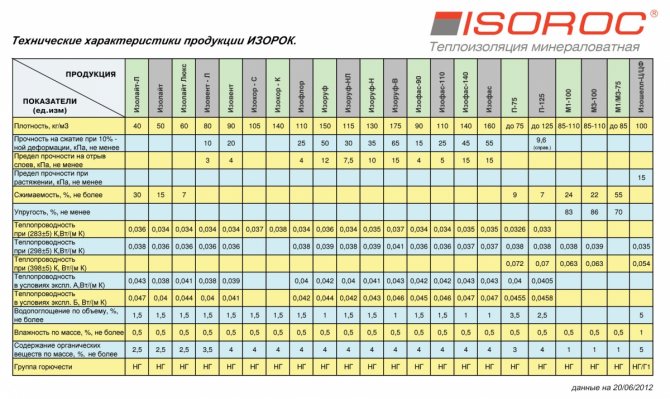

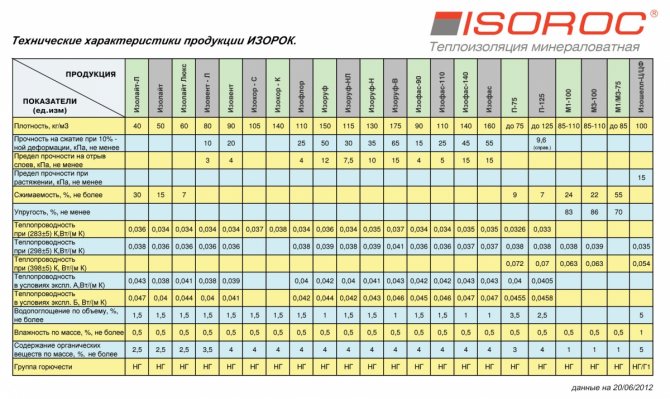

Table. Technical characteristics of insulation materials ISOROC

Installation features

Under the screed, Izorok slabs are laid tightly to each other, without gaps

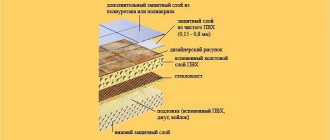

The peculiarities of mounting Izorok boards and rolls for surfaces of various classes are manifested in the requirement to adhere to certain rules. They depend on the conditions in which this material is supposed to be used as a heat insulator. However, in any case, its use is permissible only in combination with steam and waterproofing.

Cement floor screed

Installation of insulation on a floor base begins with preparatory operations, which include the following steps:

- The screed is cleared of accumulated layers of dirt.

- All cracks found on the floor are closed, followed by leveling its surface.

- A waterproofing layer is installed, on top of which Izorok mats are laid.

When laying them, you will need to ensure that the workpieces are located end-to-end without noticeable gaps.

On top of the thermal insulation, another waterproofing layer is laid, on which a reinforcing mesh is then placed. The laid reinforcement is poured with a cement screed. When carrying out these works, it is important to take into account that the total thickness of the coating increases significantly.

Thermal insulation of external walls of frame structures

For external walls, a metal frame is formed for mineral wool

Before purchasing Izorok slabs, their total volume is calculated based on the fact that two layers of protective material are formed. Installation works are carried out in the following sequence:

- On the walls, a lathing is attached based on wooden battens or a metal profile.

- During installation, the distance between the individual elements must match the dimensions of the insulation boards.

- Laying is organized in such a way that the slabs in layers are staggered, the workpieces of the second row completely overlap the joints of the previous one.

To fix the outer sheets on the walls, piece hardware of the fungal type is used, hammered in at 5 points. Waterproofing is mounted on top of the insulated surface, which provides reliable protection of the formed coating.

Insulation of flat roofs

For insulation of roofs, Izorok material with a high density index is selected, laid on a base made of reinforced concrete slabs or a metal profile. Work order:

- A vapor barrier layer is mounted to prevent moisture from entering between the layers of the heat insulator.

- The edges of the protective film must be folded under the insulation, which does not allow vapors to penetrate into it.

- With multi-layer installation, the joints of the slabs are located with a slight offset.

- For the upper layer, a material of higher density is selected than for the lower coating.

- Waterproofing is installed on top of the insulation.

Isoroc insulation is a reliable and high-quality material used in a wide variety of production areas. Due to the ease of installation and availability, this type of heat insulator is constantly in demand among professionals and people involved in construction at an amateur level.

Heaters

18 votes

+

Voice for!

—

Against!

High energy efficiency of buildings against the background of rising prices and obvious energy savings is a need of our time. There are many methods for these purposes, and one of them is insulation. The choice of quality material plays an important role here. New production lines have made it possible to produce high-quality materials intended for the insulation of building envelopes and structures. The article will focus on Izorok insulation.

All manufactured products under the Izorok brand meet all world quality requirements and are one of the leaders in thermal insulation materials. The excellent performance properties of the insulation, combined with an affordable price, ensure its widespread use in the construction of new and renovation of old premises, increasing their energy efficiency.

Isoroc characteristics

For the entire line of insulation Izorok, which has many varieties of material, the following properties are characteristic.

- Low thermal conductivity. The presence of a large number of air pores in the slabs allows accumulating and retaining heat in the walls of buildings and reducing energy consumption.

- High level of sound insulation. Mineral wool insulation, due to the structure consisting of small fibers, has excellent sound insulating properties. Fibers of different lengths are able to efficiently absorb the energy of any sound waves. Using miniplates, you can successfully solve the problem of soundproofing premises.

- Excellent tensile strength.The high resistance of the plates to mechanical stress contributes to an increase in the properties characteristic of insulation - sound and heat insulation.

- Excellent resistance to deformation. Insulation Izorok has excellent strength properties that provide strength and durability.

- Excellent water repellency. This characteristic has become possible due to special hydrophobic additives that prevent moisture from penetrating into the material, and the thermal insulation properties of the slabs increase.

- High refractory properties. Natural incombustible elements that make up the composition enable the fibers to retain their original properties at the widest temperature range.

- Environmental friendliness of the product. All Izorok products are made from pure natural raw materials, which ensures high environmental performance of the finished material. The use of mineral wool insulation of this brand is a guarantee of ensuring favorable living conditions in any insulated room.

- High resistance of the entire line of insulation to the destructive effects of aggressive environments.

- The water resistance of mineral wool boards makes it possible to insulate them on their basis using aqueous solutions.

- The high strength of the material, which is achieved during the production process, ensures the absence of shrinkage, breakage, deformation of the insulation sheets, and, accordingly, the high quality of the work performed.

- Resistance to fungi and microorganisms is due to the inorganic nature of the material.

All types of insulation of the Izorok brand are durable and stably maintain their performance even after the expiration of the warranty period, which is the best recommendation for both large developers and individuals who want to insulate their homes with high quality and reliable insulation.

The use of insulation Izorok

All Izorok products are diverse and include boards for heat and sound insulation, steam and waterproofing membranes, and stitched mineral wool mats. Insulation of the Izorok brand has a wide range of purposes and is used in the construction of various structures, buildings and structures of industrial and residential stock, for their reconstruction and repair. This list may include both temporary structures and structures intended for long-term use.

Depending on the density of the Izoroca, it is used for:

- internal thermal insulation of walls;

- insulation of floors;

- insulation of attic structures and roofs of various buildings;

- in apartment buildings for soundproofing individual rooms;

- thermal insulation of various kinds of communications;

- increasing the indicators of antiseismic characteristics of any structures.

Industrial products are mainly used for:

- thermal insulation of pipelines above the ground and in basements;

- insulation of pipes working with liquids with positive and negative temperatures.

For each type of work, there are brands of insulation, with their properties and characteristics that are best suited for them. In order to make the right choice, you need to know the brand and its purpose. So it will be easier to choose the appropriate one, which will guarantee the quality of work.

Brands and purpose of Izorok heaters

Insulation for interior work:

- Isolite... Miniplates are designed for insulation and sound insulation of various building structures. These structures include vertical, inclined and horizontal surfaces. Isolite can be used for insulating wall frame structures, including for creating partitions, as a heater in frame walls, interfloor ceilings and attics.

- Isoruf... Minplates are used as a heat-insulating layer for equipment of horizontal structures. These can be flat roofs, multilayer insulation is allowed.Another example of use is thermal insulation of floors in the event that the rough base is made by a dry method, that is, there is no cement-sand screed. Isoruf is recommended for use in single-layer coatings. In multilayer insulation, two types of this insulation are usually used: the upper layer is laid with Isoruf B material, and the lower one - with Isoruf N. These varieties can also be used as a heat-insulating layer in "sandwich panels" with a metal sheath.

- Isoflor... High-density mats, used in construction work as an intermediate layer in reinforced concrete structures, for the organization of sound and heat insulation of interfloor floors. The same material is used to insulate the floor when arranging a wet screed or self-leveling floor. Isoflor can also be an element of "sandwich panels" with a metal sheath.

Insulation for external work.

- Isovent... Mineral wool slabs, the brand of which is used in construction in the form of heat and sound insulation of various structures, such as layered or well masonry. The same option will be the most suitable if the building is insulated using a system of hinged ventilated facades.

- Isofas... It is recommended to use miniplates for arranging the insulation of the outer perimeter of the walls of the building, if the work is carried out using the wet method. Isofas and Isofas 140 slabs are mainly used as facade insulation, where plastering is used. Isofas 90 and 110 grades - respectively, in cases where the plaster layer is thick. Plastering is carried out using a steel reinforcing mesh.

The most popular among private construction is insulation slabs izorok 50 (density 50kg / m3) and izorok 75 (density 75kg / m3). On average, their cost is 350 rubles / pack. They are suitable for indoor and outdoor use

Izorok technical insulation. These products are stitched mats and heat insulating cylinders.

- Izorok M1-100, M2-100... This is a heat and sound insulating material, the scope of which includes the insulation of building structures of various types, as well as industrial equipment used in a temperature range from - 180 to an impressive +700 C. Another option for insulation is M2-100 stitched mats, among other things, produced on a metal mesh. And the last representative from this line - M3-100 mats - have an additional coating made of another heat-insulating material - fiberglass.

- Isoshell - C and Isoshell - ZF... Foiled heat-insulating cylinders and half-cylinders are designed for thermal insulation of technological pipelines. Working temperature range from -180 to + 400C. The price of a heater of this brand ranges from 400-500 rubles / pack.

Installation of insulation Izorok

There are rules for performing insulation with Izorok plates of different types of surfaces. For most technologies, it is necessary to use steam and waterproofing in order to maintain the quality of the insulation. To ensure the best performance, it is imperative to use the products of the same company.

Cement floor screed with insulation Izorok

- Before proceeding with the installation of the insulation, it is necessary to remove the obsolete floor covering, clean the old screed from the dirt located there, fill up the cracks and cracks, level the entire surface, lay the waterproofing material, then the mats of the izorok, which should be located end-to-end, thus so that there are not even minimal gaps between them. Then the waterproofing layer is again laid, and a reinforcing mesh is placed on it, onto which the cement screed is poured.

- If under the screed there is a room in which it is warm and humid, for example, a sauna, then there is a need for additional vapor barrier, which in this case is located under the sheets of insulation.If at the bottom there is a cold and damp room such as a cellar, then the vapor barrier is located on top of the insulation.

Izorokom insulation of outer walls of frame structures

- In wall structures of this type, slabs have proven themselves in the best possible way. Insulation is of the highest quality when it is made with two layers of material.

- A crate is mounted on the walls from wooden slats 5 cm wide (by the thickness of the mats) or a metal profile. The distance between them is equal to the length or width of the insulation.

- Laying is carried out in such a way that the slabs located outside overlap the seams of the layer of material located inside. The sheet is fixed with self-tapping screws of fungi at 5 points.

- The outer layer of insulation must be protected by a wind and waterproofing film.

Insulation by Izoroki of the walls of frame structures from the inside

- As a rule, even at the stage of building the frame, the distance between the wooden posts is set equal to the width of the insulation, that is, 60 cm.

- Therefore, there is no need to make a crate, a piece is simply placed in 3 layers (15 cm) in these niches and is not attached in any way. On top, it is fixed with a vapor barrier film, which is strongly stretched.

- Although it is said about the environmental friendliness of the material, when mineral wool particles get on the skin, severe itching begins, which cannot be washed off within a day. Therefore, it is important to wear personal protective equipment and wear rubberized gloves.

Dry method of floor insulation Izorokom

The floor is insulated according to the following scheme:

- a layer of waterproofing is laid on the already existing wooden floor with tightly laid boards. Logs are laid on top of the boards, in the intervals of which insulation is placed close to them. It is necessary to do this at a distance so that there are no gaps and gaps;

- the next layer is vapor barrier. Its presence prevents the penetration of moisture from a warm room into the cold insulation layer. This must be done in order to protect the insulation from moisture, since it is moistened, it loses its original thermal insulation properties;

- further along the logs, a rough floor is laid. It can be plywood, OSB, etc. A topcoat is placed on top of this material. It can be laminated or any other coating the homeowner wants.

Insulation of interfloor ceilings Izorokom

- Mineral slabs can be used to insulate interfloor wooden floors. For this purpose, they are laid between the beams.

- It is not necessary to place a layer of protective vapor barrier for insulation between rooms of different levels, but with the same temperature in them.

- If one of the rooms is warm, and the second is humid, for example, a bathroom or kitchen, vapor barrier is simply necessary. If the damp room is located at the top, then a layer of waterproofing is required.

- From the side of the second floor, the sequence of the arrangement of materials looks like this: floor covering, logs, if necessary, a layer of hydro or vapor barrier, insulation between the beams, if necessary - a layer of vapor barrier, boarding, ceiling finishing.

Insulation of flat roofs by Izorokom

- Isorok with high density can be used to insulate a flat roof. The base on which the insulation will be mounted is reinforced concrete floor slabs or profiled metal sheets.

- First you need to install a vapor barrier layer. It is necessary here in order to prevent the penetration of moisture vapors into the layers of thermal insulation. After all, only dry insulation can retain its properties, and wet insulation significantly reduces its characteristics. Large accumulation of steam causes unwanted deformation of the slabs. It is advisable to perform vapor barrier with fewer seams and select thicker membranes in order to provide the best quality protection.

- The edges of the film must be installed above the insulation, in order to exclude the penetration of steam into it.With multilayer insulation, the joints of the slabs are positioned with a slight offset. The upper layer should be superior in density to the lower one.

- Waterproofing is applied last. For the safety of the material, it is advisable not to walk on it.

Insulation with Izorok slabs of pitched roofs

- The first step in insulating pitched roofs is to install a waterproofing film, which is carried out over the rafter system. The material is laid across the slope with an overlap, so that the upper ones are layered on the lower ones. Individual canvases are connected with self-adhesive tape.

- From above, counter-lattice bars are stuffed, which provide the necessary in this case a small ventilation gap that will pass between the roofing and the future layer of insulation.

- Izorok is installed between two rafters of a rafter. This is done to securely fix the elements and to ensure the best thermal insulation results. It is necessary to prevent ruptures of the thermal insulation layer or its loose abutment to the rafters. Insulation izorok over the entire surface should be the same.

- The next stage is the installation of a vapor barrier. The material is fixed with brackets on the inside of the rafters. The strips are overlapped. The joints are secured with self-adhesive tapes. The last is the installation of the ceiling sheathing. A roof covering is installed on the outside of the roof.

Insulation of a wet facade with Izorokom

- The external method of insulating buildings is more preferable as the most effective in terms of thermal insulation of buildings. If you can choose between internal and external, it is recommended to choose it.

- You need to start work with surface preparation. It must be cleaned of all existing contaminants, and cracks must be repaired, if any. If there are irregularities, level them. Prime the dried finished surface.

- The next stage is the installation of a profile strip along the perimeter of the building. It is mounted at a height of about half a meter from the ground level. The bar is needed to distribute the uniform load emanating from the insulation boards. Plates are installed on it, which are attached to the base using a dowel of nails with a wide head. Insulation is arranged in rows, starting from the basement profile.

- Next is the reinforcing mesh, which is attached to a special adhesive composition. First, slopes, corners, etc. are strengthened. After installing the mesh, you can start applying plaster layers according to all the rules necessary for such work.

Ventilated facade with Izorok

- Mineral wool slabs are also used in ventilated facade systems. This is another option for high-quality external thermal insulation of buildings. The system itself consists in the fact that between the layer of insulation, which is attached to the wall and the decorative facing layer, there is an air layer. It is needed for the free outflow of moisture from the insulation layers. On the other hand, moisture that penetrates under the cladding cannot reach the thermal insulation material, since the air serves as a barrier. Another advantage of this method is that all work is performed at any temperature.

- The installation of the insulation is carried out in the same way as the installation of the heat-insulating layer, typical for the wet method. The only difference is that after installing the slabs, the frame of the ventilated facade is mounted on top.

- The question of installing a steam and wind protection film remains open. Opinions differ here. To install it or not, it is worth focusing on the installation technology provided for slabs and facade systems and the recommendations of manufacturers and specialists.

Izorok mineral slabs are reliable and high quality material.A large selection of products with different indicators and technical characteristics makes it possible to successfully use it in a variety of areas of construction work. This is an easy-to-use and affordable material that will be appreciated by both professionals and people who conduct construction on their own. In addition, in recent years, Izorok's products have received extremely positive reviews.

ISOROC

ISOROC aims to solve a number of problems: saving energy, improving living conditions, improving the quality of thermal insulation of residential and non-residential buildings, as well as meeting the needs of Russian consumers of environmentally friendly insulation.

Why choose ISOROC?

Basalt insulation ISOROC is created from environmentally friendly raw materials - natural stone, from which mineral fiber is obtained by melting. It has many unique properties - it does not burn, does not deteriorate from exposure to moisture, does not rot, does not deteriorate from time to time, and is chemically neutral, which allows the mineral fiber to maintain its integrity even when completely immersed in acids and alkalis. This material is absolutely harmless to human and domestic animal health. Therefore, the insulation made from it is only a popular product - after all, its use increases the comfort of living in the house.

By the way, the insulation is made by pressing - adding a special synthetic binder to the mineral fiber, and under pressure, at a temperature of 250 ° C, giving this mixture the shape of plates. Unfair competitors are spreading the rumor that the finished insulation releases a substance such as phenol, which is toxic and can cause serious illness. However, phenol-formaldehyde resin, which is part of the binder for mineral fibers, loses its toxic properties during the manufacture of insulation, undergoing a polymerization process. Therefore, in finished slabs, it is in an inert (inactive) state. Mineral wool insulation is capable of emitting no more than 0.003 mg / m3 of phenol into the air, and this figure is within the MPC (maximum permissible concentration), while the maximum content of this substance in the atmosphere can be 0.035 mg / m3. But if you decide buy ISOROC

, and you doubt its environmental friendliness, ask the seller for a sanitary certificate for this product to once again make sure that it is safe.

Insulation ISOROK - which one to choose?

The ISOROC company produces sixteen varieties of mineral wool insulation. Which one to choose so that the insulation of the house is of high quality and allows you to save on heating and save resources for a long time?

Of course, like any other insulation, ISOROC should be chosen based on the design features of your home. In which region is it located? What will be its foundation, roof, walls? What's inside - log floors, frame partitions, an attic or an attic? What will be the finishing of the facade? The answers to these and many other questions will help to correctly calculate the density and thickness of the insulation and select those types of insulation that will allow you to maintain the thermal characteristics of the house without overpayment and additional time costs.

In general, ISOROC produces both universal thermal insulation (which is suitable for insulating various structures of a house - walls, floors, pitched roofs, etc.), and a heater with a narrow purpose. For example, IZOFAS for "wet" facades, or IZORUF for roofing. The company also produces thermal insulation for the creation of engineering systems - for example, IZOSHELL-Ts for pipelines. The cost of insulation ISOROC

largely depends on its density and compressive strength and peel strength. Another parameter that affects the price is the thickness of this material, which can vary from 30 mm to 200 mm.Therefore, you can choose a product from the ISOROC range for any budget.

Installation of insulation ISOROC

Basalt mineral wool slabs are lightweight and have a standard size of 600x1200 mm. Therefore, they are very easy to install - after all, one person can raise the insulation to any height and fix it, without the use of construction equipment. If necessary, the ISOROC slabs can be cut with any sharp tool. They are inserted inside the frame structures when insulating the roof or walls, or laid on the base of the floor. When installing on walls without lathing or on a roofing base, the insulation is attached using glue or disc dowels. In some cases, it is recommended to use a vapor and waterproofing material that will extend the life of the insulation and allow it to maintain its operational properties.

In our store you can purchase insulation ISOROC with delivery

and at a wholesale price. We will implement any

heaters for home

from Russian and foreign manufacturers. If you do not know how to choose

insulation for walls

, facade, floor, roof or foundation, contact our specialists - they will help you solve the issue efficiently and most economically.

Review of product opinions

For a more complete picture of the technical characteristics of Izorok, you can study the properties of materials or use the feedback from buyers who decided to buy insulation:

“We've heard about mineral wool for a long time. During the construction of the house, the question of the manufacturer was raised. There are many options on the market, but most of all positive votes are in favor of Izoroc products, so the choice was stopped on him. The walls were built from cinder block, which shortens the time, but has its drawbacks: the stone practically does not protect from the cold. After calculating the required amount, we purchased 100 x 60 cm slabs with a thickness of 50 mm, which turned out to be quite sufficient for maximum effect. The insulation is mounted elementary, it is not difficult to do it with your own hands. Since the walls were subsequently planned to be sheathed with siding, when arranging the lathing they were installed on suspensions. Isoroc was attached to them, then fixed with a profile. Foam was passed at the seams for reliability. The insulation has been serving well for three years already, there are no complaints and the price is acceptable. "

Arkady, Voronezh.

“When it came time to put the dacha in order, I thought about what brand of materials to buy for insulation. The review of reviews about the manufacturer Izorok helped. The range of products is amazing, you can choose the most suitable option. After ordering, specialists arrived with insulation, the work was done very quickly and efficiently, the price was also pleased. Equipped walls, roofs, floors. A year has passed, the house does not let the cold pass at all, no drafts, mold and excess condensation. Now I plan to make the same thermal insulation for my parents, judging by the description, it lasts a long time, is laid for many years, and there are no problems during operation. "

Egor Arekhtin, Moscow.

“We planned to re-equip the loggia, it was necessary to choose a high-quality insulation. We took advantage of the reviews of friends and ordered Izorok. The husband did all the work himself, surprisingly quickly and easily. The mats fit perfectly, the main thing is to follow the correct technology and take into account all calculations and stock when buying. Sheathed with clapboard, which fit perfectly. Thanks to good insulation, we got a study that is comfortable and cozy, the microclimate is maintained no worse than in other rooms. It came out inexpensively for the price, which was a nice bonus. "

Angelina, Nizhny Novgorod.

“According to reviews, Izorok is now one of the best brands of insulation. We chose this product because of its reasonable cost and did not regret it at all. Building a house requires huge expenses, but I wanted the purchase of economical options not to end with a loss in quality. Izorok thermal insulation meets all the criteria.Brick is unable to protect the walls from frost, and in this brand there is a type of material that is ideal for masonry. Judging by the characteristics, thanks to the correct installation, it will serve us for more than a dozen years. "

Olga, Moscow region.

“Izorok was purchased as insulation for the attic, the managers helped, who gave good reviews to the material. Previously, only a foreign manufacturer was trusted, this time the domestic company pleased. It is easy to install cotton wool, it does not crumble during work. There are several types of it, for the floor we will choose another option, with suitable characteristics. The price is excellent, you can buy with a margin and not worry about saving. Now we also recommend Izorok insulation to all our friends, as the combination of cost and quality fully satisfies. "

Alexander, Tula.