The service life of heaters, which heater to prefer

Many competent sources claim that the service life of mineral wool and polystyrene foam is 25 - 35 years. At the same time, the wall, which is insulated with these brick or concrete heaters, serves for more than 100 years. Therefore, the insulation of the wall during its service must be changed at least 3 times. Was the insulation chosen correctly, because of which it is necessary to overhaul the building in such a short time?

How long do inexpensive heaters last?

The main question is - where does the service life of cheap heaters of 30 years come from? Today, some manufacturers of mineral wool in the technical characteristics for individual brands of their products indicate that its service life is 50 years.

Moreover, this figure is not explained by anything, there is only a footnote stating that today there is no standard for determining the shelf life of heaters.

Scientific articles on artificial heaters indicate that heaters containing artificial organic substances can last no more than 35 years.

During this period, the destruction of organic matter, aging of the substance occurs, the insulation "cakes" or "dries up". The main thing is that as a result of this, the insulation loses its heat-saving ability by more than 1/3. Therefore, mineral wool insulation or expanded polystyrene must be completely changed within 35 years.

How is it in Europe?

Now in European countries, according to the legislation, an energy audit of each new house, including a private one, must be carried out after the completion of its construction. According to the results of which, energy consumption is issued to the building.

Proven energy savings have a very significant impact on property values in Europe.

Repeated energy audits should be carried out after 25-30 years, after a period equal to the service life of conventional heaters. Subsequent - after about the same period of time.

As a result, it becomes clear how much the building has lost its heat-saving properties, which enclosing structures and how much reduced the resistance to heat transfer, where it is necessary to change the insulation material or carry out other repairs.

Like we have

In our country, such studies are not mandatory, although they are recommended by the standards. As a result, in most cases they are not carried out, and it is not possible to find out exactly the real service life of heaters by examining them after many years. It remains to use the data coming from abroad, according to which the indicated figures were taken.

It is advisable to carry out an energy audit of new buildings and periodic inspections of the resistance to heat transfer of the enclosing structures within the time limits recommended by the standards. Then it will be possible to control changes in the insulation of the building, to carry out the necessary repairs in time.

When to change insulation

The exact answer when to change the insulation can only be given by a special examination of the heat-saving properties of the building (energy audit). But since over the past 20 - 25 years, when the use of insulation such as foam and mineral wool began, we did not conduct such surveys, it remains for subsequent checks only to compare the results obtained with theoretical calculated values. But there is no reliable statistics for the failure of heaters.

Accordingly, it is necessary to use the recommendations for replacing non-mineral heaters within the terms indicated above.

Experts agree that the service life of existing heaters with organic components is several times less than that of the enclosing structures that are insulated with them. The use of such heaters entails premature overhaul of buildings. How can you avoid this?

Dense mineral wool and aerated concrete with a long service life

There is consensus that denser mineral wool lasts longer. Partly because the quality of workmanship is provided by eminent manufacturers, and partly - in denser mineral wool there are fewer resin binders (in total, mineral wool contains from 3 to 10% organic binders). More dense (more than 80 kg / m3) mineral wool samples last longer.

Aerated concrete made in autoclaves with a density not much more than 100 kg / m3 is now a successful replacement for mineral wool. This material has a coefficient of thermal conductivity comparable to organic insulation - 0.5 - 0.8 m W / mS.

But most importantly, this is a completely mineral compound, which is essentially a foamed stone, therefore its service life (in the absence of excess moisture) is comparable to this indicator for heavy building materials - bricks, dense concrete.

The use of insulation without organic matter will save you from many problems in the future, especially when it comes to insulating multilayer walls (how walls with clinker brick lining are insulated),

Low-density aerated concrete is a vapor-permeable insulation, its use is similar to the use of mineral wool.

Eternal foam glass

Another well-known insulation without organic matter is foam glass, the service life of which is more than a hundred years. This insulation has been used for a long time, (in particular in the secret arms sector), it has less heat-saving capabilities compared to effective insulation by about 1.5 times, it does not let water vapor through itself and does not accumulate water.

But its distribution is limited due to the increased price, although it is popular when insulating expensive houses.

Extruded polystyrene foam stands out among the foams for its predictable resistance to harmful factors and durability. It does not accumulate water, does not pass steam through itself (similar to foam glass), it has a denser structure and 2 times higher specific gravity compared to foam plastic (over 35 kg / m3).

But due to the higher price, it is used mainly in difficult conditions, in soils, for foundations, plinths, basements. In any case, among plastics, it is more recommended for use by the factor of "survivability" than other plastics.

As you can see, for the insulation of the building envelope, it is better to choose an insulation with a minimum of organic substances or without them at all.

Mineral wool or polystyrene, which insulation is better to use for warming a house and how they differ

Many building materials have good thermal insulation properties, the most popular are polystyrene and mineral wool. These materials are widely used to insulate the facades of houses, so many people have a question, which is better - mineral wool or polystyrene, what are their differences, strengths and weaknesses.

Styrofoam

Before describing all the advantages and disadvantages of foam, it is worth writing about how the popular building material is produced. Styrofoam belongs to the class of plastics, in its structure, it consists of many cells with air bubbles. It is this feature in the structure that gives the material excellent thermal insulation properties.

Foam plastic is made by foaming polystyrene granules, after which small particles are treated with heated steam. This procedure is repeated several times until the finished material is obtained. This process is necessary in order to reduce the weight and density of the foam.The material in the production stage goes through a drying process to remove excess moisture, and then it is molded into plates by pressing.

The main technical indicators of the foam is its density and compressive strength, bending, as well as heat capacity and other qualities.

In everyday life, many of us are faced with a type of foam - pressless expanded polystyrene. Depending on the components used in the production process and production technology, foams can be of different mechanical strength and density, and have varying degrees of resistance to impact.

Main advantages

The main advantage of foam is its high thermal conductivity, this feature has allowed it to be used in almost all construction industries. The thermal conductivity of the material allows you to save on heating costs during the cold season. On hot days, this property will also give positive points - coolness in the room with minimal air conditioning costs.

- The material approved for construction is not toxic, therefore it is safe for health.

- In addition to high thermal conductivity, foam has good sound insulation.

- It does not require waterproofing in its work, does not absorb moisture at all, due to this, there is no fungus and pathogenic microbes in it.

- Polyfoam perfectly withstands temperature extremes.

- The light weight of the material made it easy to use it in construction work. It is easy to install, lay and fasten.

- The low price is also a significant advantage of foam as insulation for house facades and other types of construction work.

The material also has and some disadvantagesthat may limit its use. He needs extra protection.

- When foam is used as insulation outside, it needs additional protection, since the material is not UV resistant.

- It undergoes destruction when it comes into contact with technical fluids such as acetone, benzene. It does not tolerate paints and varnishes well, therefore it is recommended to paint it with water-based agents.

- Flammability. When moments of fire occur, the material emits a small amount of toxic substances. In this regard, in the process of its production, fire retardants began to be added, a special substance gives fire resistance to the material, but in this form it is more expensive.

- In the process of work, the foam crumbles, so there are often times when it is difficult to work with it due to its fragility.

This material is obtained by melting glass (glass wool), rocks (basalt, stone wool), blast furnace slag (slag wool). All materials are fibrous and porous. They are distinguished by high thermal conductivity, for which they are widely used in construction work, especially for the insulation of houses. Mineral wool there are a number of advantages, they made the material a leader in the list of insulation materials.

- High fire resistance... Insulation can withstand very high temperatures, some types of materials are resistant to combustion at + 1000 ° C. In moments of fire, mineral wool does not support combustion, even if it comes into contact with fire.

- Good vapor permeability... Mineral wool perfectly permeates air, this property helps not to trap condensate, but to effectively remove it.

- Moisture resistance helps keep mineral wool out of water, when it gets wet, the material dries out, does not lose its shape, does not deform and retains its positive properties. Mineral wool at the production stage is treated with special oily agents or water-repellent substances.

- Thermal insulation properties made it possible to use all types of mineral wool, both for external and internal construction work. Insulation is able to regulate the indoor climate.

- Minvata is capable of absorbing many sounds, therefore it has high noise insulation.

- Environmental friendliness is also an important advantage, mineral wool does not emit substances harmful to the body. Even when exposed to high temperatures, the material is harmless.

Structures of buildings and structures

Message from: Although manufacturers of mineral wool insulation indicate a service life of up to 50 years, the practice of using the material shows that in the event of a deviation from the technology of installing mineral wool, it will last for a few years. Under ideal conditions, subject to all installation requirements, the service life does not exceed 8 - 10 years. It is known that a year after the installation of mineral wool, thermal conductivity indicators deteriorate to 40%.

Familiar builders opened a socket with a minelite after 15 years of service. Instead of minelabs - dust. I have heard several other similar stories. How can the service life of the insulation be guaranteed for 50 years? How is this done, who knows? Some kind of calculation or test? Again, 50 years - under what operating conditions (temperature, humidity, frequency of blocking and freezing, etc.). Or they should write - 50 years for all climatic regions in the Russian Federation and 100% humidity. Immediately more questions arose.

Message from Aragorn: I understand that builders will not like it if designers will lay extruded polystyrene foam everywhere, as it is quite expensive. But only he has a service life of 50 years.

Extruded polystyrene is also not a panacea. Firefighters are categorically against him. Look at stone wool, basalt. They have a 50-year guarantee. Also not 100 years old, but already better than foam. Polyfoam is very toxic. And burns out in minutes. There are a lot of videos on the net with glowing expanded polystyrene facades. I recommend only non-combustible insulation to the architects I work with. And it is also important that it is vapor-tight. I think it's clear why. And regarding the short service life of the insulation, the penoplex generally has a 25-year warranty, at best. Despite this, only he is used in basement structures. Previously, there was not all this construction chemistry. There was expanded clay - insulation. Deprecated. There were 780mm brick walls outside, and there were more than a meter. Here is a long-liver brick. But. Regarding the legal component of this whole story, after a certain service life of the building, overhaul is carried out using effective materials already for the period when the overhaul is being carried out. This is all spelled out. So, most likely they will answer you, those to whom you contact with a claim regarding violation of consumer rights.

Message from: It is also important that it is vapor-tight. I think it's clear why.

Message from Engineer SV: I recommend only non-combustible insulation to the architects I work with. And it is also important that it is vapor-tight. I think it's clear why

.

Characteristics of stone wool

- Thermal conductivity - 0.04-0.05 W / (m * C).

- Water vapor permeability - 0.25–0.3 mg / (m • h • Pa). This means that the house will "breathe", creating a healthy indoor climate.

- Water absorption by volume - from 1 to 3%.

- Density - from 25 to 200 kg / m³.

- Compressive strength (depending on the type of material) - from compressible soft products (compressibility up to 50% according to GOST 17177) to rigid plates with a compressive strength at 10% deformation equal to 0.1 MPa.

- Flammability group - NG (non-combustible).

- Environmental friendliness - despite the presence of a small amount of synthetic binder, the material is recognized as natural and absolutely safe, it is approved for use even inside residential structures and public buildings.

- Durability - manufacturers promise more than half a century without loss of performance, which is confirmed by the world experience in the use of insulation. In addition, if the material gets wet, which is unlikely, because high-quality stone wool materials have water-repellent properties - it's okay, because after drying it will not lose any of its properties. And animals and mold are not touched by cotton wool - manufacturers have created such a material that is bio-resistant.

When choosing a heater, priorities are usually placed in the indicated order with minor displacements of criteria, but the flammability group rarely comes first.Nevertheless, this is one of the most important parameters: when insulating, the house is not only "wrapped" around the entire perimeter, the insulation is also placed in the ceilings and in the rafter system. It turns out a closed circuit, which should at least restrain combustion, and ideally prevent it, and certainly not support it in any way. It is enough that the "filling" of houses, as well as the lion's share of the cladding, is combustible. Knowing the flammability group of the insulation, it is easier to select the rest of the components of the facade or roofing "pie" in order to minimize the danger, rather than enroll in future fire victims. Here are the most popular materials.

| A kind of thermal insulation material | Flammability |

| Stone wool | NG |

| Styrofoam | G3-G4 |

| Extruded polystyrene foam | G3-G4 |

| Polyurethane foam | G2 |

| Cellulose insulation (ecowool) | G2 |

| FEAST | G1-G4 |

If it is clear with non-combustible (NG) materials, then the properties of the remaining groups should be deciphered.

Federal Law "Technical Regulations on Fire Safety Requirements" dated July 22, 2008 No. 123-FZ (current edition, 2016).

But the fire safety of a material is not only a flammability group, there are other properties that can reduce the safety of a building, lead to the death of people and entail serious material damage.

Each material used in the construction and decoration of houses is considered from the point of view of fire safety and is evaluated according to five criteria:

- Flammability.

- Flammability.

- Smoke formation.

- Combustion products toxicity.

- Flame spread over the surface.

| Fire hazard criteria for building materials | Class of constructive fire hazard of building materials, depending on the groups | |||||

| KM0 | KM1 | KM2 | KM3 | KM4 | KM5 | |

| Flammability | NG | D1 | D1 | G3 | G4 | G5 |

| Flammability | IN 1 | AT 2 | AT 2 | AT 2 | AT 3 | |

| Smoke-generating ability | D 2 | D 2 | D3 | D3 | D3 | |

| Toxicity | T2 | T2 | T2 | T3 | T4 | |

| Flame spread | RP1 | RP1 | RP2 | RP2 | RP4 | |

Andrey Petrov

High-quality stone wool, being non-combustible, does not ignite, fire on its surface will also not be able to spread. With regard to smoke generation and toxicity, binders will begin to melt and burn out before fibers, but their amount in the material is too small to form a smoke screen. They are not enough to poison the air, even with an internal fire source, not to mention the external one. The melting point of stone wool is 1000⁰C, since thin fibers are easier to melt than rock, but this threshold is enough to extinguish the flame. Stone wool as fire protection withstands 240 minutes of direct flame exposure.

But regardless of the type of insulation, experts advise to be more careful with the choice of material and be based not on the lowest cost, but on the reliability of the manufacturer and the experience of use. You can "get hold of" experience both from neighbors / relatives / acquaintances, and on our portal, there is more than enough of it. As for certificates, unscrupulous manufacturers have forgeries, that is, even their presence is not a panacea, let alone products for which they do not exist at all, although by law a fire safety certificate is required.

Service life of heaters: table, characteristics, description of advantages and disadvantages

Today in this article we will consider the current issue of the service life of heaters in the table. Typically houses, buildings and other structures are insulated for a long time, therefore materials are needed as reliably and of high quality as possible... Many people believe that various types of insulation do not last more than 30 years. Taking into account that the wall, which is insulated, costs about 100 years, we come to the conclusion that during this time the procedure must be done 2-3 times. If you calculate the cost of such an upgrade, then it may be far from pleasing.

Wear resistance

Attention must be paid to how the material resists wear.Usually, manufacturers independently carry out the necessary studies, which include tests for resistance to certain types of loads. This wear can be associated with various parameters. Most often, there are temperature effects, the influence of moisture and corrosive substances. The results obtained make it possible to conclude that during the entire service life and even more, signs of wear do not appear on the foam plates. These periods are 20-50 years, depending on the type and type of material. Such conditions are quite enough to perform high-quality cladding of the external and internal walls of the house, roof, attic and foundation, where the foam can be used as waterproofing.

Back to the table of contents

What affects the life of the insulation?

As with everything, it is believed that the service life of the insulation depends on its cost and quality. Manufacturers of the inexpensive substance claim that it can last at least 50 years. In practice, this figure is not confirmed by anything, therefore, in the footnotes, they write that today there is no standard operating time for heaters.

In addition, what matters is what the material is made of. Experts confirm that man-made fibers cannot be guaranteed for more than 35 years. During this time, they dry out and collapse. But most importantly, they lose half of their heat-saving properties. While natural fibers do not lose their original qualities and can serve for a longer period.

Regulatory guidelines state that every home must undergo an energy audit after construction is completed. Such inspections should be carried out every 25 years in order to be able to assess the level of heat-saving properties at the moment. But since we are unable to find out the exact figures due to the verification, we use the data that come to us from Europe.

What results were obtained: scientific and technical report of NIISF

Analysis of the results of the study of these heat and sound insulating materials produced at the plant in Yegoryevsk, Chelyabinsk and Tambov showed that the thermal conductivity of mineral wool slabs when simulating operating conditions increases by no more than 5% after 100 cycles freeze-thaw. And this confirms that the effective life of ISOVER materials is up to 50 years inclusive. For those who value stability and half a century of dedication, this is ideal. Research carried out at the Research Institute of Building Physics of the RAASN showed that the IZOVER mineral wool thermal insulation based on quartz fiber is resistant to moisture, alkali solutions and aqueous cement extracts with an alkaline reaction. When ISOVER thermal insulation dries up after moistening with the indicated solutions, its thermal conductivity is restored to its original values. Studies according to the methods of GOST R 57418-2017 and GOST R 56732-2015, carried out at the Research Institute of Building Physics of the RAASN, showed that the effective life of ISOVER mineral wool thermal insulation is at least 50 years, there is no fiber emission when the air flow affects the thermal insulation.

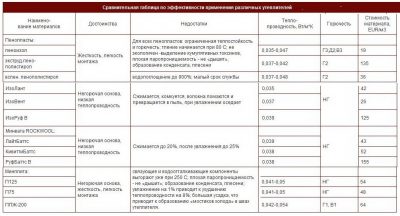

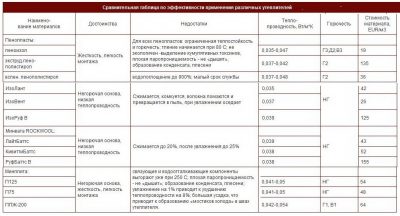

Comparative characteristics of the service life of heaters table

There are many types of insulation, but today we will consider in detail the most budgetary and reliable options. These include:

- Mineral wool.

- Basal cotton wool.

- Styrofoam.

The first type is called stone... It has a fairly high level of quality, since it is made from basalt stone. Its cost is much higher, but both the quality and the validity period meet expectations. According to statistics, mineral wool is used the most in construction. The service life is about 50 years. But this figure is still contested, and it has several nuances.At the moment, there are two types of mineral wool.

The service life of foam as insulation

Another commonly used insulation material is polystyrene foam. It is generally accepted that the shelf life of expanded polystyrene reaches several decades. Manufacturers give a guarantee for material durability for 50 years. However, with the correct insulation procedure, this period can be doubled. This is one of the main reasons it is so popular.

It should be borne in mind that there are several types of insulation made of foam:

- Polystyrene... A material that is made in the form of foam rubber. Suitable for protecting a room from the inside. It has very high performance characteristics.

- Polyvinyl chloride substances are very flexible. They have a very high resistance rate.

- Polyurethane foam... It is considered to be a hardy thermal insulation that will last quite a long time, quickly hardens, forming a very strong protection that can withstand many external influences.

Based on the above materials, we can conclude that the service life of the foam is very long and fully meets expectations.

Truth and myths about thermal insulation. We unambiguously answer questions that raise doubts

Choosing a thermal insulation material for a house, apartment or summer cottage, consumers are faced with many controversial comments and recommendations. It is not easy for a layman to distinguish fiction from truth, especially since the authors and storytellers of myths are sometimes very eloquent and convincing. In order to dispel the fog of doubt and dot the i's in the choice of thermal insulation, we have collected some frequently encountered statements and decided to explain why they are wrong.

Myth number 1: it is better to insulate with mineral wool in plates

At the heart of this myth is the misconception that a less dense material (and rolls are made of light wool) is inferior to a denser one in terms of thermal insulation characteristics. This is a fundamental mistake, contrary to the laws of physics. The fact is that air is the main and best heat insulator. The more it is able to hold the material, the more effective it is as a heater. Lightweight mineral wool, which is sold in rolls, has a low density, which allows more air to fit between its fibers.

The effectiveness of such material is clearly confirmed by the numbers. For example, the density of light grades of quartz wool can reach 14–20 kg / m3. This is two times less than that of stone wool slabs of similar thermal characteristics - 30–60 kg / m3. This effect is achieved due to the peculiarities of the structure of quartz wool: the length of its fibers is 25–30 cm with a microscopic thickness of only 3.5–5 microns, that is, the material is obtained without exaggeration as airy.

The second feature is also explained by the structure of the fibers: with this ratio of thickness and length, they are unusually elastic and form an elastic, springy structure. Thanks to this, quartz insulation, cut with a small (about 5 mm on each side) margin, slightly tucked and laid in the gaps between the crate elements, straightens and completely fills the entire space, leaving no cold bridges. Unlike rigid slabs, rolled thermal insulation does not form joints and forgives installation errors - it can be rearranged from one structure to another without creases and deformation.

Myth number 2: about the ability of mineral wool to hold in inclined and vertical structures

To prove that the insulation does not slip and does not require special fixation, I sent samples of ISOVER quartz wool for testing at the Tver Institute of Carriage Building. The material underwent a series of vibration tests with a vibration frequency of up to three thousand per minute on a stand that creates conditions similar to those of operation for 50 years.As shown by the test results, over the years, quartz wool does not slip even from vertical surfaces and does not crumble. Therefore, according to the results of tests, it was approved as a heater, including for branded trains. For the same reason, rolled quartz wool will become a reliable solution for all types of insulation and sound insulation in individual construction, especially on pitched roofs.

Myth number 3: about the insulation of a pitched roof

The myth that rolled mineral wool needs additional fasteners again brings to mind the elastic properties of quartz wool, due to the length and elasticity of its fibers. Experts call this the Formostability technology: the heat-insulating material takes the shape of the cell in which it is laid and retains it throughout its entire service life, while no fasteners are required. The main thing is to remember that when calculating the width and cutting the cotton wool, you need to leave an allowance of 5 mm on each side in order to compress the material during installation.

Myth # 4: about the lifespan of mineral wool

Once upon a time, back in the USSR, cheap insulation of poor quality - glass wool - was widespread. It was formed by short and thick (up to 500 microns) fibers, more like needles. Over time, they caked and crumbled, and this is the first source of myths about the fragility of mineral wool. Nowadays, such material is not produced or used.

The second reason for erroneous judgments is due to the properties of stone wool used in industrial construction, which, as a result of getting wet, loses its original structure and requires replacement.

Quartz wool, on the other hand, has the ability to repel moisture, so even in the event of emergency situations, the homeowner does not have to spend money on new insulation. Tests have shown that its service life is at least 50 years. Thus, one insulation is enough for the entire period of operation of a private house.

Myth number 5: about the speed and methods of installation

It is often possible to hear from theorists that it is inconvenient to insulate the roof and walls with rolled mineral wool. This statement contains a factual error. As practice shows, the installation of roll insulation on the walls is two to three times faster than pre-cut or slab. The explanation is simple. If you have to install two or three plates along the height of the room, fixing and adjusting each of them, then the roll is just enough to cut vertically, fix it at the top and roll it down.

In addition, when installing the slabs, it is necessary to carefully control the quality of the joints in order to avoid the appearance of cold bridges (see above). In some cases, the joints are additionally insulated, and often the insulation is mounted in two layers, sparsely. The use of rolls eliminates these difficulties. In addition, a lightweight roll-up insulation based on quartz wool fills all the space between the elements of the sheathing, tightly adhering to it without any additional actions and fasteners.

Similar measurements of labor costs when insulating floors and pitched roofs showed that in the case of using rolled quartz insulation material, installation is carried out three to four times faster, since in this case one roll is most often equal in length to three to four slabs.

One more fact should be taken into account - the greater the thickness of the insulation, the more time you can save on installation work. For example, for most regions of Russia, the standard thickness of the under-roof insulation layer is 200 mm. Since the slabs are most often 50 mm thick, they have to be laid in four layers, which is very laborious. It is much easier with rolled insulation: its thickness is 100 and 150 mm, so you only need to mount one or two layers. The same applies to thermal insulation of facades. At the same time, quartz wool also retains heat more efficiently.

Myth number 6: about the cost of thermal insulation

By buying the cheapest tutu on a store shelf, you won't save. The fact is that in a pack of the same size, different manufacturers supply different amounts of m2 of materials. This is due to the fact that one type of mineral wool is able to shrink several times, while the other is not. Without knowing this, many either compare the price for a pack of insulation, or calculate the volume of packed compressed rolls and compare it with the cubic capacity of slabs. Then how to correctly compare prices per square meter of expanded material.

Consideration should also be given to the benefit in the delivery of materials. Roll insulation made of quartz wool is more convenient to load and transport alone. Considering that it is highly compressed in its packaging, it can even be placed in a private car, saving on shipping costs. For the same reason, a much smaller area is required for storing rolls on a plot, in an apartment or in a utility room. In addition, they are much more convenient and faster to carry and unload. The number of approaches for material to the car and back or ascents to the floor will be significantly reduced.

Modern mineral wool based on quartz is a versatile, durable and reliable thermal insulation material that has a number of advantages that are especially significant for the owner of a private house and residents of apartment buildings. Using products that are suitable for solving specific problems, you can not only insulate a house with high quality for many years, while doing it on your own, but also significantly save both on the material itself, and on delivery, and on heating bills.

How is mineral wool made, its properties

Mineral wool is formed by melting rocks and passing them through the thinnest dies. The resulting fibers are immediately cooled at the exit from the furnace and wound onto spools. Electrical insulating woven materials are produced from stone fibers, but a certain part of them (usually rejection) is cut off the spools and ends up in beater machines, where cotton wool is produced.

Then the resulting wool is fed under the presses, where canvases are formed, rolled into rolls (low density) and slabs (medium and high density mineral wool).

By its essence and chemical composition, fibrous wool remains the same stone (mining material), which is not afraid of dampness, mold, or any other fungi. This is a chemically neutral insulation that behaves calmly when the acid-base environment changes, does not react in any way to the appearance of, for example, rust. Mineral wool is not afraid of temperature changes, it is not prone to fires, it does not conduct electric current.

The main characteristics of mineral wool

Before using mineral wool for insulation, many want to get to know this material better, so they are looking for a detailed description of it. Below is a list of the main characteristics of such wool, which will fully assess its operational properties.

Heat insulating and sound-absorbing characteristics

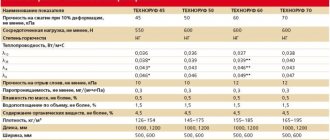

Mineral wool properties table.

Mineral wool has a very low coefficient of thermal conductivity. It is within the following limits: 0.038-0.045 W / K × m. Due to this important property, only a 10 cm layer of mineral wool replaces brickwork 117 cm thick or a solid wood wall 25 cm.High thermal insulation of this material is achieved due to the presence of numerous air pores and channels in it, which make up about 95% from its total volume.

Another important distinguishing feature of mineral wool is its ability to inhibit the penetration of sounds into the room. As a result, it is possible to create with the help of this material a comfortable atmosphere in the house, where unnecessary noise will not be present. If we talk about the exact sound insulation coefficient of mineral wool, then it is at around 0.95, while the maximum indicator is 1.Such an important characteristic is achieved due to the fact that a huge number of different fibers are located in such a material in a chaotic manner. They are excellent at absorbing sound waves.

Non-flammability and vapor permeability of mineral wool

The most valuable advantage of this insulation is its high fire safety. It is non-flammable, so it will not spread fire or sustain a flame.

The structure of mineral wool and ecowool.

Mineral wool insulation can be done even in those buildings and premises where it is planned to work at temperatures up to +1000 ° C.

Mineral wool has a high vapor permeability. The indicators of this material for this characteristic are within the following limits: 0.49-0.60 Mg / (m × h × Pa). This property is provided by the mineral wool due to its special structure, which allows it to "breathe".

This, in turn, makes it possible to provide the premises where it is used as a heater with a healthy internal microclimate. As a result, for these purposes it will not be necessary to use mechanical devices and spend money on their purchase.

Naturalness and density

All the above-mentioned technical characteristics make mineral wool one of the best among the materials for insulation, but it is also chosen because it is natural and does not contain harmful chemical compounds. So, it is made from granites, tuffs, clays, limestones and basalts using special processing with the use of fire. Therefore, the use of mineral wool in country houses and apartments is ideal, since it will not harm the health of the residents.

Mineral wool has a high density. According to this characteristic, this material is divided into several types:

Where is mineral wool used?

In general, mineral wool is an ideal insulation that is used for thermal insulation of pipelines of heating mains, water pipes, industrial boilers at thermal power plants.

In recent decades, mineral wool is increasingly used to insulate walls in housing construction. With the correct implementation of all work on heat and vapor insulation, mineral wool insulation will retain heat for as many years as the walls stand. The manufacturer calls the service life of mineral wool insulation - 50 years. But in fact, with proper installation work, it will last much longer.

Myth number 3: mineral wool is a safe insulation

Another common myth is related to the safety of mineral wool. Mineral wool consists of mineral fibers glued together with phenol-formaldehyde resins. The better the properties of the mineral wool, the more harmful resins the manufacturer adds. Over time, the resins disintegrate, getting into the house and the lungs of its residents, and the fibers crumble into dust, also penetrating into the room. Many Western experts are seriously considering the carcinogenic aspect of the impact of mineral wool on human health, considering mineral wool a possible source of asthmatic diseases.

According to the chief sanitary doctor of the country G. Onishchenko, health safety requirements for building materials need to be increased. Insulation should in no case emit formaldehyde harmful to human health, fine dust, fine fibers, which, when inhaled, cause various diseases in humans.

When choosing any building material, including insulation, you must first of all remember about the safety of your health and the health of your loved ones. Polyurethane foam Ecotermix is not only featuring thermal insulation, which retains heat in the house, but also a solid, environmentally friendly material.

What factors destroy mineral wool

At industrial facilities, even during major repairs, cotton wool cannot be replaced, because the material itself does not deteriorate as a whole, does not collapse or decompose. Breakdowns can occur when steam under pressure forms a hole in the pipe (fistula) and, breaking out, sweeps away the insulation. During the insulation work, the old insulation is not removed.

Mineral wool insulation is able to withstand a new operational period until the next major overhaul, so it is reused. New material is applied where it has become smaller for various reasons. Only those sections of the insulating layer that, once opened, become clogged with dust, dirt and stone, are subject to replacement. Thus, the first enemy of mineral wool is dust and dirt.

The next enemy of this porous and breathable insulation is moisture in the absence of air. If water or condensate enters the thermal insulation layer, but does not have an outlet, it violates the thermal insulation properties. Vata stops breathing and keeps warm. Therefore, when installing thermal insulation, technological holes are provided through which air enters the thermal insulation layer and moisture is removed.

Minvata absorbs moisture well

Some manufacturers impregnate mineral wool with water-repellent substances, and this material is suitable for thermal insulation of the roof, exterior walls of the house.

Mechanical impact

From the above, the conclusion also suggests itself that the service life of the mineral wool reduces the mechanical impact from the outside. it

- fistulas in pipelines;

- wind capable of sweeping loose casing on ground pipes;

- workers eliminating pipe leaks;

- rodents living underground and in homes.

Industrial thermal insulation is mainly subject to mechanical destruction.

Rodents

No matter what the manufacturer says, practice shows that rodents arrange nests in almost all types of insulation. They are not even intimidated by the prickly and annoying glass wool. They gnaw through passages, arrange nests, thereby destroying the insulating layer.

Thus, in order to extend the service life of the thermal insulation layer, it is necessary first of all to comply with all the requirements for thermal and steam insulation at the stage of installation work, to eliminate factors that destroy thermal insulation.

Myth number 1: mineral wool is a cheap insulation

Many buyers are firmly convinced that mineral wool is the most affordable and cheapest insulation on the market. However, they do not take into account that, firstly, when laying mineral wool, more material is required by 20-30%. Secondly, there is the problem of storing the insulation, and, in addition, up to 10% of the material is spent on trimming, since the lengths of the constructs may differ from the length of the package. In addition, few people pay attention to the complex installation of mineral wool, since in order for the mineral wool to work, it is necessary to strictly observe the technology of its installation: make a ventilation duct, close it with a windproof film, and a vapor barrier film must be installed from below from inside the house, which together makes a lot of money.

As a result, we get not the cheapest option of insulation, which, moreover, has a limited service life, due to the peculiarities of the structure of the material, which tends to gradually disintegrate into fibers over time.

Below is a comparative estimate of insulation of a soft roof with mineral wool and polyurethane foam Ecotermix. With a roof insulation of 100 sq.m., the price difference is more noticeable and it becomes clear that mineral wool, today, is not the cheapest insulation.

| Name of works | Unit. | Cost per minute watt (rub.) | Cost for PPU Ecotermix (rub.) | The cost of work | Note |

| The device of the roof truss system made of metal tiles | 1m² | 300 | 300 | 57.75 rubles / m. | |

| Sheathing device | 1m² | 220 | 220 | 30 rub / m³ | |

| Counter-lattice device (along the rafter system) | 1m² | 120 | 0 | 17.75 rubles / rm | bar 40x40 mm |

| Installation of wind and moisture protection | 1m² | 40 | 0 | 80 rub / m² | |

| Installation of vapor barrier | 1m² | 50 | 0 | 15.75 rub / rm | |

| Antiseptic treatment of the truss system | 0,5l | 34 | 15 rub / rm | ||

| Insulation device (thickness 150mm) | 1m² | 280 | 480* | 270 rub / 1m² | ** PU foam with a thickness of 100 mm is equivalent to a mineral wool with a thickness of 250 mm * |

| Installation of plywood (12mm) under soft tiles | 1m² | 240 | 240 | 350 rub / 1m² | |

| Metal tile device (including lining) | 1m² | 450 | 450 | 480 rub / 1m² | |

| Consumables (including hardware) | 55 | 35 | |||

| Total | 1789 | 1725 | 1316,25 | ||

| Total with work | Minvata 3105.25 rubles / m² | PPU Ecotermix 2672.75 rubles / m² | * PPU insulation includes the cost of material with installation work |

* according to the conclusion of the PPU Laboratory in Germany

Stone wool as an effective insulation for the home

Mineral-based stone wool (aka ecowool) is presented in the form of insulation, which is in rather high demand in the building materials market.

Basalt insulation (stone wool)

Currently, there are a considerable number of manufacturers of this type of mineral wool, which is actively used as a reliable and effective insulation.

Before you buy mineral wool slabs and start using them, you should pay attention to the reviews and technical characteristics of this insulation.

Stone wool - from what, how, in what form

A universal heat-insulating material made from rocks, predominantly of the gabbro-basalt group (a product of volcanic eruptions), which is why stone wool is often called basalt. This group of rocks is characterized not only by strength, but also by a high melting point, which determines the choice of producers. The rock is melted at a temperature of more than one and a half thousand degrees, the finest fibers are drawn from the melt.

Derivatives of phenol-formaldehyde resin are most often used as a binder that transforms individual fibers into a single, elastic and durable web. These substances are considered the most stable and durable. With regard to safety, the additives are contained within the limits of the amount allowed by the standards, which makes them absolutely safe for both humans and the environment. This is confirmed by numerous studies and tests.

This insulation is one of the few building materials with a positive ecological balance. That is, it helps to save more energy than was expended in its production, and theoretically can be subjected to endless recycling after the end of its service life.

Stone wool comes in several forms:

- Plates of various thicknesses and stiffness.

- Rolls.

- Specific products - insulation in the form of cylinders with seam or lock joints for pipelines and chimneys, laminated mats.