Materials used and methods of sealing

How to seal the sewer pipe? There are several insulating materials with which it will be possible to complete the task.

The most popular ones are:

- silicone based sealants;

- sealing tapes;

- cold welding;

- cement solution with resin tow.

The presented funds are used mainly for cast iron sewers. At the same time, the most popular are silicone-based sealants. But there are special tools designed to insulate pipes from other materials. For example, it is best to use petroleum bitumen compositions or asphalt mastic to seal a ceramic sewage system, they will cope with the task with the highest quality. And to ensure the tightness of socket joints of cast iron pipes, technical sulfur is excellent.

When you install outdoor sewerage, you must also seal the pipes from the inside. In this case, there will be no overflow of the drainage system due to the ingress of groundwater.

There are several ways to seal sewer pipes that are currently in use. Each of them has its own advantages and disadvantages. It is worth making a choice in favor of this or that method based on their characteristics.

Types of modern sealants

Sewerage sealant ensures high-quality operation of all its components.

Today, such materials as self-adhesive tapes, technical sulfur, silicone, Portland cement mortar, resin strand, epoxy resin, asphalt bitumen, etc. are known.

In the process of using them, special technologies must be observed, which will allow achieving a good result.

This is what self-adhesive tape looks like

I would like to consider the most common types of sealants.

- Self-adhesive tapes - This sewer pipe sealant is widely used and is a tape that has anti-corrosion properties. It is used as protection for such components as tie-ins, plugs, bends, bends, and also glued at the joints of pipes. The base of the tape is bitumen-rubber, there is an aluminum or copper layer on top.

Self-adhesive aluminum tape

- Silicone sealant for sewer pipes - based on silicone rubber, additional components are substances that ensure high quality processing. Silicone mixtures are characterized by a high degree of adhesion to surfaces. Depending on what type of hardener is used, the sewer pipes can be sealed with acidic or neutral pastes. After vulcanization, it becomes rubber-like.

Sewer Pipe Silicone Sealant

Sewer pipe silicone sealants

Silicone sealants are mastic coatings that harden when exposed to air. Among the advantages of this material is ease of use. The pipe surface does not need to be primed beforehand.

These sealants are made from silicone rubber with plasticizers. They increase the degree of adhesion, at the same time, the strength of the protective coating increases.

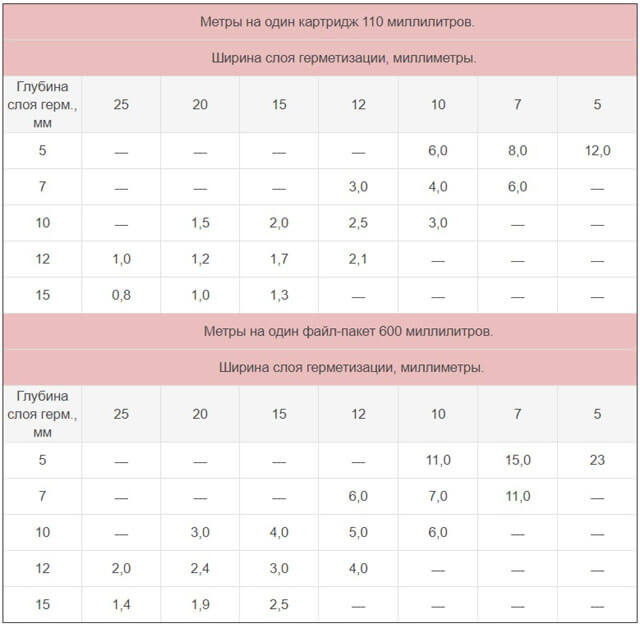

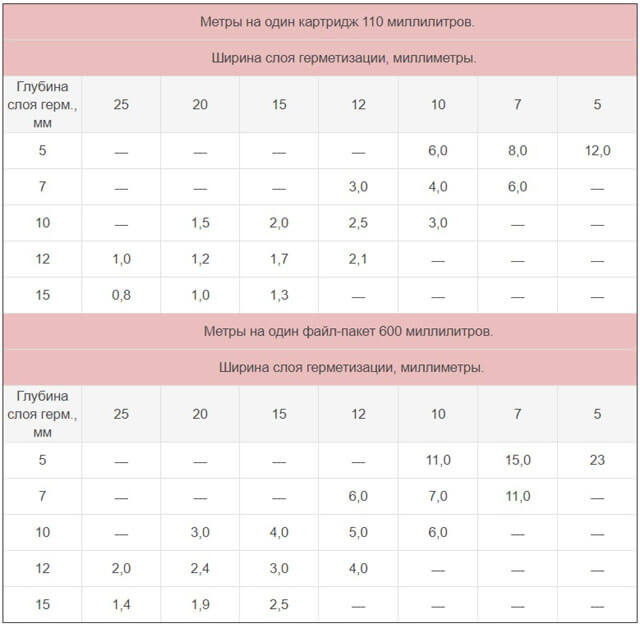

It takes a minimum of time to seal pipes with silicone sealant. Anyone can handle the task. The composition is applied with an assembly gun. If there is no tool, but an urgent need to seal the pipe, then the work can be done with an ordinary hammer.Its handle will act as a piston for supplying the composition. When the mastic dries up, it will reliably protect the joints from leakage. Silicone waterproofing for sewer pipes is simple and quick to apply.

Problems arising from poor insulation of sewer pipe joints

First of all, it is worth considering the need for high-quality insulation of the connection of elements of external sewer mains.

What sealant for sewer pipes would not be chosen (we are talking only about high-quality materials), it will solve two main problems:

Sewer pipe leaking

- Prevention of sewage leakage into the ground. The main task is not only to comply with environmental safety standards, but also to eliminate the possibility of flooding of underground parts of buildings (basements, basements).

- Elimination of leaks and the ingress of groundwater or parts of soil into the sewer system is considered no less important. Soil water can seriously damage the flow of sewage through the pipeline, in addition, there is the possibility of siltation of the sewage system.

Eliminating the consequences of any of these problems will require a considerable amount of work. At the same time, the costs of excavation work associated with the opening of the highway practically do not differ from the costs of laying a new line. Therefore, it is economically feasible to purchase materials for sealing sewer pipes, and not to spend money on work to eliminate accidents.

How to seal a pipe with cement mortar and resin tow

It is possible to seal the sewerage system with these materials. The method itself consists in the fact that two-thirds of the depth of the socket is caulked with a resin rope. And the remaining third is filled with cement mortar, mixed in a ratio of one to nine. It is necessary to use a cement composition with the M300 brand.

For people who want to insulate sewer pipe joints at a minimum cost, expanding waterproof cement is the best choice. In this case, the use of resin tow is not required. After all, such cement quickly sets, while expanding. The composition must be prepared right before use by mixing the base with water in a ratio of 1 to 2.5.

While about the species

In places where water escapes under pressure, the butt joints must be very secure.

In this case, sealants are considered not only mixtures that are familiar to us, which are in tubes with a nozzle and are fed to the abutting surfaces with the help of a special pistol, in this context these are broader concepts.

With their help, sewer pipes are sealed, and plastic structures and metal risers are joined together. (See also the article Sewerage in a private house: features of the arrangement.)

In this article, we consider:

- Ordinary and customary sealants: acid or alkaline based;

- Special tapes that are used to wrap joints like a bandage. Can be used independently, can be combined with other sealants;

- Various compositions with which the connections are minted, this type of work is characteristic precisely for old cast-iron pipes.

About the sealant again

Sealant has long been known to women as well.

Everyone knows this composition, well, if not all, then very many, it is they who not only seal the sewer pipes, but also a lot of homework related to sealing cracks. The expression "put on a sealant" has become his calling card.

In this case, we are interested in it because:

- This material, produced on an acid or alkaline base, fits perfectly on any surfaces, while their special cleaning or preparation is not needed, it is enough that they are clean and without fragments that can flake off;

- Silicone, which is part of the sealant, does not form a hard surface (its final structure is closer to rubber), can withstand a fairly wide temperature range of impacts, and besides, it copes well with the responsibilities assigned to it.

For the forgetful.

For your information! In many sources you will find information and even a theoretical justification that even sealing plastic sewer pipes is also necessary, this prevents the possibility of groundwater suction if the pipe passes in the ground, as well as moisture seepage from the pipe outside. We are inclined to believe that this is pure reinsurance, moisture seepage is possible only if the pipes are not aligned correctly, which is very difficult to do with the existing docking system. And the exit of liquid from the sewer pipe says more about the fact that the pipe is clogged - this is, firstly, and secondly, the principles of its location (angle of inclination) are violated.

The tapes this time are self-adhesive sealing

Speaking of ribbons, here they are.

An interesting invention. Sealing the joints of sewer pipes and not only them is easy. The tape can cover any pipe, of any configuration. In addition, the tape is an excellent dielectric, has anti-corrosion properties and will be very useful for metal pipes.

One minus, does not like direct sunlight, therefore, for open pipes, the use of this tape is associated with protecting it from the sun. Its application is no more difficult than using electrical tape. (See also the article.)

Judge for yourself:

- Standard surface preparation - dry, clean;

- The tape wraps the pipe with a slight stretch, which avoids the formation of various folds and irregularities;

- It is laid with a spiral overlap without changing the direction of the belt. In this case, each previous layer is overlapped by the next half. As a result of these simple manipulations, a two-layer film coating is placed on the pipe.

Standard coinage and available arsenal

And this stuff is also enough now.

In itself, chasing is a simple process, for this you need: resin rope and cement mortar.

Techniques involve variations:

- The classic option is a resin strand, which occupies at least 70% of the joint volume and filling with cement mortar in a ratio of 9 to 1 with water;

- The modified version is the same harness, but asbestos fiber is added to the cement in a ratio of 2 to 1. In this case, the dry mixture is prepared in advance, and water is added only at the time of sealing the joint;

- No resin fibers. In this case, a special cement is used, which by and large is a mixture with additives. Which is able to expand and fill all the space provided to it at the junction. Instructions for using such a mixture are prescribed on the package, but usually 2.5 parts of water are added to 1 part of cement.

In addition to the classical scheme, sealing can be carried out:

- Epoxy resin. This legendary composition can solve well the issues of sealing joints;

- Asphalt mastic and bitumen are often used independently, do not require additional reinforcing or related components.

Self-adhesive tape

Experts consider this material to be one of the best ways to isolate joints. In addition, the self-adhesive tape has dielectric and anti-corrosion properties. One of the main reasons for its popularity is its ease of use.

The material is also called FUM tape. It is used for sealing sewer pipe joints, system corners, tie-ins and plugs. In the first case, it is necessary to first prepare the surface of the products. They need to be degreased, cleaned of dirt and dust, and wait until dry. Pipes must be primed if required.

Types of sealing compounds

Sealing of sewer pipes is carried out using different materials. The choice of the option is carried out depending on the material of manufacture of the pipes. Let's describe the most popular types of sealing compounds.

Tape

It is a very convenient material to use, it is a tape with a bitumen-rubber base and a top copper or aluminum layer. Material advantages:

- simple use, the joint is simply "bandaged" with tape;

- anti-corrosion properties, provided by the presence of a metallized layer of copper or aluminum;

- reliability of sealing;

- is not a conductor of electricity.

The downside of the material is its destruction under the influence of sunlight, therefore it is used only in places protected from ultraviolet radiation. Or use an additional winding made of sunscreen material.

The material is used to seal the joints of pipes made of different materials, as well as the places where the inserts, plugs and any other elements are installed. To seal a sewer pipe, you need to do the following:

- prepare and thoroughly clean surfaces;

- apply the tape in layers with an overlap in a spiral.

Advice! To prevent wrinkling on the coating, you need to keep the tape in tension.

Silicone compounds

Silicone has excellent sealing properties, therefore, when assembling sewer systems, sealants based on this substance are often used. This material:

- provides a high level of sealing;

- has good adhesion;

- serves for a long time;

- provides high mechanical strength, resistance to high temperatures and moisture.

When performing work, a liquid sealant is applied to the workpieces, but upon contact with air, the material solidifies, forming an elastic and reliable coating. There are two types of sealants:

- Neutral. This is the best option, it is suitable for working with different types of pipes.

- Acid. This option is cheap, but it has a significant drawback - it cannot be applied to surfaces that can deteriorate in contact with acid.

Neutral sealants can be used if piping is being assembled from metal or plastic parts. It is recommended to apply the composition using a special assembly gun, this device helps to apply the material evenly.

Other compounds

In addition to the most popular sealants described above, other materials are used to prevent fluid leaks. It:

- Epoxy resin. This is a two-component compound that polymerizes in air to form a sealed film that reliably protects the joint.

- Cement mortar. This material is used when sealing cast iron pipe sockets.

- Bituminous mastic. This material is most often used in the assembly of ceramic pipelines.

- Technical sulfur. This material was used often before, nowadays it is practically not used. With the help of sulfur, the gap in the cast-iron socket is sealed. For this, sulfur is melted and poured into the gap through a funnel.

Advice! Before pouring liquid sealing compounds (cement mortar, molten sulfur, mastic), fibrous materials are wound on the pipes - sanitary tow, jute, flax.