What is a self-regulating underfloor heating?

In a warm field with a self-regulating function, the cable looks like a simple insulated two-core wire, in it two parallel-placed conductors are closed in a circuit. It is equipped with busbars that help distribute the voltage along its entire length.

The design features of the floor protect it from overheating. And the presence of a conductive matrix makes it possible to cut the cable so that there are no cold zones.

In cases of overheating of the matrix, the number of conducting bonds decreases, thereby blocking the flow of electricity. When the floor cools down, the feed resumes.

A feature of a self-regulating floor - it can adjust the power supply itself, starting from the degree of heating.

Find out how to call or make your own repair of electric underfloor heating.

Drawing up a diagram

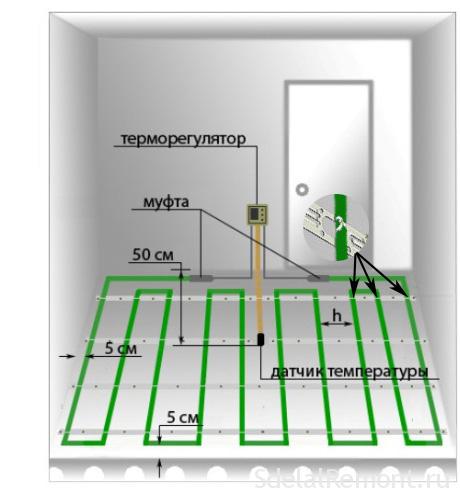

Until the direct distribution of the heating elements on the floor surface in the room, it is best to sketch a diagram on your own, on which to mark the areas with furniture, the chosen laying step and other points that will play a significant role. This scheme will be useful in the future during the flooring, so as not to damage the heating elements.

When drawing up a scheme, you should pay attention to some points that will allow you to get a high-quality result:

- The distance from the walls of the heating elements must be at least 100-150 mm.

- Straight-line distribution of heating elements is optional. Even the heating mats (sections) can be cut in every situation. The main thing is that the heating cable is not damaged. These actions are carried out in order to rationally use the heating system, reduce energy costs, and also concentrate the main heating of the subfloor in the right places.

- In the presence of bulky furniture in the room, built-in furniture, as well as heavy household appliances that are not planned to be removed from their premises, the heating elements should not be laid. Heat transfer will noticeably decrease, therefore, warm heated air will return back. This will lead to overheating of the system in a separate area and will entail repair of the warm floor.

The installation step of the electric underfloor heating displayed on the diagram is calculated using the following formula:

h = (S * 100) / L

S is the occupied area of the heating elements.

L is the length of the cable or heating mat.

The minimum pitch for laying the heating section is 80 mm. But it should not exceed 200 mm.

Types of cable for underfloor heating and their characteristics

Today the range of cable products is huge. It is divided into groups depending on the purpose, power and material from which it is made.

Resistive heating cable

This heating cable is resistively loaded and elongated. A conductor with constant resistance, it is higher than that of the power and installation wire. Heating is carried out using insulated copper or special alloy conductors. In addition, the product is equipped with a copper or foil shield with a drain core.

Screen functions:

- Reduces electromagnetic radiation, which is necessarily present in a conductor with current.

- It grounded, and in case of insulation breakdown, the electricity will be closed by the screen and go into the ground, this helps to protect a person from electric shock.In addition, circuit breakers and an RCD device are triggered.

Resistive cable products are:

- Single-core - there is only one conductive core in it. This type is one of the most inexpensive, but the installation is rather complicated, since both ends must be brought out to the same point and connected to a thermostat.

- Two-core - has two parallel conductors, enclosed in a screen. The variants of the conductors can be different, two heating or one heating type, and the second supplying. At the end, the section has a sleeve, it connects the two cores and insulates them. The advantage of this type is the ease of connection, since such a wire only needs to be placed according to the planned scheme, and there is no need to bring the other end to the thermostat. In addition, a two-wire cable produces a minimum of electromagnetic waves. Naturally, the price of cable products is much higher.

Resistive cables are manufactured in pre-fabricated sections with a fixed size and cannot be changed. The main characterizing indicator of any cable is the specific power of one meter, it should be 10 - 20 W / m, the excess is not permissible, this can disable the heating elements.

The length of the section should be selected taking into account the calculations performed. And since the cable is produced in different sizes, from 10 to 110 m, then choosing the right length is not difficult. Sometimes the product is sold wound on spools, it is permissible to cut a wire of any length from them.

Pros of the model:

- Acceptable price.

- The invariability of the main characteristics.

- There is no inrush current, so there is no need to install special circuit breakers.

But the resistive cable also has disadvantages:

- If the installation is not done correctly, then there is a possibility of overheating, which can provoke a failure of the system.

- It is impossible to change the length of the wire without adjusting the characteristics.

- Needs to ensure the required heat transfer performance.

Resistive zone cable

In the process of development of the cable industry, a sectional type of resistive model was invented - zonal. In the center are two insulated conductors. They are wound with a high voltage wire helix. This wire, through each meter, is connected to one of the central conductors in turn. Moreover, all sites are independent.

Among the positive aspects of the zone cable are:

- the same power density along the entire length;

- starting does not require large currents;

- invariability of characteristics.

Negative aspects of this type:

- local overheating is possible;

- the need for heat transfer;

- the cost is the highest, in contrast to the usual resistive cord.

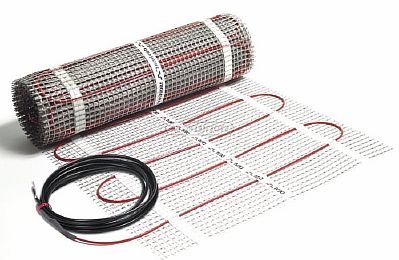

Heating mats

Heating mats are a construction consisting of a cable fixed on a special mesh with a certain pitch. The use of these mat makes the installation of underfloor heating easier, it is enough to roll them out on an even basis. It is allowed to lay them in a layer of tile adhesive. Different types of cables can be used in the mats.

Important! When fixing them in a layer of glue, the formation of air bubbles should not be allowed - this can provoke local overheating.

The main disadvantage of heating mats is the difficulty of laying them in rooms with a non-standard, geometrically complex layout.

Self-regulating cable

The most technologically advanced type of heating cables for underfloor heating is self-regulating. He is able to change the temperature based on the heating level of the room.

The presented model consists of two conductors, with a polymer matrix placed between them, which performs the function of a semiconductor. It is similar to a normal cable, but it is flattened rather than round in shape and can be of different lengths.

A decrease in temperature promotes compression of the matrix, in which heat-conducting paths with increased resistance are formed. The current, flowing, heats up the matrix and the cable. As the degree of heating increases above the required level, the polymer expands and the number of current passes decreases, as a result of which there are very few of them, and the heating of the floor stops. At the same time, all sections work autonomously.

The semiconductor is protected by a layer of heat-resistant insulation. Then comes a shield made of copper or steel, covered with additional insulation. Each cable should be selected based on the performance characteristics.

Installing sensors and checking them

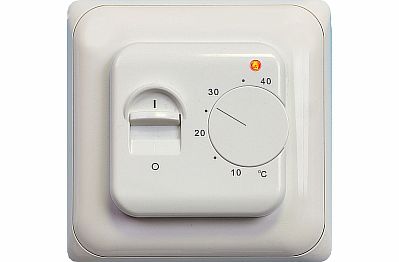

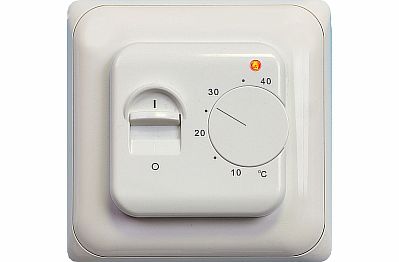

It is much easier to operate the system if the appropriate sensors and instruments are available. In underfloor heating systems, this role is played by a thermostat and a temperature sensor. All this allows you to set a certain indoor temperature depending on the needs, as well as the time for turning on and off the system.

The sensors are installed in the wall, near the socket at a distance of at least 30 cm from the base of the floor. But the temperature sensor is mounted in the floor itself. To this end, from the place with the thermostat perpendicular to the base, a strobe is made in the wall, which drops somewhat to the floor. A corrugated pipe is initially placed in it, into which the temperature sensor is placed. It should be noted that the sensor in the corrugation should not intersect with the heating elements, but be located between their turns. To prevent the solution from getting into the corrugation, all holes are sealed with a sealant.

Before laying the heating cable, the resistance is measured, which must correspond to the passport data. Only a slight deviation of no more than 10% is allowed. Here a multimeter will be an excellent assistant. If everything is correct, you can start distributing the heating elements, according to the previously created scheme.

Can I use a self-regulating cable for underfloor heating?

The main function of a self-regulating heating cable is to reduce the supply of electricity when the required heating degree is reached, while the quality and uniformity of surface heating does not suffer. This feature allows the model to be successfully used in the construction of underfloor heating in any room, from living rooms to bathrooms and toilets.

In addition, in the presence of underfloor heating with a self-regulating cable, you can rearrange the furniture in the apartment, since it has the ability to regulate the heating level, in contrast to the resistive one. That is, it is permissible to reduce heating under heavy furniture. It is impossible to change the heat supply for a resistive wire, thereby overheating of the surface may occur, which will lead to the exit from the standing system.

It is worth noting the simplicity of the construction of a self-regulating floor, since this electrical cord can be cut anywhere, and the end can be sealed with oneself. At the same time, all connections, if properly installed, can last for more than one year.

Naturally, like any self-regulating electric floor, you need to connect to the power supply observing all standard protection methods. That is, the system must have a circuit breaker and an RCD, the leakage current in which is not more than 30mA. The samreg cable must have a screen and a power of 30 - 40 watts. At the same time, the laying step of the heating element is 15 - 20 cm.

For your information! A huge achievement is the use of the self-regulating properties of the material in foil floors.

Previously, this function was not possible due to the small size of the film. Infrared film with 30% self-regulating ability is produced in Korea today.

Application features

However, despite the simplicity of the installation of a self-regulating underfloor heating, some features of its construction should be noted:

- Cutting must be done during the installation of the underfloor heating.In this case, the length of the self-regulating circuit can be either a few centimeters or several tens of meters. For different types of cord, the maximum length is different, and ranges from 70 to 160 meters.

- When installing underfloor heating with a self-regulating cable, it should be borne in mind that there is a large difference in currents between the nominal and starting value, 2 to 4 times. This should be taken into account when choosing ballasts.

Adhering to these expert advice, you can make the correct underfloor heating design with your own hands.

Two-core resistive heating wires

By using a two-core underfloor heating cable, it is possible to design more complex heating systems. The product consists of a conductor (heating element) and a conductive core. Thanks to this design, material consumption is reduced, since there is no need to return the other end of the product to the feed point. Only one end is connected to the mains, an insulating current and a sealed sleeve are put on the other. A two-core heating cable is sold with it in the store. Its cost will be slightly higher than single-core wires, but no additional cable is needed.

Both resistive types of heating elements have a number of advantages:

- the most simple design;

- simple manufacturing technology, which entails low cost;

- significant specific heat generation (the heating temperature of the underfloor heating cable is 55-700C);

- stability of characteristics throughout the entire period of operation of the heating system (provided that the sections are correctly installed, the service life is up to 15-20 years without the need for repair).

Important! If you plan to lay a cable for a warm floor with your own hands, then two-core heating elements are more convenient to install. The main thing is to carry out the installation in accordance with the technical requirements for the operation of the wire.

Pros and cons of self-regulating cable

When planning the installation of an underfloor heating with self-regulating properties, it should be remembered that the price of the conductor is high, much higher than the price of an ordinary wire. However, with a properly drawn up project, such a device will cost 40 percent more, not more. Despite this, the system is considered profitable, as it is more economical, and the installation costs will quickly pay off.

The main advantages of self-regulating underfloor heating:

- High reliability, unlike floors with a resistive cord. This wire does not overheat, so there is little chance of fire or failure.

- The heating circuit is not limited to a certain length, which allows it to be laid on any area, even less than a meter, this is not possible with a conventional wire.

- Simple installation, using the simplest regulators.

- The ability to use in rooms where the use of explosive devices is prohibited.

- Saving energy, as only cold areas are heated.

- Length-independent power density.

- Inaccuracies in installation do not affect the quality of the floor, and even overlaps do not lead to overheating.

It is worth saying that self-adjusting floors have disadvantages:

- high price;

- are not able to warm up the room completely, but only the surface of the floor;

- the possibility of laying only in a screed not less than 35 mm;

- periodic wear of the fuel matrix;

- the service life is only 10 years;

- the starting currents of such a cable are high, especially in the presence of large cold areas, therefore, there is a need for class C circuit breakers.

Important! It is necessary to take into account the readings of the protective blocks from the network, if the temperature around the cable is low, then the current at start will be 1.5 times higher than in working condition.

Which cable to choose

The choice of a cable product is influenced not only by its characteristics, but also by the rating of the company that produces it. You should give preference to trusted manufacturers who produce quality products.

Among these manufacturers, the following companies can be noted:

- "Devi" (Denmark) - produces resistive heating cables Deviflex 18T, which are designed for arranging a heated floor of the main or additional type. The length of the wire is 105 meters, the power is 1880 W. The company's products are reliability, quality and a guarantee up to 20 years.

- "Ceilhit" (Spain) - produces inexpensive and effective devices that can create comfortable indoor conditions. The main product of the company is a two-core shielded cable with a power of 220-230 W. The manufacturer's warranty for the product is 16 years.

- GK "Teplovye sistemy" (Russia) is a reliable company specializing in the production of heating cables for underfloor heating: self-regulating and resistive. The products are manufactured using modern equipment and new technologies. At the same time, the price for heating products is reasonable.

How to calculate the power and the amount of cable for heating the room

Before proceeding with the installation of a self-regulating underfloor heating, it is necessary to calculate the power and length of the circuit. We also propose to find out how much electricity a warm floor consumes per 1 m2 per hour, month.

Power calculation

It is necessary to calculate the thermal power of a self-regulating heating system taking into account the characteristics of heating. That is, the warm floor will act as the main or additional source of heat.

But as mentioned above, the self-regulating cord performs periodic stress relief to maintain the floor surface in a comfortable state. Therefore, the heat will not be enough to heat the room, and it is not advised to use a self-leveling floor as the main one.

As an auxiliary heating, it is recommended to use a cable for such a floor with a power of at least 110 - 140 W per square meter. Moreover, in order for the heating level to be at a height, it is required to make thermal insulation.

The size of the room in which the heating element will move is also of great importance. It is not recommended to place the circuit under heavy furniture and plumbing fixtures, this is an unnecessary waste of electrical energy.

Based on this, the calculation of the load looks like this - the area of the heated room is multiplied by the norm per square meter.

Determining the length of the contour

To calculate the required size of the kennel, you need to look in the passport of the cable product. It reflects the power per meter of wire. It ranges from 5W to 150W. Such a variation in the voltage of a self-regulating cable is caused by the huge scope of its use.

Let's consider the definition of the contour length using an example. When heating the electrical cord to 28 degrees, and the bottom surface of the floor covering up to 25, a wire with a power of 17 watts is required. For an area of 10 m2, 70 meters of the heating circuit will be required.

Preparation for laying a warm electric floor

Installation of an electric floor under the tiles

Regardless of the selected heating system, you will have to prepare the floor for installation. First of all, the coating is removed. After examining the old screed, its condition is found out. In some cases, dismantling is advisable. This will gain a few centimeters of room height. Before laying, materials for hydro and thermal insulation are purchased.

Installation of electric underfloor heating with self-regulating wire

The installation of any underfloor heating should begin with the acquisition of the necessary material, in accordance with the calculations made.

The process of arranging a heating structure with a self-regulating cable is similar to the installation of any electric underfloor heating:

- A thermostat is installed - its location on the wall is determined, the distance from the floor is at least 30 cm, preferably not far from the switch. A recess is made in the wall, where the thermostat is mounted. A strobe is made from it to the floor, in which the corrugated hose is placed.

- The base is being prepared - it needs to be leveled and cleaned of debris. If the floor has large differences, then it is better to fill it with a thin layer of rough screed.

- Work on hydro and thermal insulation is being carried out - two layers of material are laid. First, waterproofing - it can be a polyethylene film, on top - heat-resistant thermal insulation, preferably with a metallized surface. Before their installation, the perimeter of the room is glued with a damper tape to compensate for the thermal expansion of the screed when heated.

- A self-regulating cable is laid - it is laid according to the planned scheme ("snake" or "snail"). It must be complete, it should start from the thermostat. An important point is the step of laying the heating element. The smaller it is, the faster the floor heats up. And big steps will lead to colder zones. The recommended distance from the walls is 15 cm.

The cable is fixed to the reinforcing mesh, which is laid on the thermal insulation, or using a special adhesive tape to the substrate.

- A floor temperature sensor is mounted - the electrical cord from it should be brought to the thermostat through a corrugated pipe. A thermal sensor is installed in the center of the room, between two wires.

- The finishing screed is poured - the concrete layer should be at least 6 cm. The floor is poured in one approach, and after leveling the mortar, the concrete surface is left for 4 weeks to fully harden.

Important! The screed should be poured only after checking the cable for functionality. The resistance in the wire is checked using a tester. The indicator must coincide with the passport data, a deviation of 10% is permissible.

- The heating element is connected to the thermostat - this is done using special clamps.

- The finishing coat is laid - any material (tiles, laminate) that can be adjacent to heating.

The use of a self-regulating cable in underfloor heating is beneficial and convenient. Indeed, in such a design there is no risk of overheating of the heating element, this makes it safer. And the ability to independently regulate the temperature level allows you to easily create a comfortable atmosphere in the house.

Self-regulating heating elements for underfloor heating

The self-regulating heating cable for underfloor heating, which is based on two copper conductors and a heating conductive matrix, has completely different characteristics and structure. The last piece of the wire is the key to his design. The design of the product assumes that all parts are connected to the mains in parallel between the batteries. The matrix will play the role of a regulating and heating part. The main parts are protected by braided shielding, thermal protection and an outer casing.

The cost-saving self-regulating cable for underfloor heating works using the technology of the same name. Its principle is to generate heat only to heat the colder parts of the system. With a decrease in the temperature of the air masses, the wire begins to generate more heat. When increasing, the heating intensity decreases. Do not think that a warm floor with a self-regulating cable turns off when the required temperature of the surrounding air masses is reached. Not. It works constantly, just the power is reduced. To turn off the system, use special relays and thermostats that control heating.

Select a cable for floor heating according to the following characteristics:

- released heat power;

- permissible exposure temperature (maximum is indicated);

- working temperature.

Lay a high-quality heating cable for the floor in the screed, under the tiles and other finishing materials. It is widely used, resistant to loads and difficult operating conditions. And self-regulating products are also distinguished by their high resistance to aggressive and chemical environments.You are familiar with all the physical and technical data of the cable for a warm floor, which wire to choose will be prompted by the features of the operation of the additional heating system, the purpose of the object and personal requirements.