Plastic pipes for water supply

Plastic pipes can be used to pass cold or hot water, under pressure or not. Consider the types of plastic pipelines used for water supply networks.

Types of plastic pipes

Here are the types of plastic pipes for water supply:

- Made of polyvinyl chloride (PVC). Most common in plastic systems. The neat, beautiful appearance allows application with an open gasket. Easy to join with glue or rubber connectors. It is recommended to use cold water for plumbing.

- Polypropylene (PP). Durable, lightweight, high temperature resistant. The plastic becomes soft at + 1400C, melts at + 1750C. It is supposed to be used for passing cold and hot water. Can be used in heating pipelines.

- Polyethylene (PE). Elastic, flexible, withstand shock loads, become soft when heated. There are high and low pressure. The low pressure version (LDPE) is designed for cold water pipelines.

- Made of cross-linked polyethylene (PEX). They have flexibility, high strength, are not afraid of high temperatures, do not crack in the cold. They are characterized by a long service life. Suitable for hot and cold water pipes.

- Reinforced plastic. They have a complex structure. The top layer is made of cross-linked polyethylene, then a layer of metal foil, inside - food grade polyethylene. Suitable for drinking systems. They are flexible, can be exposed to high pressure and temperature, physical exertion. Used for heating.

Installation process

Soldering process

The diameter of plastic pipes for water supply can be completely different, because this parameter is selected depending on the load on the system in a certain area.

Regardless of what the dimensions of plastic pipes for water supply are, their installation is not complete without the use of elements such as fittings.

There are several types of such elements:

- Crimp, compression or collet;

- Self-locking;

- Threaded;

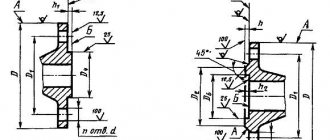

- Flanged.

In the photo - fasteners

In order to answer the question of how to solder plastic pipes for water supply, the following installation instructions should be considered:

- With the help of trimming shears, the pipe is cut perpendicular to its main axis;

- The fastening fitting of the required size is selected;

- The socket of the fastening fitting and the edge of the pipe are cleaned of dust, degreased with soapy water or alcohol, and then dried;

- Insert the fitting and the plastic pipe into the corresponding nozzle of the pipe soldering iron. The fitting is put on the drone, and the pipe is inserted to the full depth of the weld into the sleeve;

- We maintain the prescribed heating time;

Note! It is forbidden to take up soldering if the ambient temperature is below 0 degrees.

- Parts are removed from the soldering iron and connected to each other quickly, confidently, to full depth. With a correct connection, a small continuous bead should form at the edge of the fitting, in the form of a ring around the entire circumference;

- We maintain a cooling period, during which turns or deformations of the product are unacceptable.

Advice. Having no experience in soldering, to begin with, make several test connections, which for control will need to be cut along the axis and make sure that the structure is solid.

Sectional connection

Connections with an offset assembly or alignment of parts must be cut or replaced.For this reason, special attention of the installer will require connections created using tees, elbows and pipe taps. When installing the tap, make sure that the handle moves freely in any direction.

Which plastic pipes are best for plumbing

It is important to use pipelines that meet certain regulatory and hygienic requirements, because water used for food purposes will pass through them.

All 5 types of plastic pipes, which are described in the previous sections, can be used for water supply, it remains only to decide on their capabilities and the conditions in which they will be used.

https://youtu.be/kbeCGzxumFQ

Reinforced-plastic pipelines are an excellent option for private houses, summer cottages. The multilayer structure gives them lightness and strength, corrosion resistance, durability. Their installation is quite simple. Used for hot and cold water supply. Their price is quite affordable.

An inconvenient moment when using them is the need to monitor the connecting fittings, tighten the threaded connections, which relax over time, and leaks may appear in the system.

Polyethylene, polypropylene and PVC versions are also used in plumbing systems. Here it is important to determine for what purposes they will be used. If this is an on-site irrigation system, then you can choose for a technical purpose, if it is an internal water supply for food purposes, the appropriate material is also chosen.

It would be ideal to use polypropylene pipes for water supply. Unreinforced structures are used for cold water. Reinforced polypropylene is used for hot water and heating. Fiberglass reinforcement reduces thermal deformation.

Metal assortment classification

The classification of metal pipes by diameter is very important. This standard size of the rolled assortment affects its transmission capabilities and the scope of use. Also, these dimensions determine the cost of metal pipes.

Metal tube-rolling materials are widely used in various fields of human activity. These are construction, chemical and food production, agriculture, mechanical engineering and others.

This list can be continued, but it is already clear that these products are very popular with consumers. In this regard, it is set out in an extensive choice of configurations and dimensions.

Currently, seamless and welded metal products with a circular cross-section are being manufactured. The line of welded products is distinguished by a simple production process, and, accordingly, their price is not as high as that of seamless analogues. But the latest options show higher reliability, and their resistance to mechanical load is an order of magnitude higher.

Video

To extend the service life, the assortment of ferrous metal is galvanized. Regardless of the option of finishing the surface part inside, metal products show less possibility of skipping than their polymer counterparts.

The most important criterion in the selection of these products is the cross-sectional dimension. In order to create a reliable and durable joint, it is necessary that the size of the metal pipes correspond to the dimensions of the fittings.

IMPORTANT! Together with the cross-sectional dimensions, the wall thickness is also important. Having this exact indicator, it is possible to determine the maximum possible load on the structure even during the development of the project.

Usually, in the marking of steel and cast iron products, the inner size is used, and copper products are marked taking into account the outer girth.

Pipe assortment classification tables

It is very convenient to use tables to determine the exact dimensions of products prepared for connection. For example, tubular steel materials are denoted in inches.

Video

This dimension is used in classification all over the world. And polymer pipes are usually denoted in millimeters. Accordingly, in order to choose the right parts when joining rolled pipes made of various materials, you need to know the principle of matching diameters. These values help to establish tables.

The classification of pipes by diameter is set out in the provided table:

| DN pipe assortment | Thread volume (inches) | Outer Ø of water-gas pressure pipes made of steel | Outer Ø of seamless steel pipe | Outer Ø of polymer pipes |

| 10 | 3/8 | 17 | 16 | 16 |

| 15 | 1/2 | 21,3 | 20 | 20 |

| 20 | 3/4 | 26,8 | 26 | 25 |

| 25 | 1 | 33,5 | 32 | 32 |

| 32 | 1 1/4 | 42.3 | 42 | 40 |

| 40 | 1 1/2 | 48 | 45 | 50 |

| 50 | 2 | 60 | 57 | 63 |

| 65 | 2 1/2 | 75,5 | 76 | 75 |

| 80 | 3 | 88,5 | 89 | 90 |

| 90 | 3 1/2 | 101,3 | 102 | 110 |

| 100 | 4 | 114 | 108 | 125 |

| 125 | 5 | 140 | 133 | 140 |

| 150 | 6 | 165 | 159 | 160 |

This table provides the values of UD in mm, and the corresponding indicators of the external dimensions of various types of pipe assortment: seamless, electric-welded, metal-plastic. The difference in this situation can be up to 1.7 cm.

IMPORTANT! When converting inches to millimeters, all roundings are in the direction of increase.

The following table will help you to choose the exact parts for the gas supply and water supply lines:

| Volume in inches | Volume in mm |

| 1/2 | 15 |

| 3/4 | 20 |

| 1 | 25 |

| 1 1/4 | 32 |

| 1 1/2 | 40 |

| 2 | 50 |

| 2 1/2 | 65 |

| 3 | 89 |

| 4 | 100 |

The standard values for the designation of the diameter of steel pipes are as follows: 6, 10, 15, 20, 25, 32, 40, 50, 65, 80, 100, 110 and more. The UD of this pipe product, which is shown in inches, is rounded in the direction of increase if necessary to convert to metric measurement.

Video

The following diameters of these products are most often used: from 426 to 1220 mm, and in the following networks:

- plumbing;

- gas pipelines;

- drain;

- irrigation.

Small diameter pipes are used for the network supplying water and heat to multi-storey and private houses. Medium diameter options are used for risers in urban infrastructure and the oil industry.

Similar tables are used to determine the diameters of rolled pipes made of copper, brass, and plastic. Using this data, it is easy to make connections of elements from various materials. If fittings are used for work, then the joining process is easier to perform, since these nuances have already been taken into account for these connecting elements.

Advantages and Disadvantages of Plastic Water Pipes

Consider the advantages and disadvantages of plastic pipelines.

Benefits:

- durability;

- immunity to external influences;

- ease;

- not subject to corrosion;

- modern plastic does not affect the quality of water, does not emit harmful substances;

- low thermal conductivity, which keeps the temperature of the coolant;

- ease of installation;

- low cost.

Disadvantages:

- limitation in use for hot water supply;

- obtaining, under certain conditions, permanent connections.

Benefits and Recommendations

Connecting PP pipes does not require expensive equipment and can be done by hand. Anyone can do this. You will need to adhere to the technological process, you can pre-train on scraps. As a result, the family budget is saved.

In addition, the use of plastic has the following advantages:

- It is an environmentally friendly material;

- good corrosion resistance;

- long service life of more than 50 years;

- do not collapse under the influence of water;

- are distinguished by a small amount of noise produced;

- low thermal conductivity makes it possible to use them at subzero temperatures;

- hot water cools to a lesser extent;

- good resistance to temperature and pressure drops;

- ease of installation and installation, are lightweight;

- there is no need to paint them.

They offer a good balance of low installation and maintenance costs versus high performance.

DIY installation of plastic pipes for plumbing

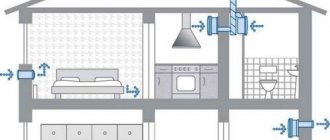

Before laying water supply networks, it is necessary to determine the choice of material and its quantity, draw up a wiring diagram and determine the number of connecting and shut-off valves. When drawing up a diagram, the following rules must be taken into account:

- the length of the pipeline is made as short as possible;

- arrange the smallest number of connections to exclude possible leaks;

- take into account that turns at an angle of 900 reduce the pressure in the pipeline.

Installation of a water supply system from polypropylene pipes

These materials are not flexible; they are cut into separate pieces to change direction. For connection, use special fittings:

- couplings are used to connect segments of the same diameter;

- adapters designed to connect different diameters;

- corners are needed to turn the pipe. They can have an angle of 45 or 900. In addition to a simple hole, the corners can be threaded, with the help of which a mixer or other sanitary equipment is installed;

- crosses and tees, they are installed at the branching points of pipelines.

To connect the elements of the polypropylene water supply system, a special soldering iron is used, which is equipped with nozzles for various diameters. Pipes and fittings are put on nozzles heated to 250-2700C and held for 5 to 10 seconds.

After heating, the pipeline elements are removed from the nozzles and the pipes and fittings are connected, avoiding twisting. Plastic elements freeze within half a minute. After complete cooling, a strong one-piece connection is obtained. Correct connection is indicated by an even shoulder around the connection point.

Installation of a water supply system from polyethylene pipes

To connect polyethylene pipelines, in addition to the methods used for polypropylene, electrofusion welding is used. This requires a special welding machine and a connecting sleeve, which is put on the ends of the elements to be connected and connected to an electrical device, the material of the sleeve softens and merges with the pipe. We get a single design.

Installation of a water supply system from metal-plastic pipes

For the device of such a pipeline, it is necessary to use metal fittings. These can be tees, bends, crosses, adapters made of metal. Consider the types of fittings and how to install them.

Push-in fittings consist of a body, ferrule, and rubber gasket. It is a reusable split design. They have a thread with which they are connected to consumer devices. During installation, nuts are put on the pipe, then the ring, then this structure is inserted into the fitting and the nut is clamped.

Compression fittings. It also uses a union nut and a compression ring, which are put on the end of the pipe, then a fitting is inserted into it, onto which the nut is then screwed and clamped. The connection is sealed with tow or thread.

Press fittings. This process is carried out using press tongs, a sealed one-piece joint is obtained. Before joining, the pipe must be calibrated and chamfered. Then the sleeve is put on and the fitting is inserted. The sleeve is clamped. This connection can be used in hidden wiring.

What pipe diameter should you use for the plumbing? Figures and detailed overview

A rather difficult plumbing problem - what pipe diameter to use for a water supply system - can not be solved independently by every person whose profession is far from repair surveys. However, alas, sometimes it is necessary to solve it. And this understanding is necessary in at least two cases.Or when the water supply system ceases to cope with its regular functions due to deterioration reasons (for example, if you bought a secondary housing, and there the water supply has not been replaced for a long time, or even since the construction of the building). Or when the dream of the whole previous life is being built - a home, a sweet home that requires close enough attention from the future owner - after all, if you really make a dream come true, then seriously and for a long time. And if you do not understand the principles of selecting these specific materials, then at the end of the repair and construction work, there is a chance to face a very uncomfortable work of the entire system being established.

Surely everyone in his life has come across a situation when a faucet open in the kitchen reduced the flow of water from the shower to a thin stream. And clearly did not feel positive emotions at such moments. And most often these negative phenomena are caused precisely by the inadequacy of the pipe sizes to the tasks and needs of the system.

What pipe diameter to use for plumbing depends on many factors that are well known to plumbing installers. Therefore, if you are building a house from scratch, do not stint and pay for the services of a professional - the re-equipment will subsequently cost much more. And the normal atmosphere in the house can be greatly shaken by problems with water. But if you have plans to replace the existing in-house water supply system, you can decide on the diameter of the pipes yourself - you do not need to lay the water supply, the main riser is mounted, so too complicated thoughts are not expected.

You just need to remember the main points. In general, if, as the famous classic poet said, you want your water supply system to be akin in quality and the expected service resource “worked by the slaves of Rome,” then certain peculiarities and nuances should be taken into account.

Something about pipes

Let's make a reservation right away: the size of a pipe means its internal, throughput diameter, and not external parameters, measured, for example, with a caliper. An external parameter cannot serve as an indicator, since the thickness of the pipe walls can be different, depending on the material from which it is made and its purpose.

Steel pipes have thicker walls than plastic pipes. And polypropylene, mounted in hot water supply, are thicker than the same ones, but for cold water, which do not need to withstand high temperatures. So it just needs to be taken into account.

One more nuance: the diameter of the pipes is always given in inches. For us, this unit of measurement is unusual, and some manufacturers and many hardware stores give dimensions in millimeters. However, to facilitate orientation, we offer a conversion chart for the most common sizes. The first two diameters are pipes that supply water to plumbing fixtures, including taps, the last are the sizes of pipes most used in risers.

In addition, it should be mentioned that the diameter, although it is an exact mathematical concept, is a very relative thing from a plumbing point of view. So, a half-inch pipe can have a diameter from 11 to 13 mm, and an inch pipe can vary between 21 and 23. This often depends on the manufacturer. So when installing a plumbing system, try to purchase all the components from the same manufacturer: so at least you will be sure of the greatest percentage of coincidences and matches in size and basic parameters.

Water pipe length

By the way, this is one of the first parameters affecting the throughput of the pipe. As a general rule, the longer the system, the larger the diameter. In the opposite case, the supplied pressure drops, and it becomes insufficient for the normal water supply and life support of the building. It makes sense to lay on the length of the pipes only if they are longer than 4 meters.

In city apartments, this is extremely rare, so that you can get by with a standard solution and, with a simple, straightforward installation, stock up on 10 mm diameter pipes familiar to everyone. It is not recommended to take smaller ones, but larger ones in diameter - it will be difficult to combine with a common divorce in an apartment, and joining will present certain difficulties.

Number of turns and transitions

Complex installation greatly reduces the pressure of the supplied water. The more joints, the greater the pressure drop. Each turn of the pipe also lowers it. And in our bathrooms there is usually not enough space, despite the fact that every owner tries to hide unsightly details - in the walls or at least under the bath. In this regard, sometimes the system resembles a coiled snake entangled in its own body.

If your scheme has more than one turn or joint of pipes per meter of length, increase the diameter of the purchased pipes to 15 mm. Otherwise, the water pressure with multiple bends will gradually fall, and it simply will simply not be enough for a more or less high-quality flush in the toilet or in order to wash in the shower in a normal way, if, for example, water is also included in the dishwasher.

Exit points

They mean the number of taps or connected water-consuming household appliances: washing machine, dishwasher, and so on. And the more of them, the thicker the pipes (remember about the shower while washing the dishes). For 2 points of water outlet (bath + kitchen) with a connected washing machine, there are enough pipes with a cross section of 10 mm. If the house has two bathrooms, and even a dishwasher, expand the diameter to 15.

With a large number of joints and turns, or if the apartment is large and the bathroom is far from the entrance, pipes with a diameter of 20 millimeters may be needed, although this will be a noticeable reinsurance. Rather, such an intensive consumption will affect the diameter of the supply pipes - they will have to be placed wider in cross section.

Standard tube 25 mm. is able to drive through itself 30 liters per minute at a standard flow rate of 0.02 km / s. If the riser is mounted from a pipe with a diameter of 32 mm, then the throughput will increase to 50 liters in the same minute. And if you are interested in what diameter of the pipe to use for the water supply in the apartment of a multi-storey building, the data provided is quite enough for the right choice. It is better to leave the development of a wiring diagram for a private house at the mercy of professional plumbers.

Fast and high-quality assembly of plastic pipes

To get a high-quality plumbing system, you need to properly follow the technology of work. Start laying from the point of connection to the water consumption device. An adapter with a ball valve is installed here, with which you can turn off the water.

The pipe is fixed to the wall with special holders, 20 mm away from it. The holders are installed with a maximum step of 1.5 m, it is imperative to install the mount at bends and when cornering. Fittings are used for turns and corners.

Before connecting the internal water supply network to engineering systems, it is necessary to install shut-off valves to turn off the water supply. A counter is also installed here.

Advantages and disadvantages.

For decades, galvanized steel pipes have been the main material for indoor cold and hot water supply systems. Meanwhile, the interest in the design of durable and reliable engineering systems, as well as the desire to have increased comfort inside the building, to ensure the safety of life, to reduce metal consumption and, accordingly, operating costs, make us think about the possibility of using these systems and other materials. Polymers have become such alternative materials.Just as the invention of cast iron pipes was revolutionary in the 15th century, so at the end of the 20th century, polymers ushered in a new era in the history of water supply. The domestic market for pipes made of plastic materials today is developing at a fairly rapid pace. What are the pros and cons of using plastic pipes? What are their main varieties and characteristics? Here are the answers to these questions:

We note the positive qualities that are equally inherent in all plastic pipes:

durability: the service life of plastic pipes is three to five times longer than that of steel pipes and, as a rule, reaches 50 years or more; corrosion resistance: this property is due to the inability of polymers to enter into electrochemical reactions; environmental friendliness of plastic pipes; low thermal conductivity; light weight; low noise of water flow; simple and quick installation; possibility of both hidden and external laying.

The disadvantages of all plastic pipes include:

impossibility of use in fire-fighting water supply systems; restrictions when used in hot water supply and heating systems; its own installation technology for each type of polymer and pipe type.

All of the above can be attributed not even to disadvantages, but to the features of plastic pipes, because, as a rule, steel water and gas pipes are meant as a standard, and inconsistencies with them are considered as disadvantages of plastic pipes.

The main types of plastic pipes.

The following types of pipes made of plastic materials are presented on the construction market:

- polyvinyl chloride (PVC) pipes,

- polypropylene (PP),

- polyethylene (PE),

- cross-linked polyethylene (PEX),

- metal-plastic pipes (PEX-AL-PEX).

We offer a short description of each of the polymers.

Polyethylene pipes

Polyethylene (PE) pressure pipes are designed for external and internal pressure pipelines (water supply, sewerage, drains). Compared to other plastic materials, polyethylene has the lowest maximum temperature of work -20 ° C, which is especially important for laying and operating pipes in winter conditions. PE pipes with an outer diameter of 20 to 63 mm are connected with brass or polypropylene fittings with a rubber O-ring, as well as with the help of electrofusion couplings. Pipes with a diameter of 63 to 160 mm are butt-welded. The industry produces pipes made of high and low pressure polyethylene: LDPE and HDPE. Non-pressure polyethylene pipes with a diameter of 50, 63, 90 and 110 mm are intended for internal sewerage. This type of pipe also comes in two types: HDPE and LDPE.

Cross-linked polyethylene (PEX) pipes

In order for polyethylene to become more durable and resistant to temperature influences, it is processed under high pressure. As a result, additional cross-links (bridges) are formed between the molecules. This process is called "crosslinking" and polyethylene is called "crosslinked polyethylene". Polyethylene processing methods are as follows: PEXa - peroxide crosslinking; PEXb - gas treatment with silane, (organosilanides are extremely toxic substances); PEXs - irradiation with an electron flow in an electromagnetic field; PEXd - treatment with nitrogen compounds. Cross-linked polyethylene is used for heating and water supply systems. Pipes made of this material are mounted using compression fittings. PEX pipes are widely used in water-heated floor systems and snow melting systems. For heating systems, cross-linked polyethylene pipes are covered with a diffusion barrier to prevent free oxygen from entering the interior of the system.

Metal polymer pipes

The age of reinforced plastic pipes is much younger than cross-linked polyethylene pipes. The first such pipes were produced about nine years ago in England. Their common designation is -PEX-AL-PEX.New developments - PE-RT-AL-PE-RT (REX - polyethylene, PE-RT - heat-resistant polyethylene, Al - aluminum). Reinforced-plastic pipes are essentially the same PEX pipes, inside which an additional layer of aluminum foil is installed. The main point of the installation is to reduce the coefficient of linear expansion of PEX pipes (this layer is also a diffusion barrier). Pipes are a complex structure of five layers:

- cross-linked polyethylene (REX or PE-RT);

- adhesive layer for tight connection of plastic and metal;

- overlap welded aluminum pipe;

- adhesive layer;

- cross-linked polyethylene.

One of the advantages of metal-plastic pipes is the ability to retain their shape when bending, which allows them to be used in an open installation (PEX pipes are installed only hidden). In addition to those mentioned, the main characteristics of metal-plastic pipes are as follows: the ability to withstand constant loads (pressure up to 10 bar at a temperature of 95 ° C); physiological suitability for drinking water and food; 100% gas tightness; slight thermal expansion; lack of structural changes and wear and tear; two types of pipe connections - pressing and screwing.

Polyvinyl chloride (PVC) pipes

Polyvinyl chloride (PVC) pipes were among the first to be used in water supply systems. PVC pipes are used in cold and hot (X-PVC) water supply systems, in technological systems (including in the food industry), and are widely used in sewer systems.

Features of PVC pipes:

no special tools are required for installation - pipes are connected by the “cold welding” method or socket on a rubber cuff; the pipes are quite rigid, so special fittings have to be used to connect them. In this way, these pipes are similar to traditional steel pipes, therefore, data and calculations for steel systems can be used for installation and design; PVC pressure systems are used mainly for underground laying with fixation at the points of pipe bends; these pipes allow both hidden and external laying. When installed externally, the mounted system has a neat aesthetic appearance; since polyvinyl chloride is one of the cheapest polymers, the cost of PVC systems is correspondingly lower than similar systems made of other polymers and even galvanized steel plates

Assortment of our store

You may be interested in this:

Polyethylene pipes

Polypropylene pipes

Underfloor heating pipes