- How to find out how much freon should be in a split system?

- Freon amount for refueling

- How to find out about an insufficient amount of freon

- How to refuel the system

- How to properly refuel the device

- Equipment diagnostics

All air conditioners and split air conditioning units operate on the basis of a refrigerant, namely freon. Sooner or later, every owner of any split system is faced with the need to refuel or completely refuel his device with freon. Therefore, in such a situation, it is important to know the amount of freon in the air conditioner. The required refueling volume depends on this.

How to find out how much freon should be in a split system?

Currently, there are several types of freon or refrigerant. In the system, this gaseous substance is not only a working element of air conditioning, but also a kind of lubricant for the compressor, which is in any installation.

Any split installation consists of two units. One is always installed outside the room, and the other inside it. From one compartment to another there is a cold line, through which freon circulates directly, as well as an electric cable and a drainage system. For wiring the route for freon, only tubes of a small cross-section in diameter, made of copper, are used.

The amount of freon in a split system directly depends on the length of the route for a given gaseous substance, as well as on the power consumption of the compressor. For example, a standard air conditioner track is up to 5 meters long. Even if you purchase a new system, then by increasing the length of the freon pipeline, you will have to refuel it into the system itself. That is why there is no unambiguous meaning for all systems, which could be guided by their refueling or full refueling.

The installation itself is usually filled directly at the factory, taking into account the available route length. It is worth noting that in air conditioning systems, the length of copper pipes is less than 3 meters.

Thus, it turns out that 0.15 kg of refrigerant is charged into the system for each meter of copper track at the plant. Plus, the power indicator of the built-in compressor is added to this mass. If we take the parameters in a general ratio, it turns out that a powerful installation has freon in it somewhere around 0.5 kg.

Naturally, over time, a gradual evaporation of freon occurs in each installation. This process is accelerated if errors were made during the installation of the system and the joints of the pipelines, or rather their connection, was performed poorly, and the gas gradually evaporated through the left slots. Of course, in these cases, before doing a new refueling or refueling, it is necessary to eliminate all existing flaws in the system.

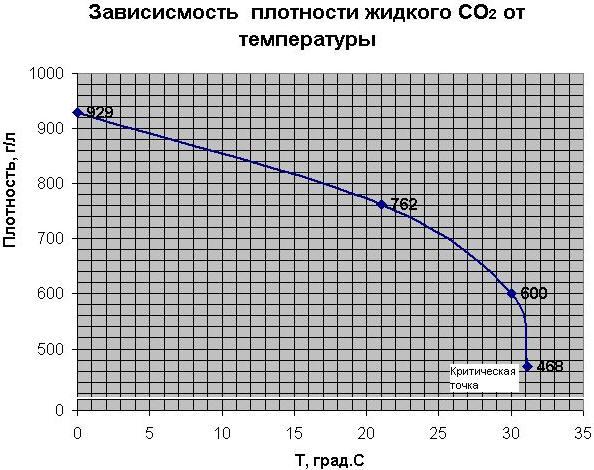

Does the pressure in the can depend on the temperature?

Carbon dioxide obeys physical laws, taking into account them, it can be determined that any gas has a critical state, which is characterized by critical pressure and critical temperature.

The critical temperature is the temperature above which the vaporization of a gas cannot turn into a liquid state, at any pressure. The critical pressure is the pressure when the difference between the liquid and vapor states disappears. In this case, both substances are the same in their density, their index is equal to zero.

What does that mean? The critical temperature for carbon dioxide is 31.2 ° C, and the pressure is 74 atmospheres, this means that a pressure of 74 atmospheres appears in the can at 31.2 ° C, and carbon dioxide acquires a critical state and, at this temperature, the consumption of CO2 during firing increases significantly, since it is not pure gas that comes out through the air valve, but an average substance between liquid and gas, which has a density of 0.47 g / dm3. cub. (carbon dioxide has a density of 1.99 g / cm3).

Moreover, such a strong cooling begins that in the barrel channel directly from this state, carbon dioxide acquires a solid state, the so-called "dry ice", and the pressure in the barrel channel is significantly reduced, this causes a decrease in the initial flight speed of the ball. Therefore, on hot days, the first shots from a pneumatic pistol (until the gas cartridge cools below the critical level) can be rather weak, and the consumption of carbon dioxide is much higher, and from the pistol you can observe the release of particles of "dry ice". For normal shooting, the gas cartridge must be cooled to + 21 ... 23 ° C.

So, we can conclude that a gas substance with a critical temperature of + 31 ... 36 ° C and a critical pressure of 210 atmospheres, non-toxic and cheap, is better suited for use in a pneumatic pistol. But the gas with these indicators is still unknown.

Air under pressure (140.8 ° C / 37.3 atmospheres), of course, is convenient for the PCP weapon, but in a small multi-charge pistol its use is impossible due to the significant dimensions of the can and the pressure drop after each shot or the installation of a reducer (which also has big sizes). Therefore, only carbon dioxide is currently considered for use in pneumatic pistols.

A little about myths. The first and most common one: in foreign gas cartridges, the pressure is much higher, in contrast to Russian ones. This is absolutely wrong, under any conditions the pressure in any can, regardless of the volume and country of origin, will be the same all the time. This will depend on physical laws and not on the manufacturer.

The next misconception: it is not uncommon to hear in shooting galleries: "Install me a new can, someone has already fired from this." The wrong judgment is not even a lack of minimal knowledge of the laws of physics, but a reluctance to listen to any explanations, even textbooks do not convince many people: “I don’t know what is written in the book, but the gun fires poorly and that's it!”. For these distrustful people, special tests were even carried out, it must be said once again: as long as there is at least a drop of liquid gas in the can, at the same temperature regime, which does not exceed the critical indicator (31.2 ° C for carbon dioxide), the pressure in the can does not change. The decrease in temperature during firing does not lower it so much to be seen with the naked eye.

Freon amount for refueling

How much refrigerant needs to be charged into the installation and how much freon is there - these data are usually indicated by the manufacturer. They are indicated on a metal plate, and the plate itself, or in other words, the nameplate is always located on the internal housing of the split system. Refueling the air conditioner is carried out taking into account the indicators indicated there.

The amount of gaseous substance that needs to be added to the air conditioner is usually calculated using a device such as a pressure gauge. Using it, the value of the pressure value in the cooling circuit is determined.

Advantages and disadvantages of R 410a freon

The refrigerant belongs to the group of hydrofluorocarbons. The promising composition is considered an ozone-friendly HFC mixture. The minimum temperature slip (0.15 K) equates its properties to one-component freons.

- The high level of specific cooling capacity does not require the installation of a powerful compressor.

- In the event of a leak, the amount of gas is easily replenished without loss of refrigerant quality.

- There are ample opportunities in terms of reducing the energy consumption of equipment.

- Cold performance is 50% higher than systems with R22 and 407c.

- Good thermal conductivity and low viscosity have a positive effect on the efficiency of the system. Heat is transferred faster and with less movement.

Cons of freon:

- High operating pressure in the system, which negatively affects the compressor, leads to rapid bearing wear.

- The pressure difference between the suction and discharge side of the refrigerant reduces the efficiency of the compressor.

- The requirements for the tightness of the circuit are increasing. The wall thickness of the copper pipes of the main must be greater than for R22. The minimum value is 0.8 mm. A significant amount of copper increases the cost of the system.

- The refrigerant is not compatible with HVAC equipment parts made of elastomers sensitive to diphtomethane and pentafluoroethane.

- The polyolester oil used in the conditioner is more expensive than the mineral oil.

How to find out about an insufficient amount of freon

Every owner should know how to find out that there is not enough refrigerant in the system, this will help to refuel on time. Usually the following factors indicate this:

- The air conditioner has become much weaker to cool the air in the room, even if it is operating at maximum mode.

- The installation has completely stopped cooling the air in the room.

- Frost has appeared in the joints of the cold line pipes and valves, which can be seen with the naked eye.

These are the most basic facts that directly indicate that there is not enough refrigerant in the installation. Before you begin to determine the amount of refrigerant in the air conditioner for refueling or its full charge, you yourself need to find out what kind of gaseous substance was charged into it. Currently, for split systems, several types of freon of different brands are used.

The very first air conditioners and indoor air conditioning systems were fueled with R-22 freon. At the same time, the freon pressure in the air conditioner at outdoor temperatures from up to 30 degrees is 4.5 bar. Subsequently, scientists found that this gas has a very negative effect on the ozone layer of the earth. In addition, with a sharp drop in temperature, the system with such a refrigerant became very inefficient in operation.

Later, new models of air conditioners and installations began to be charged with more modern refrigerants, which, moreover, were completely safe in operation and did not in any way aggravate the state of the ozone layer of the atmosphere. So, today you are unlikely to find at least one installation working on this gaseous substance.

Of course, service companies know many nuances and various factors that should be taken into account when refueling the system with freon. But if you plan to do this work on your own, then their experience and knowledge will certainly come in handy.

How to refuel the system

There are several fairly simple ways to cope with this task on your own.

- initially, the container in which the freon is located must be weighed.

- having opened the gas outlet, it is charged into the installation until the cylinder is empty to the required value.

In order not to be engaged in calculating the remaining amount of freon in the installation, it is possible not to refuel at all, but to perform a new refueling of the entire system. To carry out this process, all the freon that remains in the air conditioner is released outside through a special valve. The new amount of Freon in the air conditioner is determined using a scale. Only the amount indicated on the innermost case of the system is charged into the installation, the data that is always indicated by the manufacturer. Such refueling is a fairly simple and safe process.

The recommendations of experts say that it will be much more effective not to add the required amount of refrigerant into the split system a little, than to put an excess of it there. This is due to the chemical property of freon to pass from a liquid to a gaseous state.If there is too much refrigerant in the installation, then it simply will not have time to transform from one state to another.

It is possible to determine that there is not enough gaseous substance in a split system using an ordinary thermometer. True, this method will not work for inverter installations. So, a thermometer is brought to the fan. And if its temperature is 5-8 degrees, which is usually indicated in the passport of the device, then this is an indicator that the air conditioner is operating in normal mode, with normal power, and the amount of refrigerant is quite normal.

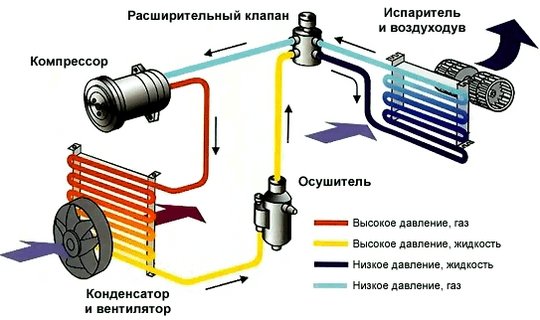

How does a car air conditioner work?

Any car air conditioner, regardless of the vehicle manufacturer, functions according to the same principle. Refrigerant passes through the branch pipes and lines of the installation, which is compressed during the operation of one of the main elements of the system - the compressor. As a result of the fact that the pressure in the installation is high enough, the refrigerant or freon can take heat from the surrounding medium and heat it up. Further, the heated gas moves through the nozzles, where, in fact, it gives off heat. At that moment, the pressure in the car's air conditioner decreases, the coolant begins to cool down, and it is at this time that the cold air flow begins to flow into the vehicle interior.

The scheme of the car air conditioning system

When the warm season comes, experienced motorists always diagnose the installation so that all the necessary preventive actions and repairs can be carried out before the onset of heat. It should be noted that the installation diagnostics procedure should be carried out at least once a year, and better - at the beginning and at the end of the season. In principle, today such a task can be performed at any specialized service station, and if you have certain knowledge, you can do it yourself. If you decide to carry out this process on your own, you need to prepare some tools and devices.

An important element of the installation is the air conditioner low pressure sensor - it is designed to control this parameter. This device is located on one of the system nozzles, it should be noted that this can be a line of not only low, but also high pressure. It is the pressure sensor in the air conditioner that allows you to accurately determine how much refrigerant is required for the normal operation of the compressor. If necessary, the regulator activates and deactivates the compressor while the unit is running.

Refueling a car air conditioner

Failure of this regulator is fraught with rather serious consequences. That is, the compressor itself may not turn on. And it can be activated at reduced pressure or its absence. In addition, due to a breakdown of the regulator, the compressor may not turn on at all if there is an excess amount of refrigerant in the system lines.

It should be noted that in any case, a breakdown of the sensor can eventually lead to a breakdown of the compressor - at one point this component can simply jam. The regulator itself may break down as a result of mechanical damage or due to oxidation of the contacts at its outputs. The type of regulator may vary depending on the vehicle manufacturer. By their design, the sensors can have different threads, the device, they can be equipped with two or more contacts, there can also be differences in the types of connectors. In fact, the more expensive and representative the car, the more difficult it is to find the right regulator for the air conditioning system.

How to properly refuel the device

If you refuel a split unit, adhering to and following certain rules, then there will be no damage to the system.

- The easiest and safest way to fill the unit with freon is to use a scale. Firstly, you can always find all the information you need on a metal nameplate that is attached to the block. Also, keep in mind that if you have used a longer refrigerant line than the manufacturer specified during installation, you will need to recharge the system.

- When there is a new charge of refrigerant into the unit, it is necessary to release the residual freon outside so that the oil remains inside the split system. To do this, the valve on the valve, through which the gas will escape, is slightly opened so as to prevent oil leakage. It takes about several hours for the refrigerant to leave the device.

Equipment diagnostics

The use of freon in refrigeration units, as well as in air conditioning units is simply irreplaceable today. And it is quite natural that after full or partial filling of the refrigerant into the air conditioner, it is necessary to carry out a thorough diagnostics of the equipment and check it for the tightness of the connecting joints and the efficiency of the entire installation.

These actions will help in the future to avoid refrigerant leakage due to loose joints and improve the performance of the entire installation. Sometimes it also happens that the efficiency of the air conditioner is not restored after refueling. Although the system itself is working properly. In this case, it is possible that some kind of damage could have occurred inside the device.