Stylish jackets parkas for women are a real find for the fair sex who prefer casual and casual smart style in clothes. For more than one season, parkas jackets remain popular and relevant in the wardrobe of women and girls who follow fashion trends.

Fashionable parka jackets will delight you with their practicality, for which no girl wants to part with the park this and next season, creating fashionable bows in different styles.

A distinctive feature of the parka jacket is a durable fabric, not blown and waterproof, the presence of a hood and a fur lining. The length of a parka jacket can be different and varies from mid-thigh, and can also be slightly below the knee.

The classic parka jacket was created specifically for cold and rainy weather conditions, in which parka jackets do an excellent job with their task. Perfectly warming, thanks to the warm lining and hood, parkas jackets do not hinder movement at all and are very comfortable and practical.

At the same time, parka jackets for the 2019-2020 season fit perfectly on the figure, emphasizing the waistline, allowing you to create practical, stylish and feminine bows for every woman.

A more practical and stylish version of outerwear, perhaps, can not be imagined. Therefore, many designers from season to season include parka jackets in their collections, fashionable parka jackets 2019-2020 were no exception.

Popular models of parka jackets can be safely worn not only in winter, but also in autumn, spring and even summer, when the parka jacket is presented in the form of a light and stylish cape.

Despite the fact that parka jackets are more of a sporty style of clothing, stylists suggest that we combine them with skirts and dresses, jeans, low-heeled boots in a masculine style, as well as shoes with heels.

Do you want to choose the most fashionable models of parka jackets 2019-2020, which were comfortable and looked beautiful on the figure? Then we offer you a fashionable selection of photos with beautiful images of girls in a parka jacket, which may inspire you and help you choose a fashionable parka jacket for 2019-2020 in a huge variety.

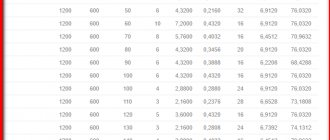

Specifications

All Ragos products have a wide range of applications. The main material of manufacture - basalt wool, which is obtained by melting a stone at a temperature of + 1500 degrees Celsius.

Thermal insulation of parks has the following performance properties:

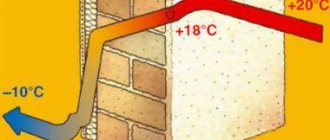

- resistance to low temperatures - a low level of thermal conductivity ensures minimal heat loss;

- increased moisture resistance - a high degree of water repellency does not allow moisture to accumulate in the insulation layer and thereby provoke its deterioration, as well as corrosion of metal structures;

- resistance to mechanical stress - lightness and increased strength make the installation process of plates easier, while the material does not lose its shape and does not shrink at elevated temperatures;

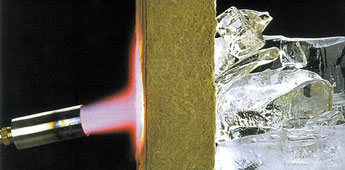

- not susceptible to fire - paroc insulation belongs to non-combustible components;

- environmental friendliness - the absence of harmful impurities makes the panels absolutely safe and non-toxic to humans.

Thermal insulation products of the park can withstand temperatures up to +200 degrees, at which the insulating properties do not change.

The stone wool park is used for various types of construction and installation work. Depending on the purpose, the following types of insulation are distinguished:

- ragos extra smart - universal thermal insulation boards for general construction purposes;

- ragos was - heat barriers for walls;

- ragos wps - windproof insulation;

- the ces line is used for thermal insulation of buildings from sandwich panels;

- rob and ros markings are intended for installation on flat roofs;

- linio 15 paroc - slabs for thermal insulation of plastered facades of premises;

- FPS grades are used as a fire retardant layer;

- ragos SSB has soundproofing properties;

- ragos GRS is used for moisture insulation of floors and foundations.

Each brand has its own properties, description, technical characteristics. Panels and mats differ in size, application and installation.

Basalt insulation is used in the following areas:

- construction (insulation of roofs, facades, floors during the construction of residential buildings);

- HVAC (insulation of pipes for water and heat supply systems, ventilation, chimneys, fire-fighting systems);

- industry (thermal protection of gas ducts, heat exchange points, boiler houses, pipelines);

- shipping (insulation of ships and oil platforms).

The products of this manufacturer ensure the evenness of the surface on which plaster can be applied, while the plates do not change their shape and original properties under the influence of high temperatures, precipitation, moisture and ultraviolet radiation.

What is a parka?

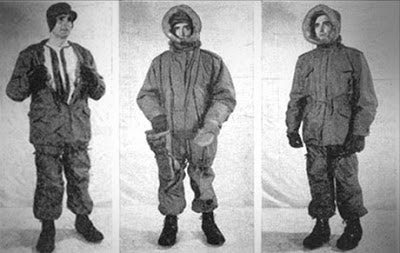

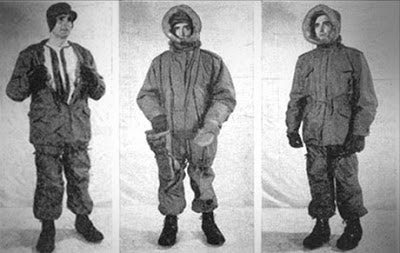

This is an elongated warm jacket, the hood of which is trimmed with sheepskin. She also has deep and roomy pockets, a high collar, laces at the waist. Initially, this jacket was worn by Eskimo hunters who needed quality protection from the cold and piercing winds. Even the word "parka" itself comes from the Eskimo language.

This invention of the Eskimos was appreciated by the American military, who, having borrowed the style from the northern inhabitants, invented their own version of the parka jacket, which, as a result, became part of the military uniform. The then parks had the following look: length to mid-thigh, bulk and a large fur hood. The lower temperature threshold for the parks of those times was -51 degrees Celsius, which proves how irreplaceable the park was in frosty conditions.

Over time, the parks became available to the civilian population, who also needed insulation for the cold seasons. They were especially fond of British youth, and specifically - fashion - a subculture of the times of the 50-60s of the last century. The parka served as protection for the more elegant garments worn underneath.

Since that time, the appearance of the jacket has not changed much, it just began to have a larger selection of colors. Modern designers offer parkas in neutral shades: khaki, brown, black, and bright, up to eccentric prints. This year, as never before, a huge range of men's parkas is presented, buy and stay fashionable all season!

Mats

Lamellar mats

Paroc HVAC Lamella Mat is filled with non-combustible basalt wool, with which you can protect ventilation equipment from moisture, as well as make sound and thermal insulation of ventilation ducts.

The lamellar mats are foil-coated with aluminum on one side, and on the other, they are equipped with adhesive tape, which is attached to the desired surface. Due to the presence of an adhesive layer, the temperature regime for the use of this material is up to +50 degrees.

The dimensions of the mats, depending on the thickness (20-50 mm), vary in width from 1000 to 500 mm.

The manufacturer recommends installing the mats at a temperature of +5 - +35 degrees. Before installation, the application surface is degreased.

Mats for hvc and industry

Paroc Pro Loose Mat 50, 80 (density 50 and 80 kg per cubic meter)

Scope of application

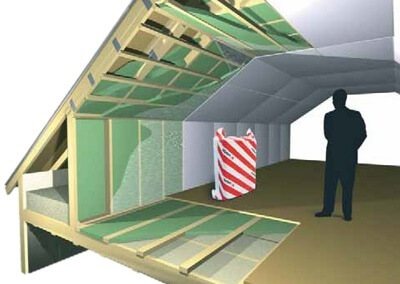

For the insulation of residential buildings, durable slabs of stone wool or expanded polystyrene are used

Heat-insulating plates protect wooden, concrete, brick surfaces from heat loss. Low-rise buildings are the priority for using Parok Extra insulation.

The material is used to insulate:

- ventilated facades, door and window frames - basalt, stone wool or expanded polystyrene, layer 20 - 30 mm;

- foundations, basements, floors, ceilings - slabs of increased rigidity and basalt mats;

- steel structures, chimneys, door leaves - non-combustible plates PPZh;

- walls of residential buildings - Paroc mineral wool, extruded polystyrene foam, polystyrene foam, stone wool.

During installation, workers do not require special protective equipment (with the exception of glass wool), since the insulation does not emit harmful substances and fibers during cutting.

Paroc pro slab 60

Semi-rigid slabs pro slab 60 paroc are a kind of technical basalt fiber with a density of up to 60 kg per cubic meter. They are used for insulating flat and cylindrical tanks with a radius of about 3 meters.

The material has the following performance characteristics:

- density - 40 kg / m 3;

- width - 600 mm;

- length - 1000 - 1200 mm;

- thickness - 50 - 120 mm;

- boundary temperature - not higher than +350 ° С;

- density - 60 kg / m3;

- strength - 3 kN / m 2;

- fire classification - non-combustible (NG).

Technical characteristics of insulation Park

Mineral wool Park is used for indoor and outdoor use

The boards are placed in a suitable frame without special fasteners. Geometric parameters are maintained precisely, the elastic edge adheres to the elements of the sheathing and prevents the appearance of cold bridges.

Material characteristics:

- density varies in the range of 27 - 32 kg / m3 and is evenly distributed throughout the entire thickness;

- the service life of thermal insulation without changing the indicators - 50 years;

- the level of protection against losses does not decrease at air humidity up to 95%, thanks to the impregnation with water-repellent compounds.

With the use of Parok mineral wool, the fire index of the structure increases, since the material does not burn and prevents the spread of flame.

Paroc pro slab 40

Pro slab 40 - medium hard rock wool slabs for processing tanks from three meters. Pro slab 40 has a lower density and is considered one of the best insulation materials for large containers with low temperatures. The manufacturer recommends keeping the temperature inside the tank no higher than 60 degrees. In the photo of the package you can see how the plate looks like.

The technical characteristics of the heat barrier comply with all quality standards:

- density - 40 kg / m 3;

- width - 600 mm;

- length - 1200 mm;

- thickness - 50-160 mm;

- boundary temperature - +350 ° С;

- thermal conductivity - X10 qC <0.034 V / (m-K);

- fire classification - non-combustible (NG).

GJO.E EVENTS AND NEWS

The second layer under the amauchi was a jacket of a similar design made of a similar material, but thinner and with fur inside - atigi. Thus, excellent thermal properties were ensured.

Some types of parkas needed regular treatment with fish oil to maintain their water-repellent properties, however, for example, the Aleutian variants were already cut from the skin of animals with natural impregnation. Hoods were often trimmed with wolverine fur - water almost completely rolls off it, without lingering or passing inside.

The production of these parkas required high hunting and sewing skills and could easily take up to one month per piece. Animal fur acquired its best properties in the summer season.

The traditions of creating parks came to the modern world in the middle of the 20th century, and although today's parks are almost never made from animal skins and skins, they retain some of the characteristic elements that made the park legendary:

▪ designed for extremely cold temperatures;

▪ long zipper from bottom to eyes;

▪ the hood is insulated from the inside with fur or nap;

▪ cut, often oversized, in order to use several layers of insulation;

▪ elongated (up to the thigh) or long (up to the knee) silhouette.

The park has become an excellent choice for field conditions due to its practicality, pocket capacity, simplicity of design and moisture resistance. What led to its natural mass distribution, which began in the 40s of the twentieth century.Clothing items similar to a park were produced in several versions, both with fur insulation, which in wartime was replaced with nap due to cost, and without it. Army versions were made of cotton poplin with a dense structural knit and were equipped with removable insulated fasteners since 1943.

Parkas for Air Force soldiers differed in cut - they were slightly shorter, and the composition of the outer fabric, they served as nylon or a mixture of dense cotton.

However, the first appearance of the park in the Air Force happened thanks to the traveler and entrepreneur Eddie Bauer from Washington, who developed flight suits specifically for pilots in Alaska in 1941, having received patents for them, and at first the American military bought a Bauer jacket for their own money, since it was much warmer and more comfortable than standard equipment. And in 1943, the US Air Force approached Eddie with a request to organize a regular supply of fleets for pilots, and he developed the B-9 down parka and the B-8 insulated pants. During the war, about 50 thousand of these kits were produced.

At-9 of those years and to this day it is in demand by collectors as an incredible example of a high-quality parka made from a mixture of cotton and nylon, which retains heat in cold weather.

At the end of the 40s, the N3B model was sewn - the version as close as possible to the modern interpretation. Similar to the B-9, it was 3/4 long with an outer material of DuPont flight silk or nylon. Wool quilted filling helped to withstand temperatures above -50 degrees, later it was replaced by synthetic polyester. A buttoned placket was additionally protected from wind penetration. N3B is a fleet for US Air Force ground units based in northern climates with low temperatures and piercing winds. In numerous pockets, it was convenient to store camping rations, equipment, medicines and ammunition. And the oversize cut made it comfortable to wear over the uniform.

The park got its second name "Snorkel" due to its resemblance to a snorkel, an air tube into which the hood was pulled out when the main zipper was fastened all the way. This greatly reduced visibility and audibility, but made it possible to minimize heat transfer from the neck and head, which was clearly preferable in harsh conditions. In the original, it had a dark blue color, which later, when equipping other units, changed to pale khaki.

Later, when the park gained mass civilian distribution, the color range expanded significantly. At the same time, many models have an orange lining - a reference to flight options - turning such a jacket inside out, the pilot found himself for his allies after the ejection.

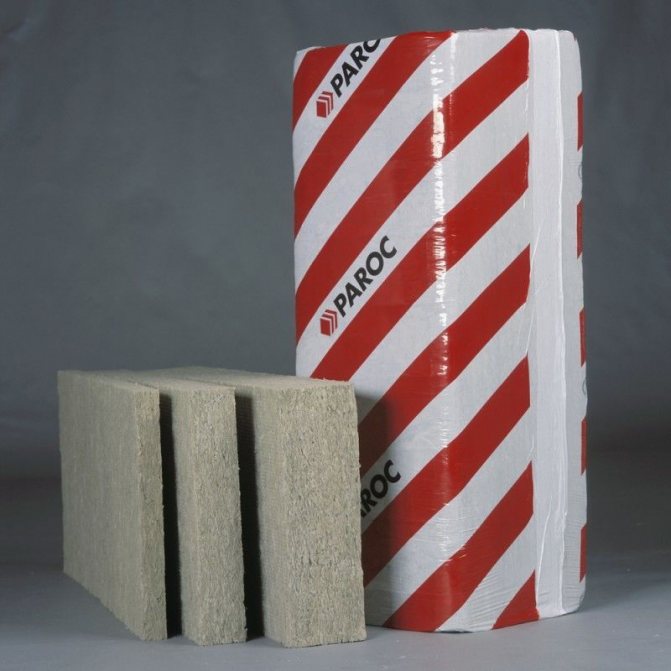

Paroc extra

Parok extra is a completely new product that does not lend itself to combustion of insulation for thermal and acoustic protection of walls, facades and roofs of premises. It is one of the most reliable and safe materials for insulating houses, summer cottages and cottages. Paroc extra boards are ideal for thermal insulation of frame structures, roofs and various partitions.

They do not emit toxic substances, keep their shape and do not crumble under the influence of high temperatures.

Paroc extra has several advantages:

- does not change shape during operation, as a result of which empty areas are not formed, filled with cold air;

- the structure of multidirectional long and thin fibers makes it possible to maintain a constant volume inside and provides high thermal insulation even when using the thinnest paroc extra 50 mm insulation;

- increased moisture resistance (as a result of the experiment, when this material is completely immersed in water, it absorbs only 1% of moisture);

- noise suppression in 7-10 dB;

- plates have received quality certificates in a number of European countries, Russia, Ukraine, Belarus and are an environmentally friendly product;

- the material has high elasticity, which makes it easy to transport (even after compression, it does not lose its shape and, after straightening, returns it).

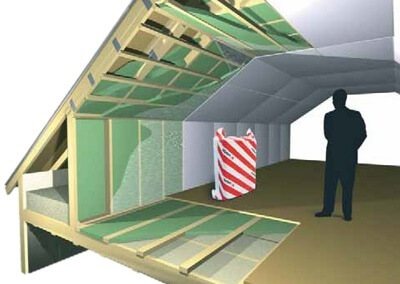

Insulation of this brand is used for thermal insulation of attics, log and concrete walls, tiled roofs, interior structures.

The instructions for the product stated such those. specifications:

- thermal conductivity - \ 0 9C <0.036 V / (m-K);

- density - 26-40 kg per m3;

- dimensions in width - 600 mm;

- dimensions in length - 1200 mm;

- dimensions in thickness - 50-200 mm (insulation plate of 200 mm type provides a higher coefficient of heat saving);

- flammability - NG.

PAROC

PAROC eXtra - universal heat-insulating non-combustible stone wool slab. It is used for heat, sound insulation and fire protection of walls, roofs and floors in all types of buildings.

Company PAROC for 70 years it has been one of the leaders in Europe in the production of mineral wool insulation based on basalt fibers. Basalt rocks are the main raw material in the production of slabs. Basalt rock is transformed into stone fiber, which is the basis of the material with high thermal insulation, fire retardant and mechanical characteristics. All PAROC heaters are certified according to the international quality system (ISO 9002).

Paroc Insulation Assortment

View:

Insulation PAROC Extra 1200x600x100mm 5.76m² 0.576m³ 8pcs / pack

1260 / pack

Add to cart

Characteristic

Insulation PAROC Extra 1200x600x50mm 11.52m² 0.576m³ 16pcs / pack (cr02 55 × 78)

1260 / pack

Add to cart

Insulation PAROC Extra 1200x600x50mm 11.52m² 0.576m³ 16pcs / pack (cr04 55 × 98)

1260 / pack

Add to cart

Insulation PAROC Extra 1200x600x50mm 11.52m² 0.576m³ 16pcs / pack (mr04 78 × 98)

1261 / unitary enterprise

Add to cart

Insulation PAROC Extra 1200x600x50mm 11.52m² 0.576m³ 16pcs / pack (mr06 78 × 118)

1261 / unitary enterprise

Add to cart

Insulation PAROC Extra 1200x600x50mm 11.52m² 0.576m³ 16pcs / pack (mr08 78x140)

1261 / unitary enterprise

Add to cart

Insulation PAROC Extra 1200x600x50mm 11.52m² 0.576m³ 16pcs / pack (mr10 78 × 160)

1261 / unitary enterprise

Add to cart

Insulation PAROC Extra 1200x600x50mm 11.52m² 0.576m³ 16pcs / pack (pr06 94 × 118)

1262 / unitary enterprise

Add to cart

Insulation PAROC Extra 1200x600x50mm 11.52m² 0.576m³ 16pcs / pack (pr08 94x140)

1262 / unitary enterprise

Add to cart

Insulation PAROC Extra 1200x600x50mm 11.52m² 0.576m³ 16pcs / pack (sr06 114 × 118)

1262 / unitary enterprise

Add to cart

Insulation PAROC Extra 1200x600x50mm 11.52m² 0.576m³ 16pcs / pack (sr08 114 × 140)

1262 / unitary enterprise

Add to cart

Insulation PAROC Extra 1200x600x50mm 11.52m² 0.576m³ 16pcs / pack (fr04 66 × 98)

1261 / unitary enterprise

Add to cart

Insulation PAROC Extra 1200x600x50mm 11.52m² 0.576m³ 16pcs / pack (fr06 66 × 118)

1261 / unitary enterprise

Add to cart

Characteristic

Parok Extra slabs can be used in vertical or horizontal structures, for insulating pitched roofs, attics, ceilings, in ventilated facade systems, and so on. PAROC eXtra provides high-quality heat saving (thermal insulation coefficient is 0.0356 W / mK) and sound insulation. The best thermal insulation properties are provided due to the structural features of the material - the small diameter of the mineral fibers with their increased length. Density of slabs Park averages 27-32 kg / m3, while the density is uniform over the entire thickness of the slab. Due to the high density, slabs subsidence during operation is excluded. The level of thermal insulation provided remains stable throughout the entire service life, which is at least 50 years.

The slabs are resilient and easy to install - and without any fasteners, they resiliently fit into frames of the appropriate size. Exact geometrical dimensions and the presence of an elastic edge create conditions for close contact with the frame. At the same time, there is no stable heat leakage (so-called cold bridges).

Treatment with water-repellent impregnations makes Park Extra insensitive to moisture, the level of thermal insulation provided does not decrease with an increase in external humidity up to 90-95%. Slabs PAROC eXtra - non-combustible material that retards the spread of flame. Its use improves the fire-fighting characteristics of the structure. The insulation does not shrink even when used for several decades, and is not subject to deformation when exposed to intermittent loads.

| Specifications | unit of measurement | Index |

| Density | kg / cubic meter | 27-32 |

| Length | mm | 1200,1220 |

| Width | mm | 600,610 |

| Thickness | mm | 50,100 |

| Thermal conductivity | ||

| - at a temperature of 10 С | W / (m.K) | 0,0355 |

| - at a temperature of 25 С | W / (m.K) | 0,038 |

| - under operating conditions A | W / (m.K) | 0,043 |

| - under operating conditions B | W / (m.K) | 0,046 |

| Flammability | Group | NG |

Paroc UNS

Insulation paroc uns 37z is universal for thermal insulation of any building. The product is produced in the form of basalt fiber slabs with a density of 30 kg / m2 with a heat conductivity coefficient of 0.042 W / m.

Uns Park has a number of positive features:

- elasticity at a high level;

- shattering resistance;

- resistance to decomposition and rodents (does not contribute to their appearance);

- resistance to oils and other chemicals in the form of solvents;

- ease of installation (easy to cut and does not require special fasteners);

- safety and non-toxicity;

- fire resistance (non-combustible material).

The dimensions of the slabs are standard: 600 * 1200 with a thickness of 50 to 200 mm.

Specifications

| Size, mm | Packaged | ||||

| length | width | thickness | pieces | m2 | m3 |

| 1200 | 600 | 50 | 14 | 10,08 | 0,5040 |

| 1200 | 600 | 100 | 8 | 5,76 | 0,5760 |

PAROC eXtra

Products of the Swedish-Finnish company PAROC It is widely used in Russian conditions for insulation, fire protection and sound insulation of various structures. For example, thermal insulation material PAROC eXtra intended for the construction and overhaul of vertical and inclined frame walls, horizontal surfaces (roofs, ceilings), floors on logs. This material is suitable for both residential construction and for thermal insulation of buildings for civil, industrial and commercial purposes.

Key Features

PAROC eXtra are mineral fiber slabs created using modern technologies from environmentally friendly raw materials (natural stone of the basalt group). The versatility of these plates makes it possible to use it both for fire protection of buildings and structures (after all, mineral fiber belongs to the class of non-combustible materials), and for their heat and sound insulation. Basalt mineral fiber is pressed into slabs that are easy to carry, cut and install. The density of PAROC eXtra is 30 kg / m3, which makes it possible to use this material in unloaded structures. The service life of this material, with its correct installation, is more than half a century, and throughout this time the insulation will retain its useful properties: low thermal conductivity, high hydrophobicity and vapor permeability, resistance to chemicals, rodents, insects and mold.

Dimensions (edit)

| Width and length | Thickness |

| 600 x 1200 mm | 40 - 200 mm |

| 565 x 1220 mm | 40 - 200 mm |

| 610 x 1220 mm | 40 - 200 mm |

| In accordance with GOST EN 822, 823 | In accordance with GOST EN 822, 823 |

Fire-technical characteristics

Fire hazard class of material

| Description | Value | In accordance with |

| Flammability | KM0 (NG) | GOST 30244-94 |

Thermal characteristics

Calculated thermal conductivity

| Description | Value | In accordance with |

| Estimated thermal conductivity under operating conditions A | 0.040 W / m * K | SP 23-101-2004, adj. E |

| Estimated thermal conductivity under operating conditions B | 0.042 W / m * K | SP 23-101-2004, adj. E |

Moisture resistance

Water absorption

| Description | Value | In accordance with |

| Water absorption at short-term immersion, WS, Wp | 1 kg / m² | EN 1609 |

To reliably insulate a building, it is necessary buy PAROC eXtra the thickness that will meet the thermal engineering requirements of the project. PAROC produces this thermal insulation with a thickness of 30-220 mm.

PAROC eXtra price in our company - one of the lowest in Moscow and the Moscow region. We offer others heaters for home at wholesale cost.

Paroc ROB 60

Mineral wool paroc rob in slabs is used to insulate the upper layer of roofs, both new and old buildings. Paroc rob 60 Paroc roof slabs from the manufacturer are made for permanent fire protection of all types of insulation films and membranes used on various surfaces.

This material has high strength and is able to withstand pressure up to 6 thousand kg / m2 during operation and installation.

In addition, the thermal barrier treatment of flat roofs with paroc rob 60 provides protection against moisture and steam at the same time.

The product retains heat at a high level, has increased sound insulation, moisture resistance and vapor permeability.

Technical properties:

- shape: plate;

- heat conductivity: 0.038 W / (m * K);

- heat resistance: group NG;

- application: flat roofs.

Characteristics of Paroc Extra insulation

Insulation Paroc Extra, the characteristics of which will allow you to understand whether to purchase it, is made on the basis of diabase or basalt. It can be used when insulating a pitched roof, walls, interfloor ceilings and partitions. The dimensions of the slabs vary from 1200x600x50 to 1200x600x200 millimeters. In the first case, the price per package will be 800 rubles, while in the latter - 900 rubles. For a cubic meter, the consumer will have to pay 1,580 rubles for the dimensions of the plates that were mentioned in the first case.

The density of the slabs is 35 kilograms per cubic meter, while the thermal conductivity is 0.036 W / m * ° C. The dimensions of the slabs are designed taking into account the standard dimensions of the frame structures of facades and roofs. This allows for ease of installation, and also ensures that there is no need to use additional fasteners. During installation, the plates are laid as tightly as possible, which allows ensuring close contact, excluding conditions for heat leakage and the formation of cold bridges. Among the advantages, a high degree of elasticity should be highlighted, which manifests itself in the absence of a constant load.

Why Paroc cylinders are good

Paroc cylinders are used to protect pipelines from temperature extremes with a maximum degree of up to +750 Celsius. When creating them, a special technology was used, which is able to evenly distribute thermal conductivity, as well as wear resistance along the entire cylinder. This makes it possible to operate them more than once, since the pipes do not deform and do not crumble during secondary installation or dismantling.

Paroc insulation for standard pipes is used in ventilation shafts, plumbing and sewer systems.

Paroc cylinders have high strength and density, reliably protect pipes from heat loss and condensation. In addition, the product is valued for its high-quality sound insulation.

The advantage of the material is that it is produced in the form of cylinders, which is not done by other companies, which are mainly focused on the manufacture of semi-cylinders. In this case, Parok products have a greater tightness than competitors.

The manufacturer has selected the optimal component density up to 100 kg per square meter. As a result, having a thickness of 50 mm, ragos cylinders perfectly absorb noise, and with a thickness of 100 mm, pipes are reliably protected from freezing and energy loss.

Another distinguishing feature of this product over competitors is the relative position of the fibers in a strict order. This gives the insulation extra rigidity and reduces compression at 100% pipe wrap.

Types of products

Linen insulation for houses from a bar

The company produces materials based on stone fibers and basalt rocks with the use of improving additives, as well as synthetic ones.

Products are manufactured in the form:

- mineral wool, basalt, glass wool slabs and mats;

- expanded polystyrene extruded and foam products;

- linen insulation;

- slabs of increased rigidity (PPZh);

- foam mats.

The insulation does not shrink after working for 3-4 decades, temporary loads do not leave traces of deformation on the slabs.

Mineral wool

Mineral wool foil roll insulation for roofs or floors

The products are distinguished by high sound and heat insulation. Improvement in technology has led to the expansion of the scope of Parok mineral wool. The material is used to protect against heat loss in fire hazardous buildings.

Depending on the density, the following types are distinguished:

- normal;

- semi-rigid;

- hard.

It goes on sale in the form of mats, rolls, slabs, sandwich panels and pipes. Fibers in the thickness are arranged in layers horizontally or vertically, collected in a corrugated or spatial structure.

Basalt wool has a high thermal resistance, the indicators of which are similar to those of wood thicker than 40 cm.

Basalt slabs characteristics:

- resists the action of chemicals and mechanical shock;

- tolerates temperature changes without destruction;

- withstands up to 200 cycles of thawing and re-freezing;

- quickly restores properties after drying.

Parok basalt insulation is produced from magmatic sediments with the addition of carbonate components to coordinate the acidity index. Bitumen, urea resins and bentonite clays are used as a binder for the fibers.

Glass wool is used to insulate walls, floors, attic

Parok glass fiber insulation is a type of mineral wool. The raw materials are soda, dolomite, sand, limestone, borax. The material is resistant to chemical irritants, it is used in laboratories, workshops of hazardous production.

Glass wool properties:

- loose density is 130 kg / m3;

- thermal conductivity of the material - 0.032 - 0.052 W / m · K;

- melting point - + 450 ° С.

The length of the glass wool fiber is 4–15 µm, which is 3–4 times longer than similar elements of stone wool. This determines the vibration resistance, elasticity and strength of the material.

Stone wool can withstand high temperatures without melting (about +850 degrees). Stone insulation The threshold does not burn, but when heated to a critical temperature, it disintegrates into dust. Thermal conductivity in the range of 0.035 - 0.039 W / mK.

Open pores in the structure provide a porosity of 0.25 - 0.35 mg / m2 · h · Pa. The density is in the range of 30 - 220 kg / m3, therefore the physical and mechanical properties of different types are different.

Extruded polystyrene foam

Expanded polystyrene does not absorb moisture, but is afraid of ultraviolet radiation, combustible

Differs in a homogeneous structure, containing gas-filled cells of 0.1-0.2 mm in the base. Granules of polystyrene and styrene copolymers dissolve in the polymer mass, natural gas is supplied and the particles increase in volume. Heat-resistant types of expanded polystyrene are filled with carbon dioxide. The material is used for insulation of private buildings and industrial facilities.

Properties of expanded polystyrene:

- low water absorption - accumulates 0.4% of the mass after being kept in water for 10 days;

- the density of any kind is 0.05 mg / m · h · Pa;

- fungi and microorganisms do not develop on the surface.

The durability of the extruded polystyrene foam in the structure is 60 - 70 years.

Styrofoam

Polyfoam Park is used for indoor and outdoor thermal insulation of a room

The material is made of foamed plastics. The main volume is occupied by gas, low density contributes to poor thermal conductivity. Foam plastics are not toxic materials and are used to insulate various categories of buildings.

Foam thermal insulation Park is available in several types:

- polyurethane;

- polyvinyl chloride;

- phenol-formaldehyde;

- urea-formaldehyde.

Polyfoam is destroyed by the action of dichloroethane, benzene, acetone or vapors of these substances.

Linen insulation

Linen is used to protect indoor and outdoor structures. Withstands high temperatures, therefore it is used in saunas, baths. The fibers of the natural insulator are bound by bicomponent polyester components, the mass does not contain formaldehyde and resins.

The material conducts steam and absorbs moisture, but quickly releases it into the environment. No additional waterproofing layer is required during installation.

PPZh plates

Stone wool slabs do not absorb moisture and do not burn

Plates additionally perform the function of sound insulation, in addition to insulation. For binding the fibers in the mass, synthetic water-soluble resins are used in accordance with technical and sanitary standards.

Varieties of PPZh slabs:

- Parok mineral wool on a synthetic binder;

- slabs with and without hydrophobizing components;

- lined with finishing material or without.

The material is used for thermal insulation and in the construction of three-layer panels in residential and industrial buildings with a surface temperature in the range of +60 - + 400 ° C.

Foamed polyethylene mats

Foamed polyethylene mats are used in underfloor heating systems

Polyethylene foam is foamed with carbon dioxide during the production process. An elastic elastic mass with a closed-cell structure is obtained. Supplied on sale in the form of sheets, rolls, bundles and shells.

Depending on the method of release, there are:

- cross-linked (PPE) foams;

- uncrosslinked (NPE) foams.

Cross-linked polyethylene heaters are distinguished by multi-stage heating during production, the output parameters depend on the ratio of functional additives and polyethylene.

Cylinders Pagos Pro Lock 100

Ragos pro lock 100 cylinders, made of basalt wool, are used for pipe insulation on an industrial scale. The product has increased rigidity, which makes it possible not to use additional supports and unloading elements, and to carry out installation much faster.

Specifications:

- density: 100 kg per m3;

- temperature regime: up to 640 С;

- thickness: 80-160 mm;

- length: 1000 mm;

- fire classification: NG group.

Testimonials

A large number of positive reviews about Park products indicate its high quality and demand. Here are just a few of them:

“A year ago I decided to find a heater for arranging a country house. After studying the information on the Internet, I decided to buy ragos extra plates. The material is packed compactly, which turned out to be very handy during transportation. According to the instructions, we managed to do everything on our own, without resorting to the help of third-party specialists. Waste and marriage were not. Plates deserve a solid top five: inexpensive, but high quality and warm. " Mikhail from Moscow

“I have an apartment on the top floor. The roof recently leaked, which created problems. I decided not to contact the housing office, but to eliminate the leak on my own. For the floors I chose ragos mineral wool, and on the roof I used rob 60. The fun was not cheap in terms of finances, but it paid off 100%. Already two winters no worries, moreover, the apartment has become noticeably warmer. " Nikolay from St. Petersburg

“Friends have long advised to take park insulation during construction. They said that he is very good, and if there is money, it is better not to save. In the store I selected the best option for insulating facades. I was satisfied, I recommend it to everyone. " Alexander from Bryansk

“During the arrangement of the restaurant's ventilation, ragos cylinders were used as soundproofing of pipes. The result paid off. Nobody complains about the noise. I advise. " Ivan, Yekaterinburg

Advantages and disadvantages

The material is easily processed with a simple cutting tool and mounted in the desired position. The insulation adheres tightly to the surface and does not swell when exposed to heat, frost and other unfavorable factors.

In the surrounding space, under normal conditions, no harmful gases or dust are detected. After installation, the Park Extra insulation does not shrink. For transportation, the material is compressed 2 times, and at the construction site it straightens in a short time.

The disadvantages include the ability to release hazardous substances at temperatures above + 200 ° C.

About Ragos

Ragos has been a leading European manufacturer of insulation and thermal insulation products for over 80 years. The park has opened 13 representative offices in Europe with headquarters in Finland. Ragos insulation and thermal insulation is sold in more than 40 countries, and production plants of the company operate in five countries.

The company enjoys a good reputation among builders, contractors, architects and industrial product dealers.

The products of this brand are easily recognizable and include fire-resistant insulation materials, sound and thermal insulation of roofs, walls, floors and basements, as well as technical protection of ships, oil platforms and NUAS systems.

Finnish insulation based on basalt wool of the park is widely used in various areas of construction and installation work. It is a universal thermal barrier for walls and plaster facades, wind and moisture protection insulation, also an excellent noise suppressor and fire protection stop. The material is produced in various shapes from mats and parka slabs to cylinders. Products of this brand are used both in construction and industrial insulation, as well as in shipping and oil refining. Due to its high quality and ergonomics, the material is easily transported, fixed and retains its technical properties for many years.

Product range and scope

Paroc insulations are widely used to insulate apartments, country houses, multi-storey residential structures, industrial buildings, etc. Thanks to the constantly expanding range of products, new products have appeared that are used in shipbuilding, utilities and industrial enterprises. The choice of thermal insulation materials is presented by products for:

- wind protection, sound insulation, fire protection;

- flat roofs, walls, floors;

- baths and saunas;

- siding, plaster facades;

- sandwich panels, foundations and floors on the ground;

- fireplaces;

- reinforced concrete structures;

- technical elbows and segments.

Insulation Park is in great demand among consumers due to its good thermal insulation

According to their purpose, building materials for insulating various surfaces are divided into construction, technical and marine. They can be in the form of lamellas, mats, slabs, rolls, etc. Regardless of the purpose of insulation, it is characterized by energy efficiency, innovative solutions and compositions, environmental friendliness, consistently high quality and durability.