Basic features and properties:

- Long service life. According to statements - up to 80 years. You understand that, given that the material is only a few years old, it has not yet been possible to test it in practice. But, as you know, mineral wool lives for a very long time.

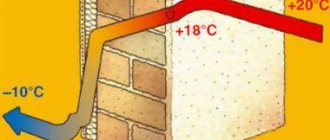

- Low thermal conductivity. It is no more than 0.034 W / (m ° C) at a temperature of plus 10 degrees.

- Compressive elasticity. The compression ratio is no more than 10%.

- Increased moisture resistance. A minimum layer of waterproofing is required.

- Soundproofing. Noise penetration is reduced by 3-4 times.

- Water vapor permeability. The material allows for a breathable facade.

So, it's not hard to see that there are enough pluses. By the way, read about the cons at the end of the article. But, in fact, there are different types of this insulation, more precisely THREE. In addition to the most common insulation Technoblock Standard, there are two more:

- Optima;

- Prof.

TechnoFAS

Price

RUB / UP

1080

from

TECHNOFAS plates - are intended for use in civil and industrial construction as heat and sound insulation in external wall insulation systems with a protective and decorative layer of thin-layer plaster. The peculiarity of TECHNOFAS boards is their high peel strength.

| Indicator name | Unit measurements | TECHNOFAS | Test Method | |

| Tensile strength for separation of layers (laminar strength), not less | kPa | 15 | GOST R EN 1607 | |

| Flammability | power | NG | GOST 30244 | |

| Thermal conductivity | λ25 | W / m S | 0,038* | GOST 7076 |

| λ A | 0,040* | GOST 7076 SP 23-101-2004 | ||

| λ B | 0,042* | GOST 7076 SP 23-101-2004 | ||

| Compressive strength at 10% deformation, not less | kPa | 45 | GOST R EN 826 | |

| Water vapor permeability, not less | Mg / (m h Pa) | 0,3 | GOST 25898 | |

| Moisture by mass, no more | % | 0,5 | GOST 17177 | |

| Water absorption by volume, no more | % | 1,0 | GOST R EN 1609 | |

| Organic matter content, no more | % | 4,5 | GOST R 52908-2008 (EN 13820-2003) | |

| Density | kg / m3 | 131-159 | GOST R EN 1602 | |

Price

RUB / UP

1240

from

Basalt insulation TECHNOFAS EFFECT Is a rigid, non-combustible, hydrophobized mineral wool slab made of mineral wool (mineral wool) based on rocks of the basalt group for insulation and sound insulation of plaster facades.

Characteristics of TECHNOFAS EFFECT insulation:

- Density, kg / m3 - 131-135

- Thermal conductivity at 10 ° C, no more than W / (m ° C) - 0.037

- Thermal conductivity at 25 ° C, no more than W / (m ° C) - 0.038

- Thermal conductivity λА, no more than W / (m ° C) - 0.040

- Thermal conductivity λB, no more than W / (m ° C) - 0.042

- Compressive strength at 10% deformation, kPa not less - 45

- Tensile strength, kPa not less - 15

- Water vapor permeability, not less than Mg / (mchPa) - 0.3

- Flammability - NG

Price

RUB / UP

1080

from

Insulation boards Technofas Cottage used for external insulation of walls up to 10 meters high. The material is created from basalt mineral wool with a low phenolic binder, due to which the optimal technical characteristics and price per m3 are achieved. Plates are resistant to temperature influences, humidity, and other external factors. They are unpretentious in operation and installation.

| Indicator name | Unit measurements | TECHNOFAS COTTAGE |

| Tensile strength for separation of layers (laminar strength), not less | kPa | 10 |

| Flammability | power | NG |

| Thermal conductivity | λ25 | 0,037 |

| λ A | 0,039 | |

| λ B | 0,041 | |

| Water vapor permeability, not less | mg / (m h Pa) | 0,3 |

| Moisture by mass, no more | % | 0,5 |

| Water absorption by volume, no more | % | 1,5 |

| Organic matter content, no more | % | 4,5 |

| Density | kg / m3 | 95-115 |

| Compressive strength at 10% deformation, not less | kPa | 20 |

Price

RUB / m3

5064

from

Classic "Technoblock"

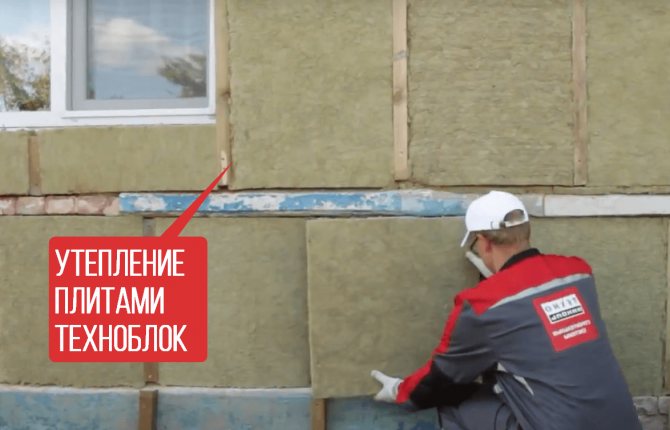

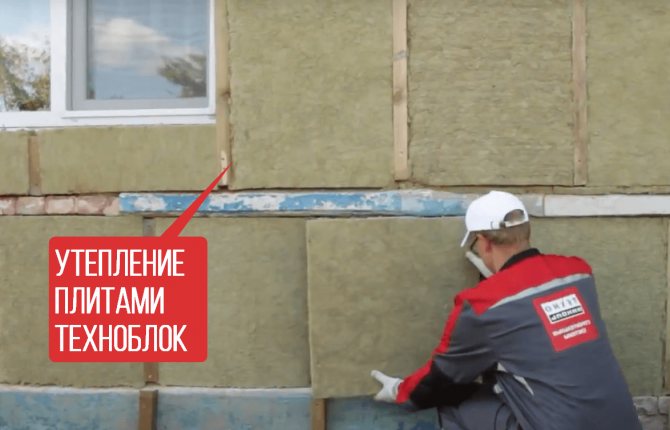

Insulation TechnoNikol Technoblok Standard has a density of 40 to 50 kg per cubic meter. This type of thermal insulation does not withstand high loads, and therefore it is used in frame structures. For example, in decorating a house for siding. The video below shows how the company's specialist insulates the wall under the crate.

The thickness of the slabs can be from 50 to 200 mm. For central Russia, the manufacturer recommends plates of 100 mm.Considering the cost, insulation of 50 mm is most often used, laying it in two layers.

Below in the table you can see all existing types of packaging and material parameters.

In the photo below, a specialist is laying Technoblok slabs on the front wall.

After installation, the thermal insulation must be covered with a vapor-waterproofing film.

Of course, the material can be used not only for insulating external walls, but also, for example, in structures:

- Interior partitions;

- When insulating the attic;

- Balcony floor.

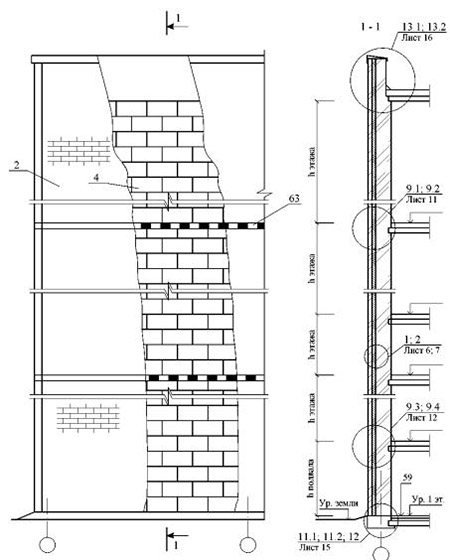

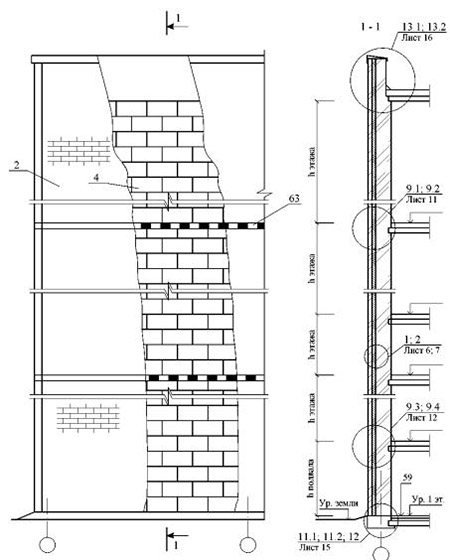

THERMAL INSULATING MATERIALS PRODUCED BY TECHNONICOL FOR DEVICE OF BUILDING STRUCTURES

WALLS, COVERINGS, ROOFS, FLOORS, PARTITIONS, FRONTING THE MANSARD STRUCTURES AND ATTIC COVERINGS WITH THE APPLICATION OF TECHNO MINERAL WOOD PLATES AND TECHNONICOL EXTRUSION FOAM POLYSTYRENE PLATES XPS TECHNONICOL. PART 4: DESIGN SOLUTIONS walls with a protective wall of brick masonry THE EXAMPLE OF APPLICATION insulation boards made of mineral wool TEHNOBLOK STANDARD TEHNOBLOK OPTIMA, TEHNOBLOK profiles or of extruded polystyrene foam CARBON XPS TECHNONICOL PRODUCTION AND DESIGN SOLUTIONS FRAME WALL OF MATERIAL SERIES TECHNOLIGHT.

PART 4. CONSTRUCTION SOLUTIONS FOR WALLS WITH A PROTECTIVE WALL FROM BRICK MASK ON THE EXAMPLE OF APPLICATION OF HEAT INSULATION BOARDS FROM MINERAL WOOL TECHNOBLOCK STANDARD, TECHNOBLOCK OPTIMA, TECHNOBLOC PROF OR XTROVODONO PREVODY EXTRUSION CARPOON.

PART 4.1. WALLS WITH A PROTECTIVE WALL FROM BRICK

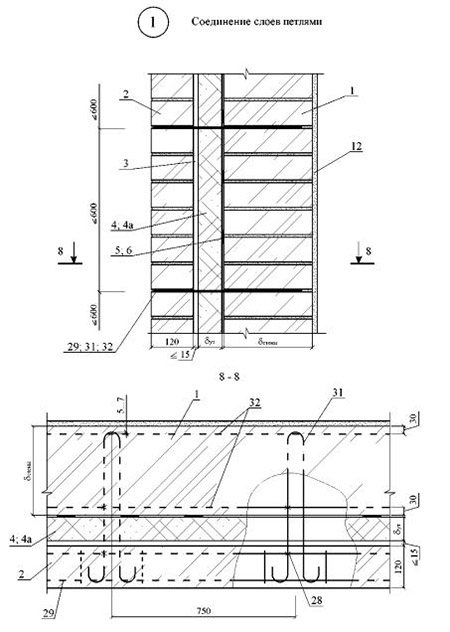

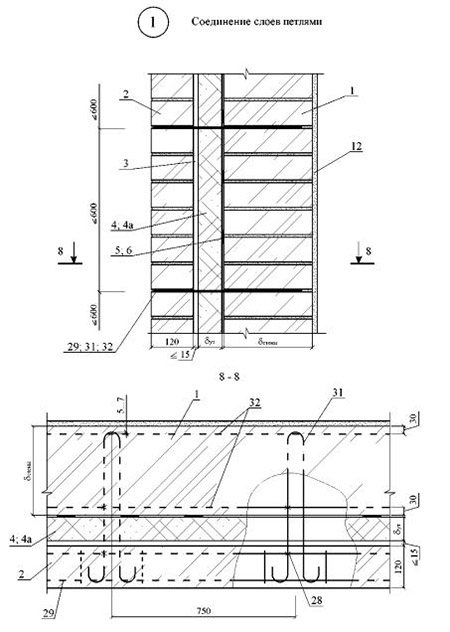

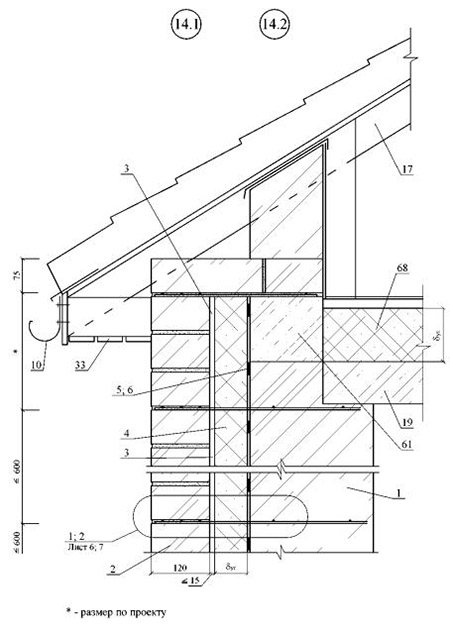

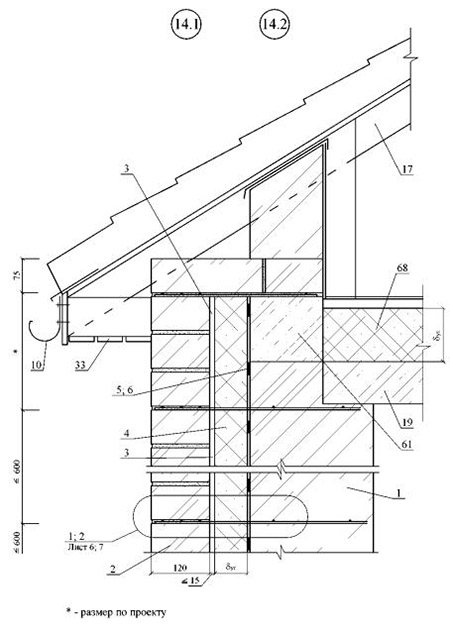

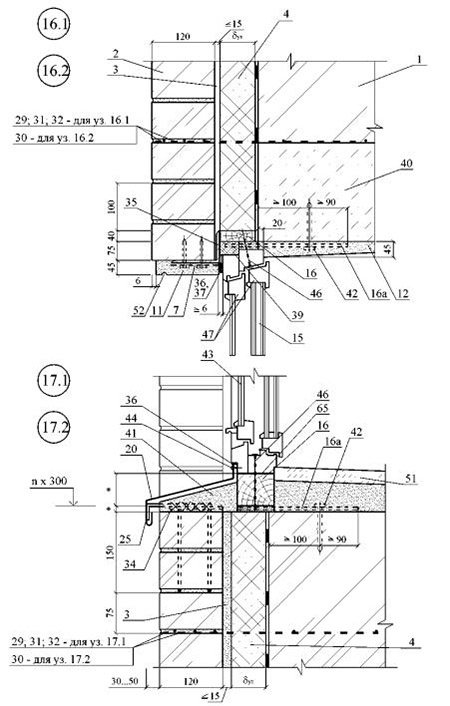

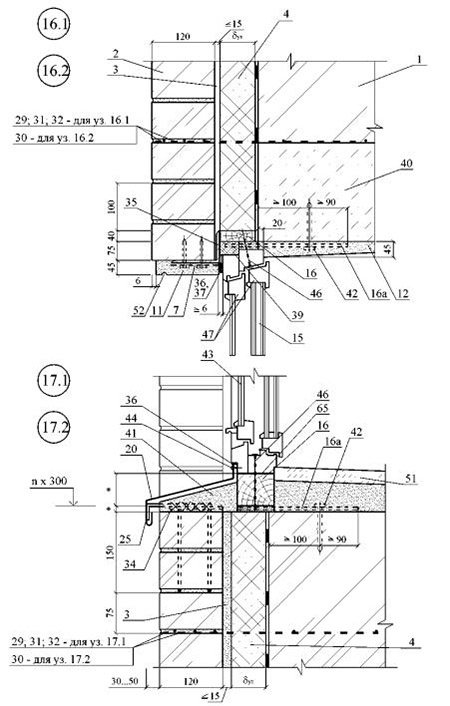

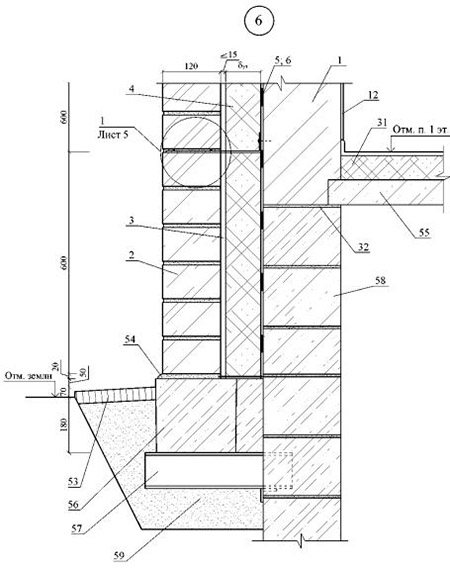

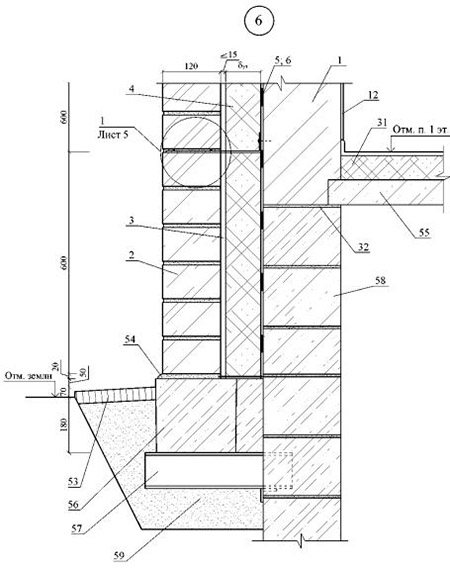

4.1.1. For walls with brick cladding with a thickness of 120 mm, plates of the TECHNOBLOK STANDARD, TECHNOBLOK OPTIMA, TECHNOBLOK PROF brands or from CARBON XPS extruded polystyrene foam are used.

4.1.2. When installing a protective brick wall, brick or ceramic facing or selected standard stones, preferably semi-dry pressing, as well as silicate bricks can be used. When facing with silicate bricks, the base, belts, parapets and cornice are made of ceramic bricks.

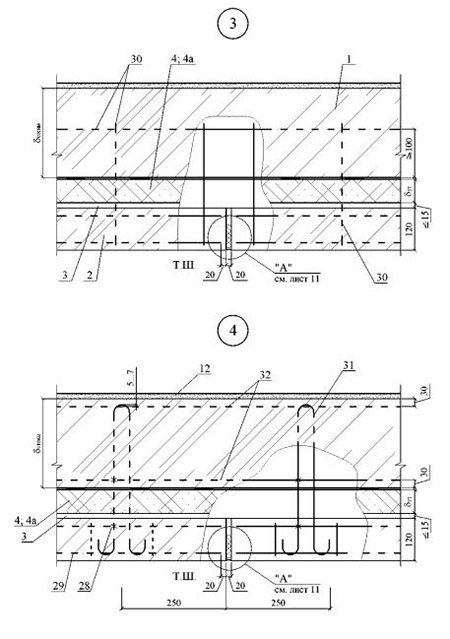

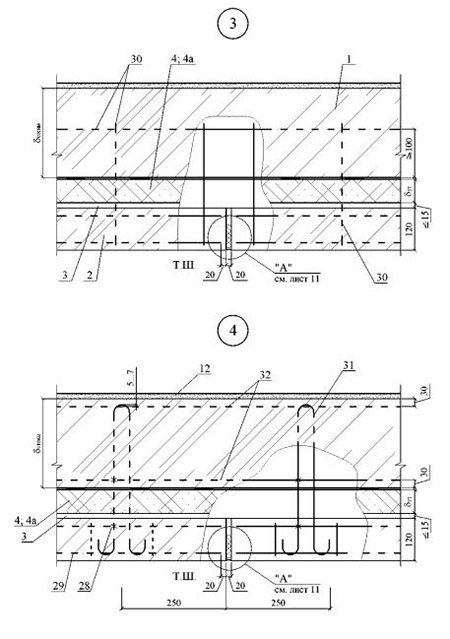

In new construction, a brick protective wall can be extended to the entire height of the building. At the same time, it can be self-supporting up to a height of 6-7 m, and then hinged with support on belts (belt supporting beam) protruding from the load-bearing wall every 2 floors (6-7 m) along the height of the building.

In this case, the load-bearing part of the wall and the chord beam are attached to the ceilings with anchors with a cross section of at least 0.5 cm2. The step of the anchors should be no more than 6 m.

During reconstruction, a brick protective wall is required in the form of a basement with a height of at least 2.5 m from the planning mark. For architectural reasons, it can be self-supporting and of greater height.

4.1.3. With a protective brick wall, the masonry is carried out with the obligatory filling of horizontal and vertical joints with mortar and joining from the front side.

The spacing of the expansion joints in the brick cladding is adopted as for non-heated buildings.

4.1.4. When facing with brickwork in new construction, the latter is reinforced with the load-bearing part of the wall with welded reinforcing meshes located at a height of 600 mm; the area of transverse rods (ties) must be at least 0.4 cm2 / m2.

During the reconstruction, the brick cladding is connected to the existing masonry using brackets fixed to the dowels.

4.1.5. Parapets, belts, window sills, etc. must have reliable galvanized steel drains, which ensure the removal of atmospheric moisture and exclude the possibility of its escape directly along the wall.

4.1.6. All exposed surfaces of steel elements facing the facade and anchors installed in masonry must be protected from corrosion by metallization with a layer of 120 microns thick or paint and varnish.

4.1.7. It is recommended to finish the plinth from materials of increased strength and decorativeness that can be cleaned and washed, for example, from facing bricks, slabs of natural or artificial stone, ceramic and glass tiles, etc.

The upper edge of this protective and decorative finish must be at least 2.5 m from the level of the planning.

Wall corners, portals of doors, arches, gates, window frames or separate sections of blank walls can have a similar finish.

PART 4.2. FRAME WALLS

4.2.1.The frame structures of the walls can be made by layer-by-layer assembly or from three-layer panels of an enlarged assembly.

4.2.2. In order to reduce the labor intensity of work, it is advisable to assemble panels with their subsequent installation at the construction site.

4.2.3. The panels have an outer frame made of steel channels, to which a profiled sheet of the inner cladding and an inner frame of the panel are fixed on rivets, and to it the profiled sheet of the outer cladding.

4.2.4. Thermal insulation is made of mineral wool boards of the brand "TECHNOLIGHT EXTRA", "TECHNOLIGHT OPTIMA", "TECHNOLIGHT PROF", "TECHNOBLOK STANDARD", "TECHNOBLOK OPTIMA", "TECHNOBLOK PROF" on the inside, if necessary, a layer of vapor barrier.

4.2.5. Fastening of pre-assembled panels to the supporting structures of the steel frame is carried out on high-strength bolts.

In order to read the entire instruction, follow the links below: Part 1 Part 2 Part 3 Part 4 Part 5 Part 6 Part 7 Part 8 Part 9 Part 10 Part 11 You can purchase all the required materials for organizing roofing carpet and repairing roofs by calling us, or by making an application in the online store on our website. You can also pick up the material from our warehouse. Helpful !!! In conclusion to this material, we recommend watching on our YOUTUBE channel a series of detailed videos on the organization of installation work on the installation of facades using thermal insulation mineral wool boards TECHNOBLOK STANDARD, TECHNOBLOK OPTIMA, TECHNOBLOK PROF facade components, installation equipment and other building insulation materials produced by TechnoNICOL Corporation ... Organization of installation work for the installation of mineral wool boards TECHNOBLOK STANDARD, TECHNOBLOK OPTIMA, TECHNOBLOK PROF: www.youtube.com/TK CentroStroy / Thermal insulation TechnoNICOL TECHNOBLOCK STANDARD

Professional insulation

For the most severe operating conditions, Technoblok Prof.

The density of the insulation is 60–70 kg per cubic meter. And the compression ratio is only 5%. And yet, this material is a semi-rigid mineral wool slab. This must be taken into account when choosing this type of insulation.

Technoblok Prof is a semi-rigid mineral wool slab

Prof can be from 50 to 150 mm thick. All types of slabs are shown in the table.

So, we saw that the main differences between the three types of this material are in density, that is, rigidity.

Below is a comparative table of characteristics

| Feature type | |||

| TECHNOBLOCK STANDARD | TECHNOBLOCK OPTIMA | TECHNOBLOCK PROF | |

| Density, kg / m3 | 45 ± 5 | 50-60 | 60-70 |

| Compression% is not large | 10 | 8 | 5 |

| Thermal conductivity at 10 ° С, W / (m. ° C) not more | 0.034 | 0.034 | 0.033 |

| Thermal conductivity at 25 ° С, W / (m. ° C) not more | 0.036 | 0.036 | 0.035 |

| Thermal conductivity under operating conditions A, W / (m. ° C) not more | 0.043 | 0.041 | 0.04 |

| Steam permeability, mg / (m.h.Pa) not less | 0.3 | 0.3 | 0.3 |

| Moisture at mass% not more | 0.5 | 0.5 | 0.5 |

| Water absorption at a volume% not more | 1.5 | 1.5 | 1.5 |

| Organic matter content% not more | 2.5 | 2.5 | 2.5 |

| Flammability | NG | NG | NG |

Does this insulation have any disadvantages? Alas, where without them. Let's highlight the main two:

- Relatively high cost;

- The need for a waterproofing layer, albeit a small one.

TECHNOBLOCK

Technoblock is a hydrophobic heat or sound insulation plate that is not subject to fire. Such slabs are created using mineral wool, which is based on rocks of the basalt category on a low phenolic binder.

Features of the use of mineral wool boards

Using Technoblock Standard slabs, it is possible to reliably fill the cavities that have arisen during the construction of various structuresIn addition, this material is used as an interlayer in the organization of sound and heat insulation of buildings.

When mounting on surfaces located vertically or at a slight slope, the mentioned type of material is point-fixed using special parts. In cases of horizontal installation, the use of such fasteners is optional.

Technoblok Standard it is mounted quite easily and does not require the use of specialized types of construction tools. In addition, when using these plates, there is no need to gain experience and skills, but it is still necessary to adhere to the safety rules that are provided when working with the described material. We are talking about personal protective equipment.

Technoblok Standard is already completely ready for use and additional fire-prevention treatment of plates is not required, since these products are non-combustible. Another advantage of such plates is that during operation there is no need to carry out maintenance and repair work, due to the fact that they are made from high-quality mineral raw materials. Insulation Technoblok Standard will not lose its quality characteristics after years. In addition, it does not create a significant load on the bearing elements of those objects in relation to which it was used.

Dimensions:

Width is - 500mm, 600mm; Slab length - 1000 mm, 1200 mm; The thickness ranges from 40 to 200 mm (10 mm step).

Areas of use

It is recommended to use Technoblok Standard slabs for heat and sound insulation of various layered masonry, frame walls (external walls are no exception) with any kind of finish (including siding). In addition, such material can be used as an internal primary thermal insulation layer in systems with an air gap, in cases where a two-layer insulation scheme is provided.

Material Characteristics Table

| Parameter name | TECHNOBLOCK STANDARD |

| Compressibility,% no more | 8 |

| Thermal conductivity at 10 ° С, W / (m. ° C) no more | 0,035* |

| Thermal conductivity at 25 ° С, W / (m. ° C) no more | 0,037* |

| Thermal conductivity under operating conditions A, W / (m. ° C) no more | 0,039* |

| Thermal conductivity under operating conditions B, W / (m. ° C) no more | 0,040* |

| Water vapor permeability, mg / (m.h.Pa) not less | 0,3 |

| Moisture by mass,% no more | 0,5 |

| Water absorption by volume,% no more | 1,5 |

| Organic matter content,% no more | 2,5 |

| Flammability, degree | NG |

| Average density, kg / m3 | 40-50 |

Storage features

Slabs Technoblok Standard must be stored in a covered warehouse. It is permissible to store this material under a canopy, which can provide them with protection from atmospheric precipitation. During storage, the boards should be stacked on pads or mats. You can also store products in containers. It should be noted that the height of the stack during storage should not reach a mark of more than 2 m.

Characteristics of Technoblok Standard plates

This type of material is endowed with such properties as:

- high heat-saving ability;

- stability of shape and volume;

- resistance to the influence of high temperature conditions;

- low level of moisture absorption;

- excellent sound absorbing ability;

- neutrality when used with metallic materials, as well as concrete;

- a high level of resistance to the negative influence of microorganisms and various rodents;

- ease of installation, as well as ease of preparatory work (cutting, processing). Plates are easily cut with a saw or knife.

Packaging

The material Technoblok Standard is packaged in packs, in accordance with the technical and regulatory documentation, in a heat-shrinkable polyethylene film.

Ignition resistance

Plates of the mentioned type are non-combustible products.Temperature indicators of use are in the range from - 60 to + 400 degrees Celsius. Melting of the fibers of the material is possible at temperatures of more than 1000 degrees Celsius.

Subtleties of using mineral wool material Technoblok Standard

The Technoblock can be used if necessary to fill “voids” in building structures. It can also play the role of a layer in the soundproofing systems of various premises. To fasten the material to surfaces, it is necessary to use special fasteners, and the procedure itself should be performed pointwise, but if the plate is to be fastened to the horizontal plane, this type of fastener is not necessary to apply. Our company offers the above material at a competitive cost. Only high quality products that meet all standards will be provided to everyone who contacts our company.

Save your money, time and nerves by cooperating with us, and you will be convinced that no one will provide you with better offers.

What buyers say

This section has collected several reviews of those who have already used the material in their home or insulated them to order. You may find their opinions helpful.

Density of 45 kg per cubic meter differs from 35 Rockwool LIGHT BATTS. The cost of both is kept in a similar range Alexey

I enjoyed working with the material. Used in frame, and weaving and fifty. Keep in mind that it compresses slightly worse than the Optima, its density is 35. And one more thing: if the spaces between the racks are less than 580 millimeters, you may have to cut them. Yuri

A standard Technoblock should have a density of 40–50 kg per cube, and most often 40–42, with a minimum of walking. I personally have not seen quality passports with greater density. Well, at least I'm talking about the Yurginsky plant, I don't know about the others. Plus, keep in mind that they add slag, unlike Rockwool, so that as a result, the slabs look darker and the melt pellets are visible inside. And this is not only an external joke, but also improves thermal conductivity. So, with similar prices, I would still take Rockwool. Sergey

So, we have highlighted the main characteristics, reviews and descriptions of TechnoNIKOL Technoblock Standard and its "brothers". Now you have all the information you need to make a decision about the type of insulation.

"Technoblock" and its types

"Technoblok" is a mineral wool slab containing basalt fibers. It is used for thermal insulation of buildings when installing layered masonry or for decorative finishing of facades. Thanks to special additives "Technoblok" has better characteristics in comparison with ordinary mineral wool. Its advantages are as follows:

- Does not absorb moisture.

- Does not burn.

- It has a high density.

- Differs in increased durability.

- Allows air to pass through.

- Has a long service life.

- Easy to mount.

- It is a good heat and sound insulator.

- Not afraid of rodents and insects.

Of the shortcomings, only a relatively high cost can be distinguished. Depending on the density, three types of material are distinguished:

- "Technoblok Standard". The technical characteristics of this species depend on its density, which is 40-50 kg / m3. This indicator allows the material to shrink up to 10% of its volume under the influence of load.

- Optima. Has a density of 60 kg / m3. Compresses under load by only 8%. It has the ability to completely restore its shape.

- "Technoblok Prof". It shrinks by only 5% of the volume. Its density is 65-70 kg / m3.