Greenhouse heating options

Several heating methods are currently used in agriculture. All of them can be divided into natural and technical. Solar and biological options are considered natural. Technological heating methods are as follows:

- gas;

- water;

- infrared;

- using electrical appliances;

- cable.

With solar heating, no special costs are required. All you need is a roof made of transparent material (glass, plastic, polyethylene or others). The disadvantages of this method are that it will be impossible to adjust the temperature. In some regions, there is not enough sun.

Biological heating is the placement of organic substances under the ground, which, when decomposed, generate heat. Manure is most often used. It is a very environmentally friendly and simple method, but it has low efficiency. Such heating is almost always insufficient; it is suitable for warm weather or in combination with other methods.

Technical Methods

Their difference is that electricity or technical fuel is used for heating. In northern latitudes, you cannot do without them.

Gas heating works by burning inorganic fuels. In this case, oxygen also burns out, and carbon dioxide is released. If the oxygen produced by the plants is sufficient, this will not be a problem. This is an economical method, but quite dangerous. The territory must be gasified. During installation, you need to carefully monitor the observance of safety measures.

Water heating is economical and simple, but requires fuel. With this method, it is not always easy to maintain the required temperature, which is critical for some plants.

Infrared heating is very economical and heats the soil. It is carried out using special lamps, and they must be of high quality, because inexpensive devices can even explode, which makes it unsafe for people to work in greenhouses.

Heating with electrical appliances involves the use of heat guns. Their disadvantage is their high energy consumption and the fact that they significantly reduce air humidity. But this is a very quick way to set the right temperature in the greenhouse.

Heating with an electric cable is a favorable price and high reliability. The option is easy to install and economical. Since the wire is laid underground, not only the air is heated, but also the soil. It is required to insulate the greenhouse to prevent heat loss. With proper organization, almost any temperature can be maintained, even in winter.

Electric heat generators for industrial and farm greenhouses

Electric heat generators are considered one of the best winter heating methods for industrial or farm greenhouses. This is due to the high degree of performance and the affordable cost of electricity. The most commonly installed:

- convectors;

- heaters;

- cable system;

- water heating;

- heat pumps;

- infrared generators.

When drawing up a project, the features of the structure, its location, as well as the crops grown must be taken into account.

Heating methods for agrotechnical structures

Heating is equipped in greenhouses for year-round use or for early spring planting of crops and flowers.

The following types are considered the most effective heating methods:

- stove heating with a water and air circuit;

- heated line from an electric, gas or solid fuel boiler;

- the use of gas-type heat guns;

- convector or infrared circuits with mains supply.

Heating with gas cannons is considered effective. The air heats up quickly, the fuel consumption is low, the unit itself is placed compactly and, with the right choice, is absolutely safe to use. If the greenhouse is equipped with electric heaters, experts recommend using infrared devices. Infrared rays heat the soil and plants without overdrying the air.

To save heating costs in winter - solid fuel heat generators are an advantageous solution. With their help, it is possible to heat industrial and farm greenhouses with an area of up to 1000 sq. M. They are also used for summer cottages, designing the system in such a way that heating occurs in the living room and the greenhouse installation at the same time. When installing such heat generators, it is important to observe all the necessary safety rules.

Fuel is used depending on the type of heat generator; the best option is considered to be universal models that are suitable for logs, pellets, coal and others.

Our company will help in the design and installation of the best heating method in winter for an industrial, farm or other facility.

When deciding how to heat the greenhouse, you need to remember that most of the thermal energy enters this structure in a natural way - from the sun's rays passing through polyethylene, polycarbonate or glass.

Thus, for example, heating of greenhouses (small in area) is organized. Only a small heater can be installed there, which is turned on on particularly cold or cloudy days.

Most often, solar energy is sufficient to heat a greenhouse.

However, large indoor plants for growing plants necessarily require additional heating. Let us consider in more detail how heating in a greenhouse can be arranged with our own hands.

This type of energy carrier is quite widespread, efficient, but not always economical. To avoid excessive waste, you need to choose the right heat source.

There are the following varieties:

- Radiators. A fairly effective way to maintain the air temperature required for plants. Great for small greenhouses, when only short-term heating is needed (otherwise this option will not be economical).

If it is planned to grow crops not only in early spring, but also in winter, it is advisable to purchase fan heaters complete with radiators. They allow you to quickly raise the temperature and prevent condensation from forming on the walls of the structure.

In the photo - electric heating radiators installed in the greenhouse

Choose modern models of electric radiators and fan heaters, using which you can accurately control the amount of heat produced. In addition, their special shaped heat exchangers heat up the air more evenly and, thanks to convection, organize its circulation throughout the greenhouse space.

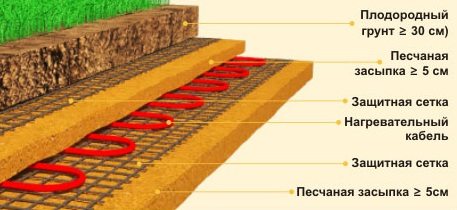

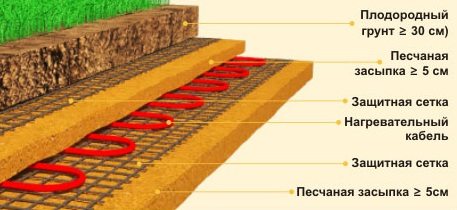

- Cable heating. This method is similar to the well-known "warm floor" system, which is installed in dwellings. For its arrangement, special electrical cables are used.

Their installation is carried out as follows:

- part of the fertile soil layer is removed;

- at the bottom of the resulting pit, a heat-insulating material is laid, which will prevent unproductive heat consumption and protect the electrical cable from mechanical damage;

- after that, a layer of fine-grained sand is poured;

- a cable is laid on the sand;

- from above, backfilling of previously removed soil is performed.

Layout of cables for heating agricultural buildings in covered ground

The advantages of such a solution are obvious:

- economical energy consumption;

- the ability to accurately regulate the temperature thanks to thermostats;

- uniform distribution of heat energy over the entire area of the greenhouse;

- small time and money costs for equipment installation.

- Infrared emitters. This is one of the newer heating methods that is often used in greenhouses covered with polycarbonate sheets.

The arrangement of such a system is as simple as possible: it is enough to buy and install a certain number of heating devices in the right places.

- There are many advantages to this method of heating air in a greenhouse:

- improved germination of seeds sown in the ground;

- the ability to organize zones of intense and weaker heating within the same room (for example, separately for seedlings and already planted plants);

- long service life of the purchased wires;

- economical consumption of electricity.

Infrared emitter for heating plants

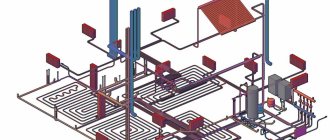

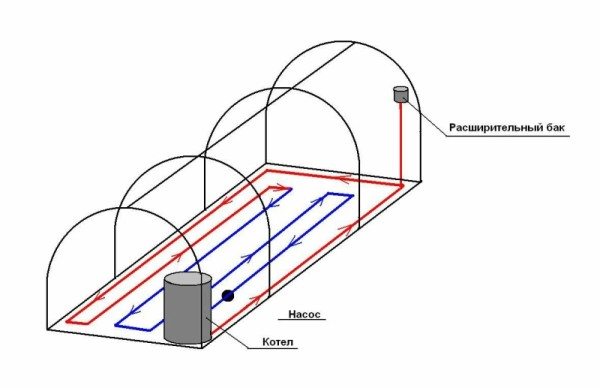

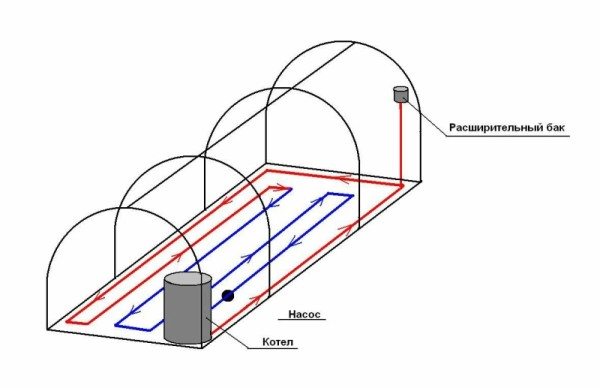

- Heating with liquid heat carrier. Do-it-yourself water heating of a greenhouse is quite difficult to assemble, but its efficiency is worth the effort. The liquid can be heated both with the help of a special boiler (for example, induction), and in a boiler. It is only important to correctly arrange the heating batteries and organize circulation, for which a water pump mounted on the return pipe is perfect.

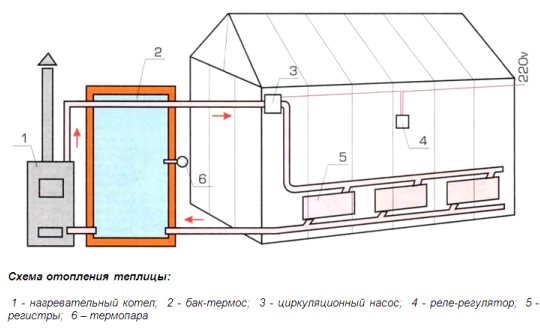

Greenhouse water heating arrangement scheme

This type of energy carrier is the most economical. But it requires a connection to the main gas network, and this procedure has many obstacles that not everyone can go through. This is, first of all, about obtaining all the necessary permits for the installation of gas equipment.

We suggest that you familiarize yourself with the black horse what color

Bureaucratic red tape can be avoided by using liquefied gas. However, with its help it is impossible to heat the greenhouse throughout the year, since it requires too frequent replacement of cylinders (or the installation of a personal gas holder).

To heat the greenhouse, a convector operating on liquefied gas can be used

Remember that the use of gas equipment involves the arrangement of supply and exhaust ventilation, which provides fresh air access to the agrotechnical structure and the removal of combustion products that can be dangerous.

Greenhouse stoves using wood, fuel pallets, pellets or coal are very common for heating individual greenhouses as well as large farm buildings. Such systems are especially popular in suburban areas where people do not lack firewood.

Wood fired boiler used to heat the greenhouse

Solid fuel boilers do not require permits before installation and are easier to install. They differ in a slightly lower efficiency than the previously considered devices, as well as in the complexity of control. Agree, it is difficult to regulate the temperature in a greenhouse that is heated with wood.

Also, such ovens require constant human attention. On dark, cold winter nights, you will have to periodically throw firewood into the furnace, otherwise the death of such an expected harvest cannot be avoided.

The advantage of the described method is the possibility of self-assembly of heating equipment. With some skills in locksmith or construction work, you can design a stove for heating yourself.

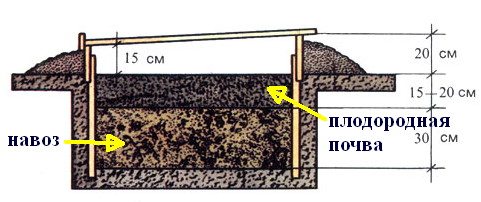

From the school course in biology, everyone knows that the waste products of animals (as well as humans), as well as the remains of wood and other plants, generate heat when rotting.Moreover, this process, which is caused by the vital activity of bacteria and other microorganisms feeding on decomposing organic matter, continues for a fairly long period of time.

Manure is an environmentally friendly fuel for a greenhouse

Therefore, it is advisable to heat a small greenhouse in this way. One organic bookmark is enough for 3-4 months of heating, which is quite enough to help the plants survive the frost.

It is necessary to bookmark "fossil fuel" as follows:

- Manure, peat or organic matter that has accumulated in your compost heap must be thoroughly dried, formed into briquettes and folded for storage. 7 days before laying in a greenhouse or greenhouse, humus must be re-moistened and loosened.

The appearance of steam will indicate the beginning of the process of vital activity of microorganisms. This will serve as a signal to put "fuel" in the greenhouse.

- The thickness of the layer to be laid depends on the area of the greenhouse and the number of days left before the onset of stable heat. As a rule, 30-60 cm is enough. If you add chopped straw to the manure, the heating duration can be extended, but the temperature of the heated soil itself will decrease.

- From above, soil is poured onto the manure, which is necessary for the growth of plants.

Scheme of laying manure for heating the greenhouse

Features of heating networks

Starting to consider the question of which heating is better for a greenhouse, it is necessary to dwell in more detail on the features of the climatic equipment that should be used to heat plants.

Heating for greenhouses can be arranged in a variety of ways.

The choice of a particular option depends on the following factors:

- the size of the plant for growing crops;

- the heating system used at home - if, for example, a liquid heat carrier is used in a dwelling, then water heating of greenhouses would be the best choice, otherwise, it is better to prefer other varieties);

- the estimated amount of money that you are willing to spend on heating - in most cases, the most economical is a heating system with a gas boiler, however, heating the greenhouse with wood is also possible (if you have the opportunity to get them cheaper or collect them for free in the nearest forest).

The heating system used is selected based on the area of the agricultural facility

Regardless of the option you choose, heating for the greenhouse should be organized so that the air warms up evenly in all corners of the agrotechnical structure.

There are several common ways to achieve this:

- Heating furnaces for greenhouses operating without batteries and heat carrier... This is not the most efficient scheme, since it does not make it possible to heat the entire required area due to the lack of air circulation. But in this way it is possible to organize stove heating of a greenhouse, which has a much smaller area.

- Greenhouse with thermal fan heating... It heats the air more efficiently and evenly, however, it greatly overdries it, which is very harmful for the grown plants. In addition, the warm air at the top, coming into contact with the glass, will quickly cool down, so the cost of operating this type of heating will be quite high.

- Water heating in a greenhouse... The most acceptable and economical way. You just need to correctly calculate the power of the batteries used and the heating boiler. The plant heating system can be part of the home climate system. In this case, it is preferable to locate the main pipelines underground in order to avoid unproductive losses of thermal energy.

Greenhouse farmers have a completely different approach to heating.

Note! Industrial greenhouses with heating are designed in a completely different way. This is due to the large area of buildings, as well as economic and other factors that do not affect the choice of a climate system for individual use. Moreover, you can hardly realize such heating of greenhouses with your own hands due to the high cost and labor intensity.

So, let's formulate the main characteristics that heating in greenhouses should correspond to:

- constant high humidity is needed, otherwise the plants will dry out and may die;

- in order to avoid unproductive heat loss, it is necessary to organize a gradual heating of the air and its slow circulation in the direction from the floor to the upper part of the structure;

- the heating system used in the greenhouse should prevent the growth of pathogens that harm agricultural crops;

- if you are designing heating for a greenhouse with your own hands, you need to choose a technology that is easily available for implementation (for example, heating a greenhouse with a heat pump is one of the best solutions, however, building such a system without using special equipment is impossible);

Some heating systems require the installation of complex and expensive equipment.

- it is important to think about the economic component, and we are talking about both the initial capital costs and the cost of subsequent operation;

- the last factor is control: it is desirable that homemade heating in the greenhouse does not require constant and vigilant attention from the gardener during work (electronic thermostats connected to temperature sensors can take care of this).

Heating of polycarbonate greenhouses, in winter, industrial systems, video

In recent years, more and more agricultural enterprises are switching to cable heating. This is a simple and affordable method that is easy to install, does not require high qualifications for maintenance, and consumes little electricity.

In difficult situations, when quick control over the microclimate of the greenhouse is required, combined systems are used, the basis for which is heating with a cable.

Several components are required for cable heating:

- heating cable of one of two types (resistive or self-regulating);

- a thermostat with a sensor or a control cabinet (for a complex system);

- electricity.

A resistive cable maintains a constant temperature throughout its entire length. It heats due to the resistance to electric current of the conductor from which the veins are made. It is converted into heat energy. The temperature of the resistive cable can be controlled through a control cabinet or a thermostat using resistors. It is an inexpensive but not always economical choice.

The self-regulating heating cable is equipped with a sensitive matrix. Different sections of such a wire can emit different amounts of heat, if this is due to temperature drops along the path of the cable. It is more expensive to buy, but more economical to use.

Greenhouses that are not equipped with a heating system are not very efficient, even those in which plants are grown in the spring. If you start heating the greenhouse in April, you can extend the harvest season by almost three months, and if you have industrial greenhouses with heating, this will be especially important. During this time, you can collect not one, but several crops.

Greenhouse heating

If you intend to grow more southerly crops, then the greenhouse must be heated during the entire cold period. Even if you build a greenhouse from the insulating material itself, such greenhouses still need additional heating.In severe frosts, insulating materials will not even be able to maintain any positive temperature, so heating of greenhouses is necessary.

The choice of a heating system, as well as what the scheme will be, mainly depends on the size of the greenhouse.

Of course, a lot of things also depend on financial capabilities. It is necessary to heat the greenhouse over the entire area, otherwise some plants may not germinate. You can use not only gas, but also heating greenhouses with wood. In order for the heat to spread to all corners of the greenhouse, a fan is required. To heat the greenhouse, you need to connect electricity to it by equipping the air heating of the greenhouses.

Heating greenhouses with wood

Winter greenhouse heating assumes that hot water pipes can also be a source of heat for heating the air in the greenhouse. Heat from such pipes is consumed quite sparingly and is given off slowly. The size of the pipe diameter determines how fast the water flows.

Convectors are more effective than pipes with warm water. Such devices have a larger reflection area and also reduce the mass of water.

Heating a greenhouse with a convector

Quite often it happens that heating for the greenhouse for the winter is overestimated. The easiest and most convenient method to find out the heat demand is to send a request to the manufacturer. This data can be quite helpful in choosing the most suitable heating system.

Total glass area * temperature difference * heat transfer coefficient = heating power.

If you make heating in a polycarbonate greenhouse and heat the greenhouse where the seedlings are located, then the period for growing crops can be increased by several weeks.

If there is gas heating in the greenhouse, then you need to carefully monitor that the required amount of oxygen is supplied for an open fire.

Polycarbonate greenhouse heating

Quite a few houses have recently been heated with electricity. Electricity will be most efficient for small greenhouses, or for those greenhouses where heat needs to be maintained from time to time. To equip such greenhouses and electric heating systems in the greenhouse in winter, you will not need to buy an air blower, you can also do with an ordinary fan designed specifically for greenhouses. Such a fan will be able to distribute heat in the most efficient and safest way.

Special heating systems, which involve heating greenhouses in winter, can make it possible to regulate the dosage of heat entering the greenhouse.

To begin with, it is best to set the smallest mode, and if the heat is not enough, then you can already open the other valves. The most durable and reliable are finned radiators equipped with a thermostat. Heat is distributed throughout their entire body. On sale you can find radiators of different sizes, from 1.5 to 2.5 m.

We suggest that you familiarize yourself with How to plant a wild apple tree

With electric blowers

You can also heat the greenhouse with electric water heating. Greenhouse water heating is one of the most beneficial for heating greenhouses or greenhouses. The greenhouse water heating device is equipped with a boiler, in which water is heated, and after that warm water is pumped into pipes by means of a circulation pump. These plastic pipes can be laid along the outer walls of the greenhouse or between plants.

Heating greenhouses with infrared heaters is also common - a fairly effective way to heat a greenhouse room.

Infrared heating of greenhouses has a number of advantages - it is an almost natural form of heating. Also, such a system does not dry the air, since not the air itself is directly heated, but the objects in the greenhouse. Polycarbonate infrared greenhouse heating is an economical option.After all, the heating of the soil occurs at a lower temperature, so the volume of heat resources is reduced by 35%.

Using infrared heaters

The most profitable option, including from a financial point of view, would be to connect to an existing heating system. However, it is necessary to find out if the boiler can provide the necessary pressure in order to allow the introduction of greenhouse heating systems. The pipes leading to the greenhouse must be insulated, and this is not cheap.

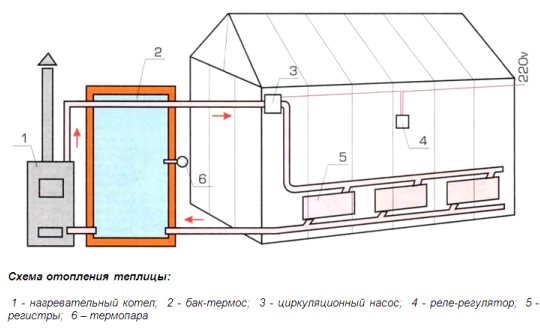

Greenhouse heating scheme

It is also not always advisable to insulate pipes. This can only be done if the greenhouse is at a short distance from the house. It is also necessary to take into account the fact that the greenhouse needs to be heated at night. Newer, more innovative heating systems can help you regulate and reduce the temperature at night.

Gas heating

Gas cylinders are the ideal solution if the greenhouse only needs to be heated for a couple of weeks a year. In order to heat the greenhouse constantly, a gas tank or connection to the general gas network system is required.

Small greenhouses can be heated with catalytic converter burners with thermostatic regulation.

Since the efficiency is the highest, such an option is excluded that carbon monoxide will be emitted. When installing gas heating in the greenhouse, you also need to make sure that the oxygen supply will be at the proper level. In this case, the best option would be to install an exhaust system.

Much of the success depends on good air circulation. The ventilation in the form of louvers is well regulated, but it is not suitable for winter greenhouses and greenhouses. Such greenhouses need to be sealed before the cold sets in. This will require an additional layer of plastic wrap. A video about heating greenhouses can be viewed below.

otoplenie-doma.org

Connection to the heating system

The most profitable option, including from a financial point of view, would be to connect to an existing heating system. However, it is necessary to find out if the boiler can provide the necessary pressure in order to allow the introduction of greenhouse heating systems. The pipes leading to the greenhouse must be insulated, and this is not cheap.

Greenhouse heating scheme

It is also not always advisable to insulate pipes. This can only be done if the greenhouse is at a short distance from the house. It is also necessary to take into account the fact that the greenhouse must be heated at night. Newer, more innovative heating systems can help you regulate and reduce the temperature at night.

Stove heating

Furnaces for greenhouses are brick and metal. Brick structures are considered more practical, since the material itself heats up slowly and just as slowly gives off heat, which means that you can save a lot on fuel consumption. Metal structures quickly warm up, but with a reduced heat capacity of the material, they require constant fuel filling.

Metal stoves

The devices are suitable for seasonal use due to the following features:

- mobility - structures are easy to install in spring and remove in summer;

- light weight does not require foundation arrangement;

- compact dimensions allow you to install the stove in a confined space;

- when choosing the right model, it is easy to connect a circuit with a liquid coolant;

- the price of the devices is available;

- installation and start-up are carried out on their own without much difficulty.

The disadvantages of the units include the lack of automatic control, dry air. In the greenhouse, you will have to install a container with water in order to maintain the humidity at the desired level.

It is not difficult to install heating in a greenhouse with your own hands, it is enough to put a stove in a utility room or in a vestibule, and bring a circuit with a water or air coolant into the greenhouse. The chimney is allowed to be brought into the greenhouse by placing the pipe at an inclination of 15 degrees, the heat from the chimney will serve as additional heating if the pipe is also made of metal and there is no insulation. But if the chimney is brought out, it will have to be insulated to reduce heat loss.

The most popular types of metal furnaces:

- Vesuvius mini. Potbelly stove with a simple design and low cost. Thermal power of 4 kW is enough to warm up 80 m3, that is, greenhouses with an area of up to 30 m2. Heating with wood, the top panel is suitable for heating water.

- Cinderella. Small-format metal stove with side convectors that distribute heat flows. Power 6 kW, heats up to 60 m2. Solid fuel, there is a burner on the top panel.

- Teplodar Pechurka plus. A 5 kW model will heat up to 50 m2 of area. There is a casing with convection holes, which guarantees an even heat dissipation. Heat with wood, there is a burner. Light weight and size, increased stability are the advantages.

Step-by-step installation technique:

- preparation of a base from a durable material, for example, paving slabs in the center of the greenhouse;

- install the unit, checking the convenience of loading fuel, cleaning ash;

- if the greenhouse is equipped with a solid wall, the stove is placed next to it, turning the unit with its back wall to the wall panel;

- connect the chimney to the flue pipe, seal the connection with heat-resistant sealant;

- connect the water, air circuit.

Brick ovens

Brick ovens are used in greenhouses for year-round use, they are able to maintain heat in severe frosts, and have a high heat capacity.

To form heating the greenhouse with a wood-fired boiler with your own hands you will need:

- ceramic solid bricks 220 pcs.;

- fireclay bricks 80 pcs.;

- mortar for styling with clay 80 l;

- mortar for laying refractory 30 l;

- foundation concrete 0.25 m3;

- grate, combustion chamber, blowing and cleaning doors, smoke valves;

- tools for laying out the solution;

- tape measure, pencil, level, suspension.

You can take a drawing as a basis. In the diagram, the height of the furnace before the beginning of the chimney is 2.15 m, the structure is placed in a greenhouse of a standard size. Horizontal dimensions 51x77 cm.

Step by step construction:

- To fill the foundation, remove soil up to 40 cm thick from an area of 70x100 cm.Fill the bottom of the excavation with 20 cm of sand, then install a plank formwork, lay reinforcing bars with a diameter of 12 mm with a two-row lattice with a step of 20 cm. Knead the concrete composition and pour onto the prepared structure. Drying of the foundation requires 3 weeks with regular wetting of the surface.

- You need to start laying out with an ash pan and a firebox according to the scheme. The first 4 rows are red brick with clay mortar. Installing the ash pan door requires wire fixing in the masonry itself. Rows 5-12 - fireclay bricks for refractory mortar. A grate is mounted in the 5th row, a furnace door is installed in 6-8 rows, rows 9-12 are the firebox vault.

- Rows 13-15 - fireclay bricks, and in row 15, install a cleaning door. Laying out red bricks from the 16th row, and in the 16th row, the installation of the cleaning door continues, and the 17-21 rows form smoke channels. In row 22, you need to put the first smoke damper.

- Rows 23-27 are a continuation of the smoke channels, at 28 you need to lay out a narrowing, and at 29 you need to put a second smoke damper. Rows 30-31 - the roof of the furnace, starting from row 32, a chimney of the required height is laid out of 4 bricks with bandaging.

To clarify all the nuances, watch the video.

How to organize heating of industrial greenhouses? Choose a cable from the catalog

The heating system of an industrial greenhouse will work efficiently if it is properly organized.In addition to thermal characteristics, it is worth considering:

We invite you to familiarize yourself with Automatic ventilation of greenhouses -> Main page

- air humidity;

- the amount of carbon dioxide;

- the possibility of an emergency temperature drop.

When choosing the power of the heating cable and the density of its laying, it is necessary to focus on the climatic zone in which the greenhouse is located. On average, to provide heat to 1 sq. m. will need from 70 to 120 watts of power. One wire should not heat more than 20 W / m, so that the root system of plants does not dry out and overheat. 15 W / m is the optimal value for root vegetation.

The choice of power is also influenced by the amount of insulation in the greenhouse. Polycarbonate will require less heat consumption for heating than glass walls. The installation of equipment that will automatically adjust the parameters of the system's operation will help reduce the cost of its operation and avoid an emergency temperature drop to which employees may not react in time.

System installation

To install cable heating, you need to follow several steps in sequence:

- remove from 30 to 50 cm of soil;

- level the area for laying;

- lay a 5 cm layer of sand for drainage, level it (for this it is better to moisten it);

- lay hydro- and then thermal insulation on the sand so that the heat does not go down. Styrofoam or polystyrene foam will do. Waterproofing can be made of polyethylene;

- install a mounting grid on which the cable will be fixed;

- fix the wire itself with ties;

- if required, install temperature sensors in the right places;

- apply another 5 cm sand drainage layer, tamp it;

- lay a fine-mesh galvanized reinforcing mesh on top to protect the wire from garden tools;

- now a layer of soil is being laid, the thickness of which is usually 25-40 cm.

Our factory produces resistive and self-regulating cables that can be used for industrial greenhouses. When choosing, you should take into account the calculated data for power per 1 sq. m.

Greenhouse heating water

The water heating circuit of the greenhouse can be organized by connecting the greenhouse to the centralized heating system of the house or by installing a separate boiler. If a tie-in is formed into the main line of the house, it is recommended to build a separate circuit for the subsequent drainage of the coolant. A gas, electric, solid fuel or universal type device is selected as a separate boiler.

It all depends on the capabilities of the owner and the features of the units:

- Gas equipment is considered economical and convenient. The automatic control system makes it easy to operate. The coaxial flue does not heat up.

- The solid fuel boiler runs on wood, coal, pellets. Inexpensive fuel is a plus, a low level of automation is a minus.

- Electric boilers are compact, noiseless and automated. The high price is a minus, as well as the increased electricity costs.

Boiler selection rules:

- Selection of equipment power according to the size of the greenhouse area, the required temperature.

- If there is a gas pipeline nearby, it is more profitable to equip gas heating for industrial greenhouses and private greenhouses. In the absence of a line for greenhouses with an area of 50 m2 or more, it is more convenient to install solid fuel boilers, the costs are paid off in 1-3 years. In small-format greenhouses, it is more convenient to install electric boilers without a special chimney, energy costs will be low.

An important point is the calculation of the heating of the greenhouse. For rooms up to 3 m high, calculations are carried out by area using the formula S = a * b, where:

- S - area in m2;

- a, b - length and width in meters.

To determine the heat power, the formula P = S * 120 is used, where P is the indicator of the calculated heat power in W, S is the area in m2.To determine the number of battery sections, the formula n = P / p is used, where n is the number of sections in a radiator of the required type, and p is the thermal power of one battery section (indicated in the data sheet). The final figure of the number of sections must be evenly distributed over the entire area of the greenhouse, dividing them into several batteries.

To equip heating a polycarbonate greenhouse in winter using water heating, you need to purchase all components, which include a pump, piping, radiators, a security group, an expansion tank, valves.

When installing a solid fuel boiler, you will need a heat accumulator. To understand the heating circuit connection diagram, watch the video.

Step-by-step installation of water-type heating:

- Install the boiler. For solid fuel equipment, a vestibule is formed, gas and electric boilers can be installed in the greenhouse. Installation depends on the type of boiler - suspended, floor-standing (a solid foundation is required).

- Connect the unit to the chimney. It is better to connect solid fuel boilers to a sandwich chimney according to the scheme. Electric boilers do not need a chimney. Gas boilers are connected to a coaxial chimney through the wall in the boiler installation area.

- Connect the batteries that are hung on the walls. Install a Mayevsky valve on each battery, valves for lowering and shutting off the coolant. Greenhouse heating schemes are selected depending on the convenience of connecting radiators, it can be a bottom or top connection. The pipeline is formed from pipes with a diameter of 20-25 cm.

- All water heating systems for greenhouses require the installation of an expansion tank. It is better to take membrane equipment in the form of a sealed container with good compensation performance. The tank is installed at any point, for example, immediately after the outlet from the boiler or in front of the installation area of the circulation pump. Bottom connection via valve.

- A safety group consisting of a pressure gauge, a safety valve, an air vent is installed after the outlet pipe from the boiler.

- The circulation pump is installed on the return flow pipe in front of the boiler inlet. A coarse filter is installed in front of the pump.

After assembling the system, it is filled with a coolant and started in a test mode. Pressure testing allows you to identify problems with low tightness and is carried out with the preliminary closing of Mayevsky's taps and connecting the compressor. Pump up the pressure with a compressor, which is indicated in the data sheet of the boiler, radiators.

Heating methods for industrial greenhouses

Heating the premises is needed not only for year-round greenhouses, but also for greenhouses used for planting early-maturing crop varieties.

Greenhouse heating can be any:

- stove with water or air heat carrier;

- in the form of a water circuit connected to a gas, solid fuel or electricity boiler;

- air is heated by a gas gun, by means of convectors or infrared panels.

Some owners prefer to heat the ground by laying circuits or heating cables in the ground. Greenhouse heating systems can be combined, depending on the availability of fuel and the required heating intensity.

A little about the advantages of species:

- The convenience of the water network in laying circuits along the outer walls and in the ground - in this case, another pipeline is equipped, laid in a ditch and a coolant is started up through it.

- Gas cannons are convenient, but it is important to place the equipment correctly so that the heat does not dry out the air.

- Electric heating of industrial greenhouses requires serious maintenance costs, the devices dry the air. To reduce costs and maintain a normal level of humidity, infrared heaters allow them to transfer heat not to air, but to plants and objects.

- Convection equipment is used as a backup or temporary heat source.The heated air rises, so the temperature at the roots of the sprouts will always be lower, this can lead to the formation of rot.

Advice! To select a heater for the network, the greenhouse material, heating area, growing conditions, etc. are taken into account.

About our company

is engaged in the production and installation of cable heating systems. The engineers and foremen of the company have extensive experience and are constantly developing in this area. They are willing to share their knowledge with customers so that the systems they design are efficient and cost-effective.

If you have not yet decided what type of heating to use, then a free consultation provided by our experts will help you decide. If necessary, they will help you with all the calculations.

We also offer service and repair of communications.

Testimonials

1. Considering that electricity is not so expensive in the country, the idea of installing cable heating in greenhouses looked sound. The installation did not take long. A self-regulating cable was used. Everything works well, heats up. There is still little information about this heating method, so the opportunity to discuss everything with an engineer before starting work helped a lot.

2. The issue of heating is quite acute, even if the greenhouse facilities are located in the south, in the Krasnodar Territory. In winter, frosts happen. The wiring went smoothly, nothing complicated, as it turned out. We put temperature sensors, it's useful. In terms of costs, it turned out less than expected.

3. For half a year, the issue of heating in greenhouses was raised. It seemed that all this would be quite cheap, but profitable: you can start landing much earlier. It turned out that in order for everything to work well, greenhouses also need to be insulated. In the end, the additional costs turned out to be not so great, now the system is functioning, everything is fine.

If you are interested in creating a reliable heating system for industrial greenhouses, then use it. You can not only purchase all the components from us, but also get the assistance of competent specialists on installation and maintenance issues. All equipment is manufactured at our own production facilities. The plant is located in the Moscow region. But the installation, connection and maintenance of systems are carried out by our specialists throughout the country.