When building a house, the planner will certainly face the issue of providing heating. Within the city limits or in large settlements, gas equipment is widely used, since this is facilitated by the close location of the highway and the relatively low cost of the fuel itself. An alternative to such a system can be electricity or the energy of burning wood and coal.

The use of electricity for heating a room is not always justified due to its total cost, and frequent interruptions in electricity are fraught with unpleasant pastime in a cold room.

On the basis of such reasoning, in houses located far from large settlements, or in country houses, the good old stove heating is used. But modern stoves are completely different from those that we remember from our childhood. They have gone through several stages of modernization and are distinguished by high performance. In this issue, we do not consider brick ovens, since their use is not always appropriate, construction is accompanied by the cost of effort, money and time, there are more efficient devices for heating.

Modern appliance for home heating

Metal ready-made ovens are devices that combine the functions of a fireplace, hob, oven and, directly, the oven itself. They are so efficient that they can act as the only heater in the house. A distinctive feature is that the metal fireplace stove occupies a small area and does not require pouring the foundation. The richness of the choice of various methods of exterior decoration will allow you to choose a model for any interior that provides a single harmonious picture.

Some installation requirements

Ease of installation, which is positioned as the main distinguishing feature of finished metal furnaces, should not be taken literally. Functional and fire safety requirements impose certain restrictions:

- Firstly, each model of the device is supplied with a technical data sheet, which contains installation instructions.

- Secondly, there are generally accepted standards and their implementation is mandatory for the safe and efficient operation of the furnace.

The metal walls of the firebox and the body of the furnace contribute to efficient heat dissipation into the room. Due to this, the enclosure has a high temperature and cannot be installed close to the wall, especially if it is finished with flammable or melting materials.

Good to know: How furnaces without a chimney are implemented in practice, what they are

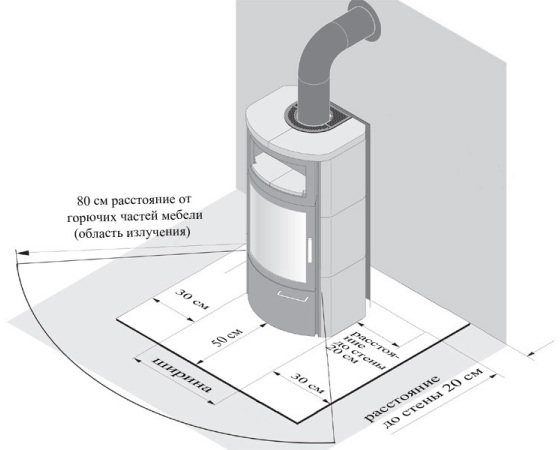

The minimum clearance from the body to the wall is specified by the manufacturer. On average, it is about 20 cm from the sides and back of the oven. To protect the dwelling from fire and remove heat from the walls inside the room, the surface is trimmed with heat-insulating material. Air has poor thermal conductivity, so the heating of the wall surface comes from radiation. Foil material perfectly reflects infrared rays.

Thermal insulation for the walls of the house

Wall decoration with tiles or next to brick is also allowed. However, brick protection will require the construction of a full-fledged foundation.

Essential requirements are also imposed on the flooring:

- The problem is that the installation of a fireplace stove can be accompanied by a partial disassembly of the floor. Although the mass of the structure is small, in order to prevent deformation of the log during its prolonged exposure, it will be necessary to put additional supports in the place of localization of the furnace under the logs.

- The floor covering must be protected from high temperatures and from the accidental fall of escaping hot coals. In models with a closed firebox, this probability is minimal, but it is necessary to protect against any dangerous situation. Fireproof glass, tiles, metal or asbestos are used as thermal protection of the floor. The base area must be larger than the area of the fireplace hearth. The protection protrudes 50 cm from the facade, and 30 cm from the side walls.

Installation diagram of the device and floor protection

The construction of a chimney is a mandatory step, which characterizes the installation of a fireplace stove in the country. To emphasize the importance of this stage, it should be recalled that the chimney is a constructive way of removing combustion products, circulating and supplying air to the combustion chamber. The main requirement for a chimney (except for fire safety) is the presence of a draft.

Often, due to the accumulation of cold air in the pipe, there is no draft when the furnace is fired up. We have to warm up the chimney, spend time on it. To avoid this phenomenon, it is recommended to use a two-layer system with insulation as a pipe. This is especially true when the smoke channel goes outside immediately after the smoke collector.

Chimney appearance

The requirements do not end there. Considering that the chimney pipes can be heated to high temperatures, it should be insulated where it passes through the opening in the ceiling and in the roof. This isolation can be done in several ways:

- In place of the slot, we install an insert made of metal or asbestos with a hole for the pipe. Such protection is quite reliable, but not aesthetically pleasing, since the insert occupies a large area.

- You can make a hole in the ceiling only a few centimeters larger than the diameter of the pipe, and fill the resulting gap with mineral heat-shielding wool.

Good to know: A stove-fireplace for a summer residence, choose between a brick and cast-iron option

On the open part, the chimney installation is determined by the distance from the pipe to the ridge. Some stove manufacturers publish information on the required chimney height, as it depends on some properties of the stove. The following provisions will serve as universal indicators:

- At a distance of no more than 1.5 m from the ridge, the chimney is erected 1 m.

- When moving away from the ridge, the height of the chimney is limited by a line drawn through the ridge at an angle of 10 ° C to the horizontal.

- Installation of a protective cap is required.

Furnaces put into operation

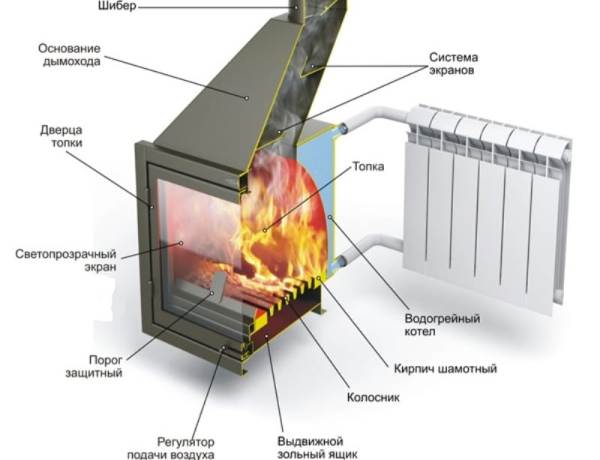

General description of the device

The number of different models of fireplaces is extremely large. The complexity of installation will depend on the type of fuel, the structural features of the house and the material of the firebox. By the type of body, the foci can be straight or angular; the first type is also divided into built-in and wall-mounted structures.

Taking into account the location, fireplaces are classified into:

- an autonomous structure, which is installed in the center of the room, regardless of the presence of walls nearby;

- frontal devices that are built near walls;

- corner fireplaces that are installed in the corner of the room.

In this video, we will consider the installation of a fireplace:

Types of fireboxes

The heating device market offers a large number of different types of furnaces for heating devices that operate on alternative fuels and can be mounted without a chimney in rooms of any purpose. By the type of fuel being pledged, a fireplace in a log house can be:

- Classic (solid fuel). Coal or firewood can be placed in the furnace of these devices. They are equipped with standard chimney designs.In this case, installing a fireplace in a wooden house with your own hands implies the obligatory pouring of a foundation independent of the base of the building, as well as thermal insulation of ceilings and surfaces that are in contact with the hearth.

- Gas. This device contains a burner inside the chamber. Liquefied or natural gas can be used as fuel. The device in a wooden house of a fireplace will require the same measures as in the presence of traditional types of equipment, including a chimney.

A fireplace is not only an element of decor, but also a means of heating in your home.

- Biofireplace for home. This device is considered a new kind. Ethanol is used as a fuel for such a fireplace. Inside the combustion chamber there is a burner and a container for refueling. The main advantage of this device is the absence of ash, soot and other harmful combustion products for the human body. To fully heat the room, this device is not enough, since its main purpose is decorative. Bio fireplaces can be floor-standing, wall-mounted, table-top or hanging. A feature of the devices is the release of steam during combustion, humidifying the air in the room. No chimney is required.

- Electric fireplace. This equipment is considered the most reliable in terms of fire safety. These devices do not have an open flame, and the air is heated by a hot electric coil. An imitation of a real hearth is created with the help of illumination - a decoration that is located inside the device. Electrical equipment is characterized by easy installation, since this does not require pouring the foundation and arranging the chimney. This device is ideal for attics and upper floors. The main thing that is needed is good electrical wiring and reliable insulation that can withstand high loads.

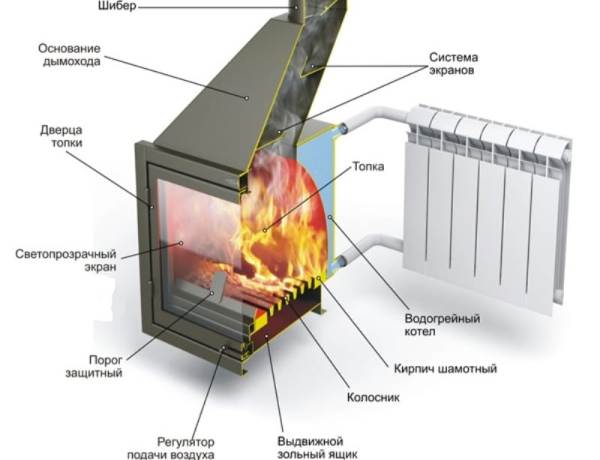

Furnace piping

In rare cases, a room is heated by a stove due to convection flows. The very status of the device implies the most efficient use of the released energy. Therefore, the heating system is supplied with a heat carrier, which can be water circulating through pipes, or air moving under the action of forced convection. The connection of the coolant channels to the furnace is called piping.

Some problems associated with the installation of a fireplace stove are concentrated precisely in the incorrect installation of the line. With hot water heating, the circulation is provided by a pump or it is carried out by natural convection. In the second case, it is important to observe a certain slope of the line, since the reverse slope will lead to stagnation of the liquid. In a closed heating system (1st case), the slope does not matter, but the system makes strict requirements for tightness. Even a small amount of entrained air will stop the circulation.

The water circuit, which the fireplace stove is equipped with, has an inlet and outlet for connection to the mains. If they are not specially marked, then it must be remembered that the hot water outlet is located below the cold water inlet.

Heating circuit connection diagram

Tying the air duct is not difficult, but laying the line under the panels or lining with plasterboard is a laborious process. The furnace, which uses air as a heating medium, is equipped with a fan system that drives the air along the line. By adjusting the flow of the flaps, you can selectively direct the heat to different rooms.

Good to know: The once forgotten electric miracle oven is back in service

Accommodation options

Initially, you should decide on the option for the location of the firebox. A homemade fireplace can be corner, take an island (central) position, or be placed near the wall of the room. There are also built-in (hanging), adjacent ovens.A wood-burning fireplace with your own hands can perform an exclusively decorative function, or act as an additional source of heating.

The central location will provide an even heating of the room. The disadvantage of the design is the size and bulkiness. The total area of the room should also be taken into account. The island position of the fireplace is appropriate in rooms over 50 sq. m.

Do-it-yourself corner wood-burning fireplace takes the most advantageous angle. The installation method saves space due to its compact design.

Wall-mounted options require special attention to fire safety measures. During installation, the need to use refractory materials and the creation of a small gap between the fireplace and the wall should be taken into account.

Suspended structures mean mounting to the wall, or in special niches. They are more often used as a decorative element, due to the low power of the mini-hearth of the country version. Adjacent fireplaces are capable of fully performing the heating function. The location of the combustion chambers on both sides makes it possible to increase the efficiency and heat capacity of the structure.

Installation of a brick structure

If a choice was made in favor of a classic stove, then it should be remembered that the construction must not only meet safety requirements, but also some technical requirements. Even before the development of the informatization of society, it was believed that such work was inaccessible for people who did not have special training. Therefore, the profession of a stove-maker was considered one of the rarest and most sought-after.

Today it is easy to find step-by-step instructions that will help you get a functional device with your own hands. However, compared to the installation of ready-made devices, the construction of a brick stove will take longer. We will list only the main steps, as detailed instructions are available in the sections entitled “finished projects”.

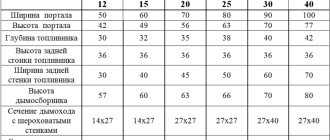

Work begins with determining the dimensions of the structure. The area of the foundation will depend on them. After pouring the base using a special ordering scheme, the furnace body with its main nodes is laid out. To appreciate the work of professionals who shared all the information, you need to know that, depending on the area of the room, each oven has its own dimensions. The calculation is made of such parameters as the height, width and depth of the furnace, the dimensions of the body, the height of the chimney, the area of the smoke channel.

Today, few of the novice masters are engaged in complex calculations, since all data is presented in a ready-made tabular form. Laying out each row, we get a formed ash pan, firebox, smoke tooth and smoke collector. This is just a simple fireplace layout, the stove has a chimney duct system. In these channels, hot air gives up the maximum possible share of energy to the stove body. It is almost impossible to carry out the construction of this part without a diagram.