When performing major repairs in an apartment, you should not limit yourself to performing an even screed on concrete slabs. An important issue is to solve the problem of a high-quality soundproofing layer.

The main goals of floor sound insulation are to maximize the level of noise penetrating into the apartments located on the floor below and to protect against noise generated by the neighbors below. Noise sources, their characteristics and noise standards are determined by SNiP 23-03-2003. This document was developed using the following regulatory documents: GOST 17187-81, GOST 27296-87, SP 23-103-2003, SNiP 2.07.01-89.

The traditional solution to this problem is to lay resilient materials such as linoleum or carpet. However, it is impossible to completely solve the issue of high-quality soundproofing of the floor from the lower neighbors in this way.

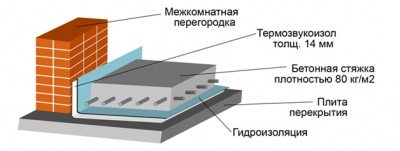

System "floating floor" - one of the options for soundproofing the floor

One of the ways to solve not only the problem of soundproofing the floor, but a number of other, no less important tasks, allows the "floating floor" system.

The term “floating floor” means a multi-layer floor covering that does not have a rigid connection with the floor. The elastic materials used in the construction effectively absorb vibration and prevent the transmission of sound into the room located below.

Although there are quite a few options for installing a floating floor using a wide range of materials, there are three main types of it: concrete floating floors, prefabricated and based on a dry screed.

A natural question arises: why use such a rather complex system, if there are traditional, simpler methods of soundproofing? The reason for the popularity of floating floor technology is due to the following reasons:

- it the most effective floor sound insulation technology.

- One of the layers of the floating floor is a heat-insulating material, most often mineral wool, which makes it possible to increase the level of heat saving in an apartment.

- Technologies "prefabricated floor" and "dry screed" simplify and speed up installation work as much as possible, since they are carried out without time-consuming "wet" processes.

- The use of such a soundproofing system makes it possible to install heating elements of an electric or water "warm floor".

- Floating floors can be installed both during construction and during renovation.

- The system perfectly solves the problem of eliminating floor irregularities.

The choice of material for soundproofing the floor in the apartment in terms of performance and prices

The modern market for building and finishing materials literally explodes from the abundance of various solutions, so it is not always easy to choose. I will briefly review the most popular materials in terms of cost, efficiency, manufacturability, general pros and cons.

Stone wool

This material has the following advantages:

- Ecological cleanliness.

- High temperature resistance.

- Non-flammability (high level of fire safety), density.

- In addition to high sound insulation properties, it simultaneously has excellent thermal insulation performance, which allows you to solve two problems at once.

Of the minuses, one can single out

- Hydrophobicity - contact of the material with moisture is unacceptable, therefore, it is necessary to equip high-quality vapor barrier, waterproofing, you cannot use cotton wool in rooms with high humidity levels: kitchens, bathrooms, saunas.

The price of stone wool 50 mm thick with a sheet size of 600 x1000 mm is 750 rubles per package or 312 rubles per 1 square meter. The cost of work is 100 rubles per 1 square meter in one layer and 150 rubles - in two layers.

Expanded clay

This soundproofing material has the following advantages:

- High level of fire safety.

- Environmental friendliness - natural material.

- Resistant to moisture.

- Not afraid of mold, mildew, pests.

- Strong enough.

Ideal for wet rooms.

- The downside is a significant increase, an increase in the level of the floor, which is not always possible if the ceilings are already low enough.

- The laying process is quite laborious.

The price of expanded clay depends on the size of the fraction, but I am considering the option most demanded for sound insulation - 10-20 mm. Its price is 1600 rubles per cubic meter or 160 rubles per square meter with a layer of 8-10 cm. The cost of work is 390 rubles (this includes filling the screed).

Cork soundproofing

This insulator has the following advantages:

- Ecological cleanliness - natural, natural material.

- The possibility of using a thin layer (0.5-3 cm), which avoids a significant rise in the floor level.

- Manufacturability - the material is easy to lay.

- Flammability.

- Vulnerability to pests.

- High price.

I consider it inappropriate to use this material as the main one due to its high cost.

The cost of technical cork sound insulation for the floor in the apartment is 650 rubles per 1 square meter with a sheet thickness of 10 mm. The installation price will be 100 rubles per square meter in one layer.

Shumoplast

A mixture of polymer granules for soundproofing concrete substrates. The basis of the material is polystyrene foam, rubber, acrylic binders.

Important advice!

Modern soundproofing of an apartment is more expensive than outdated methods, but its effectiveness is sometimes several times higher.

Among the advantages are:

- A thin layer of application - 2 cm.

- High efficiency.

- The complexity of application and the need to wait 48 hours for complete polymerization.

- In addition, it is primarily intended for the construction of floating screed floors.

The cost of this material is 250 rubles per square meter with a layer of 2 cm, and the price of the service will be 650 rubles per meter.

Soundproof

Insulation based on a two-layer bitumen-polymer material, supplied in rolls. Differs in the following advantages:

- Ease of installation and minimum layer thickness.

- Versatility - simultaneously performs soundproofing and waterproofing functions.

- Fits in any room and under almost any type of flooring.

Concrete floating floor device

This type of soundproofing flooring is a solid, reliable, durable base.

Concrete floating floors are arranged in rooms with significant floor loads - in warehouses, garages, parking lots. Also, this technology is suitable for the installation of a warm water floor, since it is important for it to have a good thermal conductivity of the upper layer of the structure.

The procedure for performing concrete floating floor technology:

- The base is cleaned, the irregularities are preliminarily eliminated - the grooves are closed up and the convex places get rid of.

- For the purpose of waterproofing, bituminous mastics are applied to the base or special dry mixtures are used.

- The edge tape is glued along the contour of the room.

- If mineral wool is used for the cushioning layer, then a vapor barrier must be laid on the base with the obligatory gluing of the joints.

- A cushioning material is laid on the prepared base, which is used as mineral wool or foam.

- A polyethylene film is placed on top of the cushioning layer, which will serve as a separating layer between the wet screed and the installed sound and heat insulation layer.

- Then a cement-sand mortar is poured, the quality of which can be improved with the help of special additives. A metal mesh is used to reinforce the screed.

FLOOR SCREW - PROFESSIONAL ADVICE AND REVIEWS

TYPES OF FLOOR SCREWS

Wet type screed

This screed is a mixture of cement, filler and various additives, which, after being combined with water, turns into a pasty state and subsequently hardens to form a durable layer. The cement-sand mixture can be simple, or it can be modified with various additives that reduce the risk of cracking, accelerating the processes of hardening and further finishing the floor. A solution prepared from such a mixture, more resistant to various loads during operation, better withstands atmospheric influences, water effects, low and high temperatures. In addition, modified screeds are much more technological and easier to apply, and also allow you to get smoother bases.

ADVANTAGES:

- high strength;

- wide range of applications - indoors and outdoors;

- durability;

- no special equipment and high qualifications of the master are required;

- the ability to create slopes;

- low cost.

FEATURES AND DISADVANTAGES:

- during application, it is necessary to isolate the base from the penetration of water from the screed. This is achieved by organizing a waterproofing layer;

- when installing such a screed, the load on the base of the building is significantly increased;

- wet screeds harden for at least 28 days.

INSTALLATION STEPS

- Repair, dedusting, priming of the base.

- Fastening the damper tape.

- Application of a waterproofing layer.

- Installation of beacons.

- Preparation of the solution. Laying out the mortar and leveling the rule.

Wet-on-wet screed installation // FORUMHOUSE

SEMI-DRY SCREED

This type of coupler has appeared relatively recently. These compositions are produced on a cement basis. When mixing a semi-dry screed, water is added to it in a much smaller amount than to a wet screed.

ADVANTAGES:

- does not require a preliminary waterproofing layer;

- dries faster than wet screed;

- characterized by high strength;

- forms a fairly even coating;

- acceptable cost;

- wide range of applications - indoors and outdoors;

- the ability to create slopes.

FEATURES AND DISADVANTAGES:

- the complexity of mixing the composition and creating a high-quality and homogeneous mass for the screed by hand. This can only be done in special devices;

- with an insufficient amount of water, there is a high risk of cracking;

- screed device requires special qualifications of workers.

PROFESSIONAL ADVICE

Scope of application

Optimal scope of application of wet screeds - leveling floors from the outside premises, inside unheated premises, installation of a blind area, raising the floor level in garages, basements, on the first floors of buildings.

Semi-dry screed is recommended for rooms where it is necessary to reduce the amount of dirty work and the likelihood of leaks.

In cases of tight repair times, if there is a need to perform the process at sub-zero temperatures or when other types cannot be used, a dry screed is used. Such a screed is preferable for older buildings where floor loading is important.

INSTALLATION STEPS

Repair, dedusting, priming, damper tape fastening, floor marking, installation of beacons - the same as in wet screed technology.

Preparation of the solution. The solution is mixed automatically, immediately in a pneumatic blower.

Backfill.Since a semi-dry screed is made of a loose material with a small water content, it is poured from a pneumatic blower along the beacons, leveled with a rule, and then rammed with a vibrating layer or manually.

Finishing treatment. The screed must dry within 24 hours before finishing. Further processing is carried out using a trowel.

Semi-dry floor screed

DRY FLOOR SCREED

A dry screed is a backfill material (usually expanded clay), which serves to raise the floor level, and sheet material (usually a gypsum fiber sheet), which is laid on expanded clay in two overlapping layers.

ADVANTAGES:

- no dirty processes;

- quick installation, after the device, the screed is immediately ready for finishing;

- leveling of significant thicknesses is possible;

- low weight of the screed, reduced load on the base;

- heat and sound insulating properties.

FEATURES AND DISADVANTAGES:

- contact with water must be avoided. For this reason, this method of leveling the floor is not suitable for a bathroom or kitchen, as well as for unheated rooms;

- poor resistance to mechanical stress. Such a screed is suitable only for rooms with minimal loads;

- low strength indicators;

- violation of the technology of the device leads to the rapid destruction of the entire structure;

- there is a strict limitation on the minimum thickness of the alignment;

- only used indoors in dry rooms;

- high price.

INSTALLATION STEPS

- Fastening the damper tape, installation of the vapor barrier with an overlap on the walls.

- Backfilling of the leveling layer (expanded clay). Alignment with removable guides. Some types of backfill require compaction of the layer.

- Installation of GVL sheets in several layers with an overlap.

Dry floor screed - Apartment renovation in a turnkey new building

We are grateful to Unis for help in preparing the material.

QUIET AND WARM FLOOR WITH YOUR OWN HANDS

"Floating" concrete screed is advisable when it is necessary to provide reliable heat and sound insulation. It is placed on a layer of insulation so that it does not come into contact with either the concrete floor or the wall.

MATERIALS

- Screed mortar

- Primer

- Fiber insulation material

- Polyester film or roofing felt

TOOLS

- Shovel

- Broom

- Bucket

- Brush

- Brush

- Concrete mixer and pump for supplying solution (for large volumes of work)

- Building level

- Hydro level

- A splint or board for leveling mortar

- Grater

- Trowels for laying and smoothing mortar

Important!

A screed is called floating if it does not come into contact with the building structure. This eliminates the formation of cold bridges.

FLOATING SCREED BY OWN HANDS

Do-it-yourself floating screed

- It is better to lay the film with a thickness of 0.2 mm in order to avoid the leakage of the solution in two layers and, if possible, straighten it without stretching.

- A special additive makes the mortar more elastic, prevents water peeling and improves the properties of the mixture.

- Expanded polystyrene strips are used as an insulating strip between the screed and the wall.

- After smoothing the solution, the guide rails are immediately removed, and the recesses from them are filled with solution.

- To level the solution with a board-rule, guide rails set to the level are used.

- The prepared solution is placed on the base and leveled.

- Large areas will require a concrete mixer and mortar pump.

- The laid solution is leveled with a grater. Any air bubbles must be filled with a solution.

- Small irregularities are smoothed out with a steel trowel, giving the screed surface a final shine.

floating floor screed

Floating prefabricated floor technology

This type of flooring includes parquet or tongue-and-groove boards or laminates.

These coatings must be laid through the cushioning material on a flat base, since irregularities will lead to deformation of the material and their rapid failure. Minor imperfections, such as scratches, are allowed.

An insulating material is laid on the base, which, most often, is polyethylene foam with a uniformly closed cellular structure. Foamed polyethylene can be used for all types of floor coverings, and is presented in two types:

- physically cross-linked (or gas-filled) expanded polyethylene;

- chemically cross-linked polyethylene.

The second option is expanded polystyrene. The thickness of the insulating material is 2-5 mm.

The elements of the finishing floor covering are laid out with a distance of 10 mm from the wall. This gap is necessary so that when the coating expands under the influence of temperature, it does not swell, resting against the wall.

Prefabricated floating floors are least effective in terms of sound and heat insulation.

We isolate the floor on the logs

If you are worried about impact and airborne noise at the same time, the material is laid on the joists:

- Used in wooden buildings.

- Suitable for rooms where concrete and cement screed cannot be used.

- Only dry work, done quickly.

- Correct installation reduces impact noise to 30 dB, and airborne noise to 10.

The logs, made of wood, are installed on the sub-floor through elastic elastomeric pads. EKO-plates or Shumanet material are mounted between them. On top of the logs, two layers of 18 mm plywood are installed with an overlap.

Do you need a refurbishment?

We have already renovated more than 500 apartments, we will be happy to help you too

Find out the cost of repair

Dry screed technology

A floating floor device of this type excludes the use of mortars. This method involves leveling the surface for the subsequent laying of the prefabricated floor. The difference between this technology of noise insulation from a concrete floating floor is that dry mixtures of fine-grained materials are poured onto the base, which are used as expanded clay or perlite sand.

Dry backfill allows you to quickly level the base on which the remaining layers are laid. This method is much cheaper than the concrete floating floor technology.

Dry screed stages:

- The subfloor is prepared by removing all old coatings. Slots and grooves are sealed with a solution prepared from a dry mixture. For this purpose, you can use "Remstream-T".

- Using a level - laser or water, mark the height of the filling.

- Between the wall and the future bedding, an edge tape is fixed, for the manufacture of which foamed polyethylene or mineral wool is used.

- Since the fine-grained bedding has a low moisture resistance, it is necessary, in order to create moisture protection, to spread a polyethylene film over the entire area with an overlapping edge of at least 250 mm. The edges are glued with reinforced tape.

- The bedding is placed up to the marked level, rammed.

- On the backfill, most often, gypsum fiber boards are laid in two layers, fastened together with glue.

This is one of the simplest options for dry screed technology.

If the initial task is to create reliable thermal protection, then expanded polystyrene or extruded polystyrene foam can be additionally placed on the bedding. If the main goal is sound insulation, then mineral wool is used. The maximum thickness of polystyrene used for these purposes is 100 mm. For noise insulation of the floor of the second and subsequent floors, as a rule, polystyrene foam plates with a thickness of 30 mm are used.

Basics of soundproofing under tiles.

The tile is considered to be a heavy and dense coating. Thanks to this, it perfectly transmits any vibrations. And the main task is to minimize this effect. Modern membrane soundproofing materials come to the rescue in such situations.The main brands that can be distinguished against the background of the entire construction market are Texound, Vibroflor and other materials.

The main advantages are ease of installation and excellent insulating characteristics.

As a result of laying the membranes, the upper floor covering (in our case it is a tile) almost completely stops transmitting vibrational sounds. As a result, unwanted noise, as a rule, is reduced by several times. We think it is clear to you that you will not be able to get rid of all types of noise, since membranes alone will not be enough for such purposes.

It should be borne in mind that for laying the tiles, a good base is required, which will not allow the entire structure to move. For this task, there are three ways to arrange a screed for a tile:

- plywood screed;

- concrete screed;

- screed from oriented strand boards.

An oriented strand board screed is considered to be a very robust structure. In addition, it has excellent soundproofing qualities, due to the fact that these plates are stacked on a pre-created crate of boards, which, in turn, is placed on damping pads. As for the screed with plywood, experts recommend laying another additional layer of membrane material (for example, texound) that can isolate the room from extraneous noise. As a result of the above, a comprehensive protection for floor sound insulation is obtained.

Cork soundproofing underlays

The traditional options for soundproofing a floor is the use of a subfloor under the final floor covering, which performs three main functions: smoothing the surface of the base, soundproofing and thermal insulation.

Experts categorically do not recommend using foam materials as a sound-insulating substrate for linoleum, since their use can lead to marks on the floor even from not very heavy objects.

A practical underlay for laminate or linoleum is cork, which has a cellular structure. Small air bubbles trapped in the millions of cells in the cork structure ensure an even distribution of the load over the entire floor area. It is an excellent material for heat and sound insulation. In addition, the cork backing is resistant to high humidity in the room, which allows you not to worry about its possible deformation.

On the basis of natural cork chips, the following materials are produced for floor sound insulation:

- Sheets made of cork chips are not subject to decay, mold formation, and are not destroyed by rodents. This chemically inert material has a lifespan of at least four decades and can reduce noise levels by 12 decibels.

- The cork rubber backing is made from a mixture of granulated natural cork chips and synthetic rubber. Can be used under all types of floor coverings. Requires an additional moisture protection device using a polyethylene film. It has the highest noise-absorbing characteristics among cork materials - it reduces the noise level by 18-21 decibels.

- The bitumen-cork substrate resembles in appearance roofing material with crumb sprinkling. Lay such a substrate with a bituminous layer upwards, with a cork downwards. Does not require additional waterproofing, the noise reduction level reaches 18 decibels. The main disadvantage is the difficulty in laying on the base.

Types of noise

Before you start getting rid of noise, you need to figure out what kind of sound interference there are and how to protect against them. Types of noise:

- Impact - in case of mechanical influences on the structure: work with a hand construction tool, blows and knocking of heels on the floor, children's jumps, etc. A noise wave occurs when acting directly on the floor. To suppress it, soundproofing panels with a cellular structure are used.

- Structural - vibration effect on building structures from operating power tools, furniture movement, etc. Transmitted in the case when there are no sound-insulating pads between the supporting structures of the house. However, it is difficult to determine where the sounds are coming from, as they spread throughout the building. To cope with structure-borne noise, it is necessary to protect the joints of structures with special gaskets.

- Air - sound transmission from the street, from other apartments or neighboring rooms: spoken language, working TVs and household appliances, traffic signals, etc. Sounds are transmitted through the air. A porous or fibrous soundproofing material helps to weaken them.

Sound reflection

A distinction should be made between sound-absorbing and sound-reflecting materials. The latter is characterized by such an indicator as the sound insulation index Rw - a characteristic that numerically shows how much the material is able to reflect sound.

According to modern SNiP, the Rw index for floors in a high-rise building should not be lower than 52 dB. Hollow-core reinforced concrete slabs with a thickness of 220 m and vibropressed slabs with a thickness of 160 mm correspond to this level. Most of the housing contains slabs with a thickness of 140 mm with an Rw of no more than 51 dB, which is clearly not enough.

It is important that there are no numerous gaps between the slabs through which noise propagates well.

With regard to the reduction of impact noise, everything is much worse, since it cannot be eliminated by one massive overlap. Additional structures are needed here, such as a "floating floor" and special topcoats such as carpet, laminate or linoleum with a backing.

Other types of materials for noise insulation

- The highest degree of sound insulation is provided by the material "Shumanet-100". With a thickness of only 3 mm, the level of noise reduction is 23 decibels, with a thickness of 5 mm - 27 decibels. The basis of such a substrate is fiberglass with a special weave. If a staple weave is used for the base, then the noise reduction level reaches 42 decibels. When laying these materials, a gap of 10 mm is left near the wall. It is designed to remove moisture.

- Heat and sound insulation Rockwool is made of stone wool. Basalt fibers can withstand temperatures up to 1000 ° C without losing their qualities. Remaining intact at such high temperatures, basalt fibers are able to protect structures from fire. Due to its high fire safety, Rockwool can be used both in multi-storey buildings and in private housing construction for soundproofing a wooden floor. The basis of the high sound-insulating and sound-absorbing characteristics of the material is its ability to absorb sound waves in a wide frequency range. Versatility, durability, high fire resistance and affordable cost make Rockwool a popular material in the insulating building materials market. Rockwool Floor Butts are used in apartment buildings, Acoustic Butts are used for soundproofing the floor on logs.

Prices for materials for soundproofing the floor

If you are in doubt about which soundproofing for the floor to choose without prejudice to the family budget, see in the table the cost of the materials indicated in the article and some other materials (prices for March 2019 for Moscow), as well as the reviews below:

| Name | units rev. | Price |

| Sound-insulating substrate Vibrostek-V300 | r.m. | 150-170 |

| Akuflex, underlay for flooring, roll 15 x 1m, thickness 4mm | 1 PC. | 1650-1725 |

| Shumanet-100, roll 15x1, thickness 4 mm | 1 PC. | 3300-3450 |

| Shumoplast-soil | 1 kg. | 150 |

| Rockwool Floor Butts | 1 PC. | 660-799 |

Floor sound insulation: reviews

You can see a brief overview of the properties and use of materials for soundproofing the floor in an apartment in this video: Illiterate installation of even the most modern soundproofing materials can lead to a complete lack of effect from their use.Therefore, before starting work on soundproofing the floor with your own hands, it is advisable to consult a qualified acoustics specialist.

TASKS AND SOLUTIONS

A dry screed can serve different purposes, depending on which its components are selected. Leveling the slab and raising the floor level. The "classic" design perfectly copes with this task. Its bottom layer is made of special expanded clay backfill. and the upper one is made of durable sheets on a gypsum or cement basis (most often GVLV 10 mm thick), which are laid in at least two layers. The easiest way to install is special KNAUF floor elements with a 50 mm wide mounting rebate.

The minimum thickness of the backfill screed is 40 mm, and the maximum thickness is 100 mm. This type of sub-floor is suitable for both slab and girder floors (monolithic, prefabricated, timber with planks, etc.).

Improving the characteristics of the overlap. Expanded clay backfill allows you to eliminate significant irregularities and differences in the level of the base, provides additional thermal insulation and satisfactory protection against air and impact noise. However, if it is required to significantly improve the thermal insulation capacity

floors (as, for example, in apartments on the ground floor) or to provide additional sound insulation of 10D6 or more (say, in a home theater room or a music studio), other solutions and materials are used.

Suppose the overlap does not have significant level differences, but only small irregularities. Then they are smoothed with a putty, and then an effective heat and sound insulation material is laid - high-density mineral wool boards (Rockwool Floor Butts, PAROC 55B 1 or their analogues) or sheets of extruded polystyrene foam; the thickness of this layer is usually 30-50 mm. GVLV or other sheet material is laid on top.

If the overlap deviates from the horizontal or there are ledges on it, a multi-layer structure is mounted, consisting (from bottom to top) of backfill, cushion sheets, heat-sound-insulating mats and two layers of GVLV. Instead of floor elements and gypsum fiber sheets, plywood, chipboard and other wood-based boards are sometimes used when installing a heat-and-sound-insulating screed, but only if we are talking about a constantly heated apartment or cottage.

Before installation, any sheet materials must be kept indoors for at least three days. Creating a base for the tiles.

Dry screeds also have one more, rather specific area of application - the preparation of a plank floor for laying ceramic coatings (in the bathroom, hallway, kitchen of a country house). In such cases, hydrophobized chipboards, cement-based boards and FSF plywood with a thickness of at least 10 mm will serve well. They are mounted with screws and / or glue without a backing (heat and sound insulating layers in a wooden floor are usually placed between the beams).

Floor preparation

Acoustic protection of rooms is an important part of the laminate installation process. Soundproofing the floor in the apartment can be done with your own hands or you can invite specialists. The result is important - noise reduction. The most popular methods are floating floor and floating screed, less often sound insulation is laid on a wooden floor.

The floating floor technology requires that the laminate does not have points of contact with the walls, and consists of the following actions, one after the other:

- accurate measurement of the room will help determine the required amount of material;

- the screed is covered with a waterproofing film;

- a soundproof layer is laid on top of the film, and parallel to the direction of the lamellas, although it is recommended perpendicular, but then you would have to walk on the substrate, which is undesirable;

- the laminate is mounted immediately on each strip of the substrate;

- the joints of the substrate are glued with tape for waterproofing purposes.

If sound insulation is made without a screed, directly to the base of the floor, then the laminate in this case cannot be used as a floor covering. Hard contact will lead to rapid destruction of the interlocks and the laminated panels themselves.

Wet screed

Placed on polyethylene.

Otherwise, part of the mixture will be absorbed into the pores of the insulating material. Therefore, first, the material is covered with a film - so that the individual sheets overlap each other by at least 20 cm and go beyond the outer walls of the formwork. Fix them with tape.

We need a reinforcing mesh.

A metal or fiberglass mesh is laid on top of a polyethylene layer. To do this, first install beacons with a height of 1-1.5 cm, which will support the grid. This puts the mesh in the middle of the cement-sand screed, and not at the bottom.

Fill in with a layer of 4-5 cm.

Previously, several metal guides are installed on the mesh (you can take profiles) so that the screed turns out to be even. Check with the level if they lay down correctly. The poured screed is leveled and rubbed, after drying, the formwork is removed and the film is cut off.

What material is better to choose

Sound and noise insulation protects against various types of noise and dampens harsh sounds. If you initially determine what kind of noise causes discomfort and anxiety to a greater extent, then to neutralize it, you can choose the most optimal protection option.

- Impact noise - steps, falling objects, rearrangement of furniture. Vibroisotex laminate, Akuflex are suitable as a soundproof substrate.

- Acoustic noise - the voices of neighbors downstairs, the sound of the TV, slamming doors. Here cork backing, Izoplat, Shumanet 100 will help out.

- Sounds inside the apartment are well extinguished by Izopor, Izoshum.

The combination of insulation materials with different properties will make noise protection most effective. Some will reflect sound waves coming from the outside, while others will absorb noise inside the room. Together they will ensure a comfortable existence in the apartment.

Why do noise insulation

Everyone understands home comfort in their own way. But all opinions will agree on one thing - the house should be quiet. This is not absolute silence, it is impossible. But you don't always want to hear the loud voices of neighbors downstairs, flinch every time an object falls to the floor, or react to the loud thump of heels on the floor.

To understand what kind of sound insulation is required, it is necessary to systematize the sources of noise:

- structural, transmitted through architectural details and other structural elements of the building;

- acoustic, looks like an echo in an empty room, walking between walls, floor, ceiling;

- spatial, or household - loud steps, slamming doors, loud sound of a TV or radio.

Soundproofing materials can be used to protect against noise. Sometimes they completely drown it out, but more often they simply reduce the volume and harshness of sounds. Noise insulation under the laminate is the most effective means of dealing with any kind of noise. A pleasant bonus is the warmth in the apartment, since the sound-absorbing layer also has heat-insulating qualities.

Laminate boards conduct and amplify any sound. To remove this effect, it is enough to use the "floating floor" technology when renovating an apartment: the laminate is laid on a sound-absorbing substrate so that it completely excludes touching the walls and the screed.

The skirting board closing the technological gaps is attached to the wall through a soundproof tape and in the same way is separated from the laminate surface. Points of contact are not allowed here either. Otherwise, "sound bridges" are formed, along which the noise will spread throughout the floor covering and fill the room.