The cross-section of the core is one of the main quantities that allow you to correctly perform electrical wiring, taking into account the total load on the network.

Knowing what wire cross-section is needed for 6 kW, you can easily choose the optimal cable product in terms of values.

Conductor material

A competent choice of material for electrical wiring is not only a matter of an affordable price, but also a guarantee of uninterrupted "delivery" of electricity, as well as safety, fire resistance and reliability during operation.

Currently, about three hundred brands and several thousand varieties of the conductor are manufactured, differing in the type of material and other technical characteristics.

Aluminum

Aluminum is a soft and light, silvery-white metal widely used in the manufacture of cable products. The most significant advantages of aluminum wiring include:

- low weight of the material, which is especially important if it is necessary to install electrical transmission lines over several kilometers;

- the cost of a high-quality cable product available to a wide range of consumers;

- resistance to oxidation under the negative influence of open air and atmospheric phenomena;

- the presence of a protective layer that occurs on aluminum during operation.

Aluminum is not devoid of some drawbacks that limit the scope of use of wires of this type. The disadvantages of the material include a high level of resistivity and a tendency to heat with weakening of contact. The film formed on the surface of aluminum reduces the current conductivity, and the metal itself, as a result of frequent overheating, becomes excessively brittle.

As the practice of using aluminum electrical wiring shows, the standard service life is about a quarter of a century, after which it is imperative to replace such a network.

Copper

Wiring in residential or industrial buildings most often involves the installation of stranded copper wires.

VVG cable products with double PVC insulation have proven themselves very well.

Also, experts recommend paying attention to copper conductors in rubber KG insulation.

This option is characterized by good flexibility and ease of use.

Copper wires are much more expensive than aluminum cables, but such wiring is more reliable and much more durable. In addition, the advantages of copper wires include a high level of strength and softness, which minimizes the risk of breakage at bends and contact joints, resistance to harmful corrosive changes, and excellent current conductivity.

VBbShv copper armored cable products are characterized by double PVC insulation and fire resistance, due to which such wiring is in great demand in outdoor work.

Which heating boiler to choose if there is no gas in the house

Depending on the raw materials used for the operation of the boiler, the following varieties can be distinguished:

- Gas (if there is a gas holder);

- liquid fuel;

- solid fuel;

- electrical;

- universal (combined)

Let's consider each of them in more detail.

One of the options for using a gas boiler in the absence of main gas is to use liquefied gas instead of natural gas.This method is quite convenient, however, when heating a large house, and even subject to permanent residence in it, it turns out to be too troublesome: to maintain a comfortable temperature in the cold season, one gas cylinder can be enough for only two or three days.

In order for the boiler to work on liquefied gas, a special burner must be included in the kit. You should also pay attention to such a parameter as the minimum gas pressure at which the boiler will operate (the lower its value, the better): in this case, the boiler will consume gas from the cylinder to the maximum.

The main differences between liquid fuel boilers and gas boilers are the burner design and the type of fuel consumed (as a rule, it is diesel fuel). The advantages of such a boiler are obvious: fully automated and streamlined system operation with minimal need for user intervention, high efficiency (up to 95%), low odor and noise levels. In addition, if an autonomous power supply is installed in addition to the oil boiler (it is necessary for the operation of automation, pumps, burners), such a system becomes completely independent of power outages.

One of the main and significant disadvantages of such a heating system is the cost of fuel, the secondary one is the need for a container for storing fuel. The approximate consumption of liquid fuel when the boiler is operating at full capacity can be calculated using the following formula: fuel consumption (l / h) = burner power (kW) x 0.1.

In solid fuel boilers, firewood, coal (brown, stone, anthracite, coke), briquettes: peat, wood, coal and others can be used as fuel. There are models that can work both on a certain type of solid fuel and working on all of the above (as a rule, with lower efficiency). The main disadvantage of most solid fuel boilers is not yet completely eradicated: they require constant additional fuel loading and cannot work in automatic mode.

Separately, one can single out boilers operating on pellets - pressed wood pellets from sawdust, shavings and other waste from the woodworking industry without the addition of chemical additives. The use of environmentally friendly raw materials, economical consumption and the possibility of automatic portioned fuel supply (unlike their solid fuel counterparts) are the main advantages of pellet boilers.

In addition to dividing into varieties according to the type of fuel used, solid fuel boilers can be divided into types according to the method of combustion: classic, pyrolysis and boilers with long (upper) combustion.

Electric heating devices also have every right to be the main source of heat carrier in the house. Of course, the main disadvantage of using such equipment is considerable costs for consumed electricity, but the advantages in the form of ease of installation, environmental friendliness, compactness, safety in operation, low price and the absence of the need for chimneys and additional ventilation leave such a system every chance of existence.

Depending on the type of water heating device, electric boilers are divided into heating elements (they are the most common), electrode and induction.

Universal boilers operating on several types of fuel (some of them are even equipped with a built-in heating element) are convenient, especially if there is a prospect of someday supplying gas to the house - in this case it makes sense to consider the option of purchasing a unit that can be converted from any type fuel for gas. The combinations of the types of fuel used in such boilers are quite diverse. Boilers with two separate combustion chambers are also produced: one for gas, the other for a different type of fuel.

The main plus of combined boilers is, of course, their versatility. Of the minuses - as a rule, a complex design, cumbersome and often an insufficient number of additional features, such as, for example, a circuit for heating water or frost protection.

Each of the boilers listed above has a number of advantages and disadvantages. The most comfortable and convenient, but quite costly to operate, are liquid fuel boilers; solid fuel boilers are much more economical, but require constant intervention in work. Therefore, the final decision, which boiler to choose in the end, has to be made by the owner of the home: after weighing all the pros and cons and based on financial capabilities, needs, wishes and characteristics of the house.

What wire cross-section is needed for a 6 kW load?

In order to correctly determine the cross-section of the conductor, it is necessary to calculate the total power of all electrical devices in use.

The full performance of a significant part of household appliances will require the use of a wire that can withstand a load of 6 kW or more.

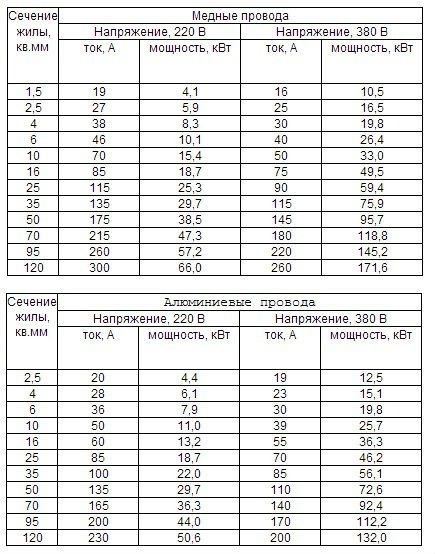

In this case, the best option would be to use a copper round wire with a cross section of at least 2.5 mm and double insulation.

Also, in conditions of such power indicators, it is allowed to perform work on the basis of a copper round wire in the form of twisted cores and double insulation.

The presence of aluminum wiring in the household, in order to ensure power indicators at the level of 6 kW, will require the installation of an aluminum flat wire with a cross section of 4.0 mm with single insulation.

A lot of outlets are required in the kitchen, as there can be a lot of equipment. Consider the options for placing outlets in the kitchen for ease of use.

You can see the wired switch connection diagram here.

You will find information on the purpose and importance of protective grounding in this article.

Criterias of choice

The main characteristics that you should pay attention to when choosing a conductor are represented by the material of the cores and their cross-section, design, thickness of the core insulation and sheath.

A quality cable product must be marked and certified.

The most important technical characteristics of the electric wire for a load of 6 kw:

- Durability. Single-insulated cable products have been in operation for about 15 years, and if double-insulated, they have been in operation for a quarter of a century.

- Oxidation stability. Aluminum belongs to metals that very actively interact with oxygen, which is accompanied by the formation of a thin film on the surface, which worsens the current conductivity. To isolate the contacts, special terminal blocks with a conductive paste are used.

- Strength indicators. Copper cable product is capable of reusable bend / unbend mode. Copper wires can withstand a little less than a hundred of such modes, and aluminum ones - about ten.

- Resistivity level. This indicator for copper cable products is 0.018 Ohm * sq.mm / m, and aluminum wires have a resistance of 0.028 Ohm * sq.mm / m.

Equally important is the ease of self-assembly. In this regard, copper wires are more convenient, since they do not require the use of special elements in the form of an end piece, terminal block or bolted connection.

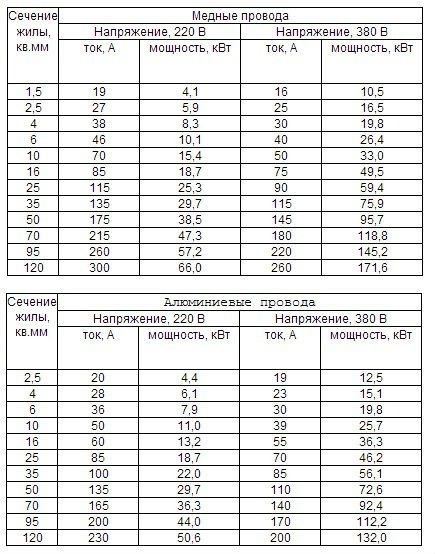

It should be remembered that copper cable products with a cross section of 2.5 mm2 are rated for 27 A, while the thickness of the aluminum wiring should not be less than 4.0 mm2.

Review of popular models and manufacturers

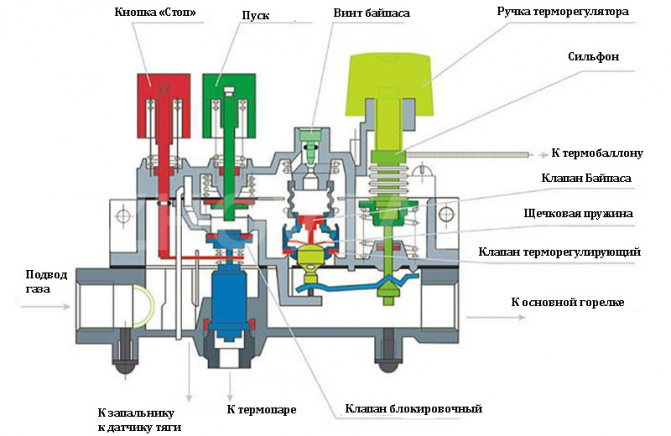

Automation of both domestic and foreign manufacturers is presented on the market of advanced gas equipment and related elements. According to the principle of operation, all devices are absolutely identical, however, in terms of construction, there are significant differences between them.

The cost of modules varies in the widest range. Simple mechanical products with a minimum of functions belong to the budget class and are sold at the lowest price. Advanced electronic panels are valued much higher, but provide the user with more detailed options for individual settings and control of work.

Electronic devices with the possibility of programming are considered luxurious. They enable the owner to set the equipment a work plan for a long period of time, taking into account seasonal weather conditions and the current air temperature outside.

No. 1 - EUROSIT 630 automation

Automatic non-volatile unit EUROSIT 630 manufactured by an Italian company Sit Group (Eurosit) in terms of sales, it occupies a leading position in the market.

It is considered versatile and works effectively with parapet and floor boilers with a capacity of 7 to 24 kW. Switching on / off, ignition of the pilot burner and setting the desired temperature are carried out with a single knob with a button.

The product is distinguished by a high level of reliability, withstands significant operational loads and has extensive functionality. Structural elements are "hidden" in the housing, to which the sensor cables and other connecting tubes are fed.

A cut-off device, a spring-loaded valve and a pressure regulator are located inside the unit. The gas supply is carried out from below or from the side according to the wishes of the user. At cost, the unit is included in the budget category.

No. 2 - Honeywell 5474 module

The Honeywell 5474 device is manufactured by the German concern Honeywellfor over a hundred years specializing in the development and sale of various types of automation. It works correctly with household gas boilers up to 32 kW.

The Honeywell 5474 automatic system is equipped with a basic set of control functions that guarantee efficient boiler operation with absolute safety for users.

The product in auto mode maintains the preset temperature of the coolant (from 40 to 90 degrees), turns off the boiler in case of fuel supply interruption, lack of draft of the required level in the chimney, occurrence of back draft or burner damping.

No. 3 - premium automation from Honeywell

In addition to inexpensive budget models, the company Honeywell manufactures other types of automatic equipment, for example, luxury chronothermostats of the ST premium series or programmed thermostats Honeywell YRLV430A1005 / U.

These electronic panels allow you to set the heating equipment the most detailed and accurate settings, up to changing the temperature regime several times a day, depending on the time of day, weather conditions and personal wishes.

# 4 - Orion device

Automatic device Orion manufactured in Russia. The package includes a piezoelectric ignition and a draft sensor.

The device turns off the gas in the event of an arbitrary burner damping or lack of the required draft. When the room temperature drops, the thermostat activates the fuel supply and the boiler resumes operation.

The transition to the flame reduction mode when a certain (user-specified) temperature is reached occurs automatically and saves fuel.

Sectional area calculation

A competent choice of wire section allows you to ensure the reliability and safety of electrical wiring. The main indicator on which the standard calculation of the area of a conductor or its cross-section is based is the level of the long-term permissible current value.

The calculation of the wire cross-section in accordance with the load involves the summation of the power of all connected electrical appliances with the expression of power in the same units of measurement - W or kW.

According to the calculations obtained, the optimal cross-section indicators are determined according to tabular data for 6 kW:

- 27 A and 220 V - the diameter of the copper conductor is 2.26 mm with a cross section of 4.0 mm2;

- 15 A and 380 V - the diameter of the copper conductor is 1.38 mm with a cross section of 1.5 mm2;

- 26 A and 220 V - the diameter of the aluminum conductor is 2.76 mm with a cross section of 6.0 mm2;

- 16 A and 380 V - the diameter of the aluminum conductor is 1.78 mm with a cross section of 2.5 mm2.

When choosing a cross-section, it must be remembered that the discrepancy between the area of the conductor and the current loads can provoke overheating, melting of the insulation, a short circuit and a fire situation.

Which cable and machine to choose for connecting a 9 kW electric boiler? - Electro Help

09.06.2019

Wire cross-section for transmission of alternating current in 220/380 Volt networks

Current, A Power, kW 220 V 380 V Section, mm2 (open) Cu Al Section, mm2 (in the pipe) Cu Al

| 6 | 10 | 13 | 16 | 20 | 25 | 32 | 40 | 50 | 63 | 80 |

| 1,2 | 2,2 | 2,9 | 3,5 | 4,4 | 5,5 | 7,0 | 8,8 | 11,0 | 13,9 | 17,6 |

| 2,3 | 3,8 | 4,9 | 6,0 | 7,6 | 9,5 | 12,2 | 15,2 | 19,0 | 23,9 | 30,4 |

| 0,5 | 0,5 | 0,75 | 1,0 | 1,5 | 2,0 | 4,0 | 4,0 | 6,0 | 10,0 | 10,0 |

| 2,5 | 2,5 | 2,5 | 2,5 | 2,5 | 4,0 | 4,0 | 6,0 | 10,0 | 16,0 | 25,0 |

| 1,0; | 1,0 | 1,0 | 2,0 | 2,5 | 4,0 | 6,0 | 10,0 | 10,0 | 16,0 | 16,0 |

| 2,5 | 2,5 | 2,5 | 2,5 | 4,0 | 6,0 | 10,0 | 16,0 | 16,0 | 25,0 | 50,0 |

Cross-section of copper wire for transmitting direct current at a voltage of 12 volts

Current, A Power, kW Cross-section, mm2 AWG value

| 16,5 | 21,5 | 25,0 | 32,0 | 43,5 | 58,5 | 77,0 | 103,0 | 142,5 |

| 0,20 | 0,26 | 0,30 | 0,38 | 0,52 | 0,70 | 0,92 | 1,24 | 1,71 |

| 0,5 | 0,75 | 1,0 | 1,5 | 2,5 | 4,0 | 6,0 | 10,0 | 16,0 |

| 20 | 18 | 17 | 15 | 13 | 11 | 9 | 7 | 5 |

Note 1. The current values for 220 / 380V wires are given according to the standard row of automatic fuses, wire cross-sections are rounded up to the standard cross-sections of produced wires from the corresponding material.

Note 2. The data are given for a temperature of 30 ° C. For higher temperatures, go to the next (larger) section for every 20 ° C.

Note 3. When laying several wires in a bundle, the wire cross-section should be increased: for 2-9 wires in a bundle by 80%, for 10-20 wires by 160%.

Note 4. “AWG Value” is the American Wire Gauge System marking for a wire, especially used for speaker cables.

A source:

Related Articles

With the onset of winter, you want your home to be warm and cozy. An electric boiler is able to provide comfortable conditions for living in a private or country house during the cold season.

There are many models of electric boilers on the market for various heating systems. When the choice has already been made, a problem arises, but how to properly install an electric heating boiler.

Let's figure this out.

Source: https://elektriki23.ru/rekomendatsii/kakoj-kabel-i-avtomat-vybrat-dlya-podklyucheniya-elektricheskogo-kotla-na-9-kvt.html

CHOICE OF ELECTRIC BOILER FOR HOME

To choose the right electric boiler for heating a house, you need to take into account many factors, including the material and thickness of the walls, the glazing area, the air temperature outside in winter in your area, the height of the ceilings and many others.

Often, such calculations are entrusted to specialists who make a house heating project that takes into account all the necessary characteristics of the system, including the type and power of the electric boiler, often even a certain specific model or several to choose from is offered.

When independently choosing the required power of an electric boiler for heating, it is usually customary to use the following formula:

1 kW of power is required for heating 10 sq.m. houses.

The rule is relevant for single-circuit boilers used only for heating rooms, but if there are two circuits, one of which is used to heat water in the hot water supply system, the calculation must be changed, the same should be done with a ceiling height above the standard 2.5-2.7 m and in some other cases.

So, in our example, house area 120 sq.m. therefore, an electric boiler with a capacity of 12 kW was chosen, model ZOTA - 12 series "Econom".

After all the theoretical calculations, let's see if this boiler is suitable for the permitted (allocated) power for the house. We have this 15kW, with a three-phase input, respectively, in terms of power, a 12kW boiler suits us.

Of course, if the electric boiler operates at the maximum of its capabilities, only 3 kW of the allowed ones will remain for the rest of the consumers at home, which is quite small. But since the boiler will be a backup, and will only turn on when the main gas boiler is faulty, such a decision was made acceptable.

Automation design

All the internal equipment of automation for gas boilers, which is used when installing a heating system, can be divided into categories, there are only two of them:

- the first category is those devices that ensure the safe and correct operation of all boiler equipment;

- the second category is those devices that can significantly increase the comfort when using the boiler.

Safety automation for gas boilers consists of the following elements:

- the module that provides control over the flame. It consists of a thermocouple and a gas valve that acts as an electromagnetic valve and shuts off the fuel supply;

- also there is a device that protects the system from overheating and maintains the required temperature regime, the thermostat takes on this task. He independently, if necessary, turns on or off the boiler, at those moments when the temperature approaches the specified peak levels;

- the sensor that controls traction. This device works on the basis of vibrations, depending on how the position of the bimetallic plate changes. It, in turn, is connected to a gas valve, which cuts off the gas supply to the burner;

- there is also a safety valve that can be responsible for dumping excess coolant (for example, air or water) in the circuit. Some manufacturers immediately provide an element to help shed excess.

The devices that are included in the security system are divided into the following types:

- mechanical;

- and powered by a power source.

They work either under the influence of a drive and the controller that controls them, or they are coordinated electronically.

Automation provides the user with more comfortable functionality, which is additional:

- automatic ignition of the burner;

- flame intensity modulation;

- self-diagnostic functions.

But this functionality is not limited to the internal design of the models.

Some design features of the models have such additions as sending data and processing them by an electronic system on equipment equipped with controllers and microprocessors. Then the following situation occurs: based on the data received, the controller itself begins to adjust the commands that activate the drives of the machine's system.

The mechanical automation of a gas boiler also requires detailed consideration.

- The gas valve is completely closed and the heating unit is inoperative.

- In order to start a mechanical gas boiler, a washer is squeezed out, which starts the fuel and opens the valve.

- The valve opened under the influence of the washer, and gas flowed to the igniter.

- Ignition is in progress.

- After that, gradual heating of the thermocouple begins.

- The electric shut-off magnet is energized to ensure its open position so that fuel access is not obstructed.

- Mechanical rotation of the washer adjusts the required power of the gas heating device, and the fuel in the required volume and with the required pressure fits onto the burner itself. The fuel ignites, and the boiler plant begins to exist in operating mode.

- And then this process is controlled by a thermostat.

You will be interested >> Buderus gas double-circuit boiler

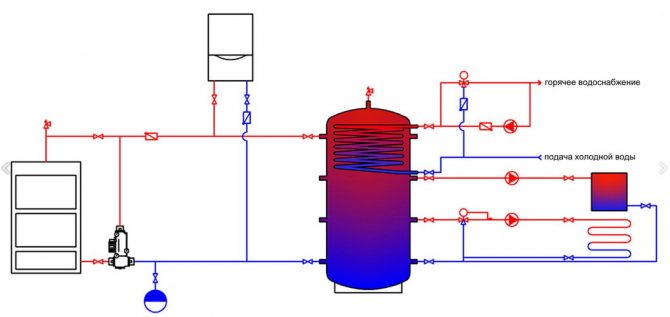

ELECTRIC WIRING FOR ELECTRIC BOILER

Now that the required boiler power for heating the house has been determined and a specific model has been selected, we make electrical wiring for it.

To do this, we will use the data from the article "Diagram of connecting the electric boiler to the mains", which shows in detail all the main schemes for connecting any electric boilers to electricity, and in addition, recommendations are given on the choice of the cable cross-section and the circuit breaker.

Our "ZOTA - 12" boiler is three-phase, designed to operate in a 380 V network, this information is reflected in the documentation for the boiler, in addition, the power consumption indirectly indicates this, 220 V boilers are rarely more than 8 kW.

In addition, you can look at the number of installed heating elements (Tubular electric heaters) and their connection diagram. For boilers for 380 V, at least three are usually installed.

Possible schemes for connecting the boiler to a three-phase network, at least two, one is used when the heating elements are designed for 220 V and are connected "star", And the other is used in cases when the heating elements of the electric boiler are designed for a voltage of 380 V and are connected"triangle».

There are several ways to determine which connection diagram is suitable for your boiler, the simplest is to refer to the diagram in the documentation, for the ZOTA-12 boiler it is located on the back of the control panel and looks like this:

As you can see, this boiler has a Zvezda connection scheme, which means that the heating elements are designed for a voltage of 220 V. This is also confirmed by a direct examination of the contacts for connecting wires to the heating elements, they are also prepared for star connection. Their contacts for connecting the neutral conductor are connected with a jumper, phases will be connected to the free contacts in turn, each with its own.

Hence it follows that the scheme for connecting a three-phase electric boiler to electricity with heating elements for 220 V, a "star" connection is suitable for us.

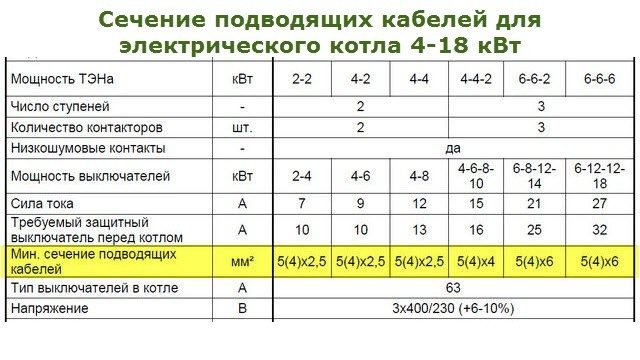

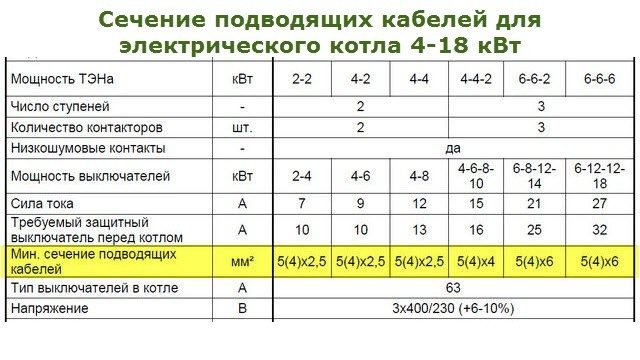

It remains to choose the required cable cross-section for the electric boiler in terms of power and the rating of the circuit breaker... To do this, look at the table from the article:

Whence it follows that with a route length of up to 50 meters, we need to lay a 12 kW power up to a three-phase electric boiler, a VVGngLS five-core cable with a conductor cross-section of 4 sq. Mm. (VVGngLS 5 × 4kv.mm.) And supply a 25A differential circuit breaker, or a circuit breaker (AB) for 25 amperes - C25 and a residual current device (RCD) for 32A.

Now, having chosen an electric boiler and having decided on the connection diagram and wiring parameters, you can install it, after which we will continue to connect to electricity.

The connection of the ZOTA electric boiler to the mains is described in the next part of the article - HERE!

Power of electric heating boilers

The relative advantage of an electric heating boiler is a wide power range of various boilers and a stepwise power regulator for each boiler separately.

There are two power ranges for electric boilers.

- Range from 4 to 18 kilowatts;

- From 22 to 60 kilowatts.

The indicated boiler ranges assumes:

- For boilers 4-8 kW, two switching stages;

- Boilers 8-18 kW three switching stages;

- For boilers 22-60 kW, there are four or three switching stages.

Stepwise switching of power allows you to quickly integrate power with the temperature "overboard", this saves electricity consumption and reduces the cost of heating. Also, do not forget that an electric boiler does not require operating costs (purchase and delivery of fuel, preparation of a special room) and practically does not require maintenance costs. The form of use is very simple: connect it correctly and use it.

The principle of operation of an electric heating boiler

The general principle of an electric heating boiler is not complicated. In fact, this is a large electric kettle, where powerful heating elements heat the coolant in the heating system. Of course, electric boiler heating devices are much more complicated. It has both an automation system and a remote control system and a temperature control system and a circulation pump.

Despite the design, type and brand of the electric boiler, they have one unifying type of work, the electric boiler must be correctly connected to the power supply.

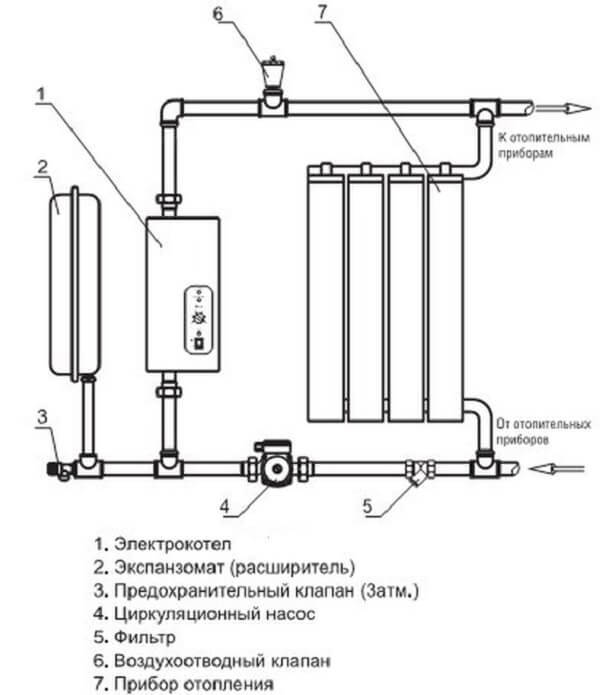

Battery connection steps

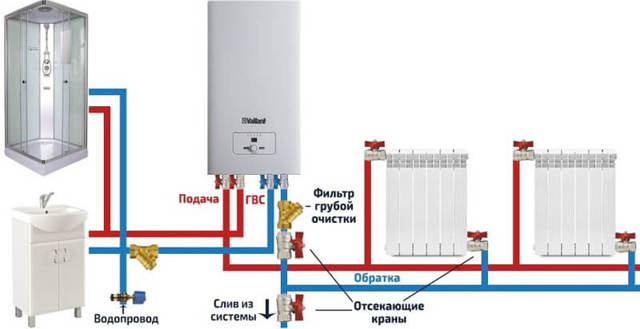

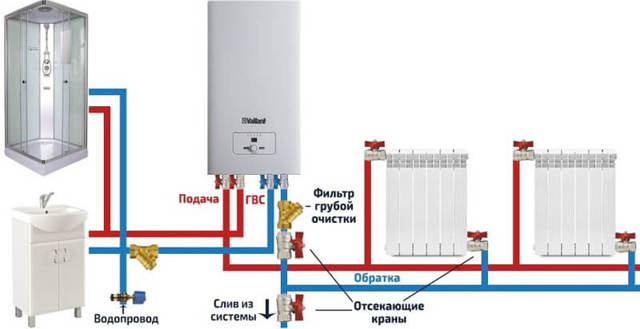

The procedure for connecting radiators in a heating network with a gas boiler depends on the circuit and its design features. Among the rules for installing heating equipment, the following can be distinguished:

- in systems with natural circulation, it is necessary to ensure the slope of the direct and return lines, and the boiler is placed below the level of the batteries;

- for the safe functioning of the boiler, it is necessary to supply a gas filter and a safety group with a safety valve, an automatic air vent and a pressure gauge;

- mandatory elements of the heating system are a coarse filter to remove impurities from the coolant, ball valves and a thermostatic valve.

When installing a combined heating network, in which radiators and "warm floor" are combined, the connection to the boiler is carried out using a distribution manifold. It evenly distributes the coolant, and the same heating is provided by installing a circulation pump in each circuit.

To control the temperature in rooms and increase the efficiency of heating networks, TM Ogint offers Mayevsky taps, thermostats and shut-off valves. They are installed during the installation of radiators and allow you to timely remove air from the system, maintain the desired microclimate and repair individual devices.

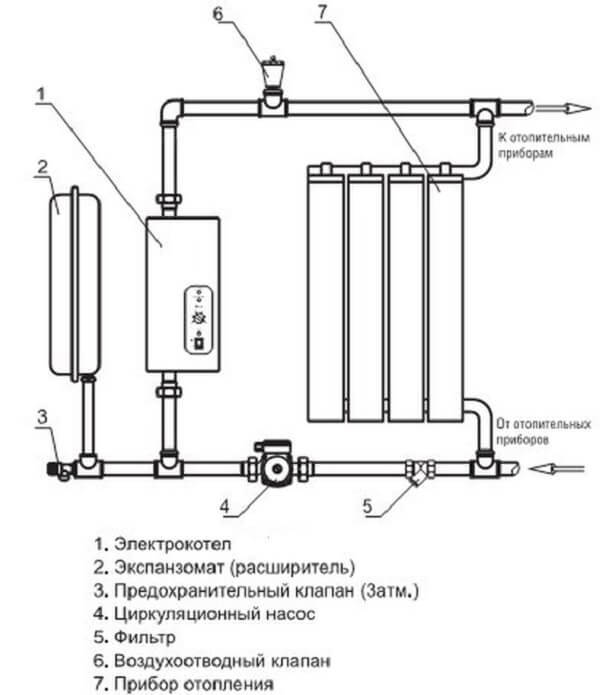

Correct connection of an electric heating boiler

By design, an electric heating boiler is a metal cabinet. Boiler mounting type is hinged. There is a special hole to enter the electric power cable into the boiler, and all the electrical equipment of the boiler is located in the electric cabinet of the boiler.

Choosing an electric cable for a heating boiler

There are no special calculations and "pitfalls" in connecting an electric heating boiler to the power supply. It must be connected like any other household appliance in terms of power consumption and according to the standards for laying electrical wiring in the house.

Rules for connecting an electric heating boiler

To connect an electric heating boiler, a separate wiring line (a separate group) is planned with its own automatic protection. A circuit breaker is used to protect the electrical cable of the boiler. The rating and type of the circuit breaker is selected according to the power of the boiler, or rather, according to the power of the heating elements included in the design of the boiler.

Heating boiler wiring

The power supply of the heating boiler depends on its design and the connection diagram of the heating elements. For the consumer, all the necessary data are indicated in the passport for the boiler.

Power circuit of an electric heating boiler with three heating elements

The heating boiler can be connected with a five-core or four-core cable. We look at the cross-sections of the cable cores in the passport for the boiler and in the table below.

As you can see in table 1, for the power supply of an average boiler, cables with a cross-section of conductors from 2.5 mm (4 kW) to 6 mm (18 kW) are needed.

Table 1

In table 2 we see cable cross-sections for more powerful heating boilers. As you can see, for powerful heating boilers with a thermal power of 60 kW, you need an electric cable with 25 mm cores and a safety circuit breaker in front of the boiler of 100 Amperes.

table 2

Let's orientate ourselves and see a simple thermal calculation for the house. I will not show the calculation with heat losses, I will not even take into account the height of the ceiling. The simple calculation is very simple.

To heat one square meter of a house, you need 0.1 kW of the boiler's thermal power. That is, for a house with an area of 100 sq. meters you need a boiler of 10 kW of thermal power; for a house of 300 sq. meters you need a boiler of 30 kW. And this means that even for a house with an area larger than the average, an electric cable with a cross-section of no more than 10 mm will be needed.

Note: Speaking about the cross-sections of the cable cores we mean only copper cores, by the core cross-section we mean the cross-sectional area of the cable core cross-section specified in the cable passport.

Diagram of connecting an electric boiler to a heating system and a network for 220 and 380 V

Modern electric boilers are very popular because they are very easy to install and configure. They do not require the construction of a chimney system and exhaust ventilation, the presence of a separate room for the boiler.

Typical modifications of electric boilers already contain all the necessary components and functional units: network pump, expansion tank, thermostat, safety group.

Correct installation affects the complexity of the connection. Photo source: termo-volga.ru

Therefore, it is very simple to connect the electric boiler, since you will need to tie up a minimum number of in-house utilities and you will not have to make a choice of an expansion tank.

Types of boilers by type of heater

Today, there are many modifications of units that differ in the connection diagram of an electric boiler, and are classified according to:

- configuration;

- characteristics of thermal conditions;

- structural solutions;

- type of heating;

- manufacturing plants;

- cost.

All electric boilers provided for water heating, according to the method of heating the coolant, are divided into 3 main categories:

- Heating elements that use tubular heating elements.

- Electrode or ionic / electrolysis, using the ability of water to heat up as it passes through an AC electrode.

- Induction, using the properties of ferromagnets to warm up under the influence of an induction current.

Boiler selection

The choice of a boiler unit for heat supply is made according to the heat output, the parameters of the electrical network and the principle of the heating element. The price of the heating kit depends on the last parameter. Such electrical units have increased functionality - all models are equipped with block automation with a temperature controller.

Modern modifications of electric boilers are implemented with various peripheral devices - weather-dependent sensors, room thermostats and GSM modules for controlling the indoor temperature at a distance from a mobile phone via the Internet.

The assembly level of block units is very high, which allows you to mount such heating yourself. The only exception is the installation and adjustment of the power supply lines to the unit, which must be carried out by certified specialists.

For example, a house with a total area of 150 m2 will require a boiler power: 150x1.2x0.1 = 18 kW.

How to connect an electric boiler to the heating system

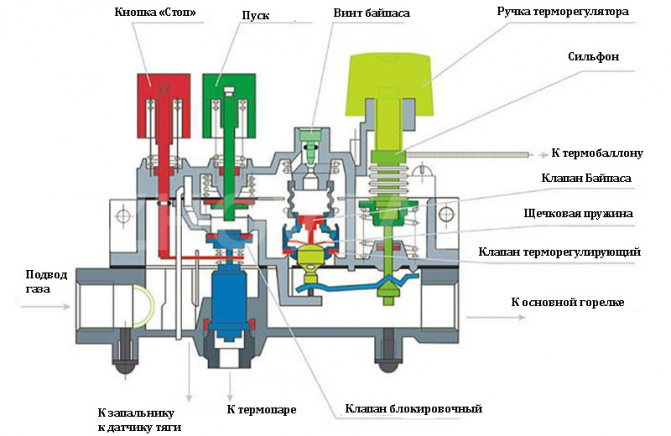

There are several standard piping schemes, one of which must be selected before connecting the electric boiler to the heating system:

- installation of the unit with the piping of the electric pump and expansion tank;

- installation of an electric boiler in a parallel operation with a solid fuel or gas boiler;

- piping with a hot water storage tank or an external electric water heater;

- connection of a double-circuit modification of an electric boiler to heating networks and hot water supply;

- connection to an indirect heating boiler.

Usually, modern electric boilers are equipped with all the necessary auxiliary equipment. The safety group protects the unit from high pressure and releases air from the closed-type water circuit using a diaphragm expansion tank.

Wiring diagram for a double-circuit electric boiler

On the straight section of the supply pipeline, a safety group is installed, and after it - a ball valve that cuts off the coolant supply. The circulation pump and dirt filter are installed in the return pipe.

If it is necessary to connect the boiler to an open heating system with natural circulation, then the heating pipes will need to be placed with a slope of 3 mm by 1 pm.

Electric boiler schemes for preparing hot water supply are used in two versions:

- double-circuit design of the boiler with two built-in heaters for the heating circuit and hot water supply;

- single-circuit boiler with external indirect heating water heater.

In the first version, the electric boiler is connected to the heating system according to the standard scheme.There are practically no difficulties here, the main thing is to correctly install the shut-off valves.

Single-circuit diagram. Photo source: twlwthrt.appspot.com

Connection with an indirect heating water heater is made using three-way shut-off valves. By a signal from a thermostat integrated in the storage tank, the valve switches the flow of heating water to heat up the DHW circuit or the heating system.

DHW loading in priority: until the water in the tank heats up to a certain temperature, the heating network will not receive heat energy.

How to connect the boiler to the mains

Before connecting the boiler equipment to the electrical network, it is necessary to thoroughly check its technical condition.

If problem areas are found, it will be necessary to carry out repair work, if it is not possible to increase the power supply of the existing line, reconstruct the in-house electrical networks with the involvement of certified specialists.

Laying the electrical cable for the heating boiler

The laying of the electrical cable is done according to the wiring regulations in accordance with the design of the house. For a wooden house in pipes or open, for a stone house in boxes or hidden.

The electric boiler is not connected through the socket, the power cable is led into the boiler through the factory connection holes and connected to the circuit breaker or terminals installed on the boiler body in the electrical cabinet.

Important! Any twisting, soldering, welding and other connections not provided for by the boiler design are prohibited.

Nuances to consider

Table of power consumption of various electrical appliances

Nobody can know exactly what household appliances will be in the house or apartment. For this reason, it follows:

- increase the total design power of a three-phase difavtomat by 50%, or apply an increase factor of 1.5;

- the reduction factor is taken into account when there are not enough outlets in the room for the simultaneous connection of equipment;

- for simplicity of calculations, the load should be divided into groups;

- powerful devices should be connected separately, taking into account the low-power load;

- to calculate a low-power load, the power will need to be divided by the voltage;

- wiring is the main factor to be guided by when choosing an automatic 3-phase switch; old aluminum wires can withstand 10 A, but if you take them for 16 A outlets, they can melt;

- in domestic conditions, models with a current rating of 6, 16, 25, 32 and 40 A are most often used.

When buying a three-phase differential machine, you need to take into account that the main markings are on the case or in the passport. Using formulas and tables will help you choose a model in accordance with the wiring in the apartment and the power of household appliances.

Connecting the heating boiler to the power supply

IN five-wire electrical network the phase power conductors of the cable are connected to the input terminals of the main circuit breaker of the boiler. The zero working conductor is connected to the connector marked with the letter "N". The protective conductor of the electrical supply cable is connected to the screw connector, which is indicated by the earth symbol.

Connecting an electric heating boiler in a five-wire system

If a the house has a four-wire network, then the phase conductors are connected in the same way, and the PEN conductor is connected to the screw connector with the earth symbol. In this case, the grounding clamp is connected to the neutral connector N with a PV-1 wire with a minimum cross-section of 2.5 mm2.

Connecting an electric heating boiler in a four-wire system

Note: Most often, the wiring diagram for an electric boiler assembled at the factory is adapted for a five-wire electrical network.

Summing up

The conclusions are ambiguous:

- A stabilizer for an electric heating boiler is an expensive pleasure.

- If the voltage in the network never drops below 170 V, then there is no point in the stabilizer. It is enough just to take a boiler with a 30% power reserve, so that, even at low voltage, it produces the required thermal power.

- If the boiler is already installed and it is imperative that it works at a very low voltage (below 170 volts), then you will have to install a stabilizer.

If you are an electrical ninja, you can try connecting only a circulation pump through the stabilizer. All other components of the electric boiler will work even at 140 volts. At the same time, the stabilizer can be taken the lowest-power and cheapest. But do not forget about reducing the power of heating elements. - The pump is the most vulnerable part of the boiler. If the boiler operates on the principle of natural circulation of the coolant (does not contain a pump), then it does not need a stabilizer.

And the most important thing: no matter how the electric boiler is connected, with or without a stabilizer, this does not save you from a complete power outage. Therefore, you always need to have a reserve in the form of a stove, "stove" or a non-volatile gas boiler that works without electricity.

Output

The connection of an electric heating boiler is done in compliance with the rules of the PUE. If you read the instructions of any boiler intended for heating a house with electricity, you will see recommendations such as "only professionals with the appropriate skills should make the connection ...". This is true. However, the connection itself is not as difficult as, say, a gas boiler. If you follow the PUE (electrical installation rules) and safety precautions when working with electricity, then you can connect the boiler yourself.

© Ehto.ru

Related Articles

What is the principle of operation of automation

If we take into consideration the principle on which the safety system of the device works, then an unambiguous conclusion will be drawn from this - the main points of the entire structure device are:

- safety valve;

- main valve.

They are responsible for stopping the gas supply to the working chamber. They also open up access to fuel. All automatic equipment for gas boilers is built on this principle.

The difference is observed only in the fact that there are functions that come as additional devices in the operation, which are equipped with automatic adjustment.

That is, the device itself works due to the fact that both valves interact.

You will be interested >> Stages of connecting a double-circuit gas boiler

Basically, all systems operate according to the following scheme:

- The regulator is set to the position required for the temperature to begin to heat the room.

- A signal is sent to the sensor that the system is working.

- The shutoff and simulator valves begin to regulate the amount of fuel flow. As a result, the intensity with which the boiler is heated is set.

In order to understand how all these internal processes occur, it is necessary to consider the very design of the automation device for gas boilers.

It is better to dwell on this point in detail, because then the question of which boiler to choose for home gas heating will be more understandable. And it will also be possible to purchase the most efficient model with a high safety threshold.