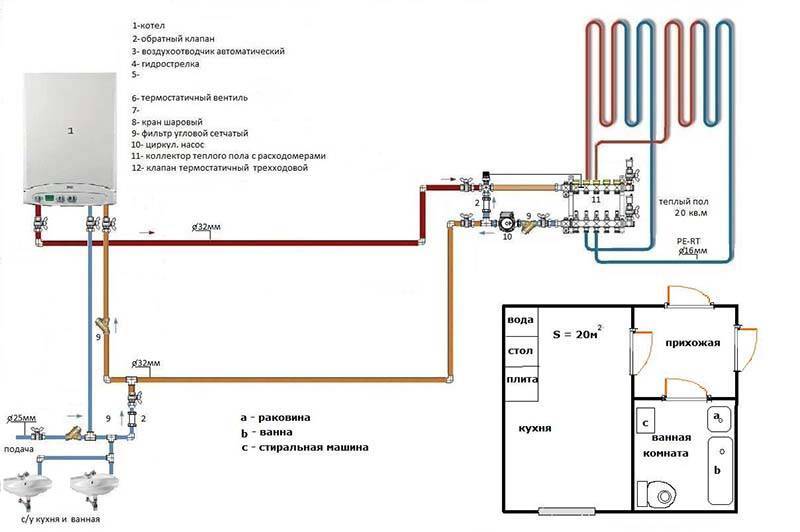

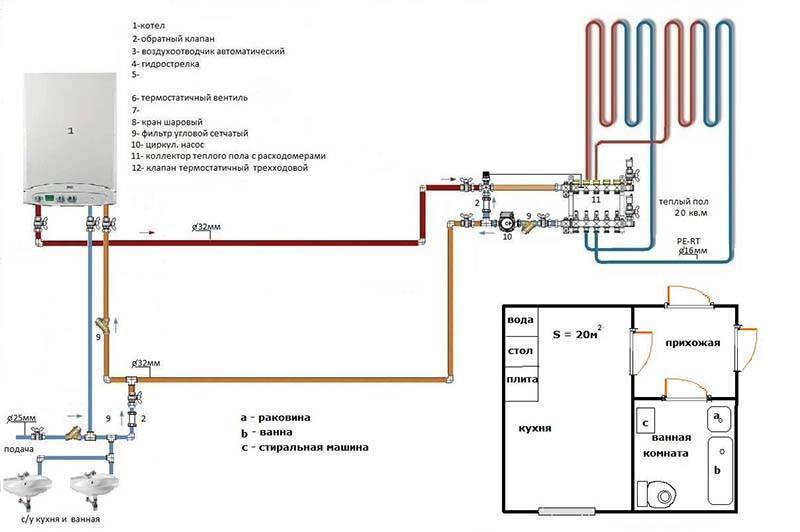

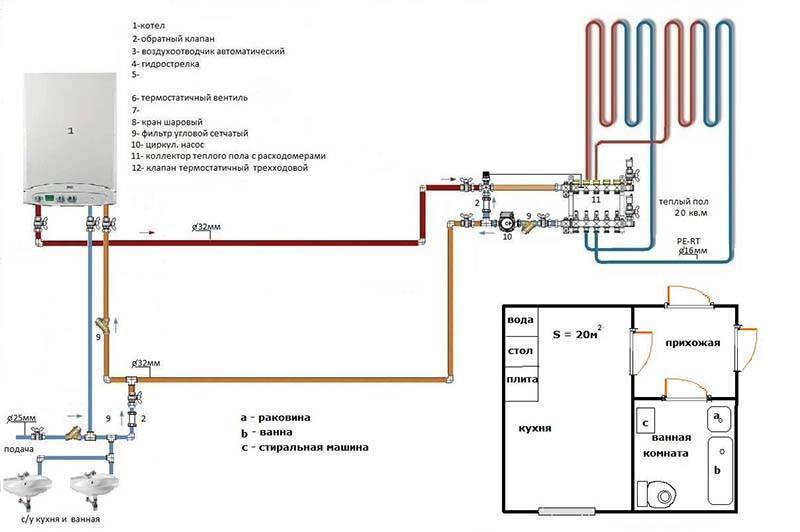

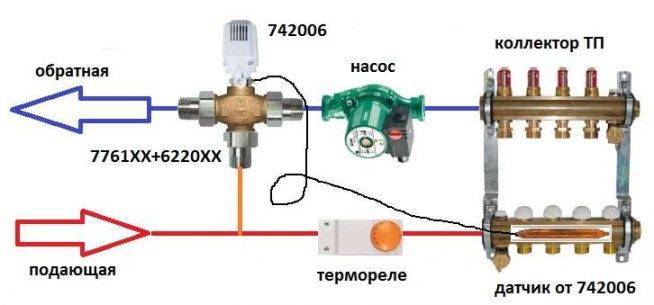

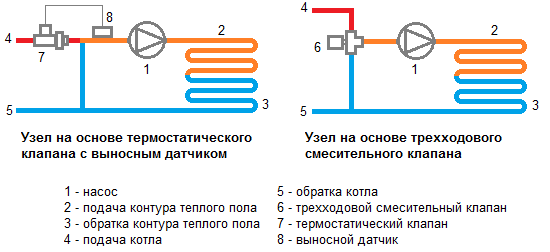

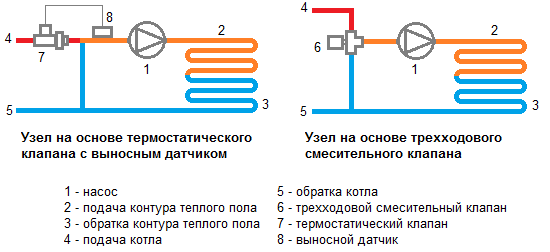

Connection via 3-way valve

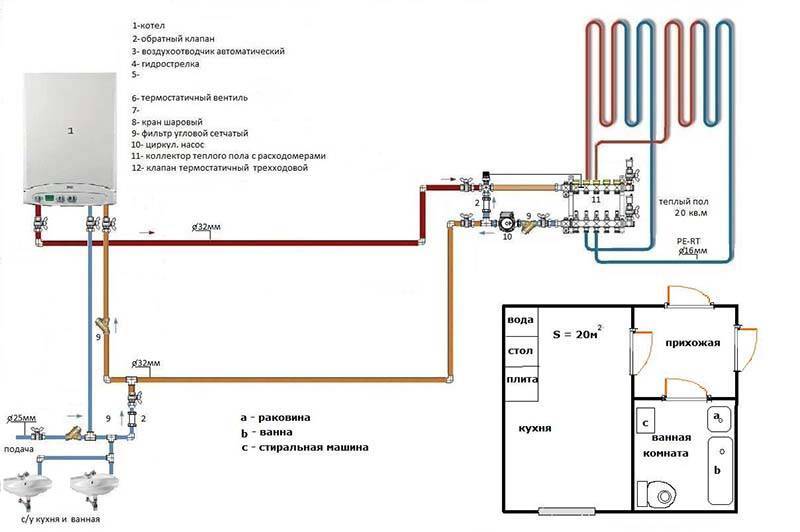

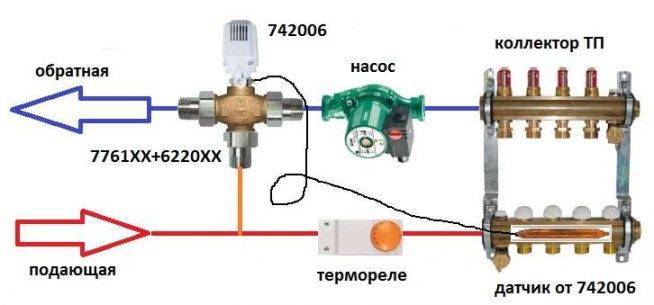

A slightly different assembly and principle of operation is the option of connecting a heated floor through a three-way valve, which is shown in the diagram below with an arrow.

This scheme is used in cases where, in addition to the warm floor, the system also contains a main heating circuit. The temperatures of the coolant in them will be different, which is why a mixing valve is needed.

Connection via 3-way valve

- This device not only regulates the supply of water to the circuit (mounted on the supply pipe in front of the circulation pump), but at the same time, using a built-in thermostat, controls its temperature, mixing the cold heat carrier with the hot one. In this case, the pressure in the pipeline corresponds to the pressure set at the pump.

- However, the valve cannot accurately meter the amount of water for mixing, therefore the temperature in the floor circuit may be either subcooled or too hot. The problem is solved by connecting a servo to it, since it is he who balances the operation of the system and protects the floors from overheating.

Three-way mixing valve

A circuit with a mixing valve is quite accessible for self-assembly, and the equipment for it does not require large costs.

Design features and principle of operation

The 3-way valve is a tee-shaped device with one outlet and two inlets. From the outlet, fluid is supplied with a predetermined temperature regime to the circuit.

The inlet openings are designed for mixing the coolant. The cooled return flow enters the first opening, and the water heated from the boiler enters the second. There is a shutter between the two inputs, which opens when the sensor heats up to the maximum temperature, which is set on the valve itself.

The working process of the three-way valve in the underfloor heating system is carried out in the following sequence:

- water flows to the installed collector unit;

- the valve sets the heating agent heating level;

- when the temperature rises above the set in the three-way device, the passage for the chilled liquid opens;

- there is a process of mixing a cold stream with a hot one;

- when the set temperature is reached, the opening for water supply from the return circuit is closed.

What does a three-way valve for underfloor heating look like?

The three-way valve contributes to the supply of coolant from the pipeline of the water floor with a set temperature, and also allows you to exclude overheating of the heating system. In this case, the device does not protect against the return flow of cold liquid in the circuit.

Two-way valve circuit

Install it on the supply from a heating device. In the place of the jumper between the supply pipeline and the return line, a balancing adjustable valve is mounted. It is adjusted in accordance with the required temperature of the supplied water, usually using a hex key. It is needed to adjust the amount of cold coolant.

The temperature sensor is placed after the pump, which in turn moves the water in the direction of the comb. Only now the intensity of movement of the heated coolant from the boiler changes. Thus, the temperature of the supplied water changes at the inlet of the pump, while the cold flow is adjusted and stable.

Mixing always takes place and water from the boiler does not directly enter the circuits, since this is impossible. This scheme can be considered more reliable.But it should be noted that the mixing group, equipped with a two-way element, is capable of heating 150-200 "squares" of the area, since there are no valves of greater capacity.

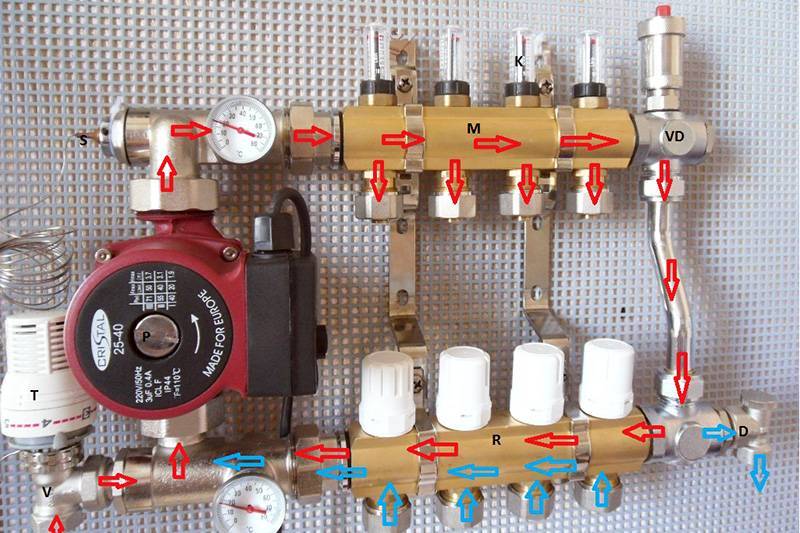

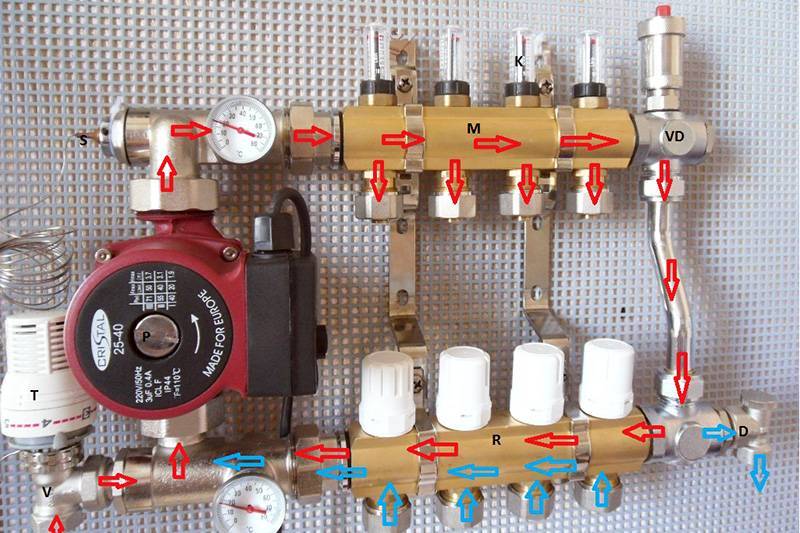

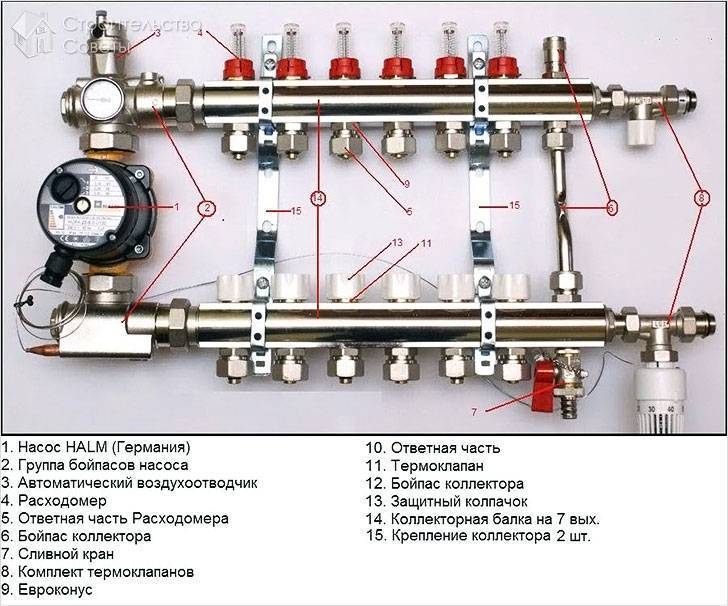

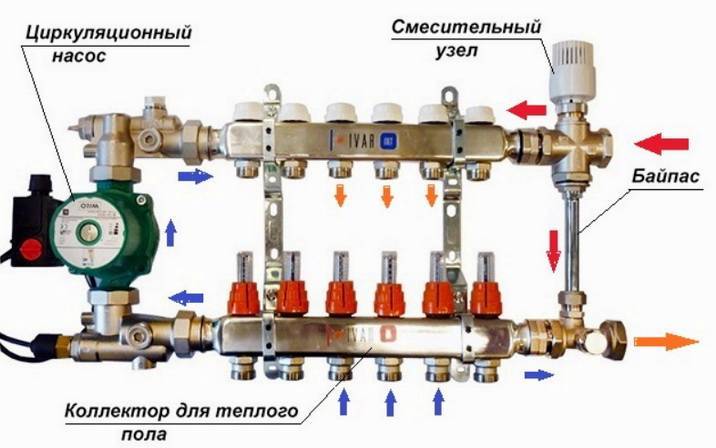

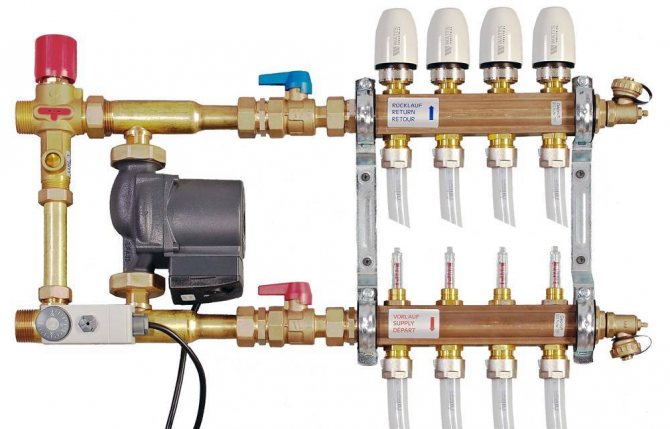

Collector for underfloor heating system

For underfloor heating, a common collector unit is most often mounted, or a separate collector is installed in front of each heating circuit. If the latter option is implemented, then all collectors are equipped with flow meters, thermostats, and the following elements:

- Return and supply mixing valve;

- Heater balancing shut-off valve;

- Overflow valve.

It is possible to assemble a collector for a warm floor yourself according to different schemes, and in some schemes of collector nodes bypasses are used, but not always - only in single-circuit systems. If the underfloor heating system is organized according to a two-circuit scheme, then the collector can be connected without a bypass to the secondary circuit.

Double-circuit underfloor heating system with a collector

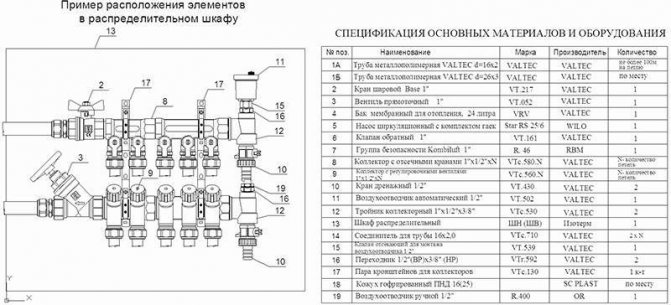

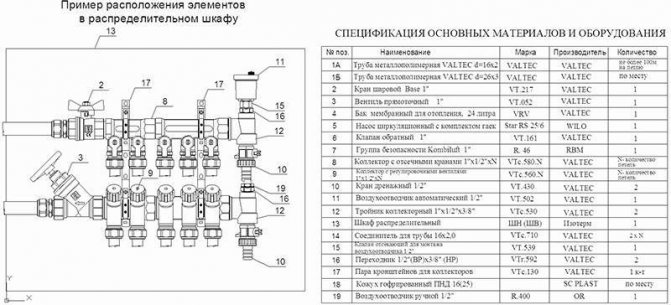

Before assembling a manifold assembly for a warm floor, weigh your possibilities - sometimes it is easier to buy a ready-made structure. If the collector is to be bought, it is better that all its parts and elements are from the same manufacturer. When assembling the unit yourself, you must choose the material from which the main components of the unit will be assembled: from copper, steel, polymers or brass.

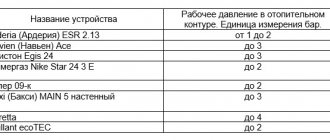

Also, when choosing an industrial design, it is important to consider the following parameters:

- How many heating circuits will be in the system (usually from 2 to 12), the total length of the pipeline and the throughput of the circuits;

- Maximum allowable pressure in pipes;

- The possibility of expanding the heating system;

- Manual or automatic control of the collector;

- Electric power of all units and assemblies;

- The diameter of the internal openings of the collector (throughput).

DIY collector

The most efficient operation of the assembled manifold assemblies can be ensured by connecting to them heating circuits of the same length. In order to equalize the pipelines in length with sufficient accuracy, they are divided into equal segments, which are connected to the collector. The easiest way to calculate the collector unit is in a special computer program or on an online calculator so that a phenomenon called "heat zebra" does not appear, that is, uneven heating of the floor.

For the calculation, you need the following data:

- Type of decorative flooring;

- the area of the heated room and the plan for placing large items in it;

- Material and diameter of the circuit pipes;

- Boiler rated power;

- Floor insulation type.

Reservoir calculation

Collector installation - recommendations

When designing a floor heating system, you first need to find the optimal place for installing the collector. As a standard, the unit is installed in a manifold cabinet, and the cabinet itself is mounted at a height of 30-40 cm from the floor level next to the supply and return.

In order not to blame your own mistakes and ensure maximum heating of the underfloor heating pipes, study the instructions for connecting the collector. Then assemble the assembly in the following sequence (this applies to the industrial manifold assembly):

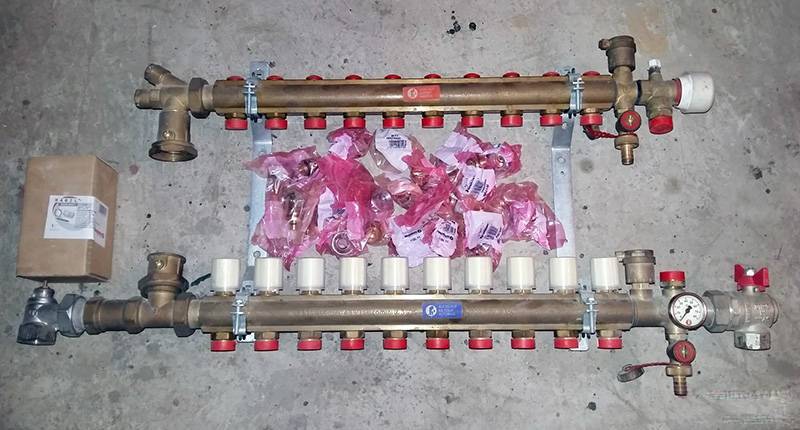

- Unpack the pipes for direct and return flow of the heating medium. The pipes must be with flow meters and supply valves. If the manifold is multi-section, assemble the sections into one structure;

- From the assembled sections, you need to assemble a unit on brackets (included);

- Next, we install shut-off valves, automation, sensors and the rest of the connecting fittings;

- We attach the unit to the wall or in the cabinet, mount the thermostat, servo drive and circulation pump;

- We connect pipes from the boiler and pipes from the heating circuits of the "warm floor" system.

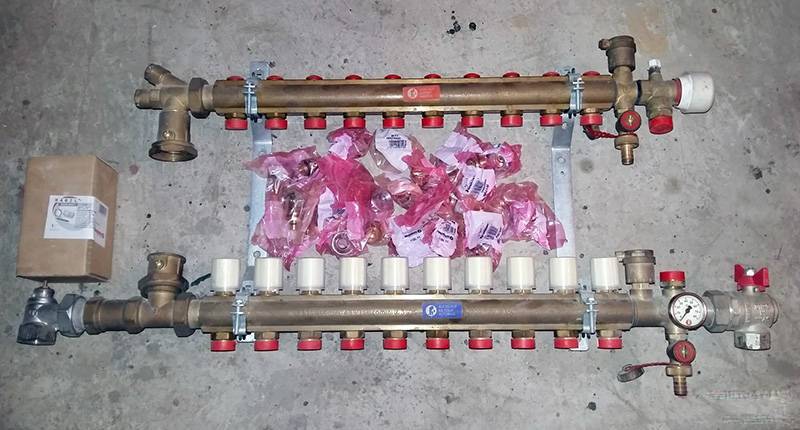

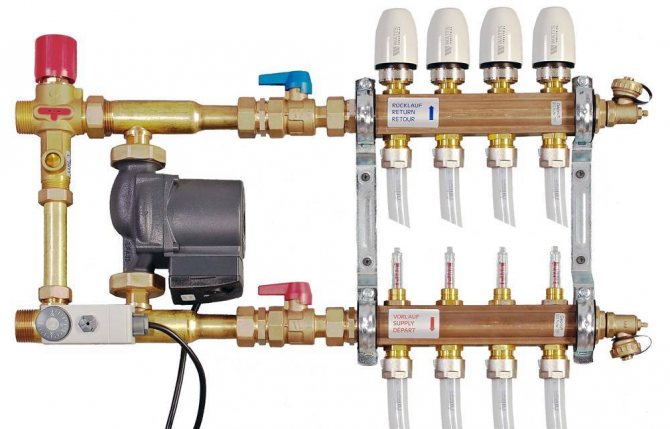

Collector set

Now the connection diagram of the underfloor heating collector is pressurized, after which the concrete screed can be poured. The thermal settings of the collector can be carried out after the installation of the topcoat.

Do-it-yourself manifold assembly

A factory collector is a rather expensive product, so many craftsmen want to make it with their own hands. Many items will still have to be purchased, but the cost will be cheaper. The easiest way is to solder a self-made collector from PVC pipes and fittings Ø 25-32 mm. You will also need tees and bends of the same diameters, and shut-off valves.

Homemade collector

The number of valves and fittings is calculated according to the number of heating circuits. Of the tools, you need a soldering iron for propylene elements and nozzles for it, special scissors for cutting pipes and a tape measure.

The marking of the collector consists in marking and cutting off the pipes of the required length, observing the minimum distance between the tees. Valves and transitions are soldered to PVC tees with a soldering iron. Fittings for connecting the pump are soldered to this structure. As you can see, everything is simple, but it is better to buy more complex manifold units ready-made.

Controlling the operation of the underfloor heating system

The efficiency of heating devices depends not only on their power and adjustments, but, first of all, on the state of the heated object. If the building is not sufficiently insulated, no system will create conditions for a comfortable life in it. Walls made of porous materials, such as sawn shell rock or foam concrete, reduce heat loss by 20 - 25% compared to ceramic bricks, additional wall insulation and wind protection, as well as insulation of the roofing cake, give approximately the same effect.

Turning to the issue of controlling the operating mode of underfloor heating, it should be noted that two main approaches are used: manual control of the mixing unit and the use of automatic control systems.

The first option is used for small buildings consisting of 2 or 3 living rooms and auxiliary premises. The mixing mode is set manually with an ordinary crane.

For complex developed heating networks, this method is unrealistic due to the multifactorial nature of the process and complex automated devices are used.

Heating control systems can be:

- group - their task is to convert the temperature of the water leaving the boiler at 75 - 90 degrees to 35 - 40 degrees at the inlet required for low-temperature circuits and control the return flow temperature by making adjustments to the mixing mode. Naturally, changes in weather conditions also affect the amount of heat transfer in the heating system;

- individual - the flow rate of the heat carrier for each circuit is set in such a way that the room has a constant temperature in the specified interval. This is achieved either by installing a room temperature sensor or by monitoring the return flow temperature downstream of the register directly at the manifold assembly.

Equipment

Within the framework of a small article, it is impossible to display all the variety of devices, so let's dwell on some of their typical representatives:

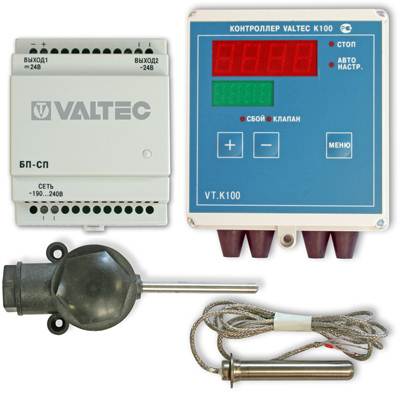

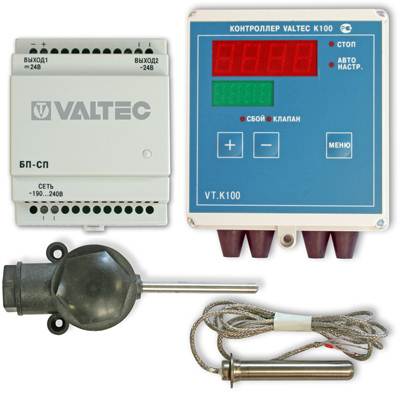

Group controllers

Heating is controlled by applying an impulse to the control valve servo, which performs the appropriate manipulation. In one controller, up to 10 channels from sensors are installed to adjust the mix in various circuits. Programming of work is possible.

Underfloor heating operating mode control unit

When an external temperature sensor is connected, the heating medium heating temperature mode changes preventively.

Thermostats

A remote device capable of measuring the temperature at the installation site and transmitting data about it to the heating system control unit. The device can transmit information both by wire and by radio. It should be installed in a place protected from sunlight and away from drafts.

Room thermostat for water floor

A device for direct control of the temperature of the heat carrier flow. P is located in the rupture of the pipeline. Usually equipped with a servo motor to control the damper. Calculated at work at a pressure in the system up to 16 atmospheres.

Three-way thermostatic valve in the underfloor heating system

Servo

A device that drives a valve shut-off device (stem). The device is small in size and generates a force of more than 10 kg.

Servo for underfloor heating valve

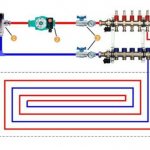

Direct connection diagram

You have a boiler, after which all safety fittings + circulation pump are installed. In some wall-mounted versions of boilers, the pump is initially built into its body.

For floor-standing copies, you will have to install it separately. From this boiler, water is first directed to the distribution manifold, and then scatters along the loops. After that, having completed the passage, it returns through the return to the heat generator.

With such a scheme, the boiler is directly adjusted to the desired temperature of the TPs themselves. You don't have any additional radiators or radiators here.

What are the main features worth paying attention to here? First, with such a direct connection, it is advisable to install a condensing boiler. In such circuits, operation at relatively low temperatures for the condenser is quite optimal.

In this mode, it will reach its highest efficiency

In such circuits, operation at relatively low temperatures for the condenser is quite optimal. In this mode, it will reach its highest efficiency.

If you use an ordinary gas boiler, you will soon say goodbye to your heat exchanger.

The second nuance concerns solid fuel boilers. When you have it installed, for direct connection to underfloor heating, you also need a buffer tank.

It is needed to limit the temperature regime. It is very difficult to regulate the temperature directly with solid fuel boilers.

How to assemble and connect the manifold correctly

Install the frame - the collector is mounted horizontally directly on the wall, or in a cut-out niche. The only condition for installation is free access to the arrow of the heating pipes. It is also possible to install a collector cabinet with your own hands.

The cabinet will allow you to hide the wiring from prying eyes, which is especially important if a bathroom or hallway is used under the boiler room.

Connection to the boiler - the coolant is supplied from the bottom, the return flow goes from the top. Ball cutoffs must be installed in front of the frame.

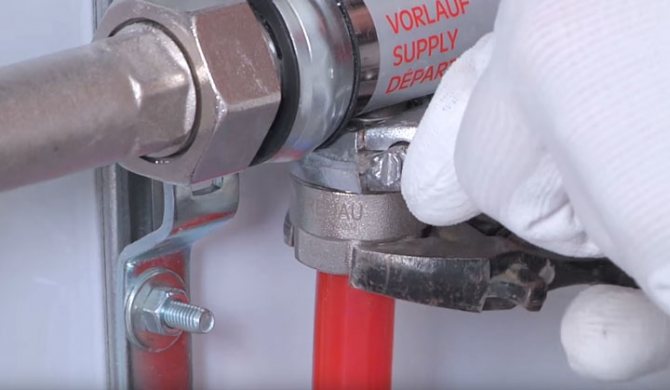

A pumping group is installed immediately behind the cranes. To maintain the required temperature, the heated heat carrier is used only partially. The pump not only creates the necessary pressure in the heating system, but also helps to mix the cooled water from the floor circuit and heated water from the boiler. A check valve with a temperature limiter is installed. A distributor manifold is installed behind the valve. The wiring of the collector for underfloor heating is performed as follows. Pipes going to the warm floor are attached from above, from the heating system from below. If you need to assemble a distribution manifold of a warm water floor with your own hands, stopcocks with a built-in thermostat are installed in the comb. Practice shows that the best option is to purchase a ready-made structure.Assembling the manifold even by a professional and self-adjusting the valves is a laborious process that requires certain skills and experience. Connecting a warm water floor collector requires the use of special accessories. Compression fittings are used, consisting of a support sleeve, a clamping ring and an intermediate brass nut. After installation, the collector is set up.

Pressure testing of the manifold - after completion of the installation work, it is necessary to check the sealing of the connections. For this, the completed collector group is connected to a pump (pressure operator). With the help of a pressure operator, pressure is built up in the system. The water circuit is left under pressure for a day. If the pressure indicators have not changed, it means that the installation of the underfloor heating collector with your own hands was done correctly and the mixing unit is ready for operation.

At first glance, assembling a collector with your own hands seems quite simple. But as practice shows, it is better not to start installation without the necessary tools and special skills.

Do you need a collector

The main disadvantage of the device is considered its high cost, but it must be taken into account that without it, warm water-type coatings will not be able to function normally. This is only possible if the cover consists of one heating circuit. In modern underfloor heating, the length of pipes for laying cannot exceed 70 meters. Since this amount will only be enough for 7 square meters of area, for a medium-sized room you will need at least three contours.

Most often, warm water-type coatings are installed in all rooms of an apartment or house. In this case, a mandatory installation of the collector will be required to evenly distribute the supply of the heat carrier. If we are talking about one small room, the collector may not be purchased. It must be remembered that without this device, the coolant will be supplied with the temperature as in the general heating system. Also, without it, it is impossible to remove air locks and control pressure.

Collector connection to the boiler

The process of connecting a warm water floor with a comb is very simple and boils down to connecting the pipes of the heating circuits to the collector, and the collector itself to the boiler. However, there are differences in the configuration of the collector. This is what we will consider in this subsection.

The collector must be installed in such a way that it is convenient to lead the heating circuit pipes to it. So, install shut-off valves on the manifold. Connect the side outlet to the pipe both for supply and return.

If you buy a ready-made manifold kit, then it will already have all the necessary valves even at the outlets of the pipes going to the boiler. The presence of taps will allow you, if necessary, to carry out repairs or temporarily disable one of the circuits. If you assemble the manifold yourself, then the assembly of the connection of each element is performed with a compression fitting. As a result, underfloor heating will be connected to the boiler through the collector.

To automate the control of the coolant temperature, the following set of equipment is additionally installed in the collector:

- Pump and mixing unit, which includes a three-way mixing valve.

- For forced circulation pump.

- Drain cock.

- Air vent.

So, instead of shut-off valves on the manifold, install thermostatic control valves. In their design, there is a thermal balloon with paraffin, which, pushing off from the air temperature in the room, narrows or expands. These actions set the capacity of the thermostatic valve. As for the pumping and mixing unit, the principle of its operation was described above.

So, we examined the basic and working schemes for connecting a warm water floor.As you can see, it is not enough to know how to properly install a water floor. It should be connected correctly. We hope this article will help you understand the intricacies of this work. And if you already have personal experience, then leave feedback and comments at the end of this article regarding the water heating floor connection schemes you use.

Connecting underfloor heating to the boiler

- There are 2 heating schemes:

- combinedwhen in the heating system, in addition to the warm floor, there are radiators;

- and heating only underfloor heating.

With a combined heating scheme, a mixing unit (three-way valve and a circulation pump) is necessarily present, since the temperature of the coolant in the radiator circuit (70 ° C) is significantly higher than the temperature of the underfloor heating circuit (30 ° C). The boiler heats the coolant to a temperature of 70 ° C, which is fed directly to the radiator circuit. And for the underfloor heating circuit, a cold return is added to the coolant coming from the boiler so that the temperature at the inlet of the underfloor heating circuit is 30 ° C.

- When heating with underfloor heating only, you can use:

- Normal gas boiler (giving high-temperature coolant to the system), but only in tandem with a mixing unit.

- Gas boiler having underfloor heating mode... But keep in mind that in low-temperature mode the heat exchanger will fail very quickly.

- Condensing gas boiler. The low-temperature mode is optimal for it, it is in this mode that the boiler has the maximum efficiency. But the price is 2-3 times higher than for conventional models.

The price of a condenser is two ordinary ones, it seems to me that the benefits of a condenser are killed by the difference in price.

The use of a condensing boiler for underfloor heating was discussed in great detail on the forum.

The connection of the underfloor heating to the boiler can be done independently. Before connecting the warm floor to the boiler, it is necessary to install a collector cabinet and, in fact, to install the warmest floor with water circulation heating.

As a rule, the system is connected to a wall-mounted gas boiler. The manufacturer does not matter in this case, since the installation process and operation of all boilers is carried out according to a similar principle. It does not matter whether the floor system is connected to the boiler or you have a radiator heating system in your home.

However, in the case of a warm water coating, the connection is usually made to the boiler.

The conclusions are as follows: exit from the hot water equipment to the heating system (supply), exit from the equipment to the hot water supply system, gas supply, cold water inlet and "return" from the heating system.

The boiler used in such systems has 5 terminals (if the equipment is double-circuit, that is, for a hot water supply and heating system).

In the process of connecting to the boiler, you must pay attention to the fact that all connections between the collector and the heating equipment are detachable: using combined couplings and union nuts.

A ball valve is installed on each pipe. In any equipment of such a plan, there is a make-up tap for making up / filling the heating system from the water supply system.

To independently connect the heating system to the boiler, you must prepare a set of simple tools.

- You will need:

- tape measure - 5-7 m;

- pliers (pliers);

- level;

- adjustable wrenches;

- regular wrenches;

- Screwdriver Set;

- grinder;

- soldering iron;

- puncher;

- gas-burner;

- pipe cutter.

Collector circuit for connecting a warm floor

The whole process of self-connecting the floor to the boiler comes down to the fact that it is necessary to connect the pipes to the collectors, and connect the collectors themselves to the pipes that come from the boiler. As already mentioned, before connecting the warm floor to the heated equipment, the collector cabinet must be installed and the floor itself must be laid.

The manifold cabinet must be located in such a place that the supply and return pipes can easily enter it. It is necessary to connect the lateral outlets of the collector to the pipes for "return" (return) and supply.

However, before this, shut-off valves (shut-off valves) must be installed on the manifolds. The shut-off valve may include a thermometer for more convenient temperature control.

It is advisable to purchase a ready-made manifold set from a well-known manufacturer, which includes shut-off valves not only at the return and supply outlets, but also at all outlets for the installation of heat transfer pipes of the heated coating. This will make it possible to turn off 1 separate circuit of the entire system for repair, so that the rest will continue to work at this time.

Pipes, taps, manifolds are connected to each other using compression fittings. The connection of the underfloor heating pipes to the collectors can be done using special connectors. The connector includes a clamping ring, support sleeve and brass nut. In the case of connecting different diameters, adapter fittings are used.

The simplest design option will consist of simple manifolds with shut-off valves. The connection of the return and supply with pipes and shut-off valves is made, the collectors and heat-transfer pipes of the water coating are connected. This completes the installation of the floor heating system for the boiler.

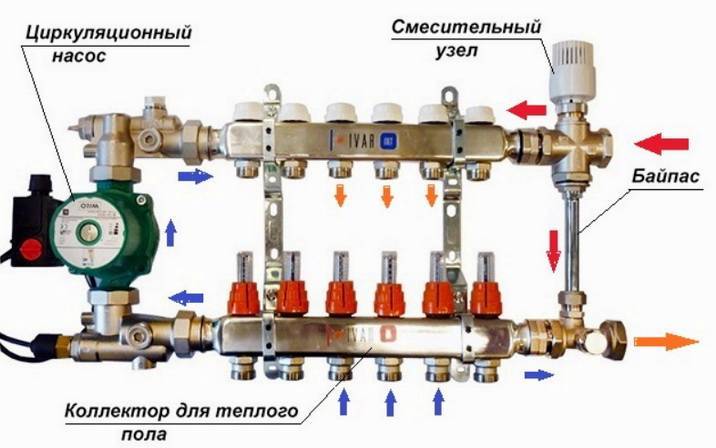

Complete manifold system

The complete system of collectors includes, in addition to shut-off valves on the pipes, a three-way mixer (or pump and mixing unit), an air vent, a drain valve, a circular pump to facilitate the circulation of the coolant in the pipes.

The inlet and outlet shut-off valves can be replaced with thermostatic control valves. They are equipped with a paraffin wax bulb, by means of which the throughput of the valve is set.

The pump-mixing unit is necessary for mixing the cooled coolant from the return flow into the supply, reducing the temperature of an excessively hot liquid.

People who live in regions with a cold climate need a mixer, because the equipment will operate in a strong heating mode, and the temperature of the coolant of the heated water coating should be no higher than 55 degrees.

The mixing pump is installed between the supply pipe and the supply manifold. The third pump outlet goes to the return flow in front of the delivery pipeline. Thus, the pump will take the coolant with a minimum temperature and add it to the supply.

System elements

System elements

All schemes are united by ease of operation, the possibility of self-assembly, as well as the location of the main elements. The supply and return are located on the left side, and the manifold with combs - on the right. The differences between the schemes are in the addition of some details. Most often, the collector is located near the mixing unit, less often - at a distance, which may be due to a lack of free space or planning features of the room.

The composition of the components depends on the material of the pipes used - from cross-linked polypropylene, metal-plastic, corrugated stainless steel or copper.

The following elements are used in the scheme:

- Shut-off valves in the form of ball valves. They do not participate in the adjustment of the main indicators of the coolant - its temperature and pressure, but are necessary when carrying out repair work when it is required to turn off individual components of the system.

- An oblique filter designed for mechanical water purification. It is used in the system if there is no certainty about the purity of the water used. This filter keeps solids out of the tuner, thus ensuring correct system operation and extending valve life.

- Thermometers that provide visual control over the temperature of the water inside the circuit.Some models are equipped with a probe that comes into direct contact with the coolant. Thermometers are available in liquid, mechanical and digital.

- The thermostatic valve is the main control element of the mixing unit. A thermostatic head is put on top of it. When the temperature of the coolant changes, the head mechanically acts on the thermal valve. If the degree is exceeded, the valve closes, and when the temperature drops, it opens.

- A bypass for cold water withdrawal is a jumper, which is formed between the supply and return pipes with the help of sanitary tees. To accurately adjust the pressure of the coolant, a balancing valve is installed on the bypass, which will ensure the optimal operation of the system and its noiselessness.

- The optimal speed of movement of water through the pipes is ensured by means of a circulation pump.

Supply choke

The two-way valve system is the simplest to implement. Control over the temperature of the water entering the pipes of the system is carried out thanks to a thermostatic head installed on the valve and a liquid sensor. The opening and closing of the valve is due to the head that passes hot water from the boiler into the circuit or cuts it off.

Thus, water from the "return" is supplied unlimited, and hot only when necessary under the control of the valve. Due to this, overheating of the warm floor is excluded and its service life is extended. The low flow capacity of the two-way valve ensures smooth regulation of the water temperature, eliminating sudden changes.

Three-way choke

Unlike a two-way valve, a three-way valve mixes water of different temperatures inside itself. This element combines a supply bypass valve and a bypass. The peculiarity lies in the possibility of adjusting the amount of hot and cold heat carrier for mixing, thanks to a damper located between the hot water pipe and the "return".

Such valves have disadvantages. There is a possibility of very hot water being supplied by a signal from a temperature sensor, which, due to a sharp drop, can provoke an increase in pressure in the pipes and a violation of the integrity of the circuits. The large flow capacity of the three-way valve can cause a sharp drop in the water temperature in the circuit, even with a minimal displacement of the device control.

How to use

The three-way valve can be installed both in the mixing unit and without it. In the second case, the device completely takes over the collector function.

The installation of a tee for adjusting the temperature of the water underfloor heating without additional mixing devices is carried out in rooms with an area not exceeding 25 square meters. The supply of liquid with the desired temperature regime is carried out by means of a regulating device and a thermostat installed in the valve itself.

Installation according to this scheme is suitable for bathrooms, toilets and balconies. The disadvantage of installing a three-way valve as the main device for mixing hot and cold coolant is the lack of the possibility of dosing flows.

When installing a floor heating system for large volumes of living space, the three-way valve is a component of the manifold group. In such cases, the device provides a full-fledged uninterrupted process of all heating equipment. Due to it, the liquid with the desired temperature enters all the circuits of the floor heating system.

The three-way valve is effectively used in facilities with a large area - more than 200 square meters. In this case, the warm floor can work both from an autonomous network and from a central heating system.

Mixing valves

Depending on the desired effect, there are various connection methods. Each of them without fail implies the installation of mixing valves. These devices are required to connect hot and cold water. The latter is supplied from the heating circuit, the first from the boiler. The system can be adjusted automatically or manually, which requires additional installation of the control servo. There are two types of mixing valves.

Two way servo

This servo is also called feed servo. Its main difference from conventional valves is the ability to conduct water in only one direction. If the valve is incorrectly reassembled, it begins to malfunction and quickly fails.

"Feeding" - conducts water only in one direction

A ball or a special rod is used as a shut-off part for it. Adjustment is made either by turning the ball or by moving the stem. To carry out these manipulations, electric drives are used.

The most popular method is a thermostatic head equipped with a water sensor, which regularly monitors the temperature of the heat carrier. Taking into account the received data, the head turns on or off the valve. So, from the return, the coolant is supplied regularly, and from the boiler only as needed.

The principle of operation of the device explains the main advantage of the manifold, which is equipped with a supply valve. The floors with this equipment do not overheat, which significantly increases their service life. The low flow capacity of the valve creates a smooth regulation of the coolant temperature, significant jumps in this case are excluded.

The supply valves are characterized by ease of installation and subsequent operation. They are quite often found in the scheme of self-made collectors for underfloor heating, but they have some limitations in their application. Two-way devices are not advised to be installed in systems that operate in rooms larger than 250 square meters.

Three-way systems

Three-way elements are arranged differently. This equipment integrates the operation of a bypass supply valve and a bypass valve. The valve consists of a body with one inlet and two outlets. For regulation, either a rotating ball or a special stem is used.

The peculiarity of this type of device is that the regulating part completely blocks the flow, and distributes the incoming water, mixing it. The temperature is adjusted automatically, for this the valve has a drive system that receives signals from different sensors.

Such valves have servo drives

As a rule, 3-way valves are equipped with servo drives, which are controlled by thermostatic sensors or weather-compensated controllers. The servo drive activates the locking mechanism, which is set to the required position to obtain the required indicator of the heated coolant and return flow.

Weather-compensated controllers are required to adjust the system power to the weather. For example, during a severe cold snap, the room will begin to cool down much faster, that is, it will be much more difficult for the heating system to do the job.

To facilitate the task, it is necessary to increase the costs of the heat carrier and increase the temperature. The main disadvantages of three-way elements include a significant throughput. Under these conditions, even a slight shift in regulation can lead to a sharp change in water temperature.

Three-way elements are used for collectors installed in rooms larger than 250 sq. m and systems with a large number of circuits. Moreover, they are used for structures that are equipped with weather-dependent sensors that determine the required floor temperature taking into account atmospheric conditions.

Equipment characteristics

The coolant from the boiler passes through the pipe line to the collector. From it, the liquid enters the floor pipeline. Giving off heat, it returns back to the collector, which has a separate return outlet for the cooled heat carrier. The circulation pump pumps water back into the boiler.

With manual control of the temperature regime, valves are installed on the circuit with cold water and a high temperature coolant. If the room has warmed up well enough, then the hot water valve is closed. If the room is cold, then the valve is opened.

For automatic regulation of the heating mode, a three-way mixer with a thermostat and an external temperature sensor is installed. This system forms a thermostatic valve. It is installed at the inlet to the manifold. The equipment is made of brass or bronze.

- The three-way valve has 3 outlets for hot and cold water and for the heating medium, which is supplied to the floor line. On the case, markers indicate the direction of flows of different temperatures.

- A mixing chamber is provided for mixing liquids of different temperatures.

- A thermostat with a temperature controller is located on the body.

- The temperature sensor is located on the thermostat.

- The valves close off the cold and hot flow outlets. They can be disc-shaped or needle-shaped. Their work depends on the thermostat.

- The thermostat is a system that consists of a liquid capsule and a spring-loaded stem. Valves are attached to it.

- The temperature sensor has a digital panel on which the heating modes are indicated.

We recommend: What are the myths about the dangers of underfloor heating?

The thermostat can be located in the thermal head or in the actuator. The devices have a different circuit, but the same principle of operation. The thermal head is a thermostat, which works with the help of a liquid: it is sensitive to temperature changes.

The servos are powered by the electrical network. The liquid is contained in a container. It contains a heating plate. The servo is installed on the manifold.

The three-way mixer is designed for heating systems of large areas. In separate rooms or in country houses, a two-way valve is connected to the collector. It is installed on a circuit with a high temperature coolant. Water flows through it in only one direction.

Installing the device

The collector for a warm water floor is mounted according to the following scheme:

- It is necessary to install a frame under the device. It is mounted directly on the wall in a horizontal position or in a specially prepared niche. When choosing a place for installation, one should be guided by the availability of free access to the device to connect the required number of pipelines. Also, a special cabinet is often used for mounting the device. In this form, the device can fit into any room.

- Connection to a heating boiler. The coolant is supplied to the system from the bottom, and the return is placed from the top. Also, in front of the frame, you need to install ball cutoffs. A circulation pump is being installed behind the taps.

- The overflow valve is being installed. It must be equipped with a temperature limiter. A distribution manifold is installed behind this unit.

- Wiring of pipelines to the warm floor is being carried out. The elements through which the coolant will enter the system are placed on top. The pipes from the underfloor heating are installed from the bottom.

- If you intend to install the device with your own hands, it is necessary to connect stopcocks, which are equipped with a thermostat, to the distribution manifold. When a ready-made kit is being assembled, you do not need to do this.

- The collector is connected to the heating system using compression fittings.This element consists of a clamping ring, a support sleeve and an intermediate nut.

- Manifold pressure testing. After the installation of all structural elements, it is necessary to check how tight the resulting system is. For this, the unit is connected to a circulation pump. It builds up pressure in the system. In this form, the water circuit is left for a day. After this time, check the pressure. If it hasn't changed, then the installation was successful.

Why the water-heated floor does not heat: malfunctions and their elimination

Water-based underfloor heating is a rather complex system of interconnected components. If the water heat-insulated floor does not work, the reasons may be different.

First of all, you need to know the main elements of this type of heating:

- Pipes - lines through which the coolant circulates, which transfers heat to the floor surface.

- Bypass.

- Circulation pump.

- Collector and electric drives of the input group, used to regulate the flow in the circuits, as well as a balancing valve designed to mix heated and already given off heat water.

- Thermostats and thermostatsallowing to regulate and maintain the set temperature. In the event of a breakdown, both cooling and critical overheating of the system are possible.

It is worth taking into account possible flaws in the installation. It will be problematic to eliminate such a malfunction as, for example, an insufficient amount of insulation and high heat loss, because you will have to raise the floor covering of the warm water floor, dismantle the screed and pipes.

Also, if the warm water floor does not heat, the reasons may lie in incorrect calculations in the design and, as a consequence, incorrectly selected system components. It often happens that for proper heating not enough energy... In this case, the matter is in the low voltage of the network or insufficient boiler power.

However, we will consider the most typical breakdowns, places and causes of their occurrence, as well as ways to solve the problem.

Damage to the pipeline

A breakthrough of a water-heated floor is manifested in a leak and often a sharp drop in pressure in the pipes. Leaking not only reduces the amount of coolant in the system, but is also fraught with destruction of the floor, flooding of neighbors and damage to property.

If the warm water floor does not heat well, and a leak is suspected, then the first step is to inspect the surface and joints of the floor covering. Wet spots may not be present. Then you should use a thermal imager.

After locating the leak, carefully dismantle the floor covering and screed locally. The method of eliminating the leak is reduced to excision of the damaged section of the pipe and replacing it with a new, whole one. The technology depends on the type of pipes used.

Before dismantling the coating and cutting the pipe, you must first shut off the coolant supply to the circuit (on the collector), and then completely drain the water from the circuit. After the repair, the circuit starts up. It is mandatory to check the solder or joint for tightness.

Before warming up the water heated floor, it is necessary to de-air it.

Uneven heating

In cases where the water-heated floor does not heat well, the reasons may lie in the uneven distribution of the coolant in the circuits. This is due to the fact that the contours, as a rule, have different lengths. If the flow rate of water on the collector in each loop is the same, then the coolant will take more time to pass a longer circuit. Accordingly, in such loops, the water cools faster.

In this case, the regulation of the coolant supply on the collector to each circuit will allow to solve the question of why the warm water floor does not warm up. It is necessary to check and adjust the levels of the electric actuators of the supply valves.

In this case, you will have to be patient, because the time it takes for a warm water floor to warm up depends on many factors (the device and thickness of the “warm cake”, the temperature and intensity of water supply, the temperature outside the windows, the material of the floor covering, what power the heater is selected for the warm water floor, etc.).

Automation tools will help to facilitate control and adjustment, namely, temperature sensors and servo drives on the manifold valves connected to an external thermostat - an analyzer that sends commands to the manifold to regulate the water supply to the loops.

Electrical malfunctions

Why is the warm water floor not heated if there is no leakage? Considering that some elements of the system require power from the mains in order to function, it can be assumed that the cause of the trouble lies precisely in them.

A common breakdown is the failure of the circulation pump and the thermostat located in the mixing unit of the manifold. It is necessary to check if they are energized. This can be done with a multimeter or indicator screwdriver. In principle, the inoperability of the pump can be determined by the absence of any noise.

After a general check of the thermostat, if no problem is identified, it is necessary to check the resistance of each of its terminals. It is possible that the temperature sensors are out of order. Therefore, it is recommended to regularly check their performance.

If you yourself could not find out why the water floor heating does not heat, while nothing else aroused suspicion, it is better to seek help from a specialist.

Types of floor heating systems

There are two fundamentally different systems, consider their strengths and weaknesses. The choice of a scheme will affect the comfort of staying in residential premises, keep this in mind when making a decision, take into account not only the technical parameters of various schemes, but also the features of the premises and existing heating systems.

Water heat-insulated floor

Allows to obtain uniform floor heating, compatible with some existing heating systems in old buildings. The disadvantages include the complexity of the equipment and installation work and the high estimated cost. In addition, the water system reduces the height of the room by at least 10 cm due to the concrete screed. To create a wiring diagram, the room is divided into separate sections, taking into account the size and configuration of the floor, each circuit must have approximately the same length of pipes, otherwise the heating will be uneven in area. Depending on the construction technology, the water floor can have several installation schemes.

- On a concrete base. It consists of a layer of thermal insulation on a concrete base, a metal mesh for laying pipes, pipelines, an upper screed and a finishing floor covering.

- Polystyrene. There is no need to do a more modern method of laying a water-heated floor, a cement-sand screed. Special polystyrene plates with places for fixing plastic pipelines are laid on the heat-insulating layer. The finished wiring is covered with gypsum fiber boards, on which the finishing flooring is laid.

A common disadvantage of water floor heating is that emergencies have very serious consequences. The most complex elements of a water-heated floor are a mixing unit and a manifold.

Description of types of mixing units

The mixing unit provides a constant and balanced circulation of heated water along the laid circuits, changes the speed of movement, independently maintains the set temperature for heating the floor and the heat carrier. Depending on the design features, it can have several types:

- with a series connection of a water pump and a two-way thermal valve;

- with a series connection of a water pump and a three-way thermal valve;

- with a series connection of a water pump, a three-way thermal valve operates with flows converging in one node;

- with parallel connection of a water pump, two-way thermal valve;

- the water pump is connected in parallel, the thermal valve is three-way.

Mixing unit for underfloor heating

Each scheme has its own characteristics, the selection is carried out taking into account the technical parameters and the number of heating circuits.

Layout of pipes for radiators and warm water floor

Distribution manifolds

Designed to connect all heating devices of the underfloor heating system in one place. Depending on the nomenclature and the number of additional special equipment, they can be simple and improved. Simple ones do not have any fittings and are only used to connect fittings. The improved ones have control sensors, performance devices, measuring instruments, etc.

How does the servo drive for underfloor heating work?

A servo drive is an electromechanical device that allows you to open and close the line on the return flow of the coolant of a separate circuit.

How does the servo drive for underfloor heating work? It consists of an electric actuator and a push rod - this rod acts on the valve, which is located in the underfloor heating manifold and, depending on the state of the thermostat, takes an open or closed position.

The flow control along the circuit is carried out from the side of the coolant supply.

The servo is screwed onto the return manifold. To the circuit that should be controlled (i.e. you must know where which circuit is on the collector where the pipe goes from it). For underfloor heating collectors (if you installed just such), the thread for installing the servo drive is unified. Those. any will do.

To install the servo, you need to remove the standard cap and screw on the servo itself.

After installing the servos on all circuits, it is necessary to connect them to the control unit (in the case of a wireless system). Configure signals from thermostats. Those. determine the channels through which they will control one or another servo. Or connect them directly to temperature sensors if they are wired. And then the control will be carried out directly by supplying or not supplying power to the servo.

Servos can be “normally open” or “normally closed”. This means, when there is no voltage, it allows the coolant to circulate (normally open). Or does not allow (normally closed).

What kind of servo drive should be used to control the temperature of a water-heated floor?

It is more logical to choose "normally open". With this option, the voltage will not be supplied to the servo drive in a larger% ratio over time and the coolant will circulate (i.e. the heating will work). However, most (if not all) thermostats or underfloor heating control units allow you to control both normally open and normally closed servos, depending on the terminals to which they are connected.