The classic question of the owner after the installation of an autonomous gas supply is "where to look how much gas is left?" But in reality, you control not only the expense. There are 8 regulating devices on the tank fittings plus a pressure gauge at the basement inlet and a condensate trap.

Some of the indicators are tracked by you, some by specialists. Let's talk about the device and the principle of operation of the gas tank - what is autonomous and what needs to be checked. What gas pressure should be and when is it time to order a refueling. We will show what the owner needs to control during the operation of the gas tank and when to call the service department.

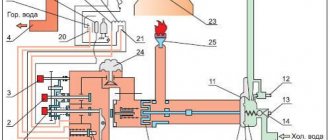

The whole article in 1 diagram

Gas holder: device and principle of operation of gas supply

The process of gassing proceeds autonomously, the owners do not interfere with it in any way, they do not correct anything, do not tune or regulate anything. After installation, refueling and initial setup, the system works without your participation.

Liquefied petroleum gas (LPG) is in the tank simultaneously in liquid and gaseous phases. LPG consists of two components:

- Propane. The boiling point is -42.1 ° C.

- Butane. Boiling point -0.5 ° С.

According to the instructions, the gas holder is buried to a depth of at least 0.6 m to the upper generatrix of the body. In practice, even lower - depending on the depth of soil freezing. Liquefied gas evaporates underground in any frost.

After increasing the pressure of the saturated gas, the vaporization process stops. The contents of the barrel come to an equilibrium state: the liquid does not boil, the gas is under constant pressure.

In this form, LPG stays for up to two years without stratification into separate gases. The container can be temporarily mothballed without pumping out the fuel. The uninterrupted operation of the gas supply can only be impeded by the flooding of the reducer and the blocked access to the valves.

If groundwater or flood waters flood the inspection well, it will be possible to get to the filling valve or emergency valve only after pumping out. If the water freezes, you'll have to melt the ice first. In both cases, the gearbox must be removed and dried.

To prevent flooding, you need to choose the right container:

| Standard. The equipment is fixed on low nozzles (up to 10 cm high). The design is suitable for installation in areas with low groundwater where there is no danger of flooding |

| With high nozzles (up to 50 cm). The armature is brought out of the possible water level. The system continues to operate even if the inspection well is flooded |

| With a high neck (50–80 cm plus 10 cm for nozzles). Used in swampy areas |

If necessary, installers lift the reducer onto the elongated pipe so that no more water can enter the interior of the device.

By the way

If you are not sure which gas tank model is best for your site, talk to an engineer.

Consult

IMPORTANT!

The use of tanks without a double-sided welded seam and not complying with GOST is a violation of the law! Your system will be dismantled according to the very first letter from your neighbor. By purchasing an explosive product that does not comply with legal requirements, you not only run the risk of receiving an order from Rostekhnadzor to dismantle the tank, but also endanger your life with property and endanger your neighbors. You shouldn't save on life and health!

Contact us, we are always sincerely glad to our clients!

Equipment inside the carpet

Explanation: The composition of the equipment depends on the model and manufacturer of the container. We provide a list for a basic gas tank connection diagram.

1

Filling valve

Used to connect to the gas carrier's refueling hose. A spring is installed inside, which opens the valve only under the influence of external pressure.

The driver of the tanker connects the hose, the valve opens under pressure, the liquid fuel enters the container. When the dispenser pulls out the hose, the valve is blocked.

Do not check. The valve does not require maintenance and inspection - the driver of the gas carrier checks the equipment and assesses its condition during refueling. If there is something wrong with the valve, the refueller will inform you.

2

Safety valve

Bleeds off excess gas when refueling. The pressure rises when the tank contains more than 85% of the fuel in a liquid state.

The valve is calibrated at the factory to operate at 15 bar. This protection is sufficient to prevent damage to the case in the event of a sudden pressure surge.

Do not check. The fittings are monitored by specialists during the annual routine maintenance. But if you find that a gas or a liquid phase is coming out of the valve - call urgently!

3

Liquid phase take-off valve

The armature is connected to a pipe that descends to the bottom of the tank. Please note that this is not an automatic pressure relief valve, but a manually operated valve.

If the valve is opened, the liquid phase will begin to flow out due to the pressure of the gaseous part of the fuel. The valve is used to drain fuel when refueling, if more than 85% of the volume is accidentally filled. Or before dismantling the tank.

Do not check.This is an emergency fittings when the liquid fuel needs to be manually drained. The crane is being checked by service technicians.

4

Level gauge

The mechanical level indicator in the gasholder works due to the movement of a rod with a float inside the tank. The scale shows the filling of the tank in percent (5–95%).

Checking - the first point of control. Do not fill the container with more than 85% of the volume - this is dangerous. If there is 20-25% left inside, it's time to call a gas carrier. It is impossible to completely empty the tank - air leaks and the formation of an explosive mixture are possible.

For more details on under-the-neck filling cases:

"5 problems and solutions for the gas tank: the experience of the owners and the comments of the engineer."

5

Gas phase take-off valve with emergency tap

The valve completely blocks or opens the flow. It is used for emergency shutdown of gas supply, when dismantling a reducer, a pressure gauge.

Do not check.Use the valve only to shut off the gas supply. No need to check or unnecessarily rotate the device.

6

Pressure gauge in front of the gearbox

The standard scale shows the pressure in bar - 0.99 atm. The working value for the gas tank is 3-6 bar. However, even a mark of more than 1.5 bar shows that gassing is proceeding normally.

Checking is the second point of control. You do not need to constantly monitor the pressure gauge. It is enough to fix the minimum pressure in the gasholder - 1–1.5 bar. If the readings fall to this mark, it is better to call a gas carrier.

A decrease in pressure indicates a weak rate of gas formation. If the temperature drops, you risk running out of gas.

7

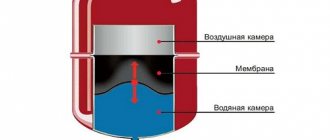

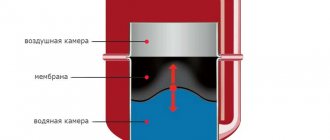

Pressure regulator (reducer)

The device accepts a gas flow at a pressure of 1–16 bar and reduces it to a stable value. The GOK models are set at 37 mbar, the REGO at 37–87 mbar.

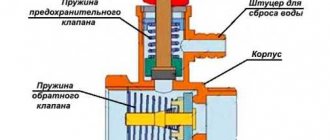

A safety relief valve is built into each gearbox. It automatically stops the gas flow when the pressure in the internal circuit rises. This happens if the diaphragm in the gearbox housing is jammed. The device then transfers the gas without lowering the pressure.

Do not check.The unit is fully automatic. If there are no problems with the gas supply, you do not need to monitor it.

Pay attention to the gearbox if it gets wet during flooding. You will have gas supply problems until you remove and dry the case.

8

Downstream pressure gauge (optional)

The device is not always installed. It is needed rather to find the problem. The second pressure gauge shows the pressure downstream of the reducer.

The mark should be appropriate for the equipment needs. The standard value is 37–87 mbar. The main requirement is a constant indicator without jumps.

Checking - optional control point. Pay attention to the stationary arrow. Oscillations are rare and indicate the unstable operation of the gearbox. Pressure drops can damage equipment, so call service.

Connection diagram from a gas tank to a private house

In addition to the reservoir, the system includes a gas pipeline and a basement input. The gas pipe needs inspection and maintenance, but the pipeline itself cannot be controlled without shutting down the tank. Therefore, it is checked and cleaned by the service personnel.

In front of the house, the installers raise the gas pipeline to the floor level of the first floor and bring it into the building - they weld the basement input. To protect it from freezing, the structure is sometimes placed in a special heat-insulating case. You do not need to monitor the input separately.

9

Condensate trap

The equipment is installed at the lowest point of the gas pipeline and is used to collect condensate: butane in the liquid phase, heavy hydrocarbons, water. Thanks to the device, the gas pipeline works normally, no plugs are formed, the liquid fraction does not enter the boiler.

Do not check.The maintenance technician will drain the condensate if there is a problem with the gas supply. In other cases, the equipment evaporates sediment fractions.

10

Basement pressure gauge

The device shows the final mark of the pressure in the internal network and possible interruptions in the gas supply. Under ideal conditions, the value corresponds to the reading on the pressure gauge downstream of the reducer (if the device is connected).

Checking - the third point of control. If the pressure has dropped and there is not enough gas, you need to look for the cause along the chain: check the LPG level, indicators before and after the reducer.

Sometimes another pressure gauge is mounted in the house - directly in front of the boiler or gas stove. The device is optional: it is installed for additional pressure testing.

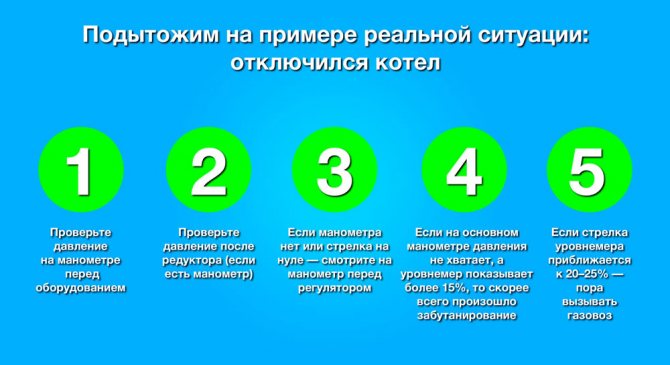

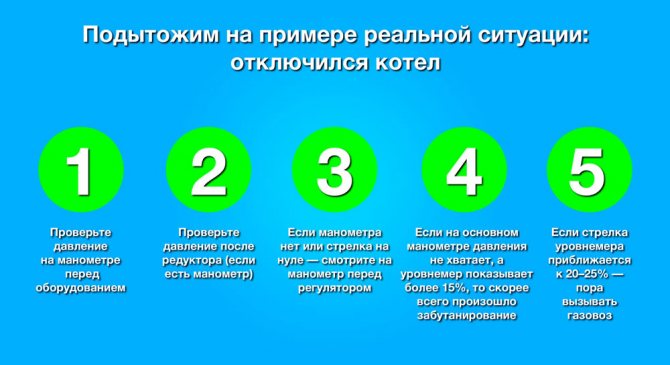

Let us summarize with an example of a real situation: the boiler has shut down

- Check the pressure on the gauge in front of the equipment. If the pressure is normal (from 37 mbar) - the reason is a boiler breakdown. We need to call the repairmen. If there is no pressure, we move along the chain to the next point.

- Check the pressure downstream of the reducer (if equipped with a pressure gauge). If everything is in order here, then the gas pipeline is clogged: the condensate collector is overfilled, a plug has formed, the condensate in the basement inlet has frozen. Call specialists for cleaning, blowing.

- If there is no pressure gauge or the arrow is at zero, look at the pressure gauge in front of the regulator. There must be at least 1.5 bar here, otherwise the reducer will not work. Is the pressure normal? So the problem is in the gearbox - most likely it's frozen. Call specialists to turn off the gas, remove, warm up and purge the regulator.

- If there is not enough pressure on the main pressure gauge, and the level gauge shows more than 15%, then it is most likely that a blockage has occurred. Most of the propane is used up, and butane cannot provide the required pressure in frosty conditions. Order delivery of a winter mixture with a high propane content.

- If the pointer of the level gauge approaches 20–25%, it is time to call the LNG carrier. Do not leave less than 15% of the liquid phase.

Result: after checking the main points, you find the cause of the interruptions and take the necessary measures. In three cases, the intervention of maintenance specialists will be required, in the rest - the call of a tanker truck with LPG.

During normal use, keep an eye on the liquid phase level during refueling - no more than 85%. And call a gas carrier when the level of LPG drops to 20-25%.

Check the pressure gauges in parallel.Such monitoring will be enough to detect a malfunction in time. The rest of the units are inspected by technicians during regular maintenance.

Manufacturers recommend that the system be checked annually. And once every 8 years, call specialists for a deeper control with an assessment of the coating, seams and the general condition of the gas holder.

How it works for us

When installing a gas tank, we conclude a contract for a year of free service. List of services: 2 preventive specialist visits (in winter and autumn) + one urgent emergency call within 24 hours. Then the service contract can be extended.

Season selection for refueling

The best time of the year for filling a gas tank is considered to be the period from February to July. It is at this time that the active consumption of gas decreases somewhat, which means that the prices for its delivery are falling, which allows the client to get some savings when buying fuel. Nevertheless, we must not forget that the composition of the propane-butane mixture can vary from season to season. If the main need for gas consumption arises in winter, then the best option would be "winter" LPG, which is characterized by a rather high degree of volatility of hydrocarbons. For those consumers who use the main gas only for cooking and heating water, it is best to refuel in the summer.