Home / Solid fuel boilers

Back to

Published: 14.05.2019

Reading time: 5 min

0

1682

Boiler manufacturers offer a wide range of boilers, differing in characteristics, purpose, fuel type and quality. Industrial boilers can be gas, electric, solid fuel, gas and oil, combined, hot water and steam.

Industrial boilers for solid fuels are used by enterprises for heating and hot water supply. Such equipment is used in industrial, administrative, commercial, agricultural buildings. Since such rooms are usually large in area, powerful equipment is used there that runs on solid fuels (pellets, briquettes, coal) with a capacity of 100 kW and above.

- 1 Pros and cons of industrial solid fuel boilers

- 2 Types of industrial boilers for solid fuels 2.1 Steam boilers

- 2.2 Hot water

- 4.1 Requirements for TT boiler rooms

Types of hot water boilers

Such heating equipment has been used for more than a dozen years, constantly improving with the advent of new developments and technologies. This led to the fact that solid fuel boilers for industrial use are presented in a large assortment and it is rather difficult for a consumer who does not have specific knowledge to understand it.

Therefore, when choosing, you need expert advice, and we will consider the main types of equipment operating on solid fuel:

- It is most advantageous for a woodworking enterprise to install a wood waste boiler. These industrial units are unpretentious in maintenance and operate on any production waste: shavings, sawdust and even wood dust. The only caveat is the requirement that fine-grained waste be no more than 30% of the mass of one fuel tab.

- Agricultural and food industries often install solid fuel steam boilers. A large amount of steam that this equipment is capable of producing is needed for the production needs of such industries (drying or humidifying products).

- For heating large areas, industrial coal-fired boilers are used. Mechanized fuel supply and forced mixing ensure complete fuel burnout, which significantly increases the efficiency of such units. It should be noted that powerful devices from 2.5 MW differ significantly in configuration from smaller analogs. Their performance is sufficient even for the processing of wet fuel.

- Apparatuses working on briquettes are rarely used. A feature of pressed fuel (most often woodworking waste) is a large release of soot and soot, clogging chimneys.

- Large capacity wood-fired hot water boilers are used for heating large areas of industrial and residential use. In addition to firewood, the unit can operate on other solid fuels. Automatic fuel supply and movable grates make the operation of the equipment simple and convenient. Some models are equipped with pre-furnaces, where the raw material is dried before entering the combustion chamber.

Advice! Combined hot water units operating on several types of fuel are considered the most successful and popular. But their lineup is severely limited by the complexity of the production and operation of such equipment.

Universal boilers

The concept of universal equipment today is most fully disclosed by the example of solid fuel and bio-boilers. The relevance of models capable of operating on several types of fuels is due to the desire of manufacturers to popularize biofuels. Not all consumers are ready to switch to fuel pellets, so developers almost as an option supply classic industrial boilers with chambers for working with the same pellets. The result is hybrid designs that are versatile and cost-effective.

Benefits of solid fuel equipment

Solid fuel equipment is an economically viable substitute for gas counterparts. The availability of cheap fuel in some cases makes the installation of such boilers the only cost-effective alternative. In addition, gas equipment requires special permits and approvals from the service personnel.

Other advantages that industrial solid fuel boilers have are:

- Ease of operation and unpretentious maintenance.

- Possibility to create complexes of increased capacity - up to 40 MW

- A wide range of solid fuel options, you can choose the most affordable and profitable in a particular case.

- Having such a device in production, you can significantly save twice: on fuel, burning solid waste, and on disposal - they will no longer need to be taken out.

The presence of mechanized fuel supply and automatic control over the equipment allow to minimize the staff of the service personnel.

The only drawback of heating systems in which industrial hot water boilers operating on solid fuels are used is the following factor. Due to the release of a large amount of soot and soot, periodic maintenance and cleaning of chimneys is necessary.

Advice! Such cleaning can be carried out with special mechanisms at the end of the heating season.

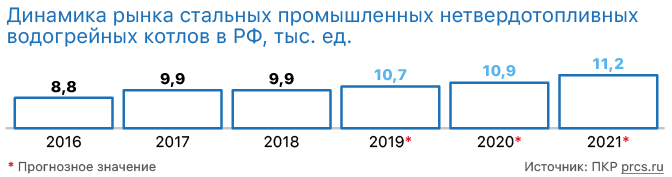

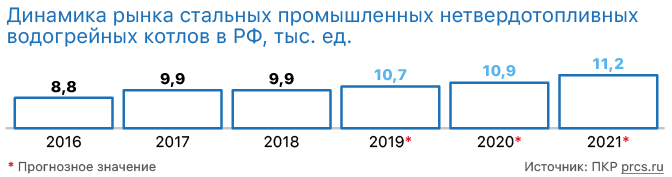

Market volume and structure

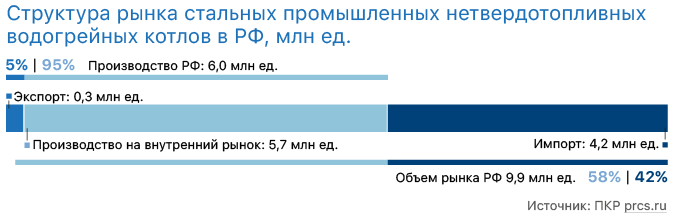

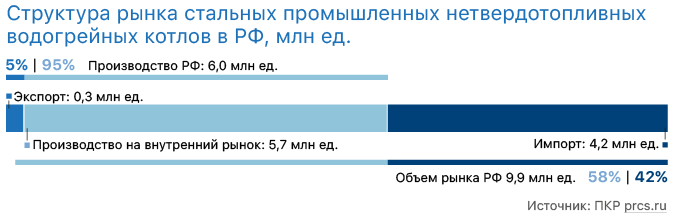

From 2020 to 2020, the dynamics of the market for steel industrial non-solid fuel hot water boilers in physical terms showed a stable increase. According to the GKR estimates, in the period under review, the volume of consumption of hot water boilers increased by 13% and amounted to about 10 thousand units.

Boilers of foreign production are widely represented on the market - they make up 42% of all products sold. The volume of Russian production in 2020 amounted to about 6 thousand units (58%).

The device and principle of operation of hot water boilers

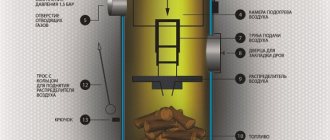

Solid fuel hot water boiler is a modular design, made in a single body, and has the following main units and mechanisms:

- heat exchanger;

- heat exchanger hatch for cleaning and maintenance;

- combustion chamber door;

- combustion chamber with grate system;

- grate cleaning mechanism;

- fuel supply mechanism.

In addition, a solid fuel boiler is equipped with an air pump that maintains the required combustion level.

Principle of operation

The principle of operation of industrial boilers is the same as that of smaller counterparts:

- The fuel, burning in the combustion chamber, heats the water circulating in the heat exchanger, which is connected to the heating system.

- The intensity of combustion and the speed of movement of gases in the combustion chamber is regulated by the injection and flue gas pump.

- The movement of the coolant in the system is provided by efficient circulation pumps.

- The safety group and safety valves in the flue ducts provide protection against overheating and explosion of combustible gases.

- After complete combustion of the fuel, the ash enters the ash pan, from where it is removed mechanically through a special hatch.

Advice! On sale there are both domestic and foreign industrial boilers operating on solid fuels.It is worth choosing domestic developments, since they are more adapted to difficult working conditions.

Solid fuel hot water boilers are quite common in all regions. It is beneficial to use them in industries and other places where there is access to a cheap type of solid fuel. Also, such equipment is used for heating residential areas where it is not possible to conduct a gas main.

Source: masterotopleniya.ru

Design features of a hot water boiler

A traditional unit of this type is a metal welded structure, in which there is necessarily a support frame, a frame equipped with heat-insulating, protective materials. The main structural element, as mentioned earlier, is the water heating pipe system - the heat exchanger through which the boiler water circulates. Outside, the boilers are sheathed with sheet metal.

The very design of the device and the principle of operation indicate that these units are quite large in size. In models of different types, there are combustion chambers designed for different methods of loading and supplying fuel.

A ready-made hot water solid fuel boiler of factory assembly is a single unit in which all structural elements can be conditionally divided into two parts: a screen and a convective surface. The surfaces are manufactured from solid rolled steel pipes with a diameter of 76 mm. Fins are provided between the pipes. This feature of the heat exchanger design allows to minimize heat losses, to reduce the leakage of hot gases through the unit body. All elements are connected into a single structure using a welding joint capable of withstanding pressure up to 10 atm.

Important! All internal connections of the water heating circuit must be welded only. High temperatures and pressures in the system place particular demands on welding.

Loading of coal or firewood is carried out through the combustion block, which is equipped with conventional or rotary grates (for boilers with manual fuel supply). Under the combustion part, during the installation of the boiler into the support frame, an air duct is installed at the lowest part through which air masses will be injected into the combustion chamber.

Cleaning of heating equipment looks especially interesting. In units with manual feeding, ash and soot are removed through a special hatch. In devices with mechanical feed, all similar processes are carried out by special mechanisms - conveyors.

Appointment

Solid fuel hot water boilers allow you to get heating and hot water in places where there is no gas pipeline and the use of gas-oil boilers is not profitable, while receiving rather inexpensive heat, long operation and safety. At present, long-term vapor-lysis units are mainly used. Unlike classical systems, steam-lysis boilers require less fuel loading, and their efficiency is higher due to the afterburning of carbon dioxide released during fuel combustion.

Solid fuel industrial boilers are single-circuit and double-circuit. Usually, for industrial purposes, double-circuit hot water boilers are used, which provide not only heat in the manned room, but also hot water. A solid fuel industrial boiler does not need to be connected to the mains, which creates additional savings.

findings

Solid fuel hot water heating boilers are rightfully in demand among consumers. They are especially in demand for the organization of heating of large production facilities and objects of small infrastructure of the city.

The popularity of hot water boilers is due to their efficiency and economical consumption of fuel resources.In addition, for the installation of solid fuel boilers that burn wood, coal or any other type of organic fossil, there is no need to obtain a special permit.

Due to the simplicity of the design, such a device can be quickly mounted directly on site and connected to the heating system. Further operation and maintenance of the device is not difficult and does not require technical training. To make it easier for consumers to disassemble the principle of operation of the equipment, a minimum of control elements and automation is installed on it.

It is noteworthy that not only common types of solid fuels can be burned in a hot water boiler, but also almost everything that burns. In this case, the fuel is burned practically without residue, due to which high efficiency is achieved. Such units are considered environmentally friendly and practically harmless to the environment.

https://youtu.be/GuwNAT_Jw_A

features

The most important factor in choosing a new unit is fuel, since it is fuel that constitutes the main item of consumption after purchasing equipment. Fuel is determined based on the tasks and capabilities of the region. For example, in places rich in wood, a unit operating on a DVO will work more economically than on coal. But for heating a small car workshop, for example, a waste oil boiler is better suited than even equipment using the cheapest fuel - gas. It is easier to get fuel for a coal-fired hot water boiler, and the price of the unit itself is lower than that of its competitors. But there are also such units that can operate on various solid fuels, without requiring changes in the design when changing.

The next factor is the boiler output. To correctly calculate the power, it is necessary to take into account the area of the heated room and all possible heat loss. A universal formula for boilers of low power is 1 kW per 10 m². To calculate all the heat loss in industrial premises, there are special calculators with more complex formulas and taking into account all the nuances. And a specialist can calculate the boiler power as accurately as possible.

Another feature of solid fuel industrial boilers is fuel supply and ash removal. It is necessary to load fuel into these boilers at regular intervals so that the operation of the equipment does not stop. And as a result of burning solid fuels, waste is formed. These two factors force a person to constantly regulate the process and be in the boiler room. But if this option is unacceptable, then all boilers can be equipped with automatic fuel supply or cleaning systems from slag and ash. And you can do both. Accordingly, the price of such equipment will increase. Therefore, it is also necessary to take into account the degree of automation when choosing boiler equipment.

And the most important factor when choosing a boiler is the manufacturer. A solid fuel hot water boiler is a device that operates at high temperatures and pressures, so it is important to choose a safe and proven product. Experts recommend taking boilers from Russian manufacturers, because they are designed for the difficult climatic conditions of individual regions and are much cheaper than foreign counterparts, since their production is usually local. It is also recommended to use control and automation systems for industrial units, which increase the safety of the boiler room.

Thus, we can conclude that when choosing a boiler, it is important to take into account the availability of any fuel in the region, the area and degree of heating of the room, the need for automation and a trusted manufacturer.

manufactures modern industrial hot water boilers for solid fuels that meet all the necessary quality and safety standards. We give a guarantee for our boilers up to two years, and our own production base allows us to keep prices low.You can buy a solid fuel hot water boiler on our website or order a call through the feedback form, and our manager will contact you where he will provide professional assistance in choosing a boiler.

Source: kotelzavod.ru

Import and export of industrial boilers

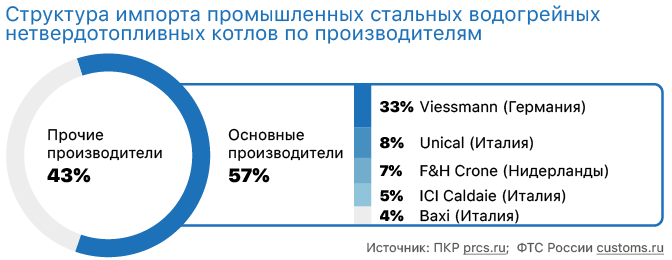

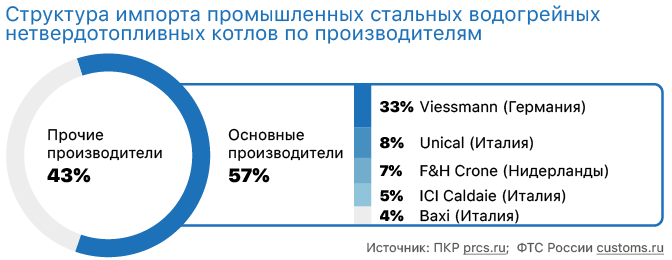

From 2020 to 2020, the volume of the considered boilers imported into the territory of the Russian Federation increased by 9%. At the same time, in value terms, supplies decreased by 3%, which is due to the general downward trend.

The total volume of imports of industrial steel water-heating non-solid fuel boilers in 2020 amounted to 4.2 thousand units. in the amount of 3.2 billion rubles.

The main importers are Viessmann (Germany) - 33%, Unical (Italy) - 8%, F&H Crone (Netherlands) - 7%, ICI Caldaie (Italy) - 5%, Baxi (Italy) - 4%, thus the five largest importers provide about 60% of industrial steel water-heating non-solid fuel boilers imported into the territory of the Russian Federation.

Export in the hot water boiler market is still insignificant, however, the growth rates and dynamics allow making a positive forecast for the development of the export direction. From 2020 to 2020, the volume of exports increased by 17% in physical terms and by 29% in value terms. The total export volume of industrial steel hot water gas boilers in 2020 amounted to 321 units. in the amount of 214 million rubles. The main exporters are 14%, BOSH Thermotekhnika LLC - 13%, Boiler Equipment Plant Energoresurs LLC - 9%, Mimax LLC - 8%, Vissman LLC - 6%.

Types of hot water TT boilers

A solid fuel boiler is a heating device that uses the energy of burning solid fuel. Most often it is firewood or coal. However, some manufacturers produce models that work on pellets and fuel briquettes.

By the type of solid fuel used, boilers are divided into:

wood burning

This category includes conventional wood-fired boilers. Their downside is that wood has low heat transfer and burns out quickly. Therefore, it is necessary to add wood to the firebox every 2-4 hours.

coal

Coal boilers operate on brown or black coal, anthracite, coke. The heat transfer of coal is 2 times higher than that of wood, besides, coal is more compact. One bookmark will last for 8-10 hours.

pellet

Pellet hot water heating boilers operate on special granules - pellets. They have a high efficiency of 85-95%. Their significant disadvantage is the high cost of the devices themselves and of the fuel for them.

universal

They can work on wood, coal or pellets to choose from. The efficiency of universal boilers is lower than that of those using one type of fuel. Manufacturers also produce two-fired models. Each type of fuel has its own combustion chamber and its own heat exchanger.

Photo 1: Fuel pellets for solid fuel boiler

According to the material of the heat exchanger, they are divided into:

cast iron

The advantage of the cast iron heat exchanger is its high heat capacity and resistance to corrosion. Such products will last 30% longer than steel counterparts. The disadvantage of cast iron heat exchangers is fragility and sensitivity to temperature extremes. Also note that cast iron is 2-3 times heavier than steel, as a result of which even low-power models have to be installed on a concrete foundation.

steel

Boilers with a steel heat exchanger are 30-60% cheaper than their cast iron counterparts. The disadvantage of a steel heat exchanger is the formation of corrosion due to condensation water.

There are two ways to burn solid fuels: classic and pyrolysis. Depending on which method is used, all models are divided into two types:

classic

In classic boilers, the combustion process takes place naturally. They are characterized by simplicity of design, and as a result, a low price. Their disadvantage is their low efficiency (75-85 percent) due to incomplete combustion of the fuel.

pyrolysis (or gas generating)

A feature of these devices is that solid fuel and the gas emitted by it burn separately. This achieves a higher efficiency compared to classical ones (about 85-92%). Such devices are much more economical and environmentally friendly than classical ones. Modern heating boilers for pyrolysis combustion are about 1.5 times more expensive than traditional ones.

According to the loading method, solid fuel boilers are distinguished:

with manual loading

To maintain a constant heating temperature, it is necessary to manually add a new portion of solid fuel every 2-4 hours.

with automatic loading

The design of the heating system is complemented by bunkers for automatic fuel supply. Depending on the volume of the bunker and the amount of solid fuel in it, the battery life reaches from several tens of hours to one month.

Photo 2: Boiler with automatic fuel supply

According to the degree of dependence on electricity, they are divided into:

non-volatile

In volatile boilers, the air will be forced into the combustion chamber by a mechanical thermosyphon.

volatile

Volatile boilers use an electric fan to force air into the combustion chamber. This process is controlled by an electronic unit that requires an electrical connection.

We figured out the classification, now let's look at the device and principle of operation of the TT of the heating boiler. It consists of the following components and assemblies:

Combustion chamber

The fuel combustion process takes place in this section of the boiler;

Heat exchanger

This device is made of cast iron or steel. It transfers the energy of the burning fuel to the coolant;

Cleaning hatch

Especially the hole in the ash pan. Ash and combustion waste are extracted through it;

Grate

A metal grate between the combustion chamber and the ash pan on which the combustion process takes place. Ash falls through holes in the grate into the ash pan, from where it is then manually removed;

Thermostat

A mechanical or automatic device that regulates the intensity of combustion, and therefore the temperature of the coolant;

Photo 3: Arrangement of a wood-fired hot water boiler

The operation of a boiler with a water heating circuit is very simple. Solid fuel is placed through the loading door into the combustion chamber. During combustion, the heat exchanger heats up and transfers energy to the heat carrier, for example water. The coolant circulates through the heating system, heating the room. Ash and other wastes from combustion accumulate in the ash pan.

Source: kotlydlyadoma.ru

Types of industrial solid fuel boilers

According to the principle of operation, classic units are practically not used anymore. Instead of them, industrial pyrolysis boilers on solid fuels of long burning are increasingly being installed. The principle of operation of gas generating equipment is based on the afterburning of carbon dioxide produced during the combustion of fuel. The industrial pyrolysis boiler is the most economical model. The payback of the equipment is achieved in 2-3 heating seasons.

According to the degree of automation, industrial solid fuel hot water heating boilers are offered with mechanical and manual fuel supply. The operation of automatic models is fully controlled by a microprocessor controller. Automation regulates the fuel supply, air injection into the furnace and the removal of combustion products. Modern models are equipped with automatic soot removal. The use of the controller increases the efficiency of devices, in comparison with classic models, by 30-40%. Additional savings from automation are achieved due to the absence of the need for the constant presence of maintenance personnel in the boiler room.

The principle of operation of an industrial solid fuel boiler is not much different from ordinary household equipment.The main difference is high productivity and, accordingly, increased fuel consumption.

High power steam boilers

Industrial steam boilers of high power on solid fuels, simultaneously work to heat the coolant and produce steam. The principle of operation is as follows:

- The water entering the heat exchanger is preheated by the air heated during fuel combustion.

- Fuel is burned at high temperatures. The water is brought to a boiling point and evaporates.

- The wet steam enters a special collector where moisture particles are removed. After that, the steam is additionally heated to the required temperature.

Distinctive features

The long-burning double-circuit solid fuel boiler is a modernized version of the classic heating equipment.

In it, among other things, there is also a built-in heat exchanger, which provides the dwelling with a full-fledged hot water supply.

The design of the two-contour model includes the following elements:

- Housing - can be produced from sheet steel or cast iron. The thickness of the metal is 4 to 6 mm.

- Furnace chamber... Usually made from the same material as the body of the instrument.

- Grate type... It is located inside the combustion chamber, the material is cast iron. Enriches the fuel with the oxygen necessary to maintain combustion.

- Ash pan... Accumulates solid waste generated during combustion.

- Chimney - removes combustion products outside the room.

- "Water jacket"... Most often, it is built into the boiler body and filled with water, which receives heat from the walls, after which it enters the heating system.

- Additional heat exchanger coil - distinguishes double-circuit models from single-circuit ones. It is built into the water jacket of heating equipment to provide hot water supply to the house.

The main disadvantage of this design is the low degree of performance.... Therefore, models made of cast iron are more popular, since they cool down longer.

Types of devices

According to the method of fuel combustion, long-burning double-circuit boilers can be subdivided into:

- Pyrolysis... Equipped with two combustion chambers. In one of them, the process of smoldering and gas evolution for pyrolysis occurs, in the other, the resulting gas is mixed with oxygen and burned. Equipment of this type is characterized by high environmental friendliness - a minimum amount of harmful substances is released into the atmosphere. The combustion process produces little soot. If the boiler is equipped with automation, it will also be possible to adjust the power.

- With an upper combustion chamber... These boilers are very easy to maintain. The number of automatics for their stable operation needs a minimum, it is possible to operate in an autonomous mode of operation without electricity. There are also disadvantages - a lot of ash is formed during operation, there is a list of requirements for the types of fuel. For example, small wood chips or sawdust are not suitable for kindling.

- Pellet... For kindling such equipment, special pellets or compressed fuel briquettes are used. Such boilers are environmentally friendly, economical and efficient, and have a long service life. One of the main disadvantages is the high price of the boiler and the special conditions that will have to be maintained for storing fuel. The room must be dry, high air humidity will deteriorate the pellets.

How to choose and what to look for?

The most important indicators when choosing solid fuel boilers for long burning with a built-in water circuit are:

- Availability of the required fuel.

- The power level of the device - depends on the area of the heated rooms and the required temperature regime of the coolant.

- The type of draft generated inside the combustion chamber. It can be forced or natural.This parameter affects the possibility of placement in a particular room and the level of boiler performance.

- Efficiency. It will depend on the type of fuel used, design features and additional equipment used (presence or absence of an exhaust hood, automation of fuel supply, etc.).

- The heat exchanger material - usually cast iron or steel - affects the reliability of the device and the characteristics of the heating technology.

- The type of location of the water jacket is important in order to correctly determine the installation location of the boiler in terms of fire safety rules.

- The weight of the unit is an important factor in determining the base where the boiler will be located. It must be strong enough and not subject to deformation.

- The method of fuel loading and the dimensions of the combustion chamber are important for determining the cycle of use of the unit and the possibility of setting up its automated maintenance.

- The design features of the ash pan and its accessibility will affect the convenience of performing maintenance and preventive maintenance work on the boiler.

- Cost Level - Depends on a combination of the factors listed above and the OEM's brand reputation.

Popular manufacturing companies

Heating equipment is always in high demand, which is why most of the technically developed world countries are engaged in the production of such units.

The following brands are best known from foreign manufacturers.:

- Stropuva - manufactures long-burning boilers operating on solid fuels, chimneys and water heating systems, as well as shut-off and control valves (Lithuania).

- Buderus - German specialist in heating technology.

- WATTEK Is a Czech company dealing with a wide range of issues - design, production, installation and maintenance of heating equipment.

- ACV Is a Belgian manufacturer of equipment for heating and hot water supply for domestic and industrial use.

- Wirbel Is a company from Austria that manufactures various types of heating boilers, both solid fuel and electric.

Rating of TOP-9 best models

| A place | Name | Price |

| TOP-9 of the best long-burning solid fuel boilers with a water circuit | ||

| 1 | Stropuva Mini S8 8 kW | Find out the price |

| 2 | ZOTA Topol-22VK 22 kW | Find out the price |

| 3 | ZOTA Topol-16VK 16 kW | Find out the price |

| 4 | ZOTA Topol-32VK 32 kW | Find out the price |

| 5 | Stropuva S30 30 kW | Find out the price |

| 6 | Stropuva S40 40 kW | Find out the price |

| 7 | TEPLOV Universal TA-40 40 kW | Find out the price |

| 8 | SAS UWT 14 14 kW | Find out the price |

| 9 | TRAYAN TPG-15 15 kW | Find out the price |

The best solid fuel boilers for long burning with a water circuit

Stropuva Mini S8 8 kW

Solid fuel heating boiler. able to heat a residential or industrial premises with an area of up to 80 m2.

It is efficient and fully prepared for intensive operating conditions, including year-round use. A separate advantage is independence from electricity. The boiler can work with different types of solid fuels - coal, wood, pellets.

Differs in compact size... Fuel loading is simplified by the vertical position of the firebox door The ash pan is designed so that cleaning can be done only a couple of times a month.

The special combustion technology used in this model allows for long-term fuel combustion with high efficiency..

One tab of raw materials will provide you with warmth for at least a day. Duration of pellet burning is up to 48 hours, depending on external conditions and fuel quality.

Specifications:

- power - 8 kW;

- heated area - up to 80m2;

- purpose - heating;

- boiler volume - 40l;

- combustion chamber type - open;

- weight - 145kg;

- dimensions - 55.5 * 136.5 × 55.5 cm.

ZOTA Topol-22VK 22 kW

In this model, the configuration of the heat exchanger was successfully changed and water-filled grates were used.... The body of the device is reliably insulated.

It has 2 combustion chambers, due to which both horizontal and vertical fuel loading is possible. The chamber doors are securely locked.

The boiler combines a relatively low cost with a high efficiency of the device..

There is a separate door that allows ash removal even while the appliance is in operation. One load of fuel will provide you with heat for 10-12 hours.

Additionally, you can install an external control panel to block the heating element, automate the combustion process.

Specifications:

- power - 22 kW;

- Efficiency - 70%;

- non-volatile;

- heated area - up to 200m2;

- purpose - heating;

- weight - 128kg;

- dimensions - 90.5 * 47 * 87 cm.

ZOTA Topol-16VK 16 kW

Another representative of the line of boilers with a water-filled grate, which guarantees an increase in the heat transfer of the device..

Its tube is triangular in shape to eliminate blockages and increase service life. The boiler can consume pellets, wood or coal as fuel.

The boiler is convenient to operate, thanks to the significant dimensions of the furnace and two ways of filling fuel - it is convenient to load coal from above, and firewood - into the skewer door.

The low cost is favorably combined with the efficiency of space heating.

Specifications:

- power - 16 kW;

- Efficiency - 70%;

- heated area - up to 160m2;

- purpose - heating;

- weight - 108kg;

- dimensions - 80.5 * 44 * 87 cm.

ZOTA Topol-32VK 32 kW

The boiler, operating on various types of solid fuels, has a high level of performance, which makes it possible to make the heating system of the house of high quality and stable.

The equipment is considered very practical because it can be converted to natural gas consumption.

The body of the equipment has good thermal insulation, which allows it to be installed in any convenient place.

The efficiency of the device is quite high, given the low price among analogs... Single loading of fuel allows you to maintain heat in the heating system for up to 12 hours.

Specifications:

- power - 32 kW;

- Efficiency - 70%;

- non-volatile;

- heated area - up to 320m2;

- purpose - heating;

- weight - 143kg;

- dimensions - 87 * 44 * 100.5 cm.

Stropuva S30 30 kW

Solid fuel heating boiler for residential and commercial installations... Cost effective, ready for seasonal or year round use.

Does not depend on electricity, can operate on different types of solid fuels, has a high efficiency.

Compact and does not require a separate room for installation, has a certificate of environmental safety... Duration of burning firewood - up to 30 hours, pellets - up to 2 days. No power supply required.

Specifications:

- power - 30 kW;

- Efficiency - 85%;

- heated area - up to 300m2;

- purpose - heating;

- weight - 143kg;

- dimensions - 87 * 44 * 100.5 cm.

Stropuva S40 40 kW

Solid fuel boiler for long burning with one circuit to provide heating of premises up to 400 m2. fuel can be firewood or wood briquettes.

Has an open combustion chamber, is installed floor.

Specifications:

- power - 40 kW;

- Efficiency - 85%;

- heated area - up to 400m2;

- purpose - heating;

- weight - 143kg;

- dimensions - 87 * 44 * 100.5 cm.

TEPLOV Universal TA-40 40 kW

Long burning water heating and heating boiler, can heat residential and industrial premises and provide them with hot water.

Suitable fuels are briquettes, wood and coal.

You can choose an automated or non-volatile device option.

In the first case, you will receive reliable protection against overheating, freezing of the liquid in the system, the ability to adjust the temperature level for day and night mode.

Specifications:

- power - 40 kW;

- Efficiency - 82%;

- heated area - up to 400m2;

- purpose - heating and hot water supply;

- weight - 390kg;

- dimensions - 147 * 48 * 77 cm.

SAS UWT 14 14 kW

Solid fuel boiler made of steel and insulated with mineral wool to reduce heat loss... It can be installed as part of closed or open systems.

Equipped with an automatic control system.

It is possible to connect a hot water boiler.

The preferred fuel is coal, but wood-burning is also possible.

Specifications:

- power - 14 kW;

- Efficiency - 83.5%;

- heated area - up to 120m2;

- purpose - heating;

- weight - 310kg;

- dimensions - 54 * 141 * 101 cm.

Industrial boilers

power from 100 to 3000 kW

Steel solid fuel boilers with mechanized fuel loading are designed for heating domestic, industrial and other premises in which a central heating system is equipped, for preparing hot water and supplying heat for technological needs. A mechanized fuel supply system is used for these boilers.

WIDE SELECTION OF FUELS

Used as fuel: wood waste (sawdust, shavings, wood chips), sawdust and peat pellets, milled peat. Fuel fraction 15x35x80 mm moisture content not more than 50%.

CONSTRUCTION OF THE BOILER

In the process of manufacturing the boiler, high-quality boiler steel with a thickness of 10-16 mm and seamless pipes D76 mm are used. The boiler is insulated with 50-100 mm thick mineral wool. The heat exchanger of the boiler is a drum type smoke tube. The firebox is a tube frame with alternating high-quality fireclay bricks. There is also an additional lining in the flame torch combustion zone, which ensures a high fuel combustion temperature. A secondary air distributor is located in the boiler furnace. The original design of this distributor allows you to regulate the secondary air not only quantitatively, but also to supply it exactly to the necessary zones of the furnace, which allows you to burn fuel of various complexity, with the same quality.

HIGH BOILER EFFICIENCY

- Thanks to the optimally lined firebox with fireclay bricks;

- Automatically maintained set mode;

- Correct separation of primary and secondary air.

Safety of use

Convenient is the fact that using the air distributor, you can easily select the required ratio of primary and secondary air, ensuring complete combustion of the fuel and thereby obtaining the highest possible efficiency. The large doorway of the furnace provides convenient loading of fuel into the boiler, as well as the maintenance of the boiler.

Firebox door, is an original construction with multilayer thermal insulation according to the "puff cake" principle. A 1600 ° C heat-resistant plate (this material is used in blast furnaces) is installed in a metal frame pre-insulated with several layers of thermal insulation. The stove is protected from mechanical destruction by a screen made of high-alloy stainless steel, which ensures the strength of the doors and a high combustion temperature in the firebox. The firebox door has a viewing window made of special quartz glass that can withstand high temperatures and an additional protective stainless steel shutter.

All doors are right. It is possible to change the location of the control panel, which is usually located on the right side of the boiler to the left.

Boiler automation ensures the consistency of the draft in the furnace by means of a "current" vacuum sensor. There is an intelligent system "anti-combustion of fuel" in the auger conveyors. Boiler unit adjustment modes occur during commissioning.

The air supply to the boiler is automatically stopped when the heating medium in the boiler reaches the set temperature set by the temperature regulator; when the coolant cools down and its temperature drops by a predetermined value, the fan turns on automatically again. The chimney-mounted damper allows you to conveniently and quickly select the desired flue gas flow, depending on the fuel used or the intensity of the furnace.

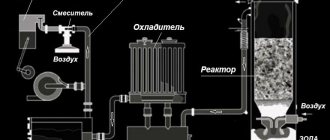

The principle of operation of boilers with mechanized fuel combustion.

Fuel, with the help of a screw conveyor or conveyors, is fed down the boiler into the retort, from where it rises up in the form of a volcano and pours grief onto the grate. The grates are made of alloyed cast iron, with a chromium content of at least 26-30%, which ensures their high thermal and wear resistance.

Primary air is supplied to several zones under the grate through openings located on the grate surface. The grate is cooled by primary air.

Boilers and fuel supply equipment are modern, processor-controlled systems that can operate in automatic mode with minimal periodic supervision and maintenance.

Sawdust or wood chips up to 50 percent moisture and up to 80 mm long are used as fuel. Long waste can be heated manually by loading it into the firebox through the firebox door.

Boiler room equipment is designed and manufactured according to the individual requirements of the customer in accordance with the specific installation conditions.

Boiler touch control panel:

WARRANTY OBLIGATIONS:

The warranty period is 24 months from the date of the first start-up of the equipment (subject to mandatory maintenance within the first 12 months), but not more than 30 months from the date of the device's release. It is possible to extend the warranty period up to 36 months, provided that the boiler is serviced by the manufacturer for 24 months.

TYPES OF BOILERS

This series includes boilers KVDG-100M, KVDG-150M, KVDG-195M, KVDG-250M, KVDG-300M, KVDG-400M.

We invite you to familiarize yourself with the detailed specification of all parameters.

Specification

COMPLETE SET:

Basic configuration:

- boiler;

- mechanized fuel bunker MPT005 1.5 m3

- blowing fans 3 pcs;

- boiler control panel;

- smoke exhauster D5

- fireman's tool;

Full set:

- boiler;

- mechanized fuel bunker MPT005 1.5 m3

- blowing fans 3 pcs;

- boiler control panel;

- smoke exhauster D5

- fireman's tool;

- multicyclone economizer

- passport, operation manual.

High performance indicators of the boilers can significantly reduce your heating costs!