The tool you need to get the job done

First of all, for work, you should find out the exact dimensions of aluminum radiators. To measure them, you will need a construction tape or a special folding rule. Also, if both types of devices are missing, you can use the standard student ruler. It should be noted that most of the rulers are only 30 centimeters long, so you will have to make notes on the radiator (it is better to use a pencil that can be easily washed off the surface).

Each new mark will be the end of the previous measurement and the start of a new one. The resulting sizes are added to the true size. Dismantling aluminum radiators requires other tools that are desirable to use for dismantling, namely:

- Complete set of wrenches (socket and ring).

- Radiator key.

- Pliers.

- Screwdriver.

Step-by-step description of dismantling works

A few words about when you may need to disassemble the heating battery:

- In the case of replacing an old radiator with a new one with greater performance and better appearance.

- If you need to add additional sections for the battery.

- If it is necessary to replace a single section or gasket that has leaked.

The instruction begins with the preparation of the necessary tools:

Step # 1: preparing the tools

Photo of nipple wrench

Sample gas wrench

Advice: a nipple wrench, given that it is rarely needed on the farm, and its price is not the lowest, it is recommended not to buy, but to rent. This will save your family budget.

Step # 2: disconnecting the battery

Before disassembling an aluminum or cast iron radiator, it is necessary to disconnect it from the heating system. To do this, it is imperative to turn off the heating and drain the water from the riser, otherwise you will simply flood the room and get burns.

Advice: it is recommended to cover the floor under the battery with a film, rags or at least newspapers before starting dismantling to avoid getting any residual liquid on it, which may end up in the circuit even after draining the riser.

Further, depending on the complexity, three situations can be distinguished:

- Polypropylene pipes. In this case, the sleeve joint is usually twisted with bare hands without causing any difficulties.

- Steel new. With some effort, you will most likely be able to spin the battery inlet and outlet with a gas wrench.

Disconnecting new steel pipes

- Old steel or cast iron pipes. First, we try, removing the paint from the docking place with a blowtorch and a metal brush, we try to untwist the connection as described in the previous version. But in systems that have worked for a long time, most often this does not work, and then we simply cut off the drive with a "grinder" or autogenous.

Cutting old sills using a grinder

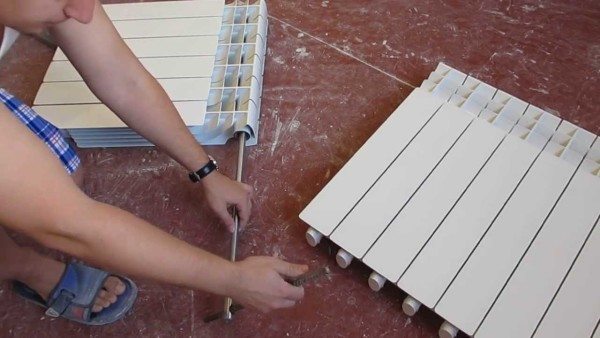

After disconnecting the battery from the pipes, remove it from the hooks and place it on a flat surface.

Step # 3: disassemble the radiator

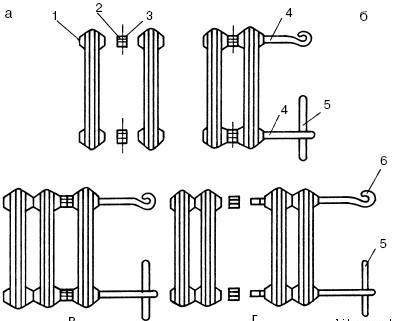

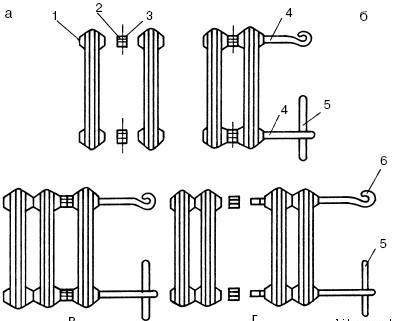

Battery section disconnection diagram

A piece of pipe or crowbar

The battery can be cast iron, aluminum or bimetallic.

The most difficult option for parsing is the first of the listed ones, and we'll start with it:

- How to disassemble a cast-iron heating radiator on your own:

Carefully, we check the thread on the futures or plugs, which can be either left or right.We insert the nipple wrench inside, we increase its torque using a piece of pipe or a crowbar. We tear off the thread by scrolling the tool a quarter of a turn, first at the top and then at the bottom. Then we also alternately continue to unscrew the nipples so that the radiator does not warp. The main problem with old batteries is that the fuses can become stuck in the course of many years of use and not give in to the key. In this case, the junction must be warmed up in a circular motion with a blowtorch, and then again try to unscrew the nipple

We repeat the procedure until the thread gives in. If, however, nothing comes of it, then you will have to cut it with an autogenous gun.

Disassembled old cast-iron heating battery

- Let's find out how to disassemble a bimetallic or aluminum radiator? The procedure is almost the same as described above, but has several differences:

- A smaller nipple wrench is used.

- It does not require as much effort when unscrewing the nipples.

- Plugs and futurocks are marked with the direction of the thread in the form of the letters S and D, where the first designates the left stroke, and the second - the right one.

- The metal gaskets between the sections are wiped, sanded and stored until the battery is reassembled.

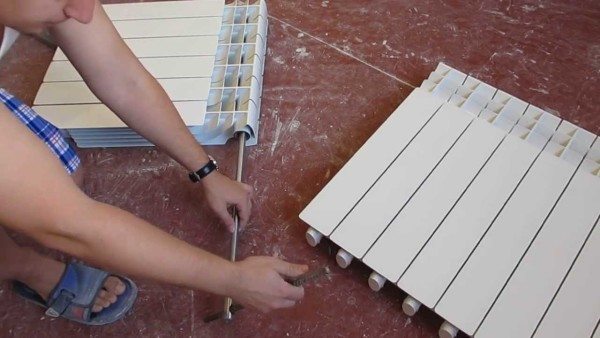

Dismantling the aluminum battery

After completing the described tasks, you can replace the leaking part, add a section, or even install a new radiator in place of the old one.

DIY heating radiator assembly

Having completed the calculation of the sections of bimetallic heating radiators, you can start assembling them. If possible, it is best to entrust this work to professionals. Most often, trading companies provide this service.

For self-assembly of the heating radiator section, you will need a special key. If this is a one-time event, it is best to rent it. Each channel of the battery must have a thread onto which a nipple is screwed - a steel pipe. Valley key bar allows you to assemble radiators with up to 7 sections.

The thread direction in the nipple is different. Those. to connect the heating radiator section, it is enough to install it in the mounting groove and tighten it with a wrench. After the final assembly, the tightness of the structure is checked and pressure testing is mandatory.

The video material describes in detail the specifics of the installation of radiator sections:

Hello everybody! this short post will focus on assembling or disassembling sectional heating radiators. Here we will talk about three types of radiators:

- Aluminum.

- Bimetallic.

- Cast iron.

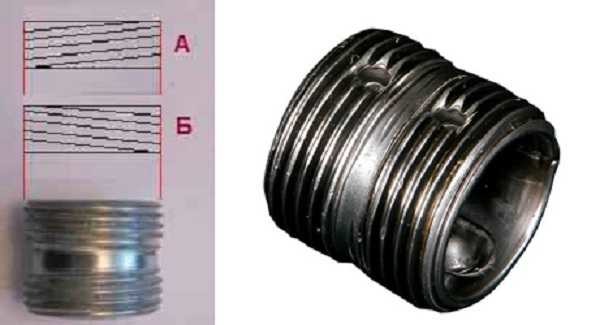

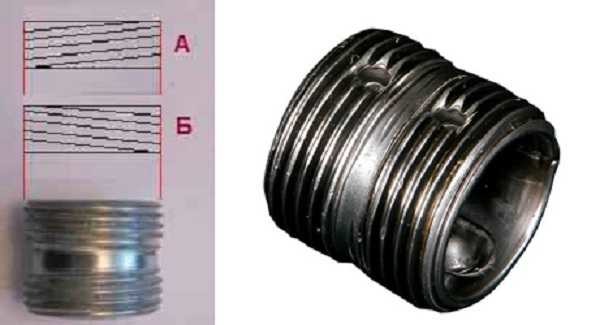

All of them are sectional and therefore they can be assembled and disassembled. Although some manufacturers specifically change the nipple so that their radiator cannot be disassembled with a regular key. So, I said an incomprehensible word - nipple. Now I will show what it is:

This is an ordinary piece of iron, on which there is a left thread on one side and a right thread on the other. The white ring in the middle is the spacer between the sections. In this case, it is made of silicone, but it can be made of paronite. The diameter of the nipple for aluminum and bimetallic radiators is one inch, but for Soviet cast-iron radiators the nipples are 1¼ inch in diameter. This means that these heaters require different keys. Now let's talk about keys.

You will need a tool to disassemble and assemble the radiator. This "miracle of technology" looks like this:

This is not the only performance option for this kind of instrument. You can find many design solutions in stores. For example, these are:

Regardless of how the key looks, its task is to unscrew and tighten the nipples. Personally, I have always assembled radiators using the first option of the key. It is desirable that the tool is made of hardened steel.Otherwise, one key will be enough for you only for a few joints, and then it will become unusable and you will have to buy a new one.

In order to build up the radiator, you will need a pair of nipples, a pair of gaskets, a key, and preferably an assistant. Twisting the radiators alone is an extremely inconvenient task. First, inspect the ends of the sections. The paint layer at the end can be thick and will need to be cleaned with a knife. There should be no sagging and unevenness at the end. This mainly applies to Chinese heating appliances, while in European ones the paint layer is usually thin, even and does not require finishing with a knife.

After finishing the ends, you should see the following picture:

Only no need to use a file to clean the end face!

You can damage the flats of the ends and they will no longer compress the gasket.

Now I will show you a brief photo-instruction for assembling / disassembling the radiator. So let's get started:

Place the radiator face up on a table. Then insert the key into it until the joint that you want to untwist. In this figure, the key must be turned in the direction of the ribbing.

Having slightly unscrewed one joint, rearrange the key (to the lower or to the upper) and repeat the operation. At the end, there should be the following result:

Unscrew the nipples to the end and that's it! The radiator is disassembled!

The radiator is assembled in the reverse order. We look at the following photos:

Here the ends of the sections have already been cleaned and gaskets are put on the nipples. Move on!

The nipples are twisted alternately. In this case, it is necessary to compress the radiator so that the nipple enters both sections equally. Otherwise, the joint will leak. Then we begin to alternately tighten the joints. You need to do this little by little, rearranging the key from one joint to another. If you twist one joint sharply, then the second will not work due to the skew of the nipple. It just won't follow the thread. Everything should be as shown below:

After the sections are closed, you need to forcefully stretch the joints. Without this, they will leak. You do not need to exert too much effort, otherwise you can break the key or it will slip in the nipple and you will injure yourself with its handle. Unfortunately, I did not have the opportunity to shoot my own video on assembling and disassembling the radiator, so I have to use someone else's, but as soon as I have the opportunity, I will replace it with my own:

For a change, let's see how cast iron radiators are disassembled:

How to disassemble an aluminum heating radiator with your own hands

Removal of the aluminum battery occurs in the following cases:

- When the system changes completely.

- It is necessary to increase or remove the extra section.

- Eliminate the leak.

Before disassembling the aluminum radiator, you need to prepare a set of wrenches and a screwdriver.

Further actions are performed in the following sequence:

The coolant is discharged from the system. If disassembly takes place during the heating season, then you should wait until the battery cools down.

Using a wrench, unscrew the coupling that connects the hose from the battery to the heating pipe.

The disconnected radiator must be freed of water residues and placed on a flat surface with the front side up.

Remove the filter from the battery and rinse thoroughly. This must be done immediately, since the dirt accumulated in it can harden and then it will be extremely difficult to remove it.

Further work is the analysis of the battery into sections. They are interconnected with special nipple nuts. To remove them, you need a key for disassembling aluminum radiators, turning it counterclockwise, they can be easily removed from the radiator

This must be done with extreme caution to avoid skewing.

After disassembly, the battery cells are washed and reassembled in the same sequence.

If it is necessary to eliminate the leak, then a special solution of epoxy resin with the addition of bronze powder is suitable for aluminum radiators. You need to work with this composition quickly, as it dries up in a matter of minutes, so the leakage must be cleaned up and prepared in advance.

How to disassemble a bimetallic heating radiator

Before disassembling a bimetallic radiator, check what metal its core is made of. If the inside of the sections is made of copper, there is a risk of deforming the ends of the horizontal tubes. In the future, this will lead to a violation of the tightness of the radiator.

To avoid damaging the copper core, use two nipple wrenches. As soon as you tore off the connecting nuts, work them synchronously (see photo). If there is no second key, then turn each side separately no more than one turn.

Simultaneous operation with two nipple keys when disassembling a bimetallic radiator.

The procedure for disassembling a bimetallic radiator is the same as for an aluminum one:

- Turn off the heating system and wait for the battery to cool completely;

- Remove it from the wall;

- Insert the nipple wrench so that its head fits into the connecting nut;

- Unscrew it as described above.

Dismantling the old radiator

In general, the process of disassembling an old cast-iron heating radiator is carried out in the same way as a new one. But the problem is that over time, all compounds become covered with scale and practically get soldered to each other. As a result, it becomes simply impossible to do with just a plumbing radial wrench.

In addition, an additional item appears in the work - flushing. The old radiator, in any case, is clogged from the inside with all kinds of dirt. Therefore, if you have already undertaken to improve it. then you need to take care of cleaning the equipment, this will allow it to work much longer and better.

It is advisable to flush outside, so you will protect the bath from damage. The procedure is carried out using ordinary running water, there is nothing complicated about it. But the further process can be quite puzzling. If you find that the nuts are firmly attached to the radiator and do not want to part with it, then you can use three different methods in order to break this union:

- the bonded joint can be separated by heating. To do this, you will need either a blowtorch or a hair dryer. The first option is much more efficient at work, but the second can also give the desired result. Use this accessory to warm up the perimeter connection you want, and then immediately try to remove the nut without waiting for it to cool. If it doesn't help right away, repeat the same procedure a few more times, after each call again trying to deal with the problem. Please note that working with hot metal is very dangerous. do not forget to protect yourself with protective clothing - gloves and an apron - and special glasses;

- if the previous procedure did not help, then you will have to try to solve the problem with a more radical method - sawing. As a tool for this, you will need a hacksaw for metal or a Bulgarian saw. The grinder does an excellent job of sawing metal, but here again the fragility of the cast-iron battery should be taken into account - if you cut the same place for too long, then the material may simply crack, and the entire radiator will have to be thrown away. To prevent this from happening, you should make the cuts in stages, giving the battery a little rest after each run. But in general. if you have the opportunity to spend a significant amount of time and effort, then it is better to use a hacksaw for cutting metal. Of course, this is a much more dreary and time-consuming process than in the case of a grinder. But on the other hand, there is no risk of damaging the radiator in those places where it is not required at all;

- the third option is even more brutal. If heating did not help to solve the problem, and cutting is impossible for some reason, then there is only one way out - just break the desired section. This is done with a sledgehammer. Naturally, you shouldn't beat at full swing, because in this case you will be left without a battery. You need to act carefully and slowly, starting from the middle of the section and gradually reaching the point of its connection with the neighboring one. As with the blowtorch, be sure to wear safety goggles - even if smashed gently, there is a risk that some of the shards will bounce off abruptly.

Dear readers, now you know how to properly disassemble a cast iron battery, even if it is three times your age and desperately wants to maintain its integrity. The assembly is carried out, in general, in the same way, but in the reverse order.

Even if the radiator is completely new, all joints must be thoroughly cleaned with sandpaper before assembly. And in the case of an old battery, this is generally a mandatory procedure. It is also advisable to replace all gaskets. If before that there were rubber ones, then replace them with more modern ones, made of silicone or paronite. These materials are much less susceptible to deformation and have a very long service life.

As you already understood, the most important thing in the process of disassembling a cast-iron heating radiator is accuracy. The fragility of the material requires an extremely leisurely approach

In addition, do not forget about safety, which, as you know, comes first. With the right approach to the process, your cast iron radiator will serve for a long time and efficiently. Good luck!

Calculation of the number of sections for heating radiators

The correct calculation of sections of bimetallic heating radiators begins with an analysis of the room where they will be installed. Its basis is the calculation of heat losses in the house. Most of them happen through walls and windows.

They should become the basis for calculating the number of heating radiator sections per room. The comfortable temperature in the room should be 18-22 ° C. Based on this, the thermal mode of heating is selected, and as a result, the parameters of the batteries.

Approximate calculation

The material of the walls and the characteristics of the insulation are not always known. In this case, an approximate calculation of the number of sections of cast-iron heating radiators is made. To do this, you can use two techniques:

- 10 m² of area requires 1 kW of thermal energy;

- For 1 m³ of room volume, the heating system must generate 34 watts.

As an example, you can calculate the number of heating radiator sections for a 20 m² room with a standard ceiling height of 2.55 m. In this case, the total volume is 51 m³. Let's assume that the heat output of one section is 160 W. We calculate their number:

- By area - 20m² * 0.1kW / 0.16kW = 12.5 or 13 sections;

- By volume - 51 * 0.34 = 17.

As you can see, when calculating according to the last method, the number of sections is significantly larger. This is due to regulatory requirements.

Exact calculation

To accurately calculate the maximum number of sections in a heating radiator, it is necessary to operate with the characteristic of the thermal conductivity of materials. This indicator determines how much heat will leave the room through the walls.

First, the total area of external walls and, separately, of window structures is calculated. Suppose the former occupy 2.55 * 5 = 12.75 m². The total area of the window is 3 m². Then, to calculate the sections of bimetallic heating radiators, we will find out what materials were used in the construction of the house. Most often it is a building brick, the thermal conductivity of which is 0.16 W / m * C.

But for the correct calculation of the number of heating radiator sections per room, you should know the thickness of the walls. This is necessary to calculate the heat transfer resistance - the coefficient inverse of thermal conductivity.On average, the thickness of the supporting structures is 0.6 m.

We calculate the heat transfer resistance for 1 m²:

0.6 / 0.16 = 3.75 m2 * s / W

Based on this, the heat losses for the wall will be:

(1 / 3.75) * 12.75 = 3.4 kV

Using the same principle, we calculate heat losses through window structures, taking the average value of heat transfer resistance 0.9 per 1 m2:

(1 / 1.9) * 3 = 1.57 kW

The final heat losses in this case will be 3.4 + 1.57 = 5 kW. This figure must be taken as a basis for the correct calculation of the number of sections of cast-iron heating radiators, in which the specific heat output is on average 200 W:

5 / 0.20 = 25 sections

This amount is not overestimated, since, according to the initial data, the wall is not insulated. If you install at least 100 mm of expanded polystyrene on the outer wall, then the estimated number of heating radiator sections will significantly decrease. The heat transfer coefficient of polystyrene foam is 0.015 W / m * s. Then the heat losses will consist of the sum of the heat transfer resistance of the walls and insulation:

(0.6 / 0.16) + (0.1 / 0.015) = 10.41 m2 * s / W

(1/10,41)*12,75=1,22

1.22 + 1.57 = 2.77 kW

2.77 / 0.2 = 14 sections

As can be seen from the calculation of the maximum number of sections in a heating radiator, even a relatively small insulation significantly reduces the heat loss of a room.

In addition to walls and window structures, heat losses through the ceiling and floor must be taken into account. This is especially important for the first floors of private houses without a basement.

Dismantling the aluminum and bimetallic radiator

Before disassembling the radiator, prepare the necessary tools.

A nipple wrench is used as the main tool (can be rented in a specialized store for little money). It is a bar with a length of about 700 mm. On the one hand, a key head with a size of 24x40 mm is welded to it, and on the other, a through hole is made. You can insert a metal bar into it. With its help, it will be easier to scroll the nut.

This is the main tool used when assembling / disassembling heating radiators.

There are several notches on the surface of the key. The distance between them corresponds to the width of the radiator section. By inserting the key inside the battery, and counting the number of notches, you can easily find the nipple for the desired section.

Before disassembling the heating battery, you need to orient yourself with the direction of rotation of the key. Place the radiator face up on a flat horizontal surface. There will be a right-hand thread on the right, and a left-hand thread on the left. In order not to get confused, you can do it easier: take the nut and bait it alternately on the right and left, and then we conclude in which direction to turn the key

This is important because the threads are easy to rip off and two new sections must be purchased. Imported manufacturers make the following designations for the thread on the plugs and butts on the front side of the section: D-right, S-left

The thread on the nipple nut can be right or left, therefore, before disassembling the radiator, we determine which direction to turn

Let's say you need to unscrew one section on the right. To do this, insert the key with a "spatula" into the upper hole to the desired location, fix it in the groove of the nipple-nut and with an effort turn the key counterclockwise, "pull it off". This is where a rod inserted into the ring on the key may be needed: a decent amount of effort is required.

We make two full turns and move the key to the bottom of the radiator. We repeat the operation by rotating the key in the same direction. We unscrew the nipple by 2 turns here too. Take out the key again and repeat the procedure for the upper part. So, one by one, unscrew the section completely. This is done so that there are no distortions.

Dismantling aluminum radiators

Diagram of aluminum heating radiators.

Aluminum or bimetallic heating radiators are disassembled in the same way as cast iron, but there are slight differences:

- these are the smaller sizes of keys and nipples;

- as a rule, these are new products, therefore, when disassembling them, you do not need to apply such significant efforts as in the case of cast iron;

- on the front side of the plugs and sleeves there are designations S and D, respectively, for left and right threads.

Metal gaskets are installed between the sealing sections. After disassembly, they should be wiped, cleaned and stored for later assembly.

Under the plugs, gaskets are usually made of silicone, during assembly they cannot be used and must be replaced with new ones.

Many models of aluminum sections are non-separable. You can disassemble them, but you will not be able to assemble them.

Disassembly requires tools and materials.

Is the boiler running at full capacity, but the temperature in the house is low? Possibly a problem with the heatsinks that cannot handle the load. It is possible to achieve an increase in the efficiency of the heating system if you understand how to disassemble a cast-iron battery, transfer it or increase it to the existing additional sections. The process of building up a heat exchanger, in which a nipple for a cast-iron radiator is a connecting link, is quite simple, but at the same time it requires meeting a number of requirements.

Product design

An aluminum radiator is a structure of separate sections, interconnected by means of nipple nuts. In fact, this connecting element is a cylinder, on each side of which an external thread is made. The inside of the cylinder is empty. Radiator sections are screwed onto each nipple-nut from both sides.

Connectors are located at both the top and bottom of the battery. Thus, each section of the radiator is attached to the adjacent one at four points. The nipple-nut is made in such a way that it is completely invisible in the assembled product.

There are projections on the inside of each connector that serve for the installation procedure. A special tool clings to them, with the help of which the nut is untwisted and tightened. In this case, the direction of the thread should be taken into account - on some elements it is right-hand, on others it is left.

In order not to play the "guessing game", just pay attention to the markings in the corresponding areas. If the letter D is indicated there, this means that the thread is right-hand

The letter S indicates the left

It is very important not to confuse, as an attempt to unscrew the nut in the opposite direction can lead to thread stripping and, consequently, damage to the element.

General connection requirements

Before installing the device, it must be properly assembled. Detailed instructions are usually supplied by the supplier to the equipment itself.

Assembling the radiator

The procedure for assembling the device is as follows:

- screw in the plugs and plugs in the radiator;

- attach shut-off valves;

- attach temperature controls;

- inspect the nipples for reliability;

- connect the air valves with the heads up.

Installing the appliance

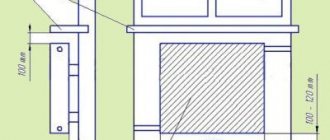

Installation of aluminum radiators can be done by yourself. For correct installation, all requirements and rules must be strictly observed. Before starting work, calculations should be made. The device should be located at a distance of at least 10 cm from the window sill, at least 12 cm from the floor and at least 3 cm from the wall. Then attach the brackets with dowels. The holes are covered with a cement mixture. The radiator is attached to the wall.

After installing the aluminum device on the brackets, you can start connecting. This requires a pipe wrench. Before doing this, make sure that the heating system is off. Tighten the sections with FUM tape. Further, a radiator is attached to the pipes using squeegees.

After all the work on the connection, the device is pressurized.Each element must be filled with coolant gradually, in order to avoid pressure shock inside the radiator. The packing film is removed after the connection is completed. It protects the device from mechanical damage.

Aluminum radiators should be checked twice a year. It is also recommended to drain the water periodically for two weeks.

Is it possible to independently change the configuration of the radiator, increase or decrease its heat transfer? This problem can be solved if you first understand the design. Therefore, you need to find out the specifics of each type of heating radiator section: quantity calculation, assembly instructions and operational properties.

Dismantling cast iron heating radiators

Dismantling cast iron radiators sometimes becomes a very laborious process, but necessary.

Diagram of disassembling cast-iron heating radiators: a - gripping the threads of the sections by 2-3 threads by the nipples; b - turning the nipples and joining the sections; c - connection of the third section; d - grouping of two radiators; 1 - section; 2 - nipple; 3 - gasket; 4 - short radiator key; 5 - crowbar; 6 - long radiator key.

Place the new or old radiator on a level place. At least on one side, you need to remove the usual footwear or blind plugs. On different sections of radiators, they can be left-handed or right-handed. Typically, cast iron fittings have a right-hand thread, and plugs have a left-hand thread. If there is no disassembly skills, and there is a free section, it is better to find out, before applying force, what kind of this thread and in which direction the key should be turned. If the thread is left-handed, turn the key clockwise when disassembling the cast-iron batteries.

As with unscrewing any nuts, you first need to "rip" the footwear from its place, ie. turn them a quarter turn on both sides of the battery. Then the foots are unscrewed so that a gap of several millimeters forms between the sections. If you let go of the footwear more, the whole structure will begin to bend under its own weight and due to the applied forces. This can jam the threads. To prevent this from happening, an assistant must stand on the disassembled battery, who will prevent bending with his weight.

Usually, the dismantling of old heating radiators is complicated by the fact that the footwear and sections are "stuck". In order to disassemble such a battery, you will have to use an autogen or a blowtorch. The junction is warmed up in a circular motion. As soon as it is warmed up enough, the shorts are unscrewed. If it was not possible to unscrew it the first time, the steps are repeated.

If you do not have enough strength to disassemble the battery, you need to increase the length of the key. An ordinary pipe is used, which serves as a stepping stone.

The built-in nipples for venting cast iron radiators are unscrewed in the same way.

If it was not possible to disassemble the cast-iron battery with the considered methods, it remains to cut it with a grinder or autogenous gun or break it in a supine position with a sledgehammer. You need to split or cut one section carefully. After this operation, the adhesion between the sections may weaken, the battery can be disassembled, the remaining sections will be saved.

The use of a "liquid key" or WD liquid does not give an effect, since in old cast-iron batteries the fittings were sealed with linen and paint, and liquids will not get on the threads.

How to disassemble a cast iron heating radiator

It is much more difficult to disassemble a cast iron battery than an aluminum or bimetallic radiator. As a rule, her age is much older, so all connections are hopelessly stuck, so you have to sweat.

To work, you need the following tool:

- Nipple wrench;

- Gas wrench, preferably with a long handle;

- Bulgarian.

In old houses, cast iron batteries were often welded to pipes. Therefore, you will have to cut off pieces of pipes from all sides, where they are brought to the radiator.

If the pipes have couplings (see photo) or nuts, unscrew them with a gas wrench. It happens so that they are firmly stuck, and paint has got into the grooves. In this case, moisten the joints with a solvent to remove the paint, then treat them with a rust converter.

Muvda for connecting a cast-iron radiator to heating pipes.

Remove the cast iron radiator from the wall mounting hooks and lay on a horizontal surface. Insert the nipple wrench into it so that it reaches the desired nut and try to unscrew it.

The nut can have left and right threads, try to strip it in both directions. If you cannot do this, do not apply excessive force - cast iron is a rather brittle metal, and you run the risk of breaking the thread. Better use a solvent and rust remover.

After the nut begins to loosen, alternately turn it two turns at the top and bottom of the section so that it does not go into distortion.

How to disassemble cast iron batteries with your own hands

Most often, old-style houses and apartments are equipped with MS-140 cast iron batteries. Nipple nuts and gaskets are also used to assemble their sections. It is especially difficult to disassemble an old battery. in the course of its long-term operation, the gaps between the sections boiled with rust. As a rule, in such cases, the key niches are eaten away by the coolant.

It is also important to keep in mind a significant mass of cast iron. For example, the weight of one battery for 12 sections is 90 kg: it will be difficult to cope with such a product alone.

To implement the procedure, the following tools are required:

- Nipple radiator wrench.

- Plumbing fixtures for unscrewing sleeves and plugs.

- Small sledgehammer and chisel.

- Blowtorch (it can be replaced with a building hair dryer).

- Steel brush.

- Wooden blocks for installing the battery on the floor.

In the role of a radiator key, a round metal rod with a diameter of 18-20 mm flattened at one end is used. The dimensions of the flattened part are 28 × 40 mm, with a thickness of 6 mm. A ring is welded to the opposite edge of the rod, through which the lever is threaded. The length of the radiator wrench should be as long as half of the largest 12-section battery, plus 30 cm.

Disassembly procedure

It is very difficult to separate stuck intersection joints. In some cases, they stick so strongly that even significant physical efforts are powerless. In such situations, the joints are warmed up before disassembly with a blowtorch or hair dryer.

How to disassemble a cast iron heating radiator:

- Cast iron is heated with a blowtorch until it starts to emit a crimson glow. After that, the disassembly procedure can begin.

- The first step is to unscrew the plugs.

- The radiator wrench is brought to the top of the battery: its head should fall on the area of unscrewing the nipple-nut. At the end of the section, you need to use chalk to mark the circle where the tool rod is located.

- The flattened part is inserted into the lower inner groove. Further, moving the tool in the desired direction, bring it to the marked circle.

Before starting the operation, it is important to find out in which direction it is necessary to twist the sections. If there is a nipple nut, it is screwed in turn on the right and left ends of the battery: this makes it possible to determine the direction of rotation of the nipple

If the thread moves, do not completely loosen it. To avoid misalignment, the top and bottom nipples must be unscrewed one full turn alternately.

From the author:

hello dear friends! Often, the question of how to disassemble an aluminum heating radiator arises before the owners of dwellings. This happens in two cases. The first is equipment breakdown, malfunction, or leakage of one of the segments.

The second - when the power of the product is not enough to heat the room with high quality. This usually happens if the required indicator is initially incorrectly calculated. That is why it is recommended to invite a specialist for preliminary calculation of the required parameter.

A professional calculates even the slightest nuances. In this situation, all factors are important - for example, the climatic zone in which you live, the area of the premises that need heating, the condition of the window frames, the presence of an insulation layer on the walls, and much more.

It is clear that a person who does not have the appropriate knowledge and experience will not be able to correctly calculate the required power. Therefore, in fact, it often turns out that an aluminum battery is simply not able to provide the required amount of heat. Fortunately, this problem can be solved quite easily by disassembling the product and adding the required number of sections. You will learn how to do this in today's article.

The main reasons for repairing an aluminum radiator

Why do such incidents occur? The fact is that aluminum heating batteries are not entirely suitable for installation and operation in such buildings, due to the limit of the permissible operating pressure of the product. For aluminum radiators, the maximum (permissible) operating pressure is within 15 atmospheres. Installing an aluminum radiator in an apartment with an external heat supply source forces the product to work at its limit, since the working pressure of the central heating system, as a rule, is within 12-15 atmospheres, and during pressure testing (system start-up) it reaches much more.

As you understand, an accident of an aluminum battery, in such operating conditions, is inevitable and can happen at any time and it is not necessary that you wake up at the same time to be at home and be the first to know about it. So, based on the above, a sudden accident of an aluminum structure can lead to large - serious financial costs that will have to be spent not only on repairing your premises - an apartment, but also on compensation for the consequences of the accident, neighbors ...

But there are other reasons that force urgent repairs, interference with the integrity of the battery design, that is, to attract a qualified specialist or disassemble and assemble an aluminum heating radiator with your own hands. If you decide to do it, in order to save money or other circumstances, on your own (on your own), then you will have to thoroughly study the topic and find out: "How to properly disassemble and assemble an aluminum heating radiator with your own hands?"

As practice shows, there are three main reasons that imply urgent, professional repair (disassembling and assembling an aluminum heating radiator on your own):

- Clogged heating battery. The radiator is barely warm (not all sections are of the same temperature), although the pipe of the heat source is hot. Such a defect involves disassembling and washing the product;

- Between sectional battery leak. Moisture appears between the joints of the sections or fluid flows - it involves disassembling the structure and replacing the sealing elements;

- Leaking radiator section. The appearance of a crack or other defect, directly, in the section itself, which provokes the allocation or leakage of the structure, implies the replacement or restoration of the sectional element, or the entire battery.

Useful Tips

Interesting fact. Many people do not want to use cast iron radiators solely because of their appearance. But recently, it is the cast-iron retro heating batteries that have become widespread. These are the models from which they so diligently left. Fans of retro style often specially order such models in stores.Admirers of more modern design can be offered to decorate cast-iron radiators with special screens.

There is no heat loss from the screens, but the batteries look somehow very simple, but stylish. Those who do not want to change their batteries can simply bring them back to their original beautiful appearance. Batteries can be repainted using modern materials or you can give them a rather unusual look yourself. When choosing materials, be sure to select those that can withstand high temperatures over 80 degrees. It is advisable to consult with sellers about painting materials. There are some paints that can change color when interacting with hot surfaces. In this case, by carefully painting the battery in a snow-white color, you can see a completely non-crystal white version during the heating period.

How to disassemble a cast-iron heating battery with your own hands

Sooner or later, it may turn out that even a cast-iron battery will require a complete replacement or you will just need to clean it. In both cases, the battery must be disassembled. How to disassemble a cast-iron heating battery with your own hands quickly enough and as professionally as possible? The fact is that such radiators are the best option for use in apartment buildings. These heating elements are able to withstand all the vicissitudes of an imperfect heating system. Sometimes, over time, even the cast iron has to be changed, because it has leaked or simply does not fit into the new apartment renovation.

Although even today, cast iron batteries are still relevant. Many users do not want to change such good heat sources for new ones, but such heat sources are so short-lived in comparison with cast iron. Therefore, most people try to get their batteries in order by simply repainting them. Some people use decorative screens for cast iron batteries. It is very convenient and looks like new radiators and there are no problems in design. (See also: DIY installation of heating radiators)

Any replacement of batteries can be performed only in the summer, when the heating season has not yet begun or, on the contrary, has just ended. But sometimes circumstances develop in such a way that it is necessary to change and disassemble the battery in winter. For example, if the battery leaks, what should I do? Wait for summer or the fact that one day the radiator will break through and the neighbors below will be flooded?

You can try to use the services of plumbers, but you can cope with the situation yourself. In order to disassemble a cast-iron battery, you need special tools and some knowledge, which we will tell you about.

Battery assembly

In principle, having the necessary tools at hand, even a beginner will be able to assemble or disassemble an aluminum radiator with his own hands.

To install an aluminum radiator heater with your own hands, you must:

Place the battery on a flat surface. This is necessary in order to inspect the device before installation and check all the joints for possible cracks or chips.

Before connecting the elements of the heater, the threads at the joints are cleaned not only of debris, but also of factory paint. This is done using fine-grained sandpaper.

This is important, as the paint layer can crack in the future, leading to a leak. For the sake of presentation, manufacturers paint not only sections of radiators, but also their joints.

When cleaning the battery from paint, you need to make sure that the sandpaper does not leave scratches on it, which can also cause leaks in the future.

All gaskets should be washed in soapy water. and if antifreeze is supposed to be used in the heating system, then they need to be degreased, since this carrier is able to penetrate into any, even the most insignificant irregularities.

Before connecting the sections, it is advisable to study the drawing of the key for assembling an aluminum radiator in order to know how to use it. This metal is very soft, so any too much force can damage the threads and then you will have to buy a new section.

A paronite seal is put on the nipple nut on both sides. The key is placed on top and can be easily turned a couple of times, the same is done with the bottom hole. Only after the joints have been tacked can you tighten them with a lever more tightly.

The hole that will not be used is closed with a plug, and the Mayevsky crane is attached to the other, and the aluminum radiator assembly is ready.

After all sections of the radiator have been assembled, it can be connected to the heating system and checked for possible leaks. Since aluminum batteries are quite lightweight, they can be easily connected by hand, even without the appropriate skills.

Some features of cleaning radiators

The main condition for the correct and effective use of the product is its purity. This procedure should be performed every year when the heating season ends. To clean the radiator you may need:

- Steel rope.

- Bronze powder.

- Epoxy resin.

The cable is necessary to perform work on cleaning the damaged area, if any. Epoxy resin and bronze powder are necessary for the preparation of mortar, which is used to putty on damaged surfaces. The user chooses the consistency of the solution on his own. The main condition is that the resin does not harden before it is applied to the damaged area of the heating system.

Cleaning from the remnants of rust, dirt that enters the system with water, is carried out after disassembly, which is described above.

After reading this manual, there should be no questions left, but if they did appear. You should consult with a professional or entrust him with the performance of this work.

The use of materials is permitted only if there is an indexed link to the page with the material.

For the first time, aluminum radiators appeared on the world markets for heating equipment in the 80s of the 20th century. Next to the heavy ribbed "monsters" of cast iron, they looked elegant and stylish.

Naturally, the demand for them was huge, but only a decade later, the first aluminum batteries showed their shortcomings.

To date, manufacturers have significantly improved the performance of aluminum batteries, so they now have much more positive qualities than before. The assembly of aluminum heating radiators has also been simplified and now they can be installed or disassembled without the involvement of specialists.

They became frequent "guests" of private houses and apartments in houses with centralized heating.

This became possible thanks to the qualities that have won the hearts of consumers around the world:

These qualities have made aluminum batteries in demand all over the world, despite the fact that they have minor disadvantages:

- Aluminum is not resistant to corrosion, but modern radiators are treated with special agents that prevent corrosion. But even after processing, it is better to keep such heaters filled with a coolant, which is difficult to do in a centralized heating system, where water is discharged after each end of the season. That is why aluminum batteries are more in demand in autonomous systems, where there are no such discharges.

- Batteries of this type are prone to air bubbles

, therefore, at the beginning of the heating season, excess air must be vented from them. - The threaded connection in aluminum models is weak and with a strong water hammer, leakage may appear at the joints.This defect can be eliminated only by knowing how to assemble an aluminum heating radiator using additional gaskets.

This type of radiator is available in two types: one-piece and sectional. The second is most common in private homes and apartments.

In principle, having the necessary tools at hand, even a beginner will be able to assemble or disassemble an aluminum radiator with his own hands.

To install an aluminum radiator heater with your own hands, you must:

After all sections of the radiator have been assembled, it can be connected to the heating system and checked for possible leaks. Since aluminum batteries are quite lightweight, they can be easily connected by hand, even without the appropriate skills.

Removal of the aluminum battery occurs in the following cases:

- When the system changes completely.

- It is necessary to increase or remove the extra section.

- Eliminate the leak.

Before disassembling the aluminum radiator, you need to prepare a set of wrenches and a screwdriver.

Further actions are performed in the following sequence:

After disassembly, the battery cells are washed and reassembled in the same sequence.

If it is necessary to eliminate the leak, then a special solution of epoxy resin with the addition of bronze powder is suitable for aluminum radiators. You need to work with this composition quickly, as it dries up in a matter of minutes, so the leakage must be cleaned up and prepared in advance.

How to solder an aluminum car radiator with your own hands

Let's move on to the soldering process. First, the problem area is carefully cleaned with a file and sandpaper. Before proceeding with the replacement of the Peugeot 307 timing belt with your own hands, you need to prepare the tools that we need for this operation on the nfu engine. If there are slats on it, they must be carefully removed with pliers. Aluminum radiator with your own hands, a car that, as already. Further, the place of repair is degreased with acetone.

When the brazing preparation is complete, the flux can be applied. After that, we begin to warm up the junction. If you are using a gas torch or blowtorch, be careful not to burn out the flux ahead of time. It is easier to apply it with a soldering iron. It is enough to dip its working element into the mixture and transfer it to the surface to be treated.

Now it's time to apply the solder. How to repair a toyota radiator It is better if it is in the form of a bar or wire. The solder is applied to the junction and carefully warmed up with a soldering iron (torch). When it spreads evenly, it is necessary to let it cool down, after which it is advisable to apply a second (safety) layer. At the end of the work, the formed nodules can be removed with sandpaper.

Dismantling and assembling an aluminum radiator with your own hands

The site where the radiator will be restored, covered with dense fabric

... If this is a table surface, then the main work will not take place on weight. The prepared place will protect soft aluminum from getting unnecessary deformations and scratches.

Important ! Before removing the union couplings, a rag is spread under the radiator to protect the floor from dirty liquid that may leak out during dismantling. You need to have a rag on hand to absorb the moisture remaining inside the sections

Disconnection from the heating network

Before starting disassembly, the radiator is disconnected from the heating network shut-off valves

... If the radiator has no shut-off valves, then

invite a housing and communal services worker

so that it turns off the heating riser for repair work.

During the heating season, after closing the radiator, pause. Since the water is still hot wait a while until the liquid cools down

, and then disconnect the radiator from the heating pipes.

Heat carrier

remaining in the battery

poured into a prepared bucket

and proceed to the separation of the sections. Immediately after dismantling, the inner surface of the battery is rinsed with running water.

How to disassemble and reassemble the battery

Aluminum sections, connected nipple nuts

... The inner part of such a connector has protrusions for which a nipple wrench grips the nut and unscrews it. The nut is like a clutch, only

her thread is external

... One nipple nut has both right-hand and left-hand threads. They are made in pairs for the top and bottom connection. When the nipple is unscrewed, the sections diverge, when tightened, they are pulled together with each other.

Preliminary all plugs and adapters are twisted from the ends

... The connector must be accessible from all sides for the nipple wrench.

Photo 1. Fastening the sections of the aluminum radiator to each other: the nipple-nuts are unscrewed when disconnected.

To disassemble the battery, the tool blade is placed through the open end of the radiator into the slots of the unscrewed top

nipple-nuts and with some pressure make a trial

scroll counterclockwise

to move the connection. If the key turns the nut normally, then it is inserted into the grooves

bottom

nipple nut and, as in the first case, try to turn it a couple of turns.

Important ! When unscrewing the connectors, follow the sequence to avoid skewing. After disconnection, the exposed thread is carefully examined for cracks and chips, for thread integrity

If necessary, the joints are cleaned with fine emery cloth

After disconnection, exposed thread carefully examined for cracks and chips

, on the

thread integrity

... If necessary, the joints are cleaned with fine emery cloth.

Starting the assembly of the radiator sections, onto the upper and lower nipple-nuts put on o-rings made of paronite

, placed between the sections. I lightly press the sections against each other and screw them up alternately.

Turning the nuts

, so as not to get skewed, is limited to

two turns of the key

.

If something went wrong

During operation joints between sections and steel nuts stick to each other

... This comes from the quality of the coolant supplied to the heating system. Sometimes even considerable physical effort is useless.

Despite the fact that sticking must be dealt with, aluminum is easily deformed

as it is a soft metal.

By heating with a construction hairdryer, the joints can be overcome stuck on rust

... If this did not help, too, having corroded too much, then the edging machine gets down to business.

Advice.

If the nipple nut does not release under strong pressure, then

no need to increase the applied force with excessive leverage

... In the worst case, not only the nut itself will break, but both sections, which sit tightly on this nut, will crack.

The grinder is trimmed leaky section

, moreover, on the reverse side and stepping back from the edge of the connection at least half the length of the coupling. This protects the working section from destruction and does not cut the connecting nut. The rust bounces off during trimming, making it easier to unwind the intact section.

What fittings may be required to assemble batteries

Installation diagram of a cast iron battery.

If the heating system is one-pipe, then tees of the following diameters will be needed: for the supply main pipe, for example, 25 mm, for the outlet to the radiator and the bypass pipe, 20 mm each. If the main supply pipe has a diameter of 35 mm, then the pipes will have diameters of 32-25-25.

For each heating radiator, you will need two such tees. On sale there are both polypropylene radiator taps and metal ones, which are somewhat more expensive. The reliability and durability of the valves depends on the quality of the coolant. Each radiator needs two such taps.

If the walls are not made of solid enough material, special brackets must be used. After all the necessary materials have been purchased, you can start assembling and installing radiators.

Before the assembly and installation of bimetallic or cast iron batteries begins, it is necessary to mark the place where they will hang. To do this, make marks on the wall with a pencil at the attachment points of the brackets. Marking must be done by level. In addition, it should be noted that the brackets must be fastened so that they are located in the gap between the battery sections.

When making markings, it is necessary to take into account the height of the radiators from the window sill and the floor. In order not to make mistakes, heating radiators are applied to the walls and a mark is made in such a way that the brackets, after fastening, are between the sections of the battery.

After marking the walls, holes of the appropriate diameter are drilled. The hole diameter must match the size of the dowel that comes with the radiator. Then the dowel is inserted and the bracket itself is screwed into it.

Diagram of a bimetallic radiator.

Before installing a bimetallic heating radiator, it must be assembled. To do this, you will need the following materials and tools:

- radiator sections;

- tow;

- Unipak paste;

- fum tape;

- radiator taps;

- brackets;

- dowels;

- electric drill;

- spanners;

- pencil.

From the radiator valve, you need to unscrew the part with the threaded connection, the winding is wound on the thread. For these purposes, it is best to use tow in combination with a special Unipak paste that can withstand high temperatures. The paste helps to achieve high tightness of threaded connections of bimetallic radiators. Instead of tow with paste, you can use fum tape or tow with paint.

Before winding the tow, you need to apply paste or paint to the threaded part of the part, evenly distributing it over the entire thread. After that, they take a previously prepared bundle of tow and wind it along the thread. Next, a union nut of the crane is put on the wrapped part and screwed into the stopper of bimetallic radiators. First you can tighten it by hand, and then with a wrench. In the same way, the Mayevsky valve and plugs are screwed into the remaining plugs.

Special rubber gaskets can be installed on the plugs of bimetallic radiators, which can be purchased separately. Another, more reliable option is to wind it from tow with a special paste. After that, the plugs are screwed into the radiator. Please note that two plugs have a left-hand thread, and two have a right-hand thread.

The union nuts of the radiator valves have O-rings so they do not need to be wound. This O-ring will fit into the chamfer on the valve threads, in which case the connection will be tight.

When the plugs are screwed into the batteries, the radiator taps are screwed on. Now you can start soldering the branch pipes with one side to the radiator valve, and the other to the tee. Here you should pay attention to the length of the branch pipes, taking into account the distance from the floor and the fact that part of the pipe will go into the inner diameter of the part to be connected.

During soldering, it is necessary to ensure that the direction of the tee coincides with the direction of the radiator valve.

To do everything right, you can position the tap and pipe on a flat surface and make pencil marks on all the details. During soldering, make sure that all pencil marks match.

https://youtu.be/9BAZDGQIlSA

The next step is to screw the radiator taps directly to the radiator. This is necessary to determine the distance to the bypass section of the supply pipe in a single-pipe heating system. After that, the bimetallic radiators are directly attached to the brackets and checked by level.All radiators after assembly are mounted in the same way. After that, they are tied to the boiler and to each other using a pipeline. The assembly and installation of bimetallic radiators can be considered complete. The main condition for such work is the accuracy of the markings. The radiator must be installed carefully, the connections must not be skewed.

Diagram of the technical characteristics of a cast iron radiator.

Before installing cast iron radiators, it is advisable to unscrew them, tighten the nipples and assemble them. These batteries are usually assembled by two people. To do this, you will need the following materials and tools:

- radiator keys;

- paint;

- brushes;

- brackets;

- dowels;

- electric drill.

The assembly of cast iron radiators is carried out on a workbench using two special keys that are inserted into the nipple holes (each nipple has both an upper and a lower hole). For convenience, a crowbar is inserted into the lower eye of the radiator key. The lower and upper nipples unfold at the same time to prevent the radiator from warping. It must be remembered that the nipples on different sides of the battery have threaded connections of different directions.

Installation diagram of cast iron radiators.

After disassembling the cast-iron radiators and unscrewing all sections, they begin to group. To make the grouping of the two sections, first grasp several threaded threads on each side with the nipples. Then screw both nipples at the same time. In the same way, you can assemble a cast iron battery with any required number of sections.

The assembled battery is then subjected to pressure testing. If water leaks are detected, the nipples are tightened. After assembly, it is advisable to paint the radiator. Before installing a cast iron battery, you need to install a mount for it. In a house with wooden walls, the batteries are installed on stands located directly on the floor, and supporting devices are mounted on the wall. When buying a radiator, you need to check the correspondence of the fastening to the type of your wall on which the heating devices will be mounted.

When installing the battery, make sure that its center coincides with the center of the window. The upper part of the radiator should be at a distance of 5 cm from the window sill, the lower part should not reach the floor at least 6 cm. one bracket each. All heaters installed in the same room must be at the same level. The brackets are usually installed at a depth of at least 12 cm and bricked up with cement mortar.

After the battery is suspended from the mount, it is connected to the heating system. To do this, unscrew the plugs, connect the valve and mount the radiator using squeegees.

Most Popular Blog Articles of the Week

Requires more care and better preparation than disassembly. The assembly of heating radiators can be carried out in any convenient place or in place, without disconnecting the batteries from the heating system (without dismantling), but it is more convenient to remove it.

The choice of the place of future work does not differ from the place of disassembling the radiator (staircase, wooden board, floor). I would like to add that if such a selection is not possible, you can put two wooden beams in parallel, with a distance of 450 - 500 mm between them. To align on a plane, you need to put something under the edge of the timber. The efficiency of the assembly () of heating radiators will depend on the evenness of the site on which the work is carried out.

Radiator assembly tool

What tool is needed to assemble or replace radiator sections? You must first select good fittings, nipples that match 1 ″ (one inch) or 1 1/4 ″ (5/4 ″ - one-quarter inch) with gaskets.Photo), for assembly with a lever and, if necessary, taps for running old threads.

How to properly assemble a cast iron radiator and what technology? The assembly of cast iron heating radiators begins with the preparation of the joints of the sections. On the radiator itself and the sections that will be connected, the support surfaces are carefully cleaned to a shine with a knife or other improvised tool, but not with a file. Often old batteries require a 1 1/4 ″ or 1 ″ inch thread to be tapped. If you do not have it, you can try to use a steel pipe with a good thread (right or left) of the desired diameter, in extreme cases, use a nipple or a futorka. The better the preparation, the more convenient, faster and better it will be done assembly of heating radiators

.

After preparation, you can start assembling the sections. To determine which thread on the nipple (foot or plug), it is enough to turn it along the axis and see in which direction the threads of the thread go (see figure), A - right, B - left. First, two nipples are screwed, with gaskets preliminarily put on them, into the radiator for one thread. To check that they are held in the thread, you should try to pull towards yourself, if they pop out, then you need to tighten a little more. This point must be taken very carefully, because excessive screwing in the thread will not allow the battery to be assembled correctly.

Next, we move the additional section or sections as tightly as possible to the nipples and begin to twist the nipples with a radiator wrench, periodically changing their order in order to avoid distortions (as when disassembling). Twisting is carried out until it stops and still with little effort. Watch the video.