Heating and ventilation costs average 30-50% of the family budget. And the problem is not in the function itself, but in poor quality energy consumption. A convenient solution was offered by Danfoss - a thermostat for controlling the temperature in the house and the operation of the heating system. This device can be used in combination with almost all boilers, including heating devices with a liquid heat carrier.

The thermal head is used at home, in an apartment, production premises, warehouses, closed greenhouses and greenhouses, in a word, wherever a relatively constant temperature regime is required. And this applies not only to heating, but also to air conditioning. So, the thermal head equally successfully interacts with air conditioners, refrigeration equipment and other units responsible for temperature.

Design features

The main purpose of the Danfoss thermostat is to maintain the temperature mode selected by the user for a long time. The design of the device includes two main parts:

- thermostatic element or as it is also called - thermostat;

- valve.

The valve is first mounted on the battery and only then the thermostat is installed on it. It is the second element that is the main one in the design of the device. It monitors the ambient temperature, after which it gives the necessary signal to the valve, which in turn opens or closes the coolant flow.

In the inner area of the Danfoss thermostat there is a bellows - a corrugated container filled with gas or liquid. When exposed to temperature, the filler begins to resize and press on the check valve. When the flow of the coolant is cut off in the heating units, the temperature indicator begins to increase.

If the room is very cold, the filler shrinks and a reverse reaction is formed - the chamber pulls the spool stem behind it, which in turn opens the gap in the valve element for the coolant to enter.

The company produces two types of thermostat - for gas and liquid. But the second option is considered more inert, it gives a signal to change the temperature regime much more slowly.

Varieties and symbols of devices

The type of filler and purpose is defined by the following abbreviation:

- RTS - liquid bellows

- RTD-G - gas appliance for one-pipe or two-pipe system, in which there is no pump

- RTD-N - gas device for one-pipe, two-pipe pumping system

In some models, in addition to the basic function, there are a number of additional options. For example, a program to protect against tampering with the installed settings by random persons. The option will be convenient for installation in public institutions or childcare facilities. The number of modes and types of functions differ depending on the selected modification.

Model range of devices

The company produces a fairly wide range of Danfoss heating temperature controllers.

The most popular variations are:

- Danfoss RDT marking 3640 - the device is intended for use on heating systems of two-pipe standard type. It is equipped with an RTD option, which excludes freezing of the line in the cold season. Used in domestic and industrial environments. It has four divisions with designations in the form of Roman numerals.

- The Danfoss RAX regulator is a liquid type of devices that is used for installation on designer-type radiators or heated towel rails.Possesses attractive external parameters and minimalistic style. On the case, there are only divisions with Roman or Arabic numerals.

- Living ECO with indoor climate monitoring. It is an advanced series that has been successfully used in commercial establishments and residential buildings. A feature of a thermostat for a heating radiator is that it has a liquid crystal screen that provides all the necessary information about the coolant. Also on the case there are three main keys for setting the modes.

- The Danfoss RA-299 gas appliance with automated temperature control is available in several colors. It reacts quickly to temperature changes. It is used exclusively for equipping traditional heating systems.

- 013 G4 001-013 G4 009 - multifunctional series of devices, suitable both for heated towel rails and for various areas of the heating device. There are left- and right-sided types.

Each of the options presented is completed with parts that simplify the fixing of the device and its subsequent use.

VIDEO: Danfoss thermostatic kits overview

Installation of the thermal head

The Danfoss thermostat is installed directly on the "hot" pipe that supplies the heating medium to the domestic heating system. Installation work does not have any difficulties, even when it comes to design variations, the installation principle is the same for everyone.

It is necessary to follow the following stages of work:

- Mark the delivery port to identify the area to be cut. When doing this, take into account the dimensions of the valve body and remove the threaded element, which will go directly into the pipe.

- Turn off the heating and drain the water so as not to flood the house during operation.

- Cut off the unnecessary pipe section according to the marks and make a thread on the outer part of the cut using a die.

- Treat the connecting part with a special plumbing paste of any manufacturer and a fumka.

- Screw the valve element onto the thread, which was made with a die, and then tighten it well with a washer. It is no longer required to seal the joint area, this connection will be enough to prevent the pipe from leaking.

- Remove the fuse, set the maximum value of "5" on the thermostat and put the housing with the scale on top. The cap is put on until it stops, the defining signal is a ringing click, it indicates the tight contact of the parts.

- Check all connections and connect the heating device back to the common heating system.

Check the function of the Danphos regulator before opening and closing the valve device for the first time. If the installation was carried out according to the rules, there should be no problems.

How to adjust the device

Although all modifications of Danfoss thermostats have differences in external parameters and technical characteristics, the device setting is done in the same way. To implement it, you will need to refer to the operating instructions and study the designations of the modes indicated on the device case. The indicators may differ depending on which model is used.

Next, set the required temperature mode on the device. To do this, move the torque element to the required mode. If an apparatus with push-button control was installed, all manipulations are carried out by pressing the "add" or "decrease" temperature buttons.

You can also choose an intermediate parameter if it is more suitable for creating a certain microclimate in the house. After a few minutes, the heating system will adjust to the selected values and will reproduce the heating of the room until the desired microclimate is obtained. The valve is set in the same way for refrigeration units.

VIDEO: How to properly install a thermal head on a radiator

The heating system is one of the most important parts of any home. Unfortunately, it is on it that the greatest costs go during the payment of utility bills, and regardless of the installed autonomous or centralized heating.

The thermostats installed on each radiator battery help to obtain a comfortable temperature and significantly reduce the cost of paying bills for consumed thermal energy.

A special effect can be obtained by installing temperature controllers for Danfoss radiators, capable of maintaining the required temperature in the room with an accuracy of 1 degree.

Popular models of Danfoss thermostats

The company's product range includes many different Danfoss thermostats for batteries. The following are popular:

- Regulator RTD marking 3640. It is used on classic 2-pipe heating systems. Equipped with an option that prevents the highway from freezing in cold weather. The Danfoss RTD thermostat is used in domestic and industrial conditions, has four divisions with marks in the form of Roman numerals.

- The RAX designation, as a rule, is for products with liquid, which are used for installation on unusual batteries or on heated towel rails. Outwardly very attractive and fit well into the design. The case has only divisions with Roman and Arabic numerals.

- The Danfoss RA-299 thermostat operates on gas, has automatic temperature control, and is produced in different colors. Reacts promptly to temperature fluctuations. It is used only for installation on classic heating systems.

- The Living ECO appliance has an option to control the indoor climate. It is boldly installed in various office buildings and residential buildings. The product is distinguished by the presence of an LCD screen that displays all the necessary data about the thermal medium. In addition, the case has mode setting buttons at the main buttons.

- There are also series with many functions, they are suitable for heated towel rails, and for different areas of equipment for heating. They can be of right- and left-sided type.

Danfoss Living Connect thermostat

All Danfoss radiator thermostats come with parts that make it easy to mount the unit and to use it in the future.

Working principle and design

Danfoss thermostats are essential to maintain the room temperature. During operation, thermostats monitor the change in room temperature using built-in heat sensors. When the temperature drops, the thermal control system opens the coolant intake, increasing its volume and circulation inside the battery.

After reaching the set temperature, the Danfoss thermostat reduces the supply of the heating medium, thereby reducing the heating temperature and the energy consumption in the heater.

The equipment consists of two main components:

- Thermostatic element is responsible for controlling the device.

- Valves regulating the return of the coolant to the radiator. Performing element.

A small corrugated cylinder is installed in the thermostatic element, which is filled with a liquid or gaseous component that responds to the slightest change in air temperature. In some models, a metal plate made of heat-conducting material is used as a thermostat, but thermostats for Danfoss heating radiators with gas-filled bellows are considered the most accurate.

The temperature control system can be mechanical or electronic. Danfoss radiator temperature controllers with electronic setting are equipped with a small display to show information about the entered program.

Danfoss radiator thermostat valves

Valves for radiator thermostats are divided into: - valves for a two-pipe pump heating system (type RA-N) of increased resistance with a device for adjusting their flow capacity to perform hydraulic balancing of the pipeline system; - valves of increased throughput type RA-G for pumping one-pipe or two-pipe gravitational heating system.

Danfoss valve bodies are made of brass. The connection allows easy and precise attachment of the thermostatic element to the control valve. To identify the RA-N valves, their protective caps are colored red and the RA-G valves are gray.

Danfoss RA-G thermostat valves

| RA-G 15 | Thermostat valve RA-G 15 for one-pipe or two-pipe system, by connection type - straight or angle, connection size - 1/2 "(DN 15). | RUB 1,930 |

| RA-G 20 | Thermostat valve RA-G 20 for one-pipe or two-pipe system, by connection type - straight or angle, connection size - 3/4 inch (DN 20). | RUB 2,460 |

| RA-G 25 | Thermostat valve RA-G 25 for one-pipe or two-pipe system, according to the type of connection - straight or angle, connection size - 1 inch (DN 25). | RUB 3,100 |

Danfoss RA-N thermostat valves

| RA-N 15 | Thermostat valve RA-N 15 for a two-pipe system, by connection type - straight or angled, connection size - 1/2 inch (DN 15). | RUB 1,600 |

| RA-N 20 | Thermostat valve RA-N 20 for a two-pipe system, by connection type - straight or angled, connection size - 3/4 inch (DN 20). | RUB 2,000 |

| RA-N 25 | Thermostat valve RA-N 25 for a two-pipe system, by the type of connection - straight or angle, connection size - 1 inch (DN 25). | RUB 3,600 |

The RA-G and RA-N series valves can be combined with the RA series.

Thermostatic element and radiator valve

The Danfoss thermostatic equipment set consists of a RA-G radiator valve (for a one-pipe or two-pipe heating system) or RA-N (for a two-pipe heating system) and a RA thermostatic element. The set is designed for automatic regulation of the room temperature. Easily installed on various types of heating devices in apartments with centralized one-pipe and two-pipe heating systems.

| RA 2994 / RA-G 15 straight Article no. 013G2164B RA-G 15 straight thermostat valve for one-pipe or two-pipe system, thermostat RA 2994. | RUB 2,990 |

| RA 2994 / RA-G 15 angular Article 013G2163B Angle valve of the RA-G 15 thermostat for one-pipe or two-pipe system, thermostat RA 2994. | RUB 2,990 |

| RA 2940 / RA-G 15 straight Article no. 013G2144 RA-G 15 straight thermostat valve for one-pipe or two-pipe systems, thermostat RA 2940. | RUB 3,200 |

| RA 2940 / RA-G 15 angular Article 013G2143 Angle valve of the RA-G 15 thermostat for one-pipe or two-pipe system, thermostat RA 2940. | RUB 3,200 |

| RA 2994 / RA-G 20 straight Article no. 013G2166B Direct thermostat valve RA-G 20 for one-pipe or two-pipe system, thermostat RA 2994. | RUB 3,390 |

| RA 2994 / RA-G 20 angular Article 013G2165B Angle valve of the RA-G 20 thermostat for one-pipe or two-pipe system, thermostat RA 2994. | RUB 3,390 |

| RA 2940 / RA-G 20 straight Article no. 013G2146 Direct thermostat valve RA-G 20 for one-pipe or two-pipe systems, thermostat RA 2940. | RUB 3,690 |

| RA 2940 / RA-G 20 angular Article 013G2145 Angle valve of the RA-G 20 thermostat for one-pipe or two-pipe system, thermostat RA 2940. | RUB 3,690 |

| RA 2940 / RA-N 15 straight Article no. 013G2154 RA-N 15 straight thermostat valve for two-pipe system, thermostat RA 2940. | RUB 2,900 |

| RA 2940 / RA-N 15 angular Article 013G2153 Angle thermostat valve RA-N 15 for two-pipe system, thermostat RA 2940. | RUB 2,900 |

| RA 2940 / RA-N 20 straight Article no. 013G2156 RA-N 20 straight thermostat valve for two-pipe system, thermostat RA 2940. | RUB 3,290 |

| RA 2940 / RA-N 20 angular Article 013G2155 Angle valve for thermostat RA-N 20 for two-pipe system, thermostat RA 2940. | RUB 3,290 |

Differences between some models

Depending on the model, the installed thermostats can be divided according to the principle of operation and design features.

- Supported temperature ranges from 5 to 30 ℃.

- Temperature measurement sensor option - it can be built-in, remotely controlled and programmable.

- They differ in the type of installation - angled, straight, for bottom or top type of connection.

The most popular are direct heat regulators for Danfoss battery, their design allows connecting batteries with bottom, top and side connections. The only thing that needs to be taken into account is the length of the shut-off valve and the length of the installation pipes must be selected accordingly.

The possibility of implementing any type of connection is carried out thanks to the stem located along the axis of the shank. The model designation of such equipment is RTD-N UK. The wide installation possibilities of the UK model valves make it possible to use them in conjunction with Danfoss floor convectors.

Corner thermostats are attached directly to the point of intake of the coolant by the radiator and require a minimum of additional installation work, do not take up unnecessary space. Sensors such as RTD - N or RTD - G are labeled depending on the model. The increased throughput makes it possible to use thermal valves in closed and open heating systems.

Another type of temperature regulator for Danfoss radiators is the option built into the radiator. Such equipment is widely used in compact devices located in niches, close to the side surfaces. Often built-in valves are equipped with external thermostats.

Thermostat functions

Comfort means maintaining different temperature regimes in the rooms and premises of an apartment or private house. It is impossible to do this in conditions of centralized heating without control equipment for several reasons:

- The radiator has strict parameters and when the temperature of the coolant changes, it will heat up more or less, regardless of the owner's desire.

- The coolant temperature is the same at the radiator inlet in all rooms of the apartment and depends only on the operation of the boiler room.

- If too hot water (steam) is supplied, the rooms will be hot, stuffy and dry.

The only way to regulate the microclimate is to install a thermostat.

Algorithm of action:

- By changing the position of the adjusting head, set the thermostat on the Danfoss battery to the required operating mode.

- At a low temperature in the room, the regulator valve is in the open position and the coolant enters the radiator without restriction - the battery is operating at full capacity, the room is warming up.

- When the required temperature is reached, the regulator gradually shuts off the coolant flow, directing part of the hot water bypassing the battery along the central riser - the battery gives off less heat, the temperature in the room decreases.

The speed and accuracy of Danfoss thermostats for radiators depends on the design of the device.

Installing and configuring the sensor

When installing automatic thermostats for Danfoss radiators, you must strictly follow the instructions. It is not recommended to position the control knob behind bulky objects, behind curtains or inside niches. This will result in distorted measurements by obstructing the uniform flow of air around the sensor.

If the installation of a thermal head for Danfoss RTD 3640 radiators or other similar models is impossible due to the hidden location of the battery, an external remote sensor must be taken care of.

Despite the possibility of installing thermostats in almost any heating system, their joint use with cast iron batteries will not bring the expected results due to the slow cooling and slow heating of the battery.

The thermostat should only be installed by professionals to avoid further problems and malfunction.

The temperature controllers for Danfoss radiators are set once, at the beginning of each heating season. For the correct setting, it is necessary to minimize the heat loss of the room as much as possible, for which the windows and doors are closed.Then a regular room thermometer is installed in the center and the shut-off valve of the thermostat opens as much as possible.

After the temperature in the room begins to slightly exceed the one that you consider most comfortable for yourself, the valve must be completely closed. In the process of gradual cooling of the air, the temperature will begin to decrease and as soon as it reaches the values you need, the thermostat can be gradually opened until the coolant is supplied to the system. Usually you just hear how water or other heat transfer fluid begins to circulate inside the radiator.

For sensors equipped with electronic regulation, it is enough to simply select the desired heating temperature and fix it in the program. If necessary, the temperature can be easily changed directly during operation.

After the end of the heating season, it is recommended to leave Danfoss radiator temperature regulators in the maximum open position in order to circulate inside the valve and reduce the possibility of blockage.

Installing a thermostat on a radiator is an opportunity to reduce heating costs, improve the microclimate in the house, as well as a careful use of the earth's energy resources.

The motives may be different, but the solution is being implemented more and more often.

Many people choose Danfoss as an equipment manufacturer.

And not surprisingly, the products of a well-known brand are easy to find on the shelves of many stores.

The technology for the production of their thermostats based on a gas-filled bellows is patented and applied at the company's own factories. If you also decide to purchase a Danfoss thermostat, the installation and operating instructions will come in handy.

The purpose of installing a thermostat is to maintain the air temperature in the house selected by the consumer.

The design of the thermostat for radiators includes two elements that complement each other:

- Thermostat (or thermostatic element).

- Danfoss thermostat valve.

The valve is connected directly to the battery, and a thermostatic element is installed on it.

The backbone of the basics is a thermostat. It is he who reacts to changes in ambient temperature and affects the valve, which blocks the flow of the coolant.

Danfoss thermostat

Inside the thermostat head there is a bellows (corrugated chamber that can change dimensions) filled with gas. Gas, depending on the temperature, changes its state of aggregation (when cooled, it condenses). This leads to a change in the volume and pressure in the chamber. The chamber decreases in size, pulls the spool stem, which opens a larger clearance in the valve for the flow of coolant.

When heated, the reverse process of expansion and overlapping of the lumen occurs (the accepted standard is 2 V ° C when the air temperature exceeds the set value).

When a comfortable temperature is set on the regulator scale, a certain compression of the tuning spring is set inside, which is interconnected with a certain gas pressure.

Danfoss manufactures gas bellows as well as liquid bellows. The latter are more inert, reacting to temperature changes more slowly.

Thermal valve - structure, purpose, types

A valve in a thermostat is very similar in structure to a conventional valve. There is a seat and a shut-off cone that opens / closes the lumen for the flow of the coolant. The temperature of the heating radiator is regulated in exactly this way: by the amount of coolant passing through the radiator.

Sectional view of the thermostatic valve

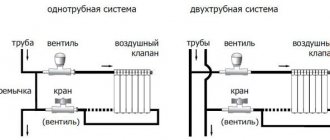

One-pipe and two-pipe valve wiring is different. The hydraulic resistance of the valve to a single-pipe system is much lower (at least twice) - this is the only way to balance it. It is impossible to mix up the valves - it will not heat.For systems with natural circulation, valves for one-pipe systems are suitable. When installed, the hydraulic resistance, of course, increases, but the system will be able to work.

Each valve has an arrow indicating the movement of the coolant. When installing, it is installed so that the direction of flow coincides with the arrow.

What materials

The valve body is made of corrosion-resistant metals, and is often additionally coated with a protective layer (nickel-plated or chrome-plated). There are valves from:

- bronze (nickel and chrome plated);

- brass (covered with a layer of nickel);

- of stainless steel.

Housings are usually brass or bronze with nickel or chrome plating

It is clear that stainless steel is the best option. It is chemically neutral, does not corrode, does not react with other metals. But the cost of such valves is high and difficult to find. Bronze and brass valves are approximately the same in terms of service life. What is important in this case is the quality of the alloy, and well-known manufacturers carefully monitor it. Whether or not to trust the unknown is a moot point, but there is one point that is better to track. An arrow must be present on the body to indicate the direction of flow. If it is not there, this is a very cheap product, which is better not to buy.

By way of execution

Since radiators are installed in different ways, the valves are made straight (straight through) and angled. Choose the type that will improve your system.

Straight (straight-through) valve and angle

| Name / company | For which system | Du, mm | Body material | Operating pressure | Price |

| Danfos, angular RA-G, customizable | one-pipe | 15 mm, 20 mm | Nickel plated brass | 10 bar | 25-32 $ |

| Danfos, straight RA-G, customizable | one-pipe | 20 mm, 25 mm | Nickel plated brass | 10 bar | 32 — 45 $ |

| Danfos, angular RA-N, customizable | two-pipe | 15 mm, 20 mm. 25 mm | Nickel plated brass | 10 bar | 30 — 40 $ |

| Danfos, straight RA-N configurable | two-pipe | 15 mm, 20 mm. 25 mm | Nickel plated brass | 10 bar | 20 — 50 $ |

| BROEN, straight with fixed setting | two-pipe | 15 mm, 20 mm | Nickel plated brass | 10 bar | 8-15 $ |

| BROEN, straight with fixed setting | two-pipe | 15 mm, 20 mm | Nickel plated brass | 10 bar | 8-15 $ |

| BROEN, corner, customizable | two-pipe | 15 mm, 20 mm | Nickel plated brass | 10 bar | 10-17 $ |

| BROEN, corner, customizable | two-pipe | 15 mm, 20 mm | Nickel plated brass | 10 bar | 10-17 $ |

| BROEN, straight with fixed setting | one-pipe | 15 mm, 20 mm | Nickel plated brass | 10 bar | 19-23 $ |

| BROEN, angular fixed setting | one-pipe | 15 mm, 20 mm | Nickel plated brass | 10 bar | 19-22 $ |

| OVENTROP, axial | 1/2″ | Nickel-plated brass, enamelled | 10 bar | 140 $ |

Types and symbols:

- RTS - liquid bellows;

- RTD-G - gas bellows for one-pipe system, or two-pipe without pump;

- RTD-N is a gas bellows for two-pipe systems, and systems with a circulation pump.

Radiator thermostat DANFOSS RA 2991

There are also modifications of thermoelements, in which:

- Protection against readjustments by random persons is provided (excellent option for public institutions and children's rooms).

- There is an external thermal sensor connected with a two-meter capillary tube, which can be installed further from the radiator, recessed into a niche or crammed with furniture, which gives a more accurate measurement result.

- With a slightly lower temperature range than conventional sensors for integration into a pay-as-you-go system.

The extraction of electricity from the earth is of interest to many people. - how to get it yourself, read the article.

You will find formulas and examples for calculating the ventilation of industrial premises.

You can find reviews on the effectiveness of electric heating convectors.

Underfloor heating system

Thermostats are also used for underfloor heating systems.A thermostat for underfloor heating is a must!

After driving the liquid into the floor contour, you need to lower its temperature from 60 - 90 V ° C to a comfortable 35 - 40 V ° C (while the surface of the floor itself will be about 25 V ° C).

Flow meters are powerless if the pressure in the system jumps, if the air is heated, for example, from the sun, and if residents want to save on heating during their absence.

The thermo-mechanical regulator is best used for small rooms, about 10 m2.

For large areas, room thermostats with underfloor heating temperature sensors are used.

Regulator operation in the underfloor heating system

The Danfoss underfloor thermostat is an important thing for the entire heating system. The device has a responsible function of adjusting the temperature to a comfortable 25 ° C.

Flow meters will not help if the pressure is unstable, the air is heated, for example, by the sun's rays, and residents are trying to save on heating while they are not at home.

Experts advise installing a mechanical regulator in small rooms of about 10 m².

In large rooms, Danfoss room thermostats with floor heating temperature sensors are used.

Danfoss thermostatic head deservedly has many positive reviews. It is an easy-to-use element that does not require special attention from the owner after installation and adjustment. As a result, the house provides a favorable microclimate, and in some cases tangible savings in money.

Heating and ventilation costs average 30-50% of the family budget. And the problem is not in the function itself, but in poor quality energy consumption. A convenient solution was offered by Danfoss - a thermostat for controlling the temperature in the house and the operation of the heating system. This device can be used in combination with almost all boilers, including heating devices with a liquid heat carrier.

The thermal head is used at home, in an apartment, production premises, warehouses, closed greenhouses and greenhouses, in a word, wherever a relatively constant temperature regime is required. And this applies not only to heating, but also to air conditioning. So, the thermal head equally successfully interacts with air conditioners, refrigeration equipment and other units responsible for temperature.

Installation of the thermostatic element

First of all, the valve is mounted on the radiator. For this, the coolant supply is shut off.

- Markings are made on the supply pipe. The area to be cut must be the same length as the valve body minus the threaded connections.

- The heating pipe is cut, an extra piece is cut out.

- A thread is made on the outside of the cut pipe with the help of a scraper, or die.

- The connection is processed with plumbing paste and fum tape.

- The valve body is screwed onto the resulting thread.

- Since the pipe cannot be twisted, an American union nut is twisted on the opposite side of the valve, and then screwed (with a hex wrench) into the radiator squeeze.

- The body of the device is screwed into its own union nut through a rubber washer. This connection does not need to be sealed somehow, the main thing is that it is clean.

- After the valve is installed on the radiator, the protective cap is removed from it (located perpendicular to the pipe).

The maximum temperature is set on the thermal head, after which it is put on the valve with a push (until it clicks).

Installing Danfoss thermal head

The device is mounted precisely on the pipe of the hot water supply circuit. Installation does not imply anything complicated, even in the case of design options, installation takes place according to the same principle. The work is carried out in stages:

- Markings are made on the supply pipe to indicate the area that needs to be cut. The dimensions of the valve body should be considered. The threaded element is taken away, which will enter directly into the pipe.

- The heating is turned off and the liquid is drained to exclude a flood in the house.

- An extra section of the pipe is cut along the marks, and a thread is made on the outer part of the cut with a die.

- The joint is treated with a special paste for plumbing work (the manufacturer is not important).

- A valve is screwed onto the thread made with a die and tightly tightened with a washer. Additional fastening of the connection is not required for tightness. The performed actions are enough for a reliable joint.

- The fuse is removed, the maximum indicator "five" is set on the regulator and a case with a scale is put on top.

- All joints are checked and the heating device is connected to the entire heating system.

If the connection of the Danfoss thermostat was made correctly, then there should be no problems. It is worth checking the operation of the device before the first opening and closing of the valve.

Sensor mounting

As already mentioned, a remote sensor is needed if the battery is built into the wall or is closed by something (furniture, screen, blackout curtains).

A sensor and a tuning unit are combined in one housing of this element.

- It is best to locate the device in an open (but without drafts) section of the wall, at a height of about 1.4 m from the floor. Avoid places near appliances that can greatly change the temperature of the environment - air conditioners, stoves, etc.

- The set of the device has a small mounting panel, which is fixed to the selected place using a pair of self-tapping screws.

- A capillary tube is wound inside the sensor. It is pulled to the required length so that the device reaches the fixed bar.

- The capillary tube is neatly fixed to the back of the valve.

- The sensor is simply snapped onto the bar.

The microclimate in the house and the humidity of the air are two inextricably linked concepts. for home and health, read about this in the article.

What kind of insulation for a warm floor to choose, read. And also you will find general information about the installation of insulation.

How to choose an automatic radiator thermostat?

- the main

- Articles

- How to choose an automatic radiator thermostat?

31.01 2003

Currently, in the heating system in front of the radiator, it is necessary to install (at least) a valve, with which it would be possible to regulate the flow of the coolant entering the radiator. This is a matter of not only comfort, but also protection, since if necessary, you can simply disconnect the radiator from the riser, which, by the way, is impossible in many old heating systems, and in some new buildings.

So, it is undoubtedly necessary to install shut-off and control valves. The question is whether to be limited to a ball valve, whether to install a cone valve or install an automatic thermostat. How convenient is this or that adjustment?

First of all, it must be said that it is not worth regulating the flow of water in the radiator using only a ball valve, since it is designed for only two positions: open and closed. By placing the valve in an intermediate position, you risk losing the tightness of your system over time.

It is safer to regulate the temperature with a manual cone valve. If it's spring outside the window, and the sun warms up well enough during the day, I think each of us will gladly close the valve on the radiator installed in a sufficiently sunny room during the day. But closing the valve is only half the battle. The second half of the battle is not to forget to open it later, and it is worth returning it exactly to the position in which it stood. If you forget to open it, you will start to freeze at night, if you open it too much, you will suffer from the heat. Therefore, if you are already engaged in rebuilding your heating system, then it is worth going to the end in this matter - to modernize it to such an extent that it requires a minimum of attention for its maintenance.And even better, so that it does not require any attention at all, but is regulated independently, that is, automatically. This is where automatic thermostats come in.

We offer our customers radiator thermostats or, as they are also called, thermostats from the Danish company Danfoss - simple and reliable devices for automatically maintaining a comfortable room temperature. They are installed in the heating system of the building in front of the heating device on the pipe supplying the coolant to it.

Danfoss has developed radiator thermostats for all heating systems. Thermostats can be installed in one- or two-pipe heating systems, under construction or existing buildings, of various storeys and purposes.

Danfoss thermostats fit perfectly into any interior, have a pleasant ergonomic design and convenient settings. Thermostats are easy to install in both new and existing heating systems. They are adapted for operation in Russian conditions, are durable and do not require preventive maintenance. After installing radiator thermostats, there is no need to open windows to regulate the temperature in the premises. The thermostats will constantly maintain the temperature in the range from 6 ° C to 26 ° C at the desired level, with an accuracy of ± 1 ° C.

Radiator thermostats guarantee the required distribution of water throughout the entire heating system. At the same time, even the most remote radiators will provide the required heat supply to the room.

By reducing the supply of excess heat from the heater during periods of heat input from sunlight, people, electrical appliances, the thermostat eliminates overheating of the room, providing it with a comfortable air temperature. In addition, if you live in a cottage with an individual boiler, thermostats can save up to 20% of the thermal energy consumed for heating buildings, thereby reducing the consumption of fuel burned and, thereby, protecting the environment. Thanks to this, the invested funds pay off many times over: the savings in thermal energy increase, the microclimate in the premises improves, and installation is also simplified and there are practically no operating costs.

The benefit from the use of thermostats will quickly be felt by the owner of a cottage heated by diesel fuel. A little warmer outside - fuel consumption immediately decreased. As a result, if, for example, 50 liters of diesel fuel was spent on heating per day, then due to the use of thermostats, this volume can be reduced to 40 liters. It seems that the effect is small, but it means that the next tank with diesel fuel can be bought a little later than usual. And within a year, the effect can become very noticeable. With cottages in general, the situation is special. Here we need to talk not about whether it is necessary to use thermostats or not (the decision in this case is obvious), but about how quickly the costs of purchasing and installing thermostats will pay off. If the cottage is heated with diesel fuel, then the purchase of thermostats pays off in almost one season.

The only argument in favor of using thermostats in urban environments, so far, remains comfort.

The first place to ask for a thermostat is in the bedroom. But the bedroom needs a thermostat last. And first of all, it is necessary in those places where there is a dynamics of temperature changes during the day. For example, in the kitchen, where there is additional heat from the stove. In a room on the sunny side, where the temperature rises during the day due to natural heating. In a room where a lot of people gather (for example, in a living room, if it is a private apartment, or in a production meeting room, if it is an office). And in the bedroom, a thermostat is needed, so to speak, in the last place, since neither heat sources nor a large crowd of people exist there.Of course, in the bedroom you can get by with an ordinary manual valve and use it to adjust the temperature to the desired one. But the thermostat, nevertheless, will cope with temperature control much better, and most importantly, more accurately.

In cottages, thermostats are primarily placed on the upper floors, because warm air rises from the bottom up the stairs. That is why it can be cold on the lower floors, but there is nothing to breathe on the upper ones. The rest of the criteria are the same as in the apartment - rooms on the sunny side, kitchens, etc.

Imported panel radiators, which have a small capacity and quickly respond to the closing and opening of thermostat valves, are very suitable for use in heating systems of cottages.

As a rule, buyers are primarily concerned about the availability of certificates for the proposed product in order to be sure of its quality. Thermostats are certified goods. Danfoss thermostats are CEN and ISO certified.

CEN is the European Committee for Standardization, which develops regulatory frameworks and tests direct-acting regulators and standardizes their performance. Danfoss RTD temperature controllers comply with the requirements of these standards, have been tested and approved for use.

ISO - International Organization for Standardization. Danfoss is an ISO 9000 certified company. ISO 9001, ISO 9002 and ISO 9003 certificates confirm the high quality of products at the stage of development, development and serial production.

The modern market offers consumers two types of thermostats: liquid and gas-filled. Danfoss is the only company that produces gas-filled thermostats. The service life of such thermostats is quite long and is more than 20 years.

The Danfoss RTD radiator thermostats are gas-filled devices. This unique solution has two major advantages: the gas will always condense in the cooler part of the sensor, which is usually away from the control valve body. Therefore, the radiator thermostat will always respond to changes in the room temperature and will not be affected by the water temperature. The thermostat reacts very quickly to changes in air temperature and, therefore, effectively uses the heat input into the room. Danfoss gas-filled radiator thermostats RTD have stable setpoints and excellent control characteristics.

What is the thermostat design?

The radiator thermostat consists of two parts: a thermostatic element and a valve.

Thermostatic element

Is a device that has a cylinder with corrugated walls (bellows) filled with a working substance that reacts to changes in the air temperature in the room. As the temperature rises, the substance increases in volume, stretching the bellows, which, in turn, moves the valve stem in the direction of decreasing the amount of coolant flowing through the heater. When the air temperature drops, the substance and the bellows are compressed, increasing the flow of the coolant through the heating device. Danfoss bellows are rated for 1 million compression-tension cycles, which equates to approximately 100 years of service RTD-N and RTD-G. They also come in straight and angular versions. The type of valve is selected depending on the type of the heating system, and its size - according to the diameter of the hole in the stopper of the heater or according to the diameter of the water supply pipe.

Valves

are of two types:

- Valves of thermostats of type RTD-G should be used: in one-pipe heating systems of any buildings; in two-pipe systems of old multi-storey buildings; in two-pipe heating systems of cottages without circulation pumps.

- Thermostat valves of type RTD-N should be used: in two-pipe heating systems of new buildings; in two-pipe heating systems of cottages, in the presence of circulation pumps.

The valve is installed, as a rule, in the hole in the stopper of the heater from the side of the hot water supply to it. It is recommended to position the valve so that then the thermostatic element is in a horizontal position, at which the influence of the heat emanating from the valve and the pipe on the thermoelement is excluded.

One-pipe systems with radiator thermostats must have a jumper (bypass) between the horizontal pipes (connections) supplying water to the heater. When installing the valve, the direction of water flow in the pipe must match the direction of the arrow on the valve body. If existing heating systems are equipped with thermostats for heating devices, the direction of water flow along the vertical pipe should be specified.

The bellows system of the thermostatic element, as we have already said, is filled with gas, which ensures proper proportional control of the room temperature. The sensor reacts to the ambient temperature. This temperature corresponds to a well-defined gas pressure in the bellows, which is balanced by the force of the regulating spring. As the ambient temperature rises, the gas pressure in the bellows increases and the valve cone moves towards the closing side. This continues until equilibrium is ensured between the gas pressure in the bellows and the spring force. When the room temperature drops, the gas pressure decreases, which allows the bellows to contract, and the valve cone moves towards the opening until the system is balanced.

Still, which bellows are better - liquid or gas-filled? This issue is still the subject of discussion both among experts and in the press. It is believed that gas-filled bellows have a faster reaction speed of the sensing element to changes in room temperature. Liquid ones better and more accurately transmit the pressure change inside the bellows (as a result of temperature changes) to the actuator. But which is better, perhaps, no one will ever determine. In our opinion, what is more reliable is better. And reliability is determined by workmanship, not by the environment inside the bellows. We mainly use Danfoss gas-filled thermostats, but we also offer our clients liquid thermostats.

How to choose the right type of thermostatic element?

Thermostatic element with built-in sensor

The built-in sensor should always be located in such a place in the room where free air circulation around it is ensured. To prevent heating by heat from the pipeline, the sensor should be installed as horizontally as possible.

Thermostatic element with remote sensor

If the built-in sensor cannot respond correctly to the room temperature, then a thermostatic element with a remote sensor should be used. This can be in the following cases:

- if the thermostat is installed in a niche;

- when the window sill is too wide (more than 220 mm), and the distance from it to the radiator is less than 100 mm;

- when the radiator depth is more than 160 mm;

- if the axis of the thermostatic element must be in a vertical position;

- if the radiator thermostat is covered with curtains.

When in doubt, always use a remote sensor.

What effect does the curtain have?

By closing the radiator with a thermostat with a heavy screen or a heavy curtain, we thereby isolate the thermostat from the main volume of the room. As a result, the thermostat sensor does not measure the temperature of the room, as it should be, but the temperature in a limited space behind the curtain. At the same time, the temperature in the room turns out to be completely different. That is why it is better to use a thermostat with a remote sensor.

How should the sensor be installed: parallel or perpendicular to the plane of the radiator?

Many people try to install the sensor not perpendicularly, but parallel to the plane of the radiator. In this position, he is simply not so striking. But this decision is not entirely correct. The streams of warm air rising from the radiator will affect the readings taken by the thermostat bellows, and there will be an error in the readings of the device. This error is not very large, but the correction for it will have to be calculated and installed on the temperature setpoint by the owner himself. Therefore, it is more correct to install it exactly perpendicular to the plane of the radiator.

How is the installation, setting and regulation of the temperature carried out?

Installation

The design of the thermostat valve body allows it to be mounted in the radiator inlet, observing the unidirectional flow of the coolant and the arrow on the valve. Radiator thermostats can be used in any of the known heating systems. A conventional wrench is used to install the thermostatic element on the valve body. Installation instructions are included in the packaging of the radiator thermostat.

During construction, when the sensor is not yet installed, the heating system can be manually adjusted using a protective cap screwed onto the valve body.

Customization

You can set the thermostat to an air temperature from 6 ° C to 26 ° C (for example, in the living room - 22 ° C, in the bedroom - 20 ° C, in the kitchen - 18 ° C) and it will automatically maintain the set temperature, changing the amount of passing through a hot water heater and, accordingly, its heat transfer without the use of electrical or other external energy.

The thermostat is adjusted by turning the knob until the indices on it align with the arrow or mark. The indices on the scale correspond to the following temperature values: I (1) - 14 ° C, II (2) - 17 ° C, III (3) - 20 ° C, IV (4) - 26 ° C. After the initial setting, the temperature can be adjusted according to your feelings.

Later, another, more correct way of adjusting thermostats was developed. The new method also allows you to configure several thermostats located in the same room, without their mutual influence on each other. You can read the configuration option from this link >>

Temperature control

The required room temperature is set by turning the setting dial. The setting scale shows the relationship between the markings on it and the room temperature. The indicated indexes are intended as a guideline only, since the actual temperature is influenced by the conditions of the location of the radiator thermostat.

The P-zone (Xp) indicates how much the room temperature should rise in order for the thermostat valve cone to move from the open position to the closed position. The temperature scale is marked on the thermostat in accordance with European standards, at Xp = 2 ° C. This means that the radiator thermostats close when the room temperature is 2 ° C higher than the set temperature value on the scale. For example, an RTD3100 set to III will maintain an indoor temperature between 18 ° C and 20 ° C, depending on the actual heat demand, if it is calibrated at Xp = 2 ° C. The smaller the presetting of the valve's flow rate, the smaller the P-band will usually be.

Blocking and limiting the setting of the radiator thermostat

If necessary, you can limit the upper and lower limits of the setting range of the radiator thermostat. More detailed information on this issue is given in the instructions supplied with the product.

Thermostat valves built into the heater.These are thermostat valves that are installed at the heaters factory inside a specially designed compact radiator design.

Danfoss valves built into the radiator can be compatible with all types and sizes of compact radiators and can be used in both two-pipe and one-pipe water heating systems for buildings for various purposes.

RLV type shut-off valve and drain cock

By means of the RLV shut-off valve, it is possible to shut off an individual radiator in order to dismantle it or maintain it without draining the water from the piping of the entire heating system. The RLV is available in straight and angle versions.

Shut-off with RLV-K shut-off valve

RLV-K valves are designed to shut off an individual compact radiator for dismantling or maintenance without emptying the entire heating system. The disconnected compact radiator is drained and filled using a special drain cock (code no. 003L0152). The RLV-K shut-off valve comes from the factory ready for use in a two-pipe heating system. For use in a one-pipe heating system, a jumper must be opened in the valve using an Allen key.

Single-family residential buildings. One-pipe and two-pipe heating systems

Retrofitting two-pipe heating systems in existing single-family buildings is very easy. In these systems, it is sufficient to replace manual control valves with automatic ones, of the RTD-N type, by installing RTD thermostatic elements on them, which will maintain constant air temperatures in the premises. In single-family buildings with one-pipe heating systems, during their reconstruction, valves of the RTD-G type are used.

In this case, it is necessary to check whether the system has closing sections (bypasses) at the radiators or not.

A valve built into the automatic control system makes it possible to completely shut off the flow of the coolant into the radiator manually, if such a need arises, or is an additional valve still needed?

By itself, an automatic thermostat does not provide such an opportunity. It only makes it possible to close the flow to a minimum (which corresponds to a value of 6 ° C - anti-freeze temperature). If you remove the thermostat head, then the valve itself will give such an opportunity. For this, a technological plastic cap is provided with the thermostat, which serves as a "lamb". But the cap is plastic, and therefore weak. More powerful and durable is the brass cap, usually sold separately. Locking by means of a thermostat valve is quite reliable and practically no additional valves are required in the system.

But there is one more factor in this issue that cannot be ignored - the subjective one. To shut off the heating medium flow using the valve, you must first remove the thermostat head. It is necessary to firmly remember in what place this very "locking" brass cap is hidden. And the valve must be turned on securely enough so that the pressure in the system does not open it by itself. This is why some customers prefer to install an additional shut-off valve. If you do this right away with the general installation of the system, then this operation increases the cost of work by almost the cost of the valve (~ $ 3.5).

The choice of radiators and automation that controls radiators, and the heating system in general, is certainly not an easy matter. And not only the choice, but also the installation itself, as well as warranty and post-warranty operation. And this difficult task must be entrusted, first of all, to professionals.

Professionals who would have the right advice on which radiators to choose in one case or another, which thermostats, etc.But for these professionals to answer for this choice, in the event of some, as they say now, force majeure circumstances. They would answer both legally and would compensate for all the losses caused by their activities. They are, first of all, subject to the effect of the law "On the Consumer", and not to a private trader who quickly installed a radiator and disappeared just as quickly. You are unlikely to be able to file a lawsuit against a private trader - you simply will not have the appropriate documents to do this. And no matter how tempting it is to save a few hundred rubles (and in fact, this amount may turn out to be much less, or even simply, there will be no savings), when inviting a private owner, think before you do it, because any accident with heating is like as a rule, it results in considerable losses, which are much higher than the funds saved when hiring a private trader.

© Technical consultant, O. V. Sizukhin

To the list of articles

Other articles

16.05 Energy efficient water heaters HAJDU

28.12 "Superpipe" in the service of the people. Pipes made of cross-linked polyethylene produced by METZERPLAS (Israel)

21.11 Cast-iron radiators RETRO are always in demand The solution of modern heating in the style of antiquity and sophistication can be a cast-iron radiator, artistic casting of which was created according to drawings and drawings of the turn of the century.

25.10 Overview of Bosch instantaneous gas water heaters

Setting a limit

The work of thermostats is based on physical laws. Therefore, it must be remembered that the conditions in which the device is located can make some adjustments (for example, distance from a heat source). There are indicative tables of the correspondence of the controller scale and temperature, which can be taken as a guideline during installation. However, after the basic setup, you will need to "understand" your thermostat.

For this:

- Set the temperature on the handle with marks.

- An hour later, control measurements are carried out with a room thermometer at several points in the room.

- If the temperature is higher or lower, the readings on the handle are corrected.

Proportional band - 2 ° C. If you set the temperature to 20 °, then the device will keep the readings in the range from 20 to 22 ° C.

Sensor after installation on a radiator

Two pins that are included with the sensor will help to set the minimum and maximum position limits for the thermocouple.

They are located at the bottom of the device:

- To set the limit to about, you need to pull out the limiter and set the sensor reading to about. Then the pin is inserted into the hole, which in this position is under the diamond symbol.

- The second limiting threshold is set in the same way. The handle turns to the desired value, only the pin is inserted into the hole under the triangle icon.

You can block the regulator at a certain temperature (protects against accidental failure or childish pranks).

For this:

- Both pins are removed.

- The handle is placed on the desired value.

- In this position, the first pin is inserted into the hole below the diamond.

- The second pin is in the hole under the triangle.

Danfoss thermostats have many positive reviews. It is a very easy-to-use device that does not require any attention after the initial installation and setup. But the result will be a more comfortable temperature in the apartment, as well as, in some cases, significant budget savings.

Main technical characteristics

Consumer qualities of the product and its safety are important for the user.

Any Danfoss battery temperature controller is guaranteed to withstand the following parameters:

- operating pressure in the system - up to 10 atm;

- test pressure - up to 16 Atm;

- the maximum temperature of the coolant is 120 degrees;

- temperature control limits - from 5 to 26 degrees.

When choosing, pay attention to the connecting dimensions of the regulator.The range of the company includes equipment for 10, 15, 20 and 25 mm.

There are housings designed for direct or angular connection, which is taken into account when purchasing. Additional fittings are purchased if necessary.

When buying devices powered by electricity, pay attention to the way the regulator is powered: from batteries, mains, or from a power supply.

Save up to 46% energy

Radiator thermostats allow you to consume exactly the amount of energy that is needed at the moment to maintain a comfortable temperature in the room. Different thermostatic elements accomplish this task in different ways. Compared to a manual regulating valve, thermostats with liquid or paraffin filling can save 31%, with gas filling 36%. Danfoss living eco electronic radiator thermostats can save up to 46% of your heating energy.

* Based on a study by the Rhine-Westphalian Technical University, Aachen, Germany.

Installation instructions

An external Danfoss water thermostat, the reviews of which are shown in the publication, must be set according to a specific technology. The first advice is the elimination of the process of installing thermal on the heater in the range of visibility. Batteries whose total capacity is 50 percent or more of all that are in the same residential area should be subject to regulation. Similarly, when there are two heaters in the room, the thermostatic valve must be on the same battery, whose capacity is considered more impressive. If you are interested in Danfoss - an external water thermostat, the setting of which is very simple, it can be purchased and supplied by you. The first part of the device, which is the valve, must be installed on the supply line of the pipes. If it is worth cutting into an already assembled system, the supply line must be disassembled. These works may suggest certain problems if the connection is made using steel pipes. The specialist will be required to stock up on a tool for cutting the material.

Fast reaction

Danfoss RA series thermostats are equipped with a gas-filled bellows. The heat capacity of a gas is much less than that of a liquid and, moreover, of paraffin. As a result, gas-filled thermostats react much faster to changes in room temperature. Therefore, Danfoss thermostats maintain the temperature more accurately and provide greater energy savings. Radiator thermostats with a gas-filled thermostatic element ("gas") are patented and manufactured only by Danfoss.

Thermostat setting

All devices of the manufacturer stand out from the outside and in terms of technical characteristics, however, their settings are still performed in the same way. To perform it, you need to look at the instructions for work and get acquainted with the designation of the modes that are indicated on the device case. Indicators may vary, it all depends on the model.

Next, to adjust the Danfoss thermostat, set the desired temperature on it. This can be created by moving the twisting element in one direction. If you have installed a device with buttons, all you need to do is press the plus or minus.

It is possible to show intermediate values when they are the best fit in order to create a certain temperature regime in the room. A couple of minutes will pass, and the heating system will have time to adjust to the specified parameters and will warm up until a good climate comes out. There is also a setting for refrigeration equipment.

You can now buy a thermostat with a modern design

Red Dot is a world-renowned "quality mark" in the field of industrial design. Only products that are exceptional in terms of aesthetics and functionality receive this praise.In 2010 Danfoss received the Red Dot award for the development of the living thermostats.

In the post-Soviet countries, up to 40% of energy resources are spent on heating and ventilation of buildings, which is several times more than in advanced European countries. The issue of energy conservation is more acute than ever, especially against the backdrop of a constant increase in the cost of energy resources. One of the devices that allows you to save thermal energy in the house is a thermostat for a battery, whose installation can reduce heat consumption by up to 20%. But for this it is necessary to choose the right regulators for the heating system and carry out their installation, which will be discussed in this article.

How the thermostatic valve works

The first thermostats for radiators, designed to maintain a constant temperature in a room, were invented back in 1943 by DANFOSS, which also holds the leading position in the market for the production and sale of such devices. For this reason, our article will be based on the materials and recommendations of the DANFOSS company, whose many years of experience are beyond doubt.

Over the years since the invention, thermostats for radiators have changed and become what we know them. Structurally, they consist of two main elements: a valve and a thermal head, which are interconnected by a locking mechanism. The purpose of the thermal head is to perceive the ambient temperature and, to regulate it, act on the actuator - the valve, which blocks the flow of the coolant entering the heater.

This control method is called quantitative, since the device affects the flow rate of the coolant passing into the radiator. There is another method - a qualitative one, with its help the temperature of the water in the system changes. This is carried out by a temperature regulator (mixing unit) installed in a boiler room or heating point.

To understand the principle of operation of the thermal head, it is proposed to study the diagram of the device shown in section:

Inside the cell body there is a bellows filled with a heat-sensitive medium. It is of two types:

- liquid;

- gas.

Liquid bellows are easier to manufacture, but they are inferior to gas bellows in terms of speed, so the latter are very widespread. So, when the air temperature rises, the substance in a closed space expands, the bellows expands and presses on the valve stem. That, in turn, moves down a special cone, which reduces the flow area of the valve. As a result, the flow rate of the coolant decreases. When the ambient air is cooled, everything happens in the opposite order, the amount of flowing water increases to a maximum, this is the principle of the thermostat operation.

Depending on the type of heating system and the installation conditions of the device, valve - thermal head sets in various combinations can be used to control the heat carrier flow. In one-pipe heating systems, it is recommended to install valves with increased flow capacity and low hydraulic resistance (DANFOSS product marking - RA-G, RA-KE, RA-KEW).

The same recommendation applies to two-pipe gravity systems, where the coolant circulates naturally, without forced induction. If the heating circuit is two-pipe with a circulation pump, then you should choose a valve with the ability to adjust the throughput (DANFOSS marking - RA-N, RA-K, RA-KW). This adjustment is quite simple and does not require a special tool.

When the issue of valve selection is resolved, you need to decide on the type of thermal head. They are offered in the following designs:

- With an internal thermocouple (as in the diagram above).

- With a remote temperature sensor.

- With external regulator.

- Electronic (programmable).

- Anti-vandal.

A conventional thermostat for heating radiators with an internal sensor is accepted for installation if it is possible to position its axis horizontally so that the room air flows freely around the body of the device, as shown in the figure:

Attention!

It is not allowed to install the thermostat on the battery in a vertical position, the heat flux rising from the supply pipeline and the valve body will affect the bellows, as a result of which the device will not work correctly.

If horizontal mounting of the head is not possible, then it is better to purchase an external temperature sensor for it complete with a capillary tube 2 m long.It is at this distance from the radiator that this device can be positioned by attaching it to the wall:

In addition to vertical mounting, there are other objective reasons for buying a remote sensor:

- heating radiators with a temperature controller are located behind blackout curtains;

- hot water pipes pass in the immediate vicinity of the thermal head or there is another heat source;

- the battery is under a wide window sill;

- the internal thermocouple enters the draft zone.

In rooms with high demands on the interior, batteries are often hidden under decorative screens made of various materials. In such cases, a thermostat caught under the casing registers the temperature of the hot air accumulating in the upper zone and can completely block the coolant. Moreover, access to the control of the head is completely closed. In this situation, the choice should be made in favor of a remote controller combined with a sensor. Its placement options are shown in the figure:

Electronic thermostats with display are also of two types: with built-in and removable control unit. The latter differs in that the electronic unit is disconnected from the thermal head, after which it continues to function as usual. The purpose of such devices is to adjust the room temperature according to the time of day in accordance with the program. This allows you to reduce the heating power during working hours, when there is no one at home and in other similar cases, which leads to additional energy savings.

When there are small children in the house who want to try everything with their pens, it is better to install an anti-vandal-type thermostat with a casing that protects the device settings from unskilled intervention. This also applies to thermostats in other public buildings: kindergartens, schools, hospitals, and so on.

Thermostatic heads

There are three types of thermostatic elements for heating thermostats - manual, mechanical and electronic. They all perform the same functions, but in different ways, provide different levels of comfort, and have different capabilities.

Manual

Manual thermostatic heads work like a regular tap - turn the regulator to one side or the other, letting in more or less coolant. The cheapest and most reliable, but not the most convenient device. To change the heat transfer, you must manually turn the valve.

Manual thermal head - the simplest and most reliable option

These devices are quite inexpensive, they can be installed at the inlet and outlet of the heating radiator instead of ball valves. It will be possible to regulate any of them.

Mechanical

A more sophisticated device that maintains the set temperature in automatic mode. The basis of this type of thermostatic head is a bellows. It is a small elastic cylinder filled with a thermal agent. A thermal agent is a gas or liquid that has a high coefficient of expansion - when heated, they greatly increase in volume.

The bellows supports the stem that overlaps the flow area of the valve. Until the material in the bellows is heated, the stem is raised.As the temperature rises, the cylinder begins to increase in size (gas or liquid expands), it presses on the rod, which more and more overlaps the flow area. Less and less coolant passes through the radiator, it gradually cools down. The substance in the bellows also cools down, due to which the cylinder decreases in size, the rod rises, more coolant passes through the radiator, it starts to warm up a little. Then the cycle is repeated.

Gas or liquid

In the presence of such a device, the temperature in the room is fairly maintained at exactly + - 1 ° C, but in general the delta depends on how inert the substance in the bellows is. It can be filled with some kind of gas or liquid. Gases react faster to temperature changes, but they are more difficult to produce technologically.

Liquid or gas bellows - not much difference

Fluids change volumes a little more slowly, but are easier to manufacture. In general, the difference in the accuracy of maintaining the temperature is about half a degree, which is almost impossible to notice. As a result, most of the presented thermostats for heating radiators are equipped with thermal heads with liquid bellows.

The mechanical thermostatic head must be installed so that it is directed into the room. This way the temperature is measured more accurately. Since they have a fairly decent size, this installation method is not always possible. For these cases, you can supply a thermostat for a heating radiator with an external sensor. The temperature sensor is connected to the head using a capillary tube. It can be positioned at any point where you prefer to measure the air temperature.

All changes in the heat transfer of the radiator will occur depending on the air temperature in the room. The only drawback of this solution is the high cost of such models. But the temperature is maintained more accurately.

| Name / company | Setting range | Operating temperature range | Control type | Functions / purpose | Connection type | Price |

| Danfoss living eco | 6 ° C to 28 ° C | 0 ° C to 40 ° C | Electronic | Programmable | RA AND M30X1.5 | 70$ |

| Danfoss RA 2994 with gas bellows | from 6 ° C to 26 ° C | 0 ° C to 40 ° C | Mechanical | For any radiator | clip-on | 20$ |

| Danfoss RAW-K Liquid Element | 8 ° C to 28 ° C | 0 ° C to 40 ° C | Mechanical | For steel panel radiators | M30x1.5 | 20$ |

| Danfoss RAX with liquid earphone | 8 ° C to 28 ° C | 0 ° C to 40 ° C | Mechanical | For design radiators white, black, chrome plated | M30x1.5 | 25$ |

| HERZ H 1 7260 98 with liquid earphone | 6 ° C to 28 ° C | Mechanical | M 30 x 1.5 | 11$ | ||

| Oventrop "Uni XH" with liquid earphone | from 7 ° C to 28 ° C | Mechanical | with zero mark | M 30 x 1.5 | 18$ | |

| Oventrop "Uni CH" with liquid earphone | from 7 ° C to 28 ° C | Mechanical | without zero mark | M 30 x 1.5 | 20$ |

Electronic

The size of the electronic thermostat for a heating radiator is even larger. The thermostatic element is even larger. In addition to electronic filling, two batteries are also installed in it.

In this case, the movement of the stem in the valve is controlled by a microprocessor. These models have a fairly large set of additional functions. For example, the ability to set the room temperature by the clock. How is it fashionable to use it? Doctors have long proven that it is better to sleep in a cool room. Therefore, at night, you can program the temperature lower, and by morning, when it’s time to wake up, it can be set higher. Conveniently.

The disadvantages of these models are their large size, the need to monitor the discharge of the batteries (enough for several years of operation) and the high price.

How to install a thermostat on a battery

The first recommendation is not to place thermal heads on all heaters within sight. Here the rule is the following: radiators, whose total power is 50% or more of all in one room, should be subject to regulation. For example, when there are 2 heaters in the room, then 1 battery with a higher power must be equipped with a thermostat.

Advice.

If cast-iron radiators are used as heating devices, then maintaining the microclimate with the help of thermostatic valves will be ineffective. The fact is that the work of cast-iron batteries is very inertial, after blocking the flow of the coolant, they radiate heat for a long time and vice versa, they accelerate for a long time.Mounting the valves doesn't make sense, you just waste your time and money.

The first part of the device - the valve - is recommended to be installed on the supply pipeline at the moment of connecting the radiator to the heating system. In the case when it is required to cut into the assembled system, then the supply line will have to be dismantled. This will bring some difficulties if the connection is made with steel pipes, you will need a pipe cutting and threading tool.

After the thermostat is installed on the radiator, the thermal head is mounted without any tools. It is enough just to align the marks on the bodies and to fix the head in the socket by smooth pressing. The click of the locking mechanism will serve as a signal.

It is a little more difficult to install an anti-vandal thermostat, for this you need a 2 mm Allen key. Aligning the required marks, as shown in the diagram, you need to press the thermal head, and tighten the fixing bolt located on the side with the hexagon.

Installation of the remote sensor and regulator is carried out on a section of the wall free from interior parts and furniture, placing them at a height of 1.2-1.6 m from the floor, as shown in the diagram:

First, the mounting plate is attached to the wall with dowels, and then the body is snapped onto it with a simple push. The capillary tube is fixed to the wall with plastic clips, as a rule, they are included with the product.

In addition to standard temperature control in the heads, the thermostat can be adjusted to the maximum and minimum limits, beyond which the wheel will become impossible to turn. For this purpose, limit pins are provided at the rear of the product. You need to pull out one of them and, after debugging the system, insert it into the hole under the corresponding mark:

How to adjust (readjust)

All thermostats are factory set. But their settings are standard and may not coincide with your desired parameters. If something does not suit you at work - you want it to be warmer / colder, you can reconfigure the thermostat for the heating radiator. This must be done when the heating is running. You need a thermometer. You hang it at the point where you will control the state of the atmosphere.

- Close the doors, put the thermostat head in the extreme left position - completely open. The room temperature will start to rise. When it becomes 5-6 degrees higher than what you want, turn the regulator all the way to the right.

- The radiator starts to cool down. When the temperature drops to a value that you think is comfortable, begin to slowly turn the knob to the right and listen. When you hear that the coolant is noisy, and the radiator begins to warm up, stop. Remember which number is on the handle. It will need to be set to reach the required temperature.

It is not difficult to adjust the thermostat for the radiator. And you can repeat this action several times by changing the settings.

Installing a thermostat on a radiator is an opportunity to reduce heating costs, improve the microclimate in the house, as well as a careful use of the earth's energy resources.

The motives may be different, but the solution is being implemented more and more often.

Many people choose Danfoss as an equipment manufacturer.

And not surprisingly, the products of a well-known brand are easy to find on the shelves of many stores.

The technology for the production of their thermostats based on a gas-filled bellows is patented and applied at the company's own factories. If you also decide to purchase a Danfoss thermostat, the installation and operating instructions will come in handy.