The value of pipes for the ventilation system

The ventilation duct made of PVC sewer pipes can have any bend shape

In the process of air exchange, about 30 cubic meters of fresh air should be supplied to each citizen living in a given living space. The ventilation system is obliged to provide it. Pipes are arteries of a complex ventilation mechanism. They are used to remove vapors, gases, odors from the most contaminated premises (toilet, kitchen, bathroom, workshop, etc.). In "safe" rooms (bedroom, living room, etc.) - served.

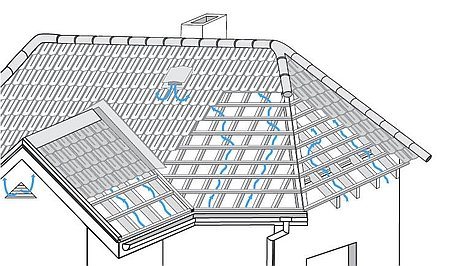

When organizing ventilation in a natural way in areas with the formation of pollution for air movement, vertical ducts are mounted with an outlet to the roof. Through them, the stale air flow escapes into the atmosphere at a considerable height: the higher the branch pipe, the more efficient the thrust. Log buildings and frame buildings, as well as buildings where ventilation was not provided at the design stage, are equipped with plastic pipes.

With mechanical air exchange, the use of pipes is a must. The system of pipes and shafts is complemented by ventilation units for inflow and exhaust. The forced system consists of special piping with rectangular or circular cross-section. The supply is carried out to each room, producing air exchange in it.

Along with metal sleeves, plastic pipes are increasingly being installed. It can be either polyurethane or polyvinyl chloride. Pipe type - medium and hard. The temperature of the passing air should not exceed + 70 ° C, otherwise the strength of the material is compromised. This applies in particular to the kitchen hood. Recommended list of premises where sewer pipes can be used as ventilation:

- small one-story residential buildings;

- production sites of small businesses;

- garages;

- change houses;

- warehouses;

- corridors.

As you can see, these are objects where increased requirements are not imposed on ventilation, but it is needed, and the traditional air exchange system is too expensive.

Misconceptions about ventilation

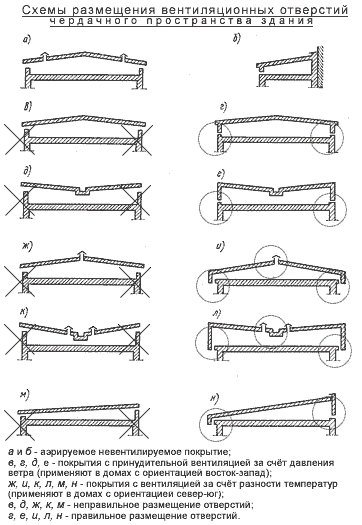

It is not enough to do the ventilation of the attic, it is important that it is done correctly. However, among the people who are going to tackle this issue, there are several common misconceptions.

They should be discussed in more detail.

- Ventilation is required only in summer. In fact, the attic not only needs to be ventilated in the heat, but also to smooth out the large temperature difference inside and outside the attic in winter. If this is not done, then the humidity will inevitably rise - an excellent environment for mold and mildew to exist. It is extremely difficult to deal with these phenomena, and in advanced cases, mold can penetrate into the rooms - then there is no need to talk about any comfort.

- Ventilation removes warm air from the room in winter. In fact, if heat is poorly retained in a house, then it is not ventilation that is to blame, but poor-quality thermal insulation. It is because of it that conditions are created under which moist and cold air gets into the attic.

- The size of the ventilation holes does not matter. In fact, the area of these holes is important. With a small ventilation area, the effect of it will be practically zero. To ensure that the room is well ventilated, and at the same time, heat leaks are not allowed, by 500 sq.m. area required 1 sq.m. ventilation openings.

How to choose a heater for heating pipes and is it needed

1. Purpose of insulation of heating pipes

2. Choosing a heater for heating pipes 3.Mineral wool materials 4. Polyurethane foam material for insulation of heating pipes 5. Foamed polymeric materials 6. Thermal insulation of heating pipes with liquid material

Owners of individual heating systems do not think about this issue, since there is no need to insulate already warm pipes. The issue of warming becomes relevant in the case of heating country houses and general house heating. In such situations, the insulation of heating pipes on the street is simply necessary, and this issue comes to the fore. This article will discuss the main issues related to the thermal insulation of pipelines, as well as what kind of insulation for heating pipes to choose.

Appointment of insulation of heating pipes

On a superficial consideration of the problem, the question raised seems absurd: why insulate pipes through which hot water is constantly flowing? Indeed, in this case, the heating system is always warmed up, and the possibility of its freezing tends to zero, along with the probability of a breakthrough. It is not surprising that it is always cold in the house of owners who think in this way.

The main reason is that insulation is needed not only to protect pipes from freezing, but also to reduce possible losses of thermal energy. Insulation of heating pipes becomes especially important in the case of apartment buildings, which are heated by means of a boiler room installed at a certain distance from the building. Installing a boiler room in the basement of a multi-storey building will not solve the problem, since the very presence of cold air next to the pipes already leads to losses.

In addition, in some cases, it becomes relevant to insulate heating pipes in the attic: some households install them there (about

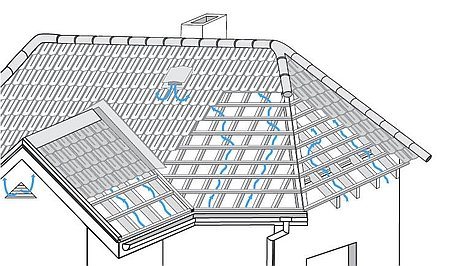

Ventilation aerators

Roofing aerators device

Roofing aerator is a modern and convenient type of ventilation. It is a pipe covered with a cap on top. Aerators remove steam, moisture and stagnant air, providing ventilation to a cold attic in a private home. Aerators are installed on roof slopes, where air movement is provided by temperature and pressure differences, replacing ridge vents. Aerators are continuous and point. Spot aerators are equipped with fans and guarantee good air movement. Outwardly, they resemble fungi.

Continuous aerators are a plate along the ridge with holes. Covered from above by a roof, they are practically invisible and provide intensive air movement due to their large openings.

Various types of aerators are created specifically for roofing from:

- bituminous tiles;

- flat roof;

- cermets;

- ceramics.

Aerators are installed only where eaves air vents are provided. There are other conditions for their installation:

- only roofs with a slope of 15 - 45 degrees are suitable;

- a distance of at least 30 cm is maintained from the chimney or wall;

- aerators protrude 25 cm above the slot at both ends of the ridge;

- point models are mounted no further than 50 cm from the ridge.

Why is thermal insulation needed?

As we noted above, many people do not understand the very purpose of insulating pipes through which hot water passes. At first glance, the situation looks somewhat absurd: he heats up the pipe itself, and even in the most severe frost it cannot freeze, which means that a breakthrough is practically impossible.

But the fact is that the task of thermal insulation of heating systems is not at all to protect them from freezing.

- If the house is heated by means of a separate boiler room, then all highways through which the coolant flows must be effectively insulated. This is done to reduce heat losses during the passage of hot water from the boiler room to the consumer.

- The same applies to pipes in the basement of an apartment building: the more efficient the thermal insulation of the pipes, the higher the temperature of the batteries in the premises.

- In private houses with individual heating, the situation is somewhat different, but even in them it sometimes becomes necessary to protect pipelines from heat loss. For example, if the boiler is located in a remote wing of a building, then the pipes passing through the basements and storerooms can be covered with thermal insulation.

Naturally, in such a situation, insulated pipes for heating provide us with a double benefit: on the one hand, the temperature rises in the room, and on the other, we reduce the cost of purchasing energy resources.

Why you need to ventilate the attic

Competently equipped with your own hands ventilation of the attic allows you to eliminate the condensation that appears on the elements of the roofing cake. During ventilation, an air flow is provided, which precisely removes residual moisture. Due to the removal of this moisture, the service life of all wooden structures, which the roofing cake is very rich in, is increased.

In addition, there are two more seasonal features for airing

:

In winter, properly organized ventilation allows you to effectively deal with icing, especially on eaves

Frost can appear due to poor ventilation, as a result, excess heat will turn into condensate, and this, in turn, into ice build-ups. In the summer, the moving air stream will contribute to some cooling of the roofing materials, which is especially important for bitumen-containing materials.

Plastic pipes for ventilation why choose

Plastic pipes practically do not exert mechanical stress on the supporting structures of the building

The air exhaust structure can be made of polypropylene, polyethylene, polyurethane or PVC pipes. Ventilation from PVC pipes is the most popular of the listed types. It is mounted quickly and does not require any special skills. Plastic pipes have many valuable characteristics:

The tubular composition is easily assembled using fittings. Their variety makes it possible to assemble an air duct of any shape. Moreover, its sagging does not exceed 4%. You can always choose the desired section size from the standard range (mm): 100, 125 or 150, 200. But there are also non-standard (atypical) sizes. The inner surface of the pipes with a minimum degree of roughness does not allow contaminants ejected with air to settle on the walls in the form of deposits.

Recommendations for arranging ventilation

pay attention to the strength of the ventilation, it must withstand any fluctuations in the weather; you can put continuous soffits under the eaves with a fine mesh screen. To prevent corrosion, the holes must be made of aluminum or plastic; to prevent the formation of frost in the attic, install air vents inside the room between the rafters and make holes so that they cannot get clogged with debris; you can install a fan on the roof for better air extraction

The distance between it and the supply system must be at least 8 m; the supply unit should be located in the cleanest place in the attic; install a recuperator that can cool or heat the air, thereby preventing condensation from forming in the cold attic; equip ventilation pipes with grilles or diffusers;

At first glance, there is nothing complicated in arranging ventilation, but in fact it is better to take this issue seriously and consult with specialists. Indeed, the microclimate in the house and your health, as well as the durability of the building itself, depend on its quality.

How to insulate pipes in the basement with your own hands

It is important to insulate pipes in the basement of a private house in order to exclude the appearance of condensation on communications.

If the basement of the house is cold or the house does not use water for a long time, then a layer of insulation will protect the pipe from possible freezing.

Consider methods of insulating water pipes in the basement of an apartment building and a one-story building with various materials. At the end of the article, we will show a video from a pipe insulation manufacturer.

Photo. Insulation of pipes in the basement of a private house

For insulation, they used to use any available materials - old blankets, foam rubber, synthetic winterizer from old jackets, etc.

But today, pipe heaters are presented on the construction market in a wide range: from expanded polystyrene shells, polyurethane foam and mineral wool to simple roll insulation made of foamed foam and izolone.

To begin with, we will analyze the advantage of pipe insulation, the better to protect the pipes in the basement from freezing.

Do I need to insulate pipes in the basement of the house

How to insulate water pipes in a basement

You should think about the insulation of pipes from the well to the house and in the basement before the onset of cold weather.

Characteristics of heaters

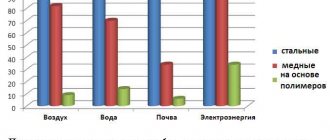

The choice of material for thermal insulation of ventilation pipes is carried out according to the following criteria:

- thermal conductivity;

- vapor permeability;

- resistance to various reagents;

- temperature limit;

- compliance with sanitary and hygienic standards

Each insulation for ventilation pipes has both its advantages and disadvantages, which are determined by its structure and technical parameters.

Mineral wool

Refers to the traditional type of insulation and has good thermal insulation properties. In addition, mineral wool and other fibers are among the most affordable materials. However, when used for internal insulation, a seal will be required, and for external insulation, reliable protection from moisture will be required.

Mineral wool with foil-clad outer layer

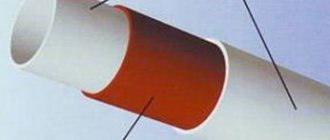

Foamed polyethylene

It is produced in the form of shells that tightly fit the surface of the pipes, or in rolls. Differs in durability, long-term use, affordable price, resistance to moisture and chemicals. In addition, foamed polyethylene is not only a good insulation, but also contributes to a significant reduction in the vibration of air ducts.

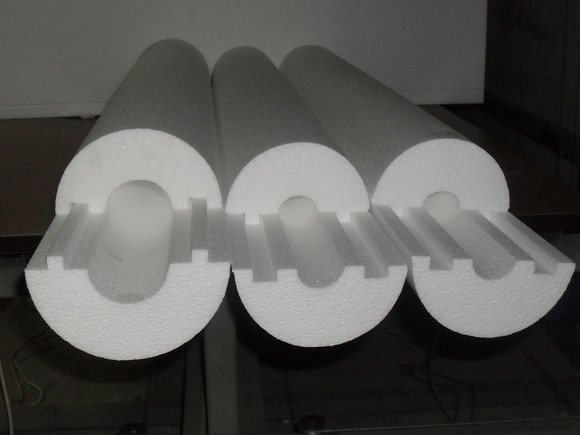

Expanded polystyrene

It is characterized by resistance to moisture, prevents the appearance of microorganisms and corrosion. This provides reliable protection of the metal from destruction, therefore, with the help of expanded polystyrene, not only the insulation of the air ducts is performed, but also the insulation of the gas pipe.

Using shell-shaped insulation, it is possible to provide access to the ventilation pipe for repair work.

Expanded polystyrene shell to protect ventilation pipes

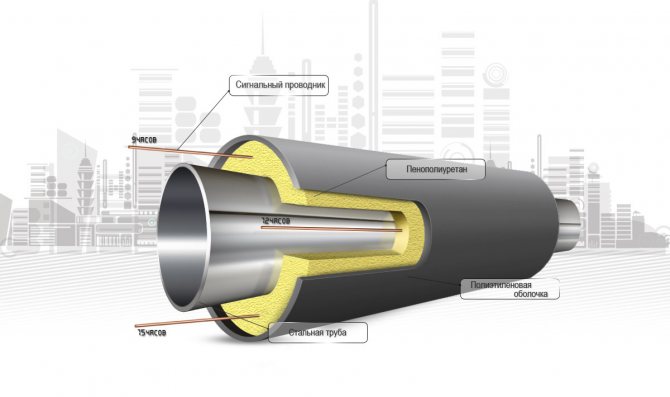

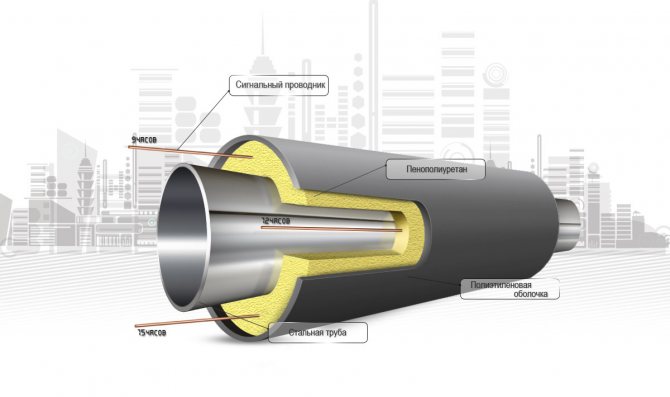

Polyurethane foam

It is produced in the form of a shell and in many respects coincides with expanded polystyrene, but is more resistant to fire. Therefore, polyurethane foam will be a reliable obstacle in the event of a fire and will not allow the fire to spread.

How to insulate heating pipes in the attic?

»Heating» Insulation of heating pipes in the attic

Foamed polyethylene and mineral wool - excellent insulation of the heating main in the attic

Hello. Today I want to talk about how to insulate heating pipes with my own hands inside and outside construction sites. The topic is of considerable interest, since the correct thermal insulation allows you to reduce the level of heat loss during transportation of the coolant from the thermogenerator to the heater. I hope you find the instructions in this article interesting and helpful.

How to choose the right insulation for heating pipes

Owners of private houses often consider thermal insulation of heating system pipelines to be a waste of money.But such events are a direct way to significant savings in thermal energy.

Source: https://arthouse188.com/chem-uteplit-truby-otopleniya-na-cherdake/

Professional recommendations

And, at the end of the day, a few important tips for those who are interested in how to properly ventilate the attic:

All ventilation elements must be resistant to any weather conditions; Be very careful about the location of the ridge vents. They are installed as close to the ridge as possible; Continuous spotlights work effectively as eaves. The best materials for them are non-rusting aluminum or plastic. The surface of the spotlights is covered with a fine mesh; When equipping attic ventilation without skylights, special attention should be paid to the airflow between the rafters

It is important that during operation they are not clogged with debris and dust; To calculate the ventilation of the attic above the attic, involve a professional; Install decorative ventilation windows in the attic to add charm and style to your home; Equip supply ventilation to the attic in accordance with all the rules. Install the supply unit in the cleanest place, no closer than 8 meters from the exhaust pipe.

Insulation of ventilation pipes

Ventilation pipes must be insulated in the attic and above the roof level. This procedure is performed to avoid the accumulation of condensate, which will accumulate on the inner walls and drain down. Since the joints of the ventilation pipes are not made airtight, moisture will penetrate the supporting structures, ruin the finish and lead to the gradual destruction of the building. And the ventilation ducts themselves suffer from contact with moisture if they are made of galvanized pipes.

In winter, the lumen of the ventilation duct is overgrown with frost and in just a month a standard pipe 15 cm in diameter will completely close.

The appearance of condensation in the ventilation ducts is inevitable: people exhale water vapor, wash dishes, bathe and wash. This releases moisture into the air. The humidity of the warm air of a residential building can reach 100%. In contact with the cool surface of the ventilation shafts, water settles on it.

To prevent this process, the ventilation pipes are insulated in the attic. Here is the border between the warm air of the house and the cold unheated attic.

The cheapest insulation option: mineral wool. It does not burn, but when it gets wet it completely loses its qualities. It is easier to mount a corrugation with mineral wool insulation.

Styrofoam in the form of special removable "shells" is very easy to install and inexpensive. But it burns well, emitting toxic smoke, therefore it is not recommended for residential buildings.

The best materials for insulation of ventilation ducts: polyurethane foam, polyethylene foam, polypropylene foam.

Insulation of heating pipes in the basement - Pipes and plumbing

House heating costs increase annually. Each owner is looking for ways to save money: the boiler turns on periodically, or constantly works only at a minimum, and so on. The use of such methods leads to a significant decrease in the temperature in the house. But few people think about how efficiently the residential area is heated, because most of the heat is lost on the way to it.

If heat losses can be minimized, then the rooms will warm up better and faster, accordingly, continuous operation of the boiler will not be required, and it will be possible to resort to savings without affecting the temperature. Since boilers are often located in basements and other utility rooms, we will consider how to insulate heating pipes in the basement and other possible places where the system passes.

Styrofoam for pipes in the basement

The technology of insulation depends on the choice of a specific material, which is selected depending on the conditions in which it will be used in the future.The most important difference between basements and other possible pipe locations is the high level of humidity. Therefore, it is necessary to choose the material taking into account this important feature.

It is best to insulate heating pipes on the basement and basement floors with foam, foam glass, foam insulation or expanded polystyrene. This group of heaters has the lowest moisture absorption rates. Among the materials mentioned are both budgetary and more expensive options.

Before starting the insulation, the surface of the products must be thoroughly cleaned of rust and dried from moisture. It is advisable to cover the elements with protective agents - special paint that can withstand high temperatures.

After that, you can start fixing the insulation on them. You should start either from the beginning of the exit of the element from the wall, or from the junction of two elements at right angles.

Insulation segments have an elementary connection system with each other - a thorn-groove.

The first half of the insulation is applied to the pipe, and then the second is applied and fixed. The material is easy to cut but does not bend. It will not be difficult to adjust the dimensions of an unnecessarily long segment to the required ones, but to insulate the corners, you will have to cut rings with different widths of the sides.

Glass wool for pipes in the attic

Unlike the previous location of the pipes, high humidity is rarely observed here, this is due to the strong blowing capacity. Complete insulation of attic rooms is not yet so common. That is why a distinctive feature is high freezing temperatures.

The choice of material should be determined by its thermal conductivity, as well as the ability to connect segments without the risk of cold bridges. Based on this, it turns out that the insulation of heating pipes in the attic is best done with glass wool, slag wool, stone wool and basalt wool.

The products are sold in rolls, which is convenient when working with pipes. In addition, joining the edges of the overlap canvases avoids the formation of weak points in the insulation. Cheaper options are used if the region of residence has mild winters. Otherwise, you should turn your attention to higher quality and more expensive materials.

Before starting work, the elements should be cleaned from dust, debris and dirt. It is advisable to cover them with radiator paint to protect them from rust. When working with this material, gloves, a respirator, goggles and a full-body robe must be worn.

The material is cut into canvases, the dimensions of which depend on the diameter of the pipes, as well as the number of wrapping layers. It is advisable to wrap each section of the system at least twice. The edge of each next canvas is overlapped on the edge of the previous one. Further, clamps are put on the insulated pipes for heating.

They are tightened at the joints of the canvases, securely fixing them in place.

Foil foam for pipes on the street

The passage of heating pipes on the street greatly affects the temperature drop in the house. In addition, areas of the system that are located in the open air deteriorate faster due to the constant exposure to adverse weather conditions. Therefore, the insulation of heating pipes on the street should be carried out using materials with the lowest rates of thermal conductivity and moisture absorption.

In order for the heaters to last as long as possible, they must be closed without fail. For these purposes, a waterproofing membrane is most often used.

Warming in this case is carried out mainly by means of foamed polyethylene or polyurethane, as well as foamed foam.

The highest quality insulation with the longest service life will be carried out using heat-insulating paint.This material is several times superior in its properties to other options.

The surface of pipes located on the street must be thoroughly cleaned before insulation, this step is especially important for elements that have been installed a long time ago. Next is the process of painting this section of the system, and it is necessary to apply paint for radiators in two or three layers. After it dries, insulation segments are installed.

Its inner diameter must exactly match the outer diameter of the pipes. This material is laid in exactly the same way as the foam considered. The final step will be wrapping the waterproofing membrane in several layers around the insulated element. Her canvases, as well as when wrapping glass wool, are overlapped.

Then clamps are installed in these places.

It is quite simple to insulate heating pipes with your own hands. You don't need an electric tool. Only the purchase of materials will be costly, which will pay off already in the first heating season. And changes in the quality of heating of residential premises will be noticeable immediately, since the heat will not be wasted.

Insulation of heating pipes in the basement and in the attic: the order of work and materials, Portal about pipes Why insulate heating pipes. How to properly insulate heating pipes in the attic, in the basement, on the street. Selection of materials and order of work

Source: trubsovet.ru

[content-egg module = GdeSlon template = compare]

Heat loss in the pipeline is the main problem of both autonomous and central heating systems. And if the reduction of heat loss within the region is entrusted to utilities, then the owner of a private house needs to take care of the heating pipes insulation on their own, and in view of the small amount of work, do it yourself.

Is it necessary to insulate heating pipes and what does it give?

Thermal insulation for heating pipes allows:

- to reduce heat losses in those places where pipes pass along the ground, are mounted by air (ground) or are located in an unheated room;

- prevent the freezing of the liquid, which is the heat carrier (freezing is fraught with pipe breakage);

- reducing the likelihood of corrosion on the pipe surface (for metal pipelines);

- saving money on heating the house.

Source: https://trubyisantehnika.ru/uteplenie-trub-otopleniya-v-podvale.html

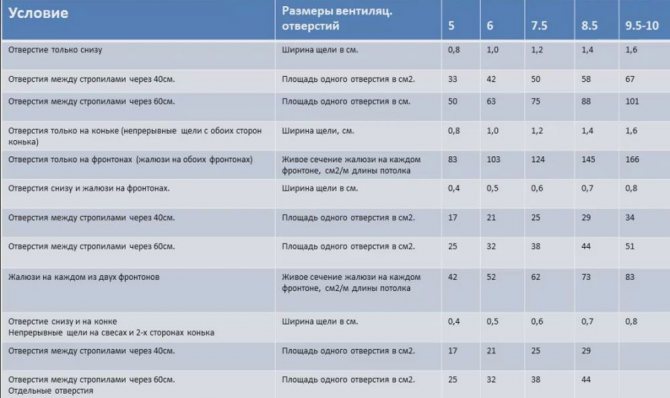

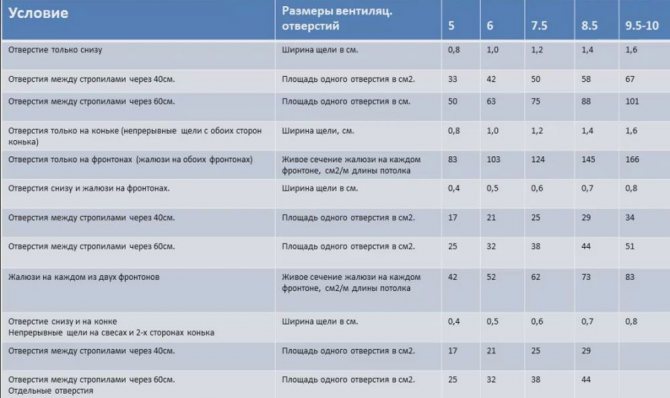

Calculation of ventilation attic

For those who decide to equip the ventilation of the attic with their own hands, before starting work, it is necessary to carry out calculations. Only a specialist can guarantee the best result. And for the most daring, we have prepared a hint:

Roof ventilation summary table

The ratio of the area of the vents to the area of the attic is 1: 500.

500 sq. meters of the attic area should be 1 sq. meter of vents. As a last resort, you can be guided by a ratio of 1: 300, per 200 sq. meters of the attic should have a minimum of 0.4 sq. meter of air. The calculations take into account the area of true ventilation, that is, even the width of the grilles is excluded, the ribs of which interfere with the movement of air flows.

The excess of the area of the vents is also undesirable, as well as a disadvantage. Holes that are too large can get snow and rain, because these are the most vulnerable spots of the roof, which must be remembered.

The area of the hood (ridge and pitched grates) should exceed the area of the inflow (cornice vents) by 12 - 15%.

Ventilation device for the attic of a private house air vents, dormers, grilles

Owners are often afraid to equip cold attic ventilation in their private homes, guided by the following assumptions.

Heat escapes from the house through the ventilation grilles of the attic. It is believed that the building will cool down faster.But most often the problem lies in poor thermal insulation of walls or ceilings. By the way, humid warm air enters the attic through a poorly insulated ceiling. In what its danger we will tell in the next chapter; Ventilation of the cold attic of a hip roof or hip roof is necessary only in summer. According to many, ventilation grilles and windows in the attic are needed only for ventilation in the stuffy atmosphere.

In fact, in winter, the ceiling of an unheated and unventilated attic will turn into a cave overgrown with ice stalactites; It doesn't matter what size the ventilation ducts are. The area of ventilation windows and air vents in the attic must be carefully calculated.

How to do it right - read on.

Attic ventilation in a private house is the most important element of thermoregulation. Properly organized, it allows you to save money on heating or cooling the living space and preserve the structure itself intact. Ventilation of the attic above the attic is especially important.

Attic ventilation

An attic in a private house needs ventilation both in winter and in summer.

So, in the hot season, a hot roof heats the air in the attic to 150 degrees. Most of this heat is given off to the upper floor ceiling, and the air conditioner has to work with increased load to eliminate the excess heat. If there is no air conditioning, the owners are exhausted from the heat and stuffiness.

In winter, air exchange is necessary to remove excess moisture. According to the technical requirements, the temperature difference between the outside and the attic must be 4 degrees or less. Temperature fluctuations between the residential floor and the street contribute to the accumulation of condensation on the roof rafters. The moisture gradually freezes, creating whole cascades of icicles. In the thaw, they melt and moisture drips onto the floor of the attic. The supporting structures of the roof and ceiling are destroyed. Mold develops on wooden rafters.

By the way, high-quality ventilation of the cold attic prevents the accumulation of snow and ice on the roof of the house.

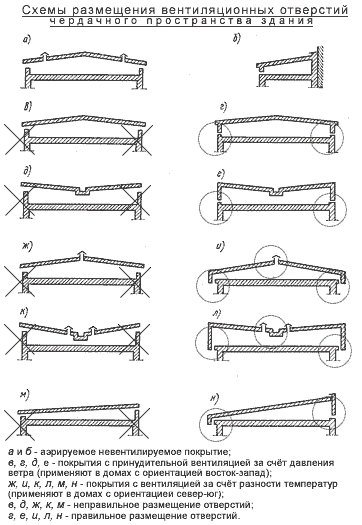

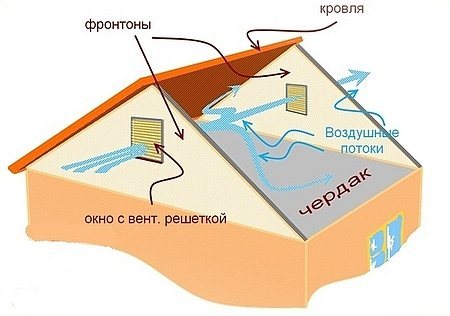

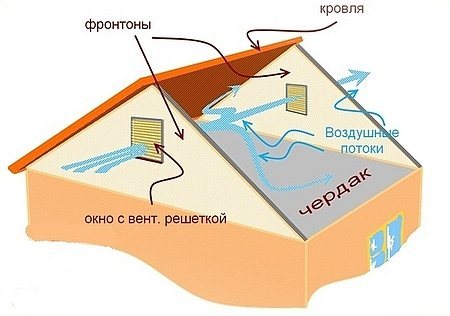

Ventilating a cold attic

Ventilation of a cold attic can be easily done by hand. This will require knowledge of a little theory and some practical skills. Providing adequate ventilation in a cold attic will not pose any particular difficulties due to the large air volume and the absence of obstacles to normal air circulation. Air exchange can be carried out through the eaves, ridge and ridge of the roof, as well as gable windows and grilles.

For gable roofs, ventilation of cold attics is done either through the gables or through a loosely fitting wooden filing of the eaves. If the gables are made of stone, then holes can be made in them for dormer windows with ventilation grilles.

Dormers should be installed on opposite sides to ensure adequate ventilation of the attic.

There is also an alternative, more economical option. For this, standard ventilation grilles (pediment vents) are installed, one of them being adjustable, and the other turned downward with air vents. To protect against insects, such a grill is equipped with a protective mosquito net.

Hip roofs do not have gables due to the peculiarities of the shape of their design, therefore, for them there is another option for providing ventilation in the attic - with the help of cornice overhangs. The air will flow through the roof sheathing and exit from the top of the ridge. If the filing is made of wood with your own hands, then small gaps are left between the bars for the passage of air. When covering the cornice with plastic soffits, such a procedure is not necessary, due to the presence of pre-made holes on the elements - perforations.

The air outlet is from the top, through the ridge of the roof. Its design features depend on the type of roofing material used. As a rule, any manufacturer of roofing materials has their own ready-made and practical solutions.

!

Endows (gutters) are one of the problematic and difficult sections of the roof. To make normal ventilation of the attic space, point aerators are placed along the passage of the valley. However, this method is acceptable for roofs with a slope angle of 45 ° or more.

... On shallow roofs, there is a high probability of snow accumulation in the valley area and therefore such ventilation becomes ineffective in winter. You can fight this by installing forced ventilation - inertial turbines, roof electric fans, or using high nozzles that will not be covered with snow.

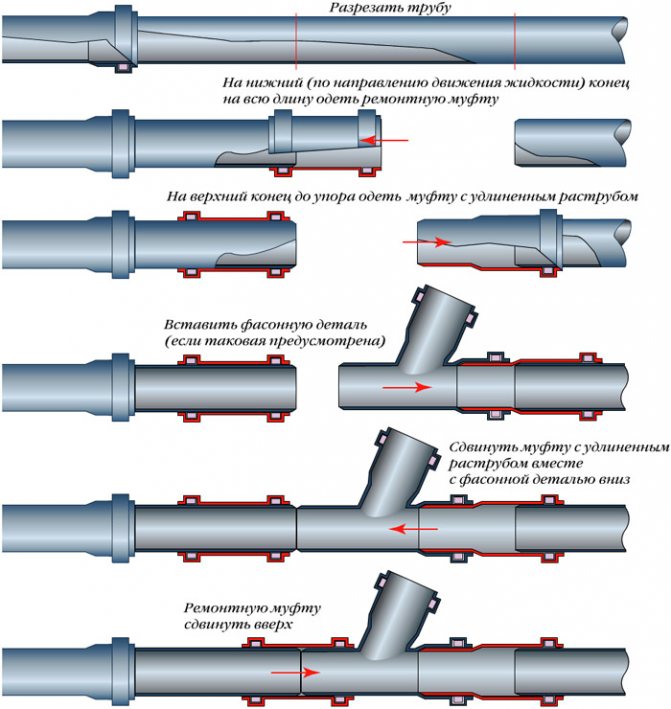

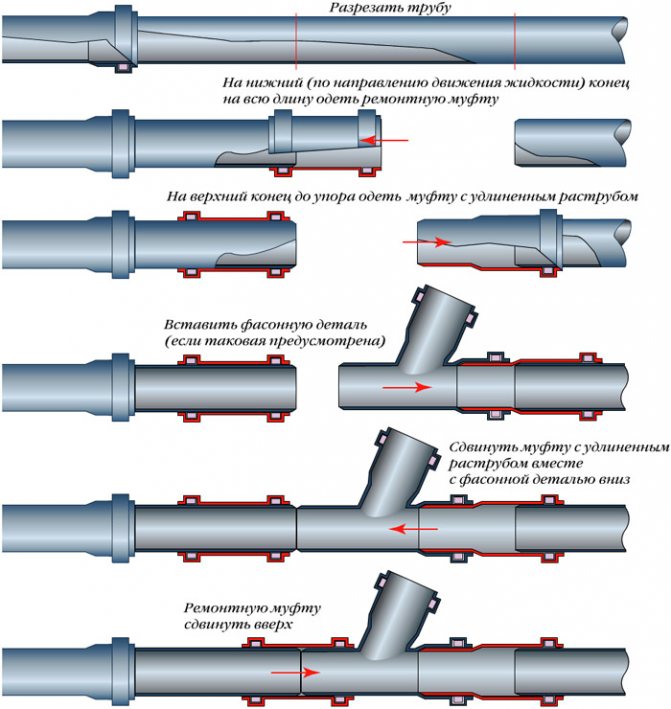

DIY piping system installation

Options for connecting parts of a pipeline system made of polymer pipes

- If sewer pipes are selected for arranging air exchange, then the entire air duct must be collected only from them. This will prevent the formation of a stepped structure inside the duct, which interferes with air movement.

- The future system is shown schematically in advance.

- According to the scheme, the markings are made in place.

- Be sure to apply dimensions for each section and position of the fittings.

- The cross-section of the pipes is being specified. Standard sizes: round section 120 mm or square section 150x150 mm.

- The diameter of the duct is calculated (you can use the online program).

- Equipment, fasteners, pipes are purchased. When buying, you should be careful and take into account that the documents give the size of the outer circumference, not the inner one.

- The presence of all connecting and other elements is checked. For full compatibility of system parts and tightness of connections, it is better to purchase from one manufacturer.

- Fasteners for future communications are fixed along the entire marked route.

- The lines prepared for installation are checked for defects on the outside, as well as inside the pipes. They should be smooth with an anti-static layer applied.

- A riser is assembled from elements of a larger section.

- Air ducts are assembled and installed.

- Sections (branches) can be fastened to each other with one-piece or collapsible joints. The second method is preferable because you can always disassemble the system for prevention.

- It will not be superfluous to seal all joints.

- Elements for connecting individual parts of pipes are selected with unsharp transitions and without sharp corners.

- The ventilation sleeves are fixed to the ceiling with cable ties.

- They are mated with each other using fittings of the required diameters.

- All pipe sleeves converge in one place at the highest point.

- With mechanical air exchange, fans, valves, etc. are installed.

- The common branch pipe is carried out to the roof above the roof.

- The entire system is tested in operation.

Plastic fan ventilation is a popular engineering solution for air exchange in a drainage system

In the case of using PVC pipes without warranty certificates, in order to avoid the dangerous effects of the substances emitted from them on people, it is best to make an exhaust hose out of them. This will exclude even the accidental ingress of toxins into the room.

The decision to install ventilation using sewer pipes in a private house is economically justified. In addition, their operational characteristics do not cause complaints from users, even though the auxiliary parts for assembling and fixing the system will need much more than with the traditional ventilation "classic".

Insulation of heating pipes in the attic

»Heating» Insulation of heating pipes in the attic

Foamed polyethylene and mineral wool - excellent insulation of the heating main in the attic

Hello. Today I want to talk about how to insulate heating pipes with my own hands inside and outside construction sites.The topic is of considerable interest, since the correct thermal insulation allows you to reduce the level of heat loss during transportation of the coolant from the thermogenerator to the heater. I hope you find the instructions in this article interesting and helpful.

A few words about current insulation methods

Insulated pipes for heating are used if the route passes outside the construction site or through outbuildings, attics, basements and other non-residential premises. There is no need to insulate the pipes in the living area, as the piping releases heat into the environment and acts as a heating radiator.

Pictured is a polyurethane foam shell with a reflective foil surface

At the moment, there are many types of thermal insulation materials and methods of their application. Pipelines, depending on their configuration and location, are insulated with expanded polystyrene, foamed polyethylene, foamed rubber, mineral wool, foil insulation, etc.

Current methods of pipeline insulation are distinguished by such characteristics as the thermal conductivity of the finished result, the temperature range at which long-term operation of the insulation is possible and, of course, the price.

Unfortunately, not all methods of pipeline insulation are available for DIY. Therefore, in my review I will tell you about the technologies that I myself have encountered and the result of which I am satisfied with.

So what are we going to cover in this article?

- The use of liquid insulating compounds;

- The use of polyurethane foam;

- The use of mineral wool;

- Insulating shell application.

Application of coating liquid insulation on a heating main

Heating mains covered with perlite-based coating insulation

The simplest to implement insulation of heating pipes in the basement, in the attic and in outbuildings is carried out using liquid coatings, such as "BRONYA CLASSIC" (ultra-thin thermal insulation).

The product is intended for application to polymer and metal surfaces at an ambient temperature of at least + 7 ° C. Storage of the material is allowed only at positive temperatures. Operation of the material is allowed in the temperature range from + 200 ° С to –60 ° С.

According to the manufacturer's statements, the service life of insulation is at least 15 years.

Standard five-liter packaging of "BRONIA CLASSIC"

Pipeline insulation instructions are shown in the following diagram.

Coating insulation technology

Let's consider the main stages of working with liquid insulation in more detail:

- We prepare the surface, namely, we clean off crumbling rust, dust and dirt from the material, and then wipe it with a rag dipped in a thinner;

- While the surface is drying, we prepare the material - open the jar and mix the contents;

Liquid insulation is used with the consistency of thick sour cream, therefore it is not recommended to dilute the products with water to liquefy.

- Apply the liquid thermal insulation with an ordinary swing brush over the entire surface in 2-3 layers with a break for drying each previous layer.

The applied layer does not look very neat, but it copes with the task perfectly

Explanations for installation work:

- Despite the fact that the product is not toxic, we use protective gloves and goggles when working with it;

- We work in good lighting so that when covering the working surface there are no unpainted areas;

- We do not paint over fittings and moving parts of stop valves, since liquid thermal insulation forms a dense crust when it dries, which will not be easy to remove later.

How to insulate the track using PPU

In one of the previous articles, I talked about how the spraying of polyurethane foam is performed.Polyurethane foam is a versatile material that can be applied to various surfaces including heating pipes.

The method that I want to talk about next is one of the options for using hard foam.

To complete the planned work you will need:

- installation for spraying PPU;

- components for obtaining foam;

- roofing material and soft aluminum wire;

- plywood for cutting stiffeners.

Insulation instructions are shown in the diagram.

The technology of applying polyurethane foam to the heating main

Let's consider the listed stages in more detail using the example of insulation of a polyethylene pipe:

- cut out rings with a slot from plywood or fiberboard in order to put them on the pipe on the basis that the diameter of the ring should be twice the diameter of the pipe;

Installation of lintels - stiffeners

- we expose the rings at a distance of about 60 cm from each other;

When installing the rings, the cut is directed up. To make the rings easier to fall into place, the edges of the slots are unbend, and then shifted.

- in the slots on the rings, we install the PPU supply hose so that its end reaches the last ring;

- we fix the hose in place with electrical tape or a plastic clamp so that it can be pulled out later;

Roofing material winding

- then we wind the roofing material so that the strip with its edges lies on two adjacent rings and the edges come out about 10 cm;

Fixing the wire winding

- we connect the winding of roofing material with a soft wire;

- along the entire length of the pipe in the shell, through each meter, we punch holes with a diameter of 5 mm;

- after the shell is assembled, press the open end with a piece of plywood or fiberboard and let the foam go;

Hold a piece of plywood to prevent the foam from flowing out

- when the foam appears from the end of the pipe, covered with a piece of plywood, pull out the hose 0.5 meters;

Foam breaks through the control holes, which means you can pull out the hose

- when foam appears from the first hole made in the shell from the end, we pull out the hose for another half meter, etc.;

It looks like an insulated pipeline

- as a result, after the hose is fully extended, the pipe will be surrounded by strong and reliable insulation.

We leave the roofing material without removing even after the foam is completely dry. Firstly, roofing material will protect the foam insulation from mechanical stress. Secondly, the presence of an outer shell will prevent the effect of UV radiation on the foam, which will extend the life of the insulation.

If the given instructions seem complicated to you, you can do it easier and apply a uniform layer of polyurethane foam from a spray can to the track surface.

Unfortunately, the price of foam from a cylinder in terms of the treated area is high. In addition, using a balloon it is not easy to evenly process all parts of the pipe and it is even more difficult to apply a uniform layer without bald spots and without bumps.

Other methods of thermal insulation

For thermal insulation of heating mains located in the open air, mineral wool has long been used. Thermal insulation was constructed as follows:

- mineral wool strips were wound over the pipeline and fastened with wire;

- a chain-link mesh was installed over the insulating winding;

- a layer of cement-sand plaster was applied over the netting of the chain-link, which was designed to protect the insulation from atmospheric precipitation.

You can implement this method yourself, especially since there is nothing complicated about it. If the pipeline is small in diameter and runs through the basement or in the attic, instead of full-fledged reinforcement, a layer of dense plastic film can be wound over the mineral wool.

Insulation of heating pipes in the attic using mineral wool shells

Finally, a few words about shells, which are made of mineral wool, expanded polystyrene and polyurethane foam.

Foil-wrapped polyurethane foam shell

It is believed that polyurethane foam shells are intended for heating pipelines, while polystyrene foam, that is, foam with a dense structure, is intended for insulating water pipes and sewers. In fact, heating pipes can be insulated with both shells, since the foam melts at a temperature of + 160 ° С, while most heating mains do not heat up more than + 80 ° С.

Extruded polystyrene foam shell

The use of the shell is reliable and simple. Two or three halves (depending on the modification and diameter) are folded together. The finished structure is pulled together with clamps or the locks are foamed with polyurethane foam.

Output

So, now you know how to insulate heating pipes on the street. Moreover, you can choose one of the listed methods and cope with its implementation yourself.

Source: https://teplo-ltd.ru/otoplenie/uteplenie-trub-otopleniya-na-cherdake.html

The right approach to insulation

To answer the question: how to insulate a ventilation pipe in a private house correctly and at the same time economically - you need to understand the reasons for the appearance of condensation. The temperature difference always leads to the appearance of condensation, but the most abundant release of "dew" is observed in the segment of active contact between warm and cold air. The closer you can move it to the outlet of the pipeline, the less potential danger and damage from condensation will be.

The ideal case is a situation in which the mixing of cold and hot air takes place in a section of the ventilation pipe located outside the building. But it is not always possible to implement this in practice.

Therefore, for chimneys and air ducts in an unheated attic, duct insulation is considered mandatory. Thanks to this, it will be possible to remove the "wet" zone - the place of the most active dew formation - beyond the walls of the building. Such a solution will help prevent moisture from entering the walls even with the active appearance of a large amount of condensate, provoking the appearance of dampness, fungus and other related troubles.

Finding the best place

A vertical chimney from a stove heating, fireplace or gas boiler, thanks to the outlet of hot air, will be completely cleaned of moisture during the heating of the room. Horizontal air ducts, the outlet of which is located in the wall, should initially be installed with a downward slope of at least a few degrees. This allows accumulated moisture to drain outside and not inside the room. Therefore, the most important point before insulating such air channels is to check the presence of a slope for its output. Otherwise, even insulated ventilation pipes will become a source of problems in the future, albeit much later than without thermal insulation at all.

An unheated attic space is a mandatory place for insulating air duct pipes. It is in it that the temperature difference in the cold season becomes a source of problems due to the formation of moisture. Condensation on them, regardless of whether plastic or metal pipes are used, forms both inside and outside.

Choosing the best material

In order for the thermal insulation of any: plastic, metal and various other ventilation pipes to be effective enough, but not to hit the budget, you should choose the right insulation. Today there is a fairly rich selection of materials for this, both available and quite expensive. The most recommended options are the following types of insulation:

- Mineral wool. An inexpensive fire safe option available at almost any hardware store. The downside of the availability of mineral wool is the laboriousness of installation and the need for its subsequent protection with foil or galvanized. Afraid of moisture.

- Stone wool.It has the advantages of mineral wool, as well as its disadvantages. Over time, it cakes and loses its thermal insulation properties.

- Polyurethane foam and plastic foam. Split structures for pipes of a certain diameter. Inexpensive, but providing excellent heat and moisture insulation. The disadvantage of materials is high fire hazard and rather low resistance to mechanical damage.

- Foamed polyethylene. Insulation, offered in the form of ready-made tubes of different diameters. Inexpensive, they are distinguished by good indicators of thermal insulation, they are not afraid of moisture. The disadvantage is the need to put the heat insulator on the duct pipe, which is inconvenient or even sometimes impossible.

The choice - how to insulate the ventilation pipe - everyone makes himself. The basic rule on which it is recommended to rely on when choosing is to purchase the material that will most completely solve the problem of condensate in a private ventilation network.

Requirements for thermal insulation of heating pipes

You need to understand that insulated piping is a must in the home supply system. Many are deeply mistaken asserting that insulation is not a particularly necessary process, because pipes in which warm water flows will not freeze anyway. This is not a correct statement, since, first of all, pipes are insulated to minimize heat loss.

Insulation of heating pipes in basements with polyurethane foam is an effective solution

The main requirement for heating pipes is their efficiency. After all, it is this criterion that helps prevent heat loss. During the heating season, the temperature in apartments is kept within the average, but with high-quality insulation, the heating efficiency can be increased by several degrees, thereby reducing utility bills. Therefore, insulated pipes in the basement of a private house will not only increase heat, but also save a lot of money.

In addition to all the above requirements, there is one more, basic one. All insulated communication must be carried out in full compliance with the technical specifications.