For more efficient ventilation in the room, the supply air should not flow in a stream, but should be evenly distributed throughout the entire space of the room. After all, when the air flows in one stream, drafts are created, and they negatively affect people's health. In addition, only a certain part of the room is ventilated with a jet stream of air. Therefore, in order to ventilate the space as efficiently as possible, ventilation diffusers are installed.

A ventilation diffuser - what is it? This is a part of the ventilation system, the purpose of which is to dissipate the input / output air flows over the space of the room.

What is a diffuser?

A diffuser for a ventilation system is a device that has the shape of a grill on the outside. The purpose of this unit is to evenly distribute the incoming and outgoing air masses of the room. There are three types of devices that help diffuse air currents:

- Supply air;

- Exhaust;

- Supply and exhaust (universal);

Diffusers in air conditioning

The purpose of such devices is to evenly distribute air flows from an air conditioner or fan through the air ducts into the room.

Difference between diffuser and ventilation grill

The difference between these devices is only in the design and the intensity of air movement.

Air circulation is taken into account during the calculation and design of air dispersion equipment. Therefore, the arrangement of the blades and partitions of the structure is carried out so that the air flows are most efficiently mixed and evenly distributed over the space of the room.

The diffuser, like the ventilation grilles, contributes to a more intense air flow to the air ducts from the air conditioner, only it does so in a slower and smoother form.

Ventilation diffusers: types and materials

Depending on the features of the application, ventilation diffusers are produced:

- supply air for uniform distribution of the supplied air;

- exhaust - remove air with minimal resistance;

- supply and exhaust - quite effective in both cases;

- combined models - simultaneous operation for supply and extract air with appropriate connection to the exhaust and supply networks.

Depending on the materials used, the ventilation diffuser can be:

- plastic;

- metal made of aluminum;

- metal from steel.

Plastic modern ventilation diffusers most applicable in residential construction due to their significant advantages:

- the lowest cost;

- durability;

- lack of corrosion;

- light weight;

- convenient connection to plastic air ducts.

Metal ventilation diffuser has the following advantages:

- increased strength;

- reliability in work;

- resistance to damage during operation.

They are very often used in industrial and warehouse premises. The materials of the products can be lightweight aluminum, ordinary steel with protective coatings, stainless steel, which provides an improved appearance.

By geometry differ rectangular, round, square models.

Depending on the place of installation, the ventilation diffuser can be:

- wall-mounted;

- outdoor;

- ceiling.

Floor-standing models are rarely used. They are usually necessary when placing a supply ventilation unit in the basement. Wall devices are also rarely mounted.The most applicable are ceiling ventilation diffusers due to the ease of installation, the prevalence of false ceilings and the advantages of air intake and flow into the upper parts of the premises.

Application and operating principle of a ventilation diffuser

The air distributor can be used for ventilation systems of premises of any purpose - residential buildings, offices, in production. With these tools you can:

Eliminate drafts

Drafts have a negative impact on human health. People with weak immunity are especially susceptible to their influence. They arise as a result of the fact that the streams of air masses form a single jet. This phenomenon is eliminated by the supply air distributor. It promotes divergence and dispersion of the air flow.

Effective ventilation

If there are no units in the ventilation system, with the help of which it is possible to disperse the flows of air masses, only that part of the room in which the air circulates is ventilated, since the air inflow is carried out by the jet method. When ventilated with an air distributor, the jet air flow is evenly dispersed throughout the entire space of the room. Scattering is mainly carried out by the vortex principle. And ventilation deflectors help to reduce the intensity of air movement through a flexible air duct, or to accelerate the movement of air masses that have entered the outflow system.

Upgrade the exhaust system

Outflow (exhaust) diffusers are used to modernize the exhaust system. They are installed in the ventilation system. Without the presence of an air distributor, the exhaust structure, although it discharges air masses, still forms jets of air streams. This factor negatively affects the atmosphere of the room. Plus, the volume of exhaust air entering the exhaust hole directly depends on changes in the direction of its flow - the larger the change, the lower the throughput. With the help of an air diffuser, this problem can be solved.

Control air flows

The air inflow / outflow with the help of the diffuser can be controlled by a specially configured control panel. Thus, you can provide additional comfort and prevent the formation of drafts or poor-quality ventilation. Another advantage of this device is sound insulation. With the help of this unit, it is possible to eliminate the noise of air flows "walking" in the room.

Examples of mounting swirl and slot diffusers

Vortex

Schelevoy

Excellent article 0

- Even more interesting:

Discussion: there is 1 comment

- Pauline:

08/02/2018 at 19:06It seems to me that such forced ventilation is needed in every home.

Reply

Classification

Types of ventilation diffusers The ventilation equipment market has a fairly wide range of diffusers. They are divided into several types according to the following characteristics:

By body material

Plastic diffusers for ventilation.

Such devices are made of plastic, resistant to corrosion and decay processes. These air diffusers are very lightweight and come in different shapes and colors.

Metal diffusers for ventilation

These air diffusers are made of aluminum or steel. The advantages of these products are their high strength. They are reliable in operation and have an optimal design. Metal diffusers are considerably heavier than plastic ones. Also, sometimes there may be problems with their installation.

Do not confuse a metal supply air diffuser and a diffuser.Unlike a diffuser, an anemostat can be used to control the volume of circulating air flows (it is not possible in diffusers). Also, the body of the device is made only in a round shape, and the diffuser can have various shapes (both round and rectangular).

The price of the device depends on the material from which the diffuser housing is made. Steel fixtures are much more expensive than plastic fixtures.

By form

Circular (swirl) diffusers for ventilation

Such models are divided into:

- Serrated - often mounted in the ceiling, using specially provided clips. These models of air diffusers are equipped with an air mass flow valve.

- Poppet - rarely found in operation, as they do not meet design requirements.

Slot diffusers for ventilation

The boxes for the installation of such devices are very compact and practically invisible on the surface. Due to their shape, they allow you to adjust the direction and angle of air flows.

Mounting of such units does not require much effort. It is produced using brackets.

By appointment

Supply air diffusers

Devices for supply ventilation are designed to scoop and quickly deliver to the room or ventilation unit the flow of fresh air masses from the outside and their uniform distribution.

Exhaust diffusers

They are used for prompt removal of exhaust air from the room outside. At the same time, they contribute to the uniform distribution of air throughout the space of the room and ventilation of its maximum area.

Universal (supply and exhaust) diffusers

Such units are used for inflow - outflow of air into the room, as well as for circulation through the ventilation system.

Nozzle diffusers

Such units are used to create narrow jet streams of air.

At the place of installation

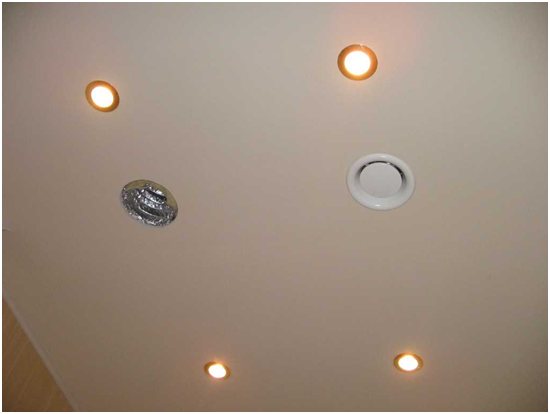

Ceiling diffusers for ventilation

Since the mixing of air flows in the room is carried out at the top (under the ceiling), such air diffusers are very common in operation - 95%. They are used for both supply and exhaust ventilation systems.

Floor diffusers for ventilation

This type of fixture is used for rooms in which supply ventilation is carried out through the basement.

Wall diffusers for ventilation

Such diffusers for ventilation are quite rare in operation, since ventilation grilles are mainly used for walls.

Basically, such units are mounted when it is necessary to install ventilation through a hole in the wall.

Design features

Vortex

The external structure of such air flow distributors consists of partitions and grids, which are located in such a way as to create a swirl of the air masses. This makes it possible to accelerate the movement of air masses and increase the efficiency of such a system.

Often, in vortex diffusers, the placement of the bridges is radial. They are used in rooms with large areas, high ceilings. Also, such units are well suited for rooms in which a quick change of air is required (bathroom, toilet, etc.).

From the inside, such a unit has the shape of a cylinder. The lattice to it can be of various shapes. Moreover, its holes should be located only around the circumference.

The vortex air mass distributors for the supply ventilation system have an additional impeller. It is located behind the bars, in the body of the device. This part can be movable and stationary, controlled and not controlled. The controlled impeller can have several operating speeds.

Swirl diffusers can have a static pressure chamber.With its help, too active movement of air currents is eliminated, thus, the appearance of drafts is prevented.

Slotted

The shape of these diffusers resembles slits. Since the distribution of air mass flows directly depends on the position of the partitions, their shape, size and direction, the design of such units is specially developed and calculated.

Such devices are used for rooms in which there is a low or medium performance of the ventilation system.

Slotted devices for diffusing air flows can be adjustable and change the direction of the supplied air masses (similar to the blinds of air conditioners). Such diffusers may have a static pressure chamber.

The design of slot diffusers and grilles for them can be of various shapes.

Adjustable

These ventilation diffusers are equipped with adjustable sliding plates. This is a regulating element of the structure, due to which the throughput of the device is controlled.

Such devices are called anemostats. The flow of air masses is regulated due to the movements of the central part of the unit clockwise or counterclockwise. The lamellas in the device are movably fixed. This allows them to change position and open or close the gap to generate air masses.

There are anemostats equipped with presence sensors and analyzers of the composition of air masses. Such units are connected to the room climate control system. Such a system works in automatic mode. Its task is to maintain a given indoor climate.

Stream distribution

Each manufacturer produces devices of different shapes and designs of the air diffuser. There is no strict classification of diffusers according to the air flow characteristics, but they can be divided into the following types:

- Slotted - the flow distribution passes through several slots, as in gratings.

- Jet - air is supplied with one or several jets of high speed and over long distances.

- Perforated - a large number of small holes are arranged in their surface through which air enters the room or is removed from it evenly and at a low speed.

- Vortex - the slots in them are located in such a way that the air enters the room, swirling in the form of a funnel.

- Linear - elongated with a small number of slots.

We recommend that you familiarize yourself with: Refrigerated air dryer

There are other types of narrow applications or for specific systems.

Perforated diffuser

Diy diffuser installation

So that during the installation of the equipment there are no problems, you need to prepare the hole for installation in advance. The opening must match the size and shape of the fixture.

The accessory components for mounting the diffuser are always supplied with special fixing clips. With their help, the unit can be installed both in a flexible duct and in a rigid duct.

Installation features:

Installing a diffuser in a rigid duct

- Before purchasing an air diffuser, you need to accurately measure the size and shape of the hole for the device. The unit must be selected in strict accordance with these parameters.

- The installation of the device consists in smoothly moving the device into a previously prepared hole, until a characteristic sound appears - a click. The installation of the device must be done carefully in order to avoid damage to the case (if pressed firmly, the case may burst).

- Then you need to carefully inspect the surface and make sure that there are no irregularities or protrusions between the opening and the unit.

- If installation defects are found, you need to check all latches and make sure that they worked.Otherwise, you need to press on the necessary part of the device until it is fixed.

Installing the diffuser in the soft channel

- First, you need to get the sleeve out of the hole in the wall and attach a device to diffuse air currents to it.

- Then, the sleeve is placed in the channel, followed by the unit.

- When the system begins to come into contact with the wall surface, you need to fix the device. To do this, you will need to slowly, without making any special efforts, press on the diffuser until the fastening mechanisms work.

- Make sure that there are no installation defects (protrusions, irregularities above the wall surface).

Installing the diffuser in ductless exhaust ventilation (hole in the wall)

- Initially, you need to prepare an opening in which the unit will be installed to diffuse air flows. For these purposes, it is recommended to use a pipe, the parameters of which will correspond to the size of the diffuser.

- The opening itself in the wall can be made from a pipe. To do this, you need to measure the length of the hole from the outer wall to the inner one, then adjust the pipe to these dimensions.

- Insert the fitted pipe into the hole and install the device in it according to the principle described above.

- Fastening the pipe to the hole can be done with mounting foam.

If the diffuser accessories do not include clips for fastening, they can be replaced with glue, anchors, sealant or self-tapping screws.

Ceiling diffuser: installation

There are two ways to connect diffusers to ventilation ducts: directly or through an adapter (plenum box). More correct is the second option, but it requires a larger gap between the base and decorative ceiling.

If the shape and dimensions of ceiling diffusers and ventilation pipes are the same

To connect the ceiling diffuser directly to the ventilation pipes (bends), a tee / splitter is placed in the ventilation pipe at the installation site. In the free - the third - exit and put the device.

Cutting a hole right in the pipe for its installation is not the right decision. The body protrudes beyond the pipe, making it difficult for air to flow, the performance of the system decreases, over time, a dust plug still forms, which can generally block the lumen. In general, this should be avoided.

Select the taps from the main pipe so that it is convenient to connect them to the diffusers. It is not difficult to connect a round diffuser to a round outlet from the duct, and a rectangular one to a rectangular one. It is also important that their sizes match. This simple truth must be remembered when creating a system, choosing tees or making bends with the appropriate parameters.

If the shape and size match, installing a ceiling diffuser is not a problem

Diffusers of the same size are installed in ventilation ducts by simply inserting them. Models that are small in size and weight can be fixed to the box with a sealant (silicone neutral). This is how models with a round base are usually attached.

For suspended ceilings of various types (plasterboard, plastic, Armstrong), a special fixation system has been developed - Clip in. It is a spacer of the type seen on recessed ceiling luminaires.

More massive square / rectangular models are attached to the box walls with self-tapping screws or suspended from the ceiling. The first option is easier, but it is better not to use it, since dust collects on the protruding screw of the self-tapping screw. Is that the design provides for special protrusions for fasteners. Otherwise, over time, a solid plug will form in the place where the self-tapping screw sticks out, preventing the passage of air.

An example of using an adapter - a circular ceiling diffuser is connected to a rectangular ventilation duct

If the branch is made of corrugated material or there is a desire to do everything "right", heavy cases are suspended from the ceiling on studs or hangers.

Diffuser selection features

Diffuser, what is it? This is a ventilation element that must perform certain functions. When choosing a device, you must first of all decide what functions you need to maintain an optimal indoor climate.

Supply elements - designed for a quick flow of fresh air into the room. Their principle of operation is based on capturing air masses from the street and transporting them to the ventilation system.

Exhaust elements - designed for quick exhaust of exhaust air to the outside. They work on the hood principle and are good for installation in rooms where there is high humidity and the formation of household odors.

Universal elements - capable of operating both for outflow and inflow of air Nozzle elements - are designed to create a directed air flow at a given distance. These models are used in rooms where it is impossible to lay a complete ventilation system.

Also, when choosing, you need to pay attention to the material of execution. Metal elements are more durable, they have a long service life and excellent technical characteristics

Most often they are made of steel or aluminum. Plastic models are not subject to corrosion, have a lower cost and can be made in different colors. An important parameter when purchasing a device is the presence of air flow regulation. Adjustable models have special grilles that allow you to change the direction and strength of the air flow.

Experts advise purchasing diffusers from well-known manufacturers. Despite the fact that the design of this element is quite simple, its service life will depend on the quality of performance. For industrial premises and public facilities, it is better to choose metal elements, they have improved performance characteristics and are less susceptible to failure.

Installation

The installation method depends on the type of ceiling finish and the shape of the ventilation element itself. Round and square ceiling diffusers are used for suspended plasterboard structures and stretch ceilings. These works should be carried out at the stage of installation of suspended and tension structures.

Installation highlights:

- Determine the location of the diffuser. There cannot be many options here, since it is attached strictly to the outlet of the ventilation duct.

- The device is applied to the surface and a contour is drawn along its perimeter on the surface.

- Everything that remains inside the contour is drilled to a shallow depth, focusing on the fact that the lattice is ultimately flush with the ceiling. The perimeter needs to be slightly widened - 5-6 mm in each direction.

- Reapply the device and mark the attachment points.

- Holes are made in the marked places with a drill or perforator. Dowels are inserted into the holes obtained.

- The perimeter of the installation site is treated with a sealant, which prevents the penetration of air outside the device.

- Now the diffuser is applied and fixed to the surface with self-tapping screws.

Round models are almost invisible, therefore they fit into the interior of any ceiling without any problems.

Square grilles are most often used for cassette ceilings, they are fixed instead of decorative tiles. This ceiling model provides easy access to the ventilation system for maintenance.

It is necessary to provide for ease of maintenance when installing any diffuser. It must organically fit into the interior and fulfill its functions fully.

Choosing the right diffuser

Each specific ventilation system requires an individual approach when selecting components. The ventilation product must be selected based on the following parameters:

- The cross-sectional dimensions must be equal to the dimensions of the duct for which the device is intended.

- The power of the air distributor is selected in accordance with the needs of the room or building.

- The material of manufacture must correlate with the parameters of the transported air masses and the characteristics of the operated premises. For outdoor use, a metal case is best, inside - plastic products.

- It is reasonable to choose the design of the structure for the corresponding style of interior decoration.

In addition, when choosing a suitable air diffuser model, consumers pay attention to the design and color.

Floor diffusers

Floor ventilation grilles deserve special attention. They are installed in places where they are least exposed to mechanical stress, and are also made exclusively of metal. It is forbidden to place floor diffusers directly under the workplace. The ventilation device must be at least 40 cm away from it. Air supply is carried out due to excess static pressure, which is formed in the underfloor space, or in a specially designed chamber. The advantages of this type include: extremely low noise level, uniform temperature distribution throughout the entire serviced area. Most often, this type of diffuser is used for ventilation of premises in theaters, auditoriums, concert halls, etc.

Advantages and disadvantages of the air distributor

Installing a diffuser as part of a ventilation system for any type of room provides dual-use benefits - functional and decorative:

- This device is capable of providing high-quality air exchange both in individual rooms and throughout the building.

- With it, you can adjust the direction of movement and the power of the air flow.

- The nozzle allows you to extinguish noise from the operation of equipment and moving air flows through the conductive channels.

- The device serves as a protective agent against foreign objects, debris, dust, dirt, insects, and rodents entering the ventilation system.

- The stylish air diffuser is a wonderful decorative element that can beautify any interior in any style.

The disadvantages of this device are practically absent with the right choice and proper installation. A certain feature can be considered the possibility of a draft. However, this problem is solved by simply installing a special pressure stabilizing chamber.

Output

With the help of diffusers, it is possible to ensure not only the direction and volume of the air inflow, but also its outflow. In this case, the correct distribution of air masses occurs throughout the building or a specific room, with minimal heat loss.

The industry offers models made of various materials and different colors, so when choosing, you should pay attention to the technical characteristics of the devices.

The video in this article will help you find additional information on this topic.

Did you like the article? Subscribe to our channel Yandex.Zen

Installation nuances

Installation is carried out after the completion of finishing works. And the product can be mounted in the following ways:

In a metal hose (corrugation).

Into the wall opening (channelless ventilation).

Into a rigid sleeve (box).

Installation in a metal hose (corrugation)

The end of the corrugation is pulled out of the channel.

A diffuser is attached to the corrugation.

The corrugation together with the attached diffuser is gently inserted into the channel.

When the product reaches the stop, you need to gently press on it until it clicks so that the latches snap into place.

Installation in a wall hole (channelless ventilation)

A hole is drilled (or cut) in the wall to fit the size of the diffuser with a margin of 5-10 mm.

A socket is installed: a pipe is taken the same size as the diffuser opening.The pipe must be cut to the thickness of the wall.

The trim is inserted into a hole in the wall and secured with foam.

A diffuser is inserted into the installed socket.

The diffuser is selected according to the shape and size of the channel.

The product is inserted into the slot (box) until it clicks.

Correct use of the device

Supply and exhaust air distribution devices of different types are developed taking into account the peculiarities of the air flow, which will determine the location of the impeller and grilles relative to the base. For this reason, models have been created that can meet the different needs of users: directional and non-directional ventilation diffusers. Such devices are installed taking into account the wishes of the home owner.

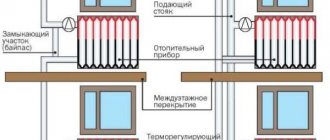

In most cases, the ventilation diffuser is mounted on plasterboard structures (ceiling, wall). At the same time, the efficiency of the ventilation pipe, built-in, for example, behind a suspended ceiling and connected to the main channel of an apartment building, increases.

If there are no such structures in the room, you can use the simplest diffusers, which are in many ways similar to ventilation grilles.

The devices in question operate without the need for human intervention. An increase or decrease in the intensity of the inflow / outflow of air is provided by such a phenomenon as rarefaction of the air environment. Due to the specially developed design, the universal diffuser creates a difference in pressure. This changes the direction of movement of air molecules. Universal models are controlled by a remote control. In this case, the operating mode changes, which is accompanied by a change in the direction of the air flow.

Places of use and purpose of diffusers

Air distribution devices are most often used in places such as:

- Office rooms.

- Places of public catering.

- Apartments of increased comfort.

- Trade departments.

The intended purpose for the installation of the air distributor includes:

- Creation of a comfortable microclimate in a closed ventilated room.

- Changing the oxygen supply to rooms.

- Dilution of heat load.

- Removal of the smallest dust particles in the air using an exhaust system.

- Maintaining the set temperature unevenness and maintaining the speed of air movement.

With the help of the membrane, it is possible, if necessary, to adjust the volume (increase or decrease) of the oxygen entering the ventilated room.

Design features

Ceiling diffusers are available in different designs. There are vortex and slot. These types can be made of any material, for any installation method. But, as agreed, we are talking about ceiling models.

Ceiling diffusers come in a variety of designs

Vortex

In them, the lattice partitions are located in such a way as to create turbulences of air masses. This significantly increases the speed of air mixing, increases the performance of the system. It is easy to recognize them by the characteristic radial arrangement of the bridges. A vortex ceiling diffuser is used where rapid air changes are required. It makes sense to install them in bathrooms and toilets - to quickly restore a normal atmosphere, although they are usually used in rooms with a large area and height of ceilings.

Scope of diffusers

It is recommended to install a diffuser for ventilation in all rooms equipped with a fresh air supply system. Vortex devices are installed in the form of decorative finishing panels of various shapes and colors. In order to achieve the highest efficiency in operation, the diffusers are mounted using a special gasket.

The front part is fixed with a screw connection to the back box. Previously, devices were produced with spraying in one direction only, now they spray the flow in all directions.The production of models for installation in damp places is provided, with a special moisture-resistant coating. Bath complexes, swimming pools and industrial facilities are equipped with such devices.